Practical training device for large electromechanical equipment maintenance teaching

A technology of electromechanical equipment and training devices, which is applied in the field of training devices, can solve problems such as the inability to adjust the position and height of the writing board, the inability to rotate the workbench, and affect the maintenance of electromechanical equipment, so as to achieve the effect of improving practicability and simple and convenient rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

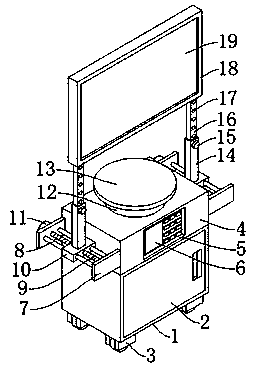

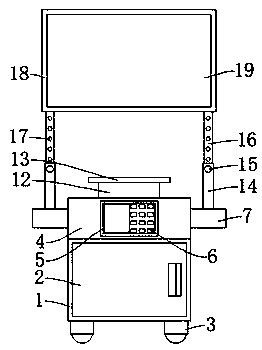

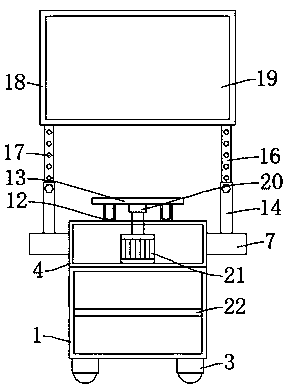

[0044] refer to Figure 1-Figure 18 , the present invention provides a kind of training device for the maintenance teaching of large-scale electromechanical equipment, comprising tool box 1, partition board 22, box door 2, moving wheel 3, tool box 1 is fixed with partition board 22 inside, partition board 22 front A box door 2 is installed on the top of the tool box 1, and a moving wheel 3 is installed under the tool box 1. The moving wheel 3 is used for moving the device. A protective shell 4 is fixed on the top of the tool box 1. In order to prevent the teacher from touching the control panel 6 by mistake, the control panel 6 is electrically connected to the controller 29 . In the present invention, what described controller 29 adopts is the existing controller product, and its model is MB20, because this controller can carry out programmable setting, so those skilled in the art only need according to the required function, through available The programming device presets t...

Embodiment 2

[0048] The difference between Embodiment 2 and Embodiment 1 is that in the silent motor, the shock absorbing groove 271, the shock absorbing seat 273, and the first spring 272 are replaced with a limit rod 274, a limit ring 275, a second spring 276, and a bottom plate 277 , when the device shakes during operation, the support mechanism 23 moves down to squeeze the second spring 276, and the second spring 276 will resume its elastic stroke after being squeezed, and the elastic potential energy of the spring is converted into the kinetic energy of the support mechanism 23, driving the support mechanism 23 moves up, thereby alleviates the rocking amplitude of device, to reach the effect of damping.

[0049] In the present invention, the high-torque motor includes a base plate 28, a controller 29 and a slide rail 33 are arranged on the top of the base plate 28, a switching mechanism 30 is arranged on one side of the controller 29, and a power mechanism is arranged between the switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com