Two-way stirring equipment for chemical processing raw materials

A technology of chemical processing and raw materials, applied in chemical instruments and methods, chemical/physical processes, mixers with rotating stirring devices, etc., can solve problems affecting work efficiency, varying degrees of thickness, and easy dripping of raw materials to the outside, etc. , to achieve the effect of reducing processing steps, improving work efficiency, reducing adhesion and upper cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0028] see Figure 1-Figure 11 , the specific embodiments of the present invention are as follows:

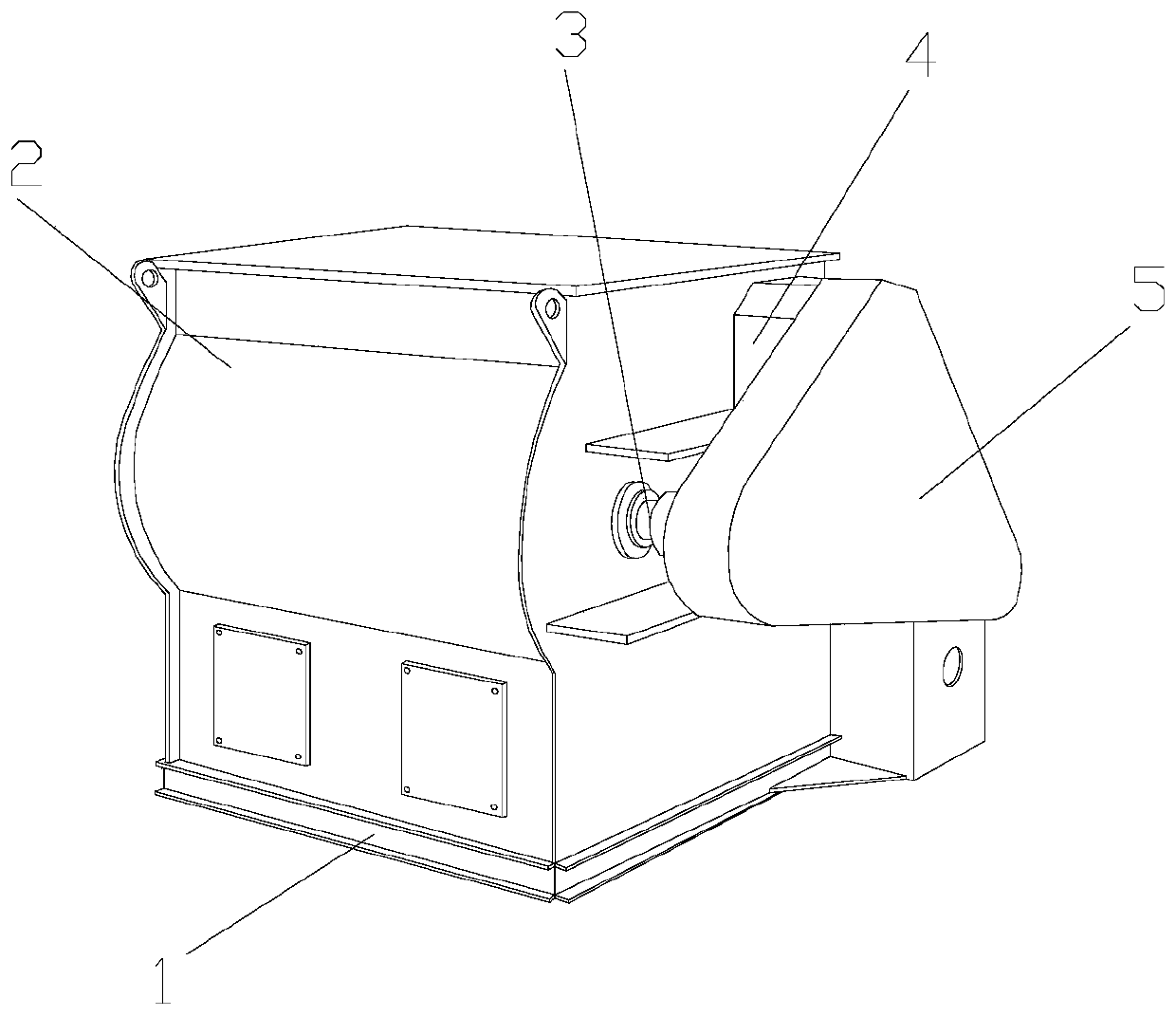

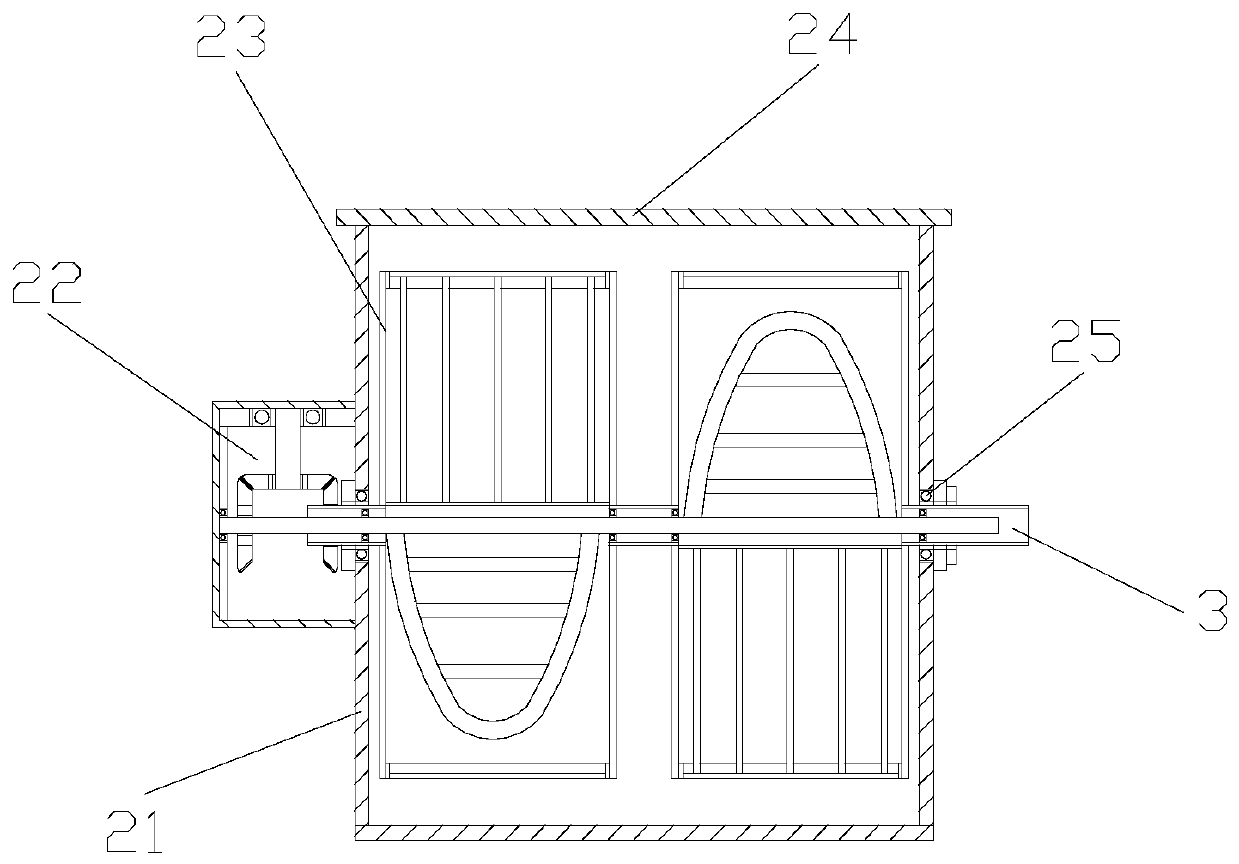

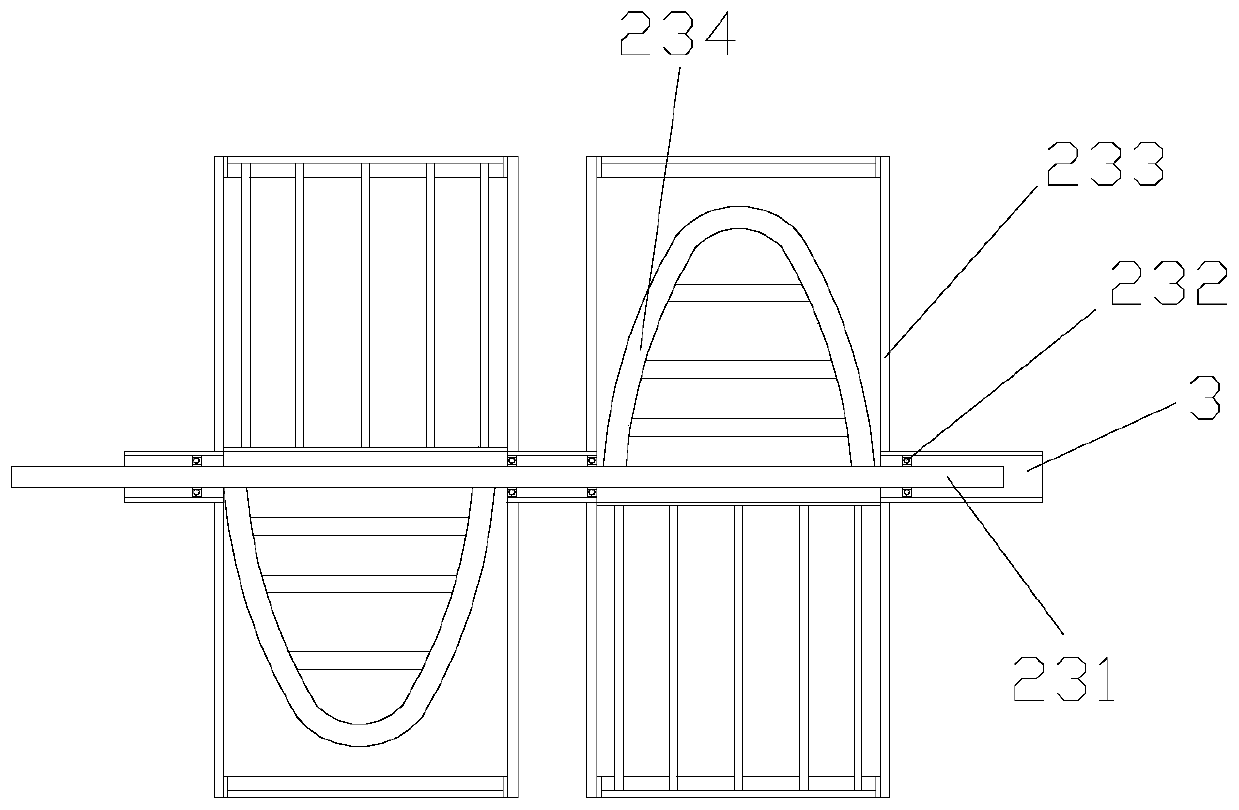

[0029] Its structure includes a base 1, a mixing structure 2, a drive shaft 3, a transmission box 4, and a driving box 5. The mixing structure 2 is horizontally installed on the upper end of the base 1 and welded to each other. There are two Outlet, the drive shaft 3 runs through the right side of the mixing structure 2 and is embedded and installed inside. The drive box 5 is installed on the right side surface of the mixing structure 2 and is mechanically connected. The drive box 5 passes through the transmission box 4 is connected with the drive shaft 3; the mixing structure 2 includes a mixing box 21, a transmission box 22, a mixing structure 23, an upper cover 24, and an outer bearing 25, and the driving shaft 3 runs through the inside of the mixing box 21 and An outer bearing 25 is installed between them. The transmission box 22 is installed on the left side of the mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com