Submersed nozzle slag line automatic control method based on molten steel superheat degree

An immersion and superheating technology, applied in the field of iron and steel metallurgical continuous casting, can solve the problems of inaccurate slag line position and inability to meet the surface quality requirements, so as to improve the service life, reduce the cost and improve the quality significantly, and ensure the service time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

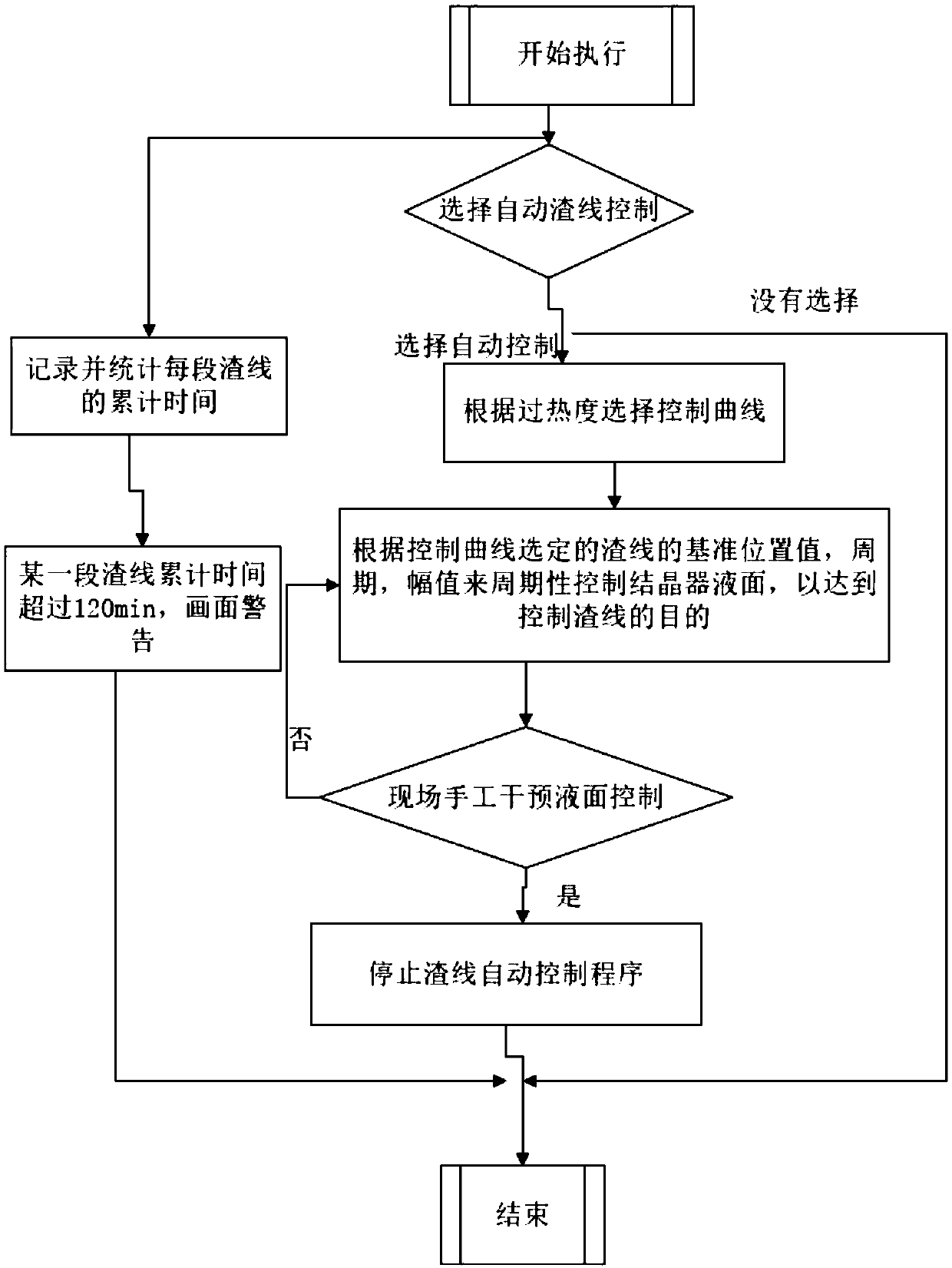

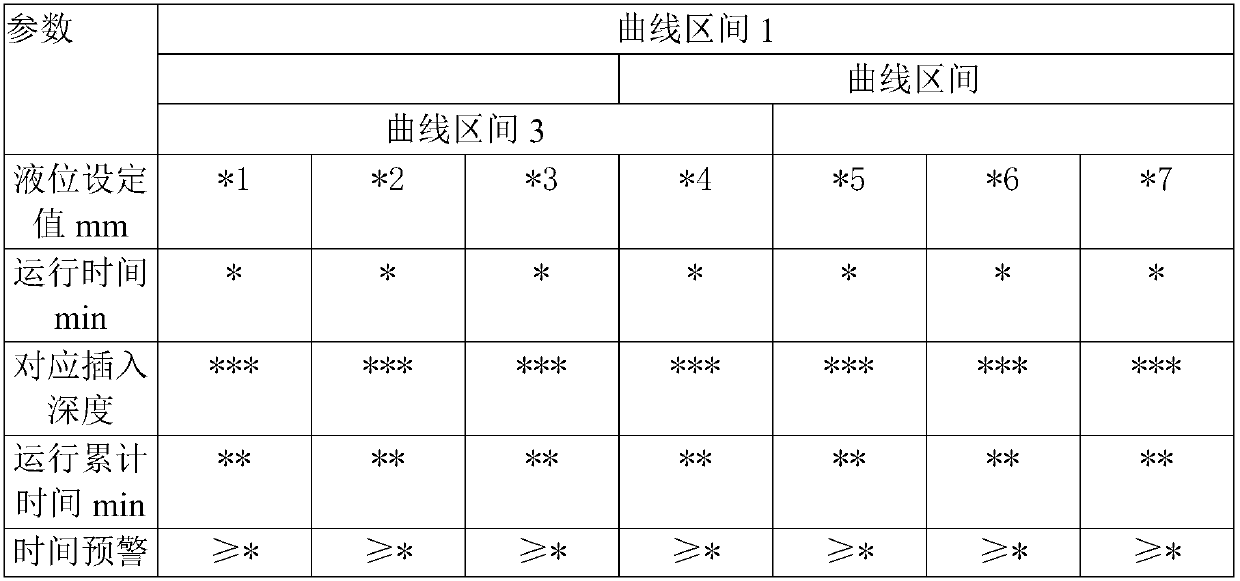

[0033] Example 1: see figure 1 , figure 2 , a submerged nozzle slag line automatic control method based on molten steel superheat, said method comprising the following steps:

[0034] Step 1: Determine the position of the submerged nozzle slag line;

[0035] Step 2: Slag line automatic control process.

[0036] Described step 1: the location of the slag line of the submerged nozzle is determined, as follows:

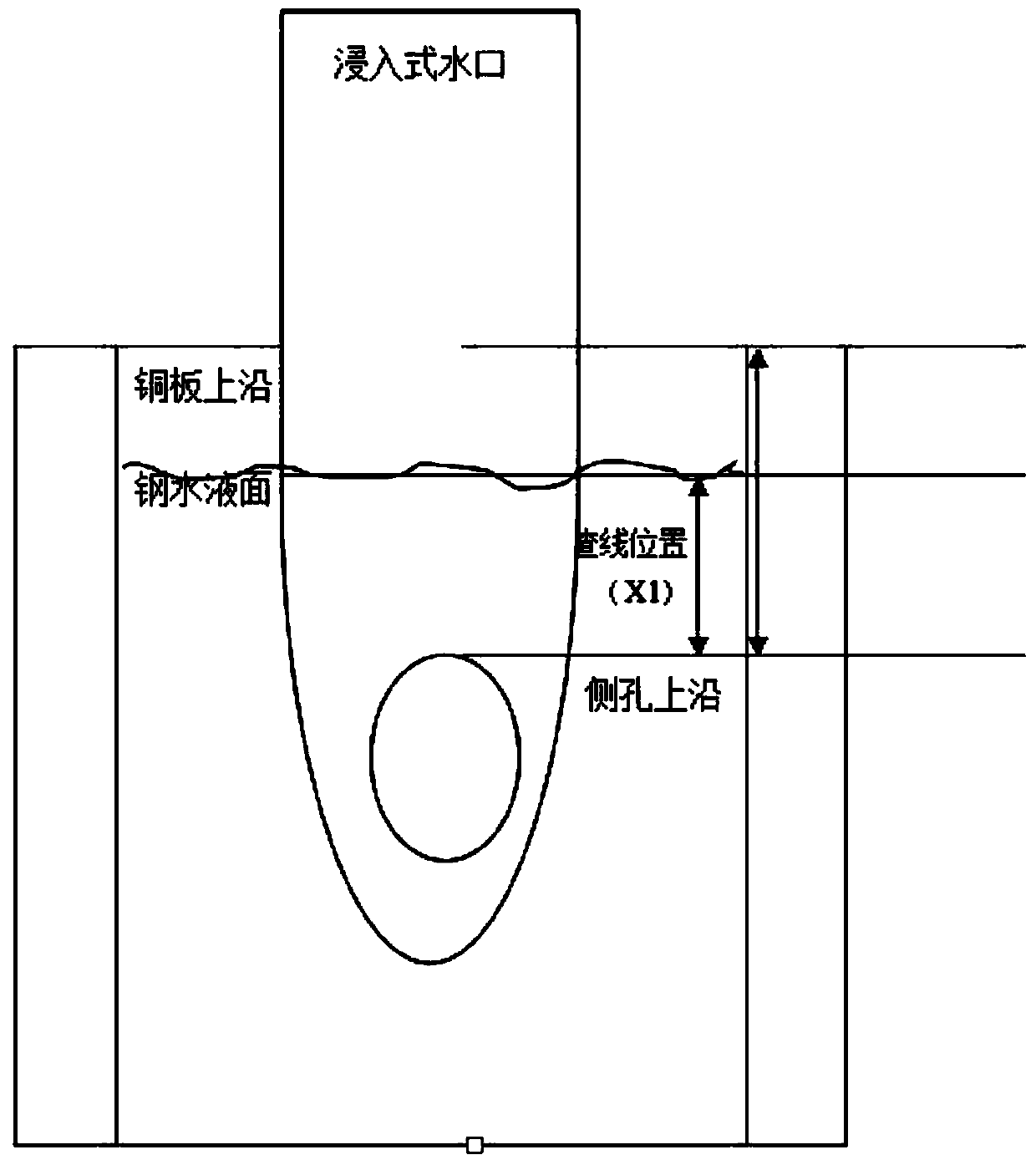

[0037] The slag line of the continuous casting submerged nozzle is the position of the slag line where the interface between molten steel and mold slag in the mold is eroded to the submerged nozzle, and the insertion depth is the distance from the upper edge of the side hole of the submerged nozzle to the position of the slag line;

[0038] 1.1 Measure the distance from the upper edge of the nozzle side hole to the upper edge of the copper plate when the pouring position of the tundish car is lowered to the lowest position, and set it as X;

[0039] 1.2 Collect the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com