A predictive control method for temperature setting of heating temperature control valve in stages

A temperature control valve and staged technology, which is applied in the expected control field of the staged temperature setting of the heating temperature control valve, can solve the problem that the indoor temperature is lower than the user, reduce energy consumption and use costs, improve comfort, save energy and reduce energy consumption. The effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

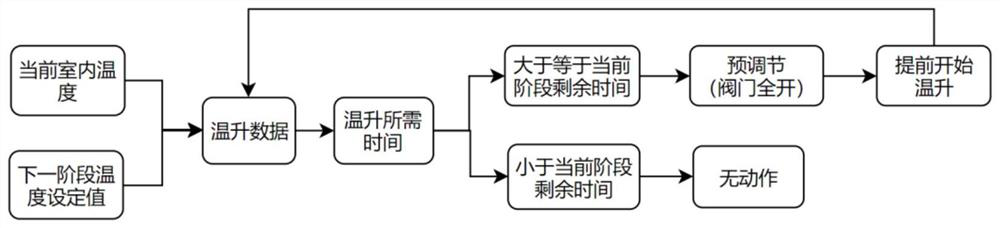

Method used

Image

Examples

Embodiment Construction

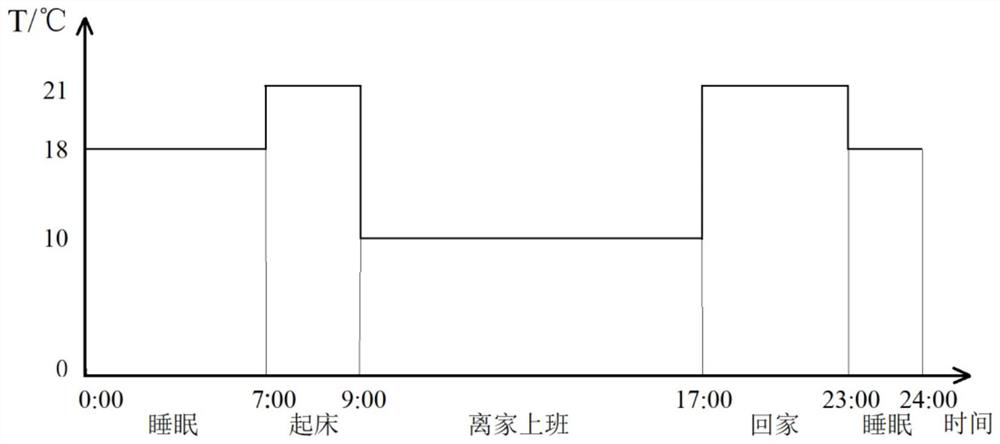

[0026] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

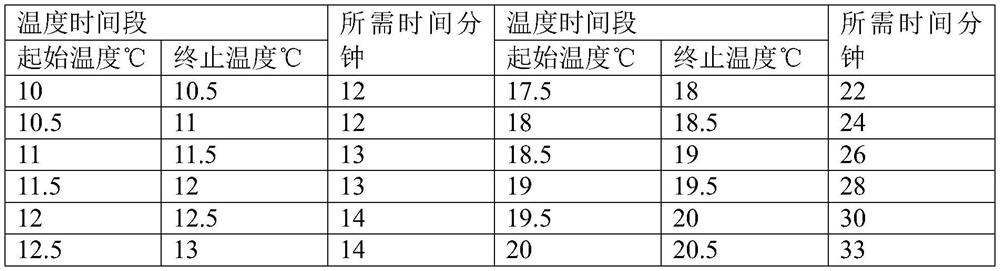

[0027] According to relevant data, the temperature rise time of the heating system is related to various factors such as the system water supply temperature, water flow, heating equipment, building structure, indoor temperature, and outdoor temperature. In the household heating system, the heating equipment and buildings are fixed structures and will not change; the water supply temperature and water flow of the household boiler are set by the user and can be considered as fixed values. Therefore, the temperature rise time is mainly related to the current indoor temperature value and outdoor temperature.

[0028] When the heating system is working normally, there is little difference in the average outdoor temperature between the two temperature rises before and after, and it will not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com