Wind pressure control method and device, gas water heater and storage medium

A wind pressure control and wind pressure technology, which is applied in the fields of gas water heaters, storage media, devices, and wind pressure control methods, can solve the problems of wind pressure response control delay, low accuracy, large error, etc., and achieves timely control response and improved Effects of Wind Pressure Compensation Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

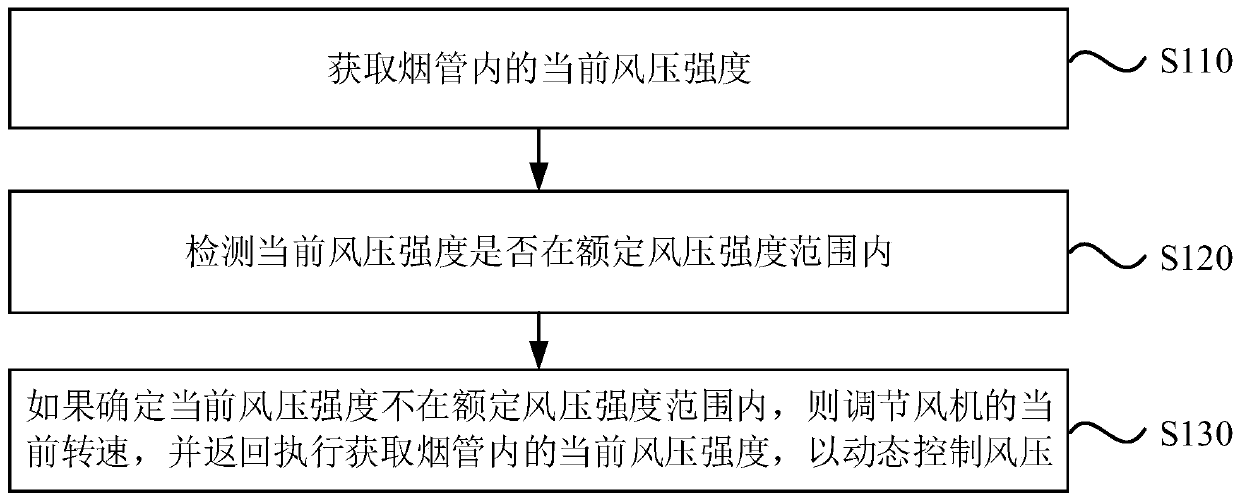

[0028] figure 1 It is a schematic flowchart of a wind pressure control method provided in Embodiment 1 of the present invention. This method is applicable to the situation of controlling the wind pressure in the flue pipe of a gas water heater, and the method can be implemented by a wind pressure control device, which can be composed of hardware and / or software, and can generally be integrated in a gas water heater and all In equipment that uses fan blast combustion heating function. Specifically include the following:

[0029] S110. Obtain the current wind pressure intensity in the smoke pipe.

[0030] Along with the widespread use of gas water heaters, gas water heaters have become one of the necessary household appliances for every household. However, in the process of using a gas water heater, when the windy weather or the exhaust port of the flue is blocked, it often occurs that it is difficult to ignite, ignite and deflagrate during the ignition process, or incomplete...

Embodiment 2

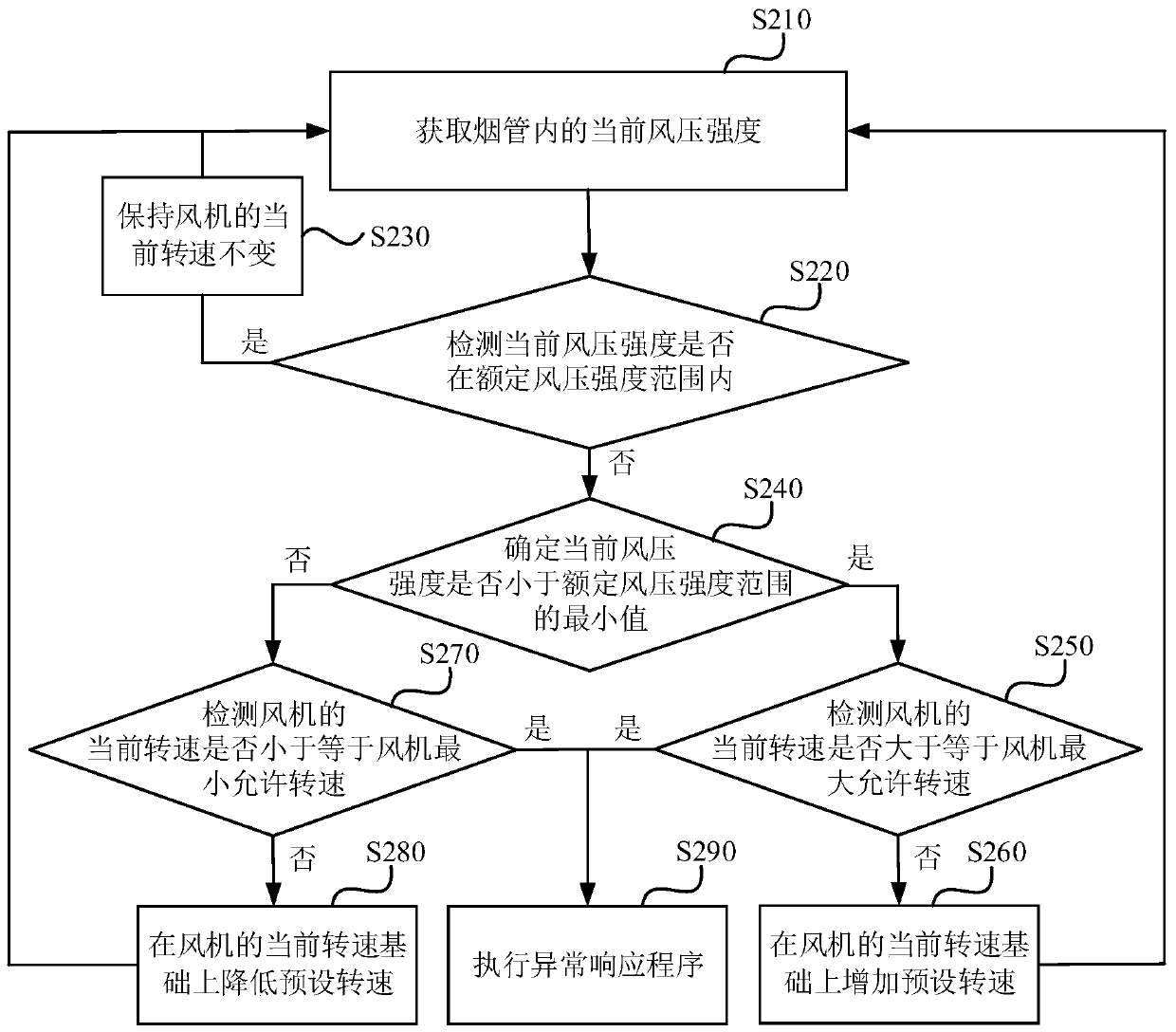

[0047] figure 2 It is a schematic flowchart of a wind pressure control method provided in Embodiment 2 of the present invention. This embodiment is optimized on the basis of the above-mentioned embodiments, and provides a preferred wind pressure control method. Specifically, if it is determined that the current wind pressure intensity is less than the minimum value of the rated wind pressure intensity range, then increase the wind pressure on the basis of the current speed of the fan. The preset speed is further optimized to include: if it is determined that the current wind pressure intensity is less than the minimum value of the rated wind pressure intensity range, then detecting whether the current speed of the fan is greater than or equal to the maximum allowable speed of the fan; if it is determined that the current speed of the fan is greater than or equal to the maximum allowable speed of the fan If it is determined that the current speed of the fan is lower than the m...

Embodiment 3

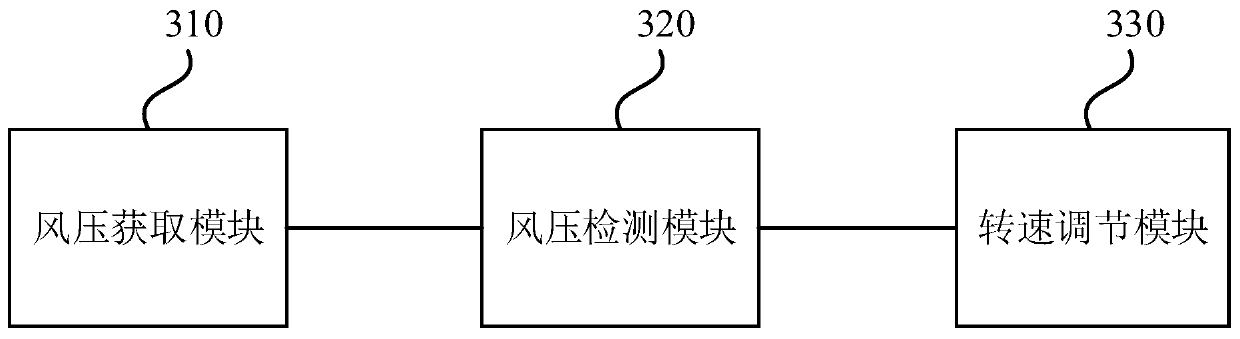

[0067] image 3 It is a schematic structural diagram of a wind pressure control device provided in Embodiment 3 of the present invention. refer to image 3 , the wind pressure control device includes: a wind pressure acquisition module 310, a wind pressure detection module 320, and a rotation speed adjustment module 330, each module will be described in detail below.

[0068] A wind pressure acquisition module 310, configured to acquire the current wind pressure intensity in the smoke pipe;

[0069] A wind pressure detection module 320, configured to detect whether the current wind pressure intensity is within the rated wind pressure intensity range;

[0070] The rotation speed adjustment module 330 is configured to adjust the current rotation speed of the blower fan if it is determined that the current wind pressure intensity is not within the rated wind pressure intensity range, and return to obtain the current wind pressure intensity in the smoke pipe to dynamically contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com