Groove machining device for thin plate

A bevel processing and thin plate technology, which is applied in the field of bevel processing devices for thin plate parts, can solve problems such as difficulty in controlling precision, easy deformation, and irregular shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

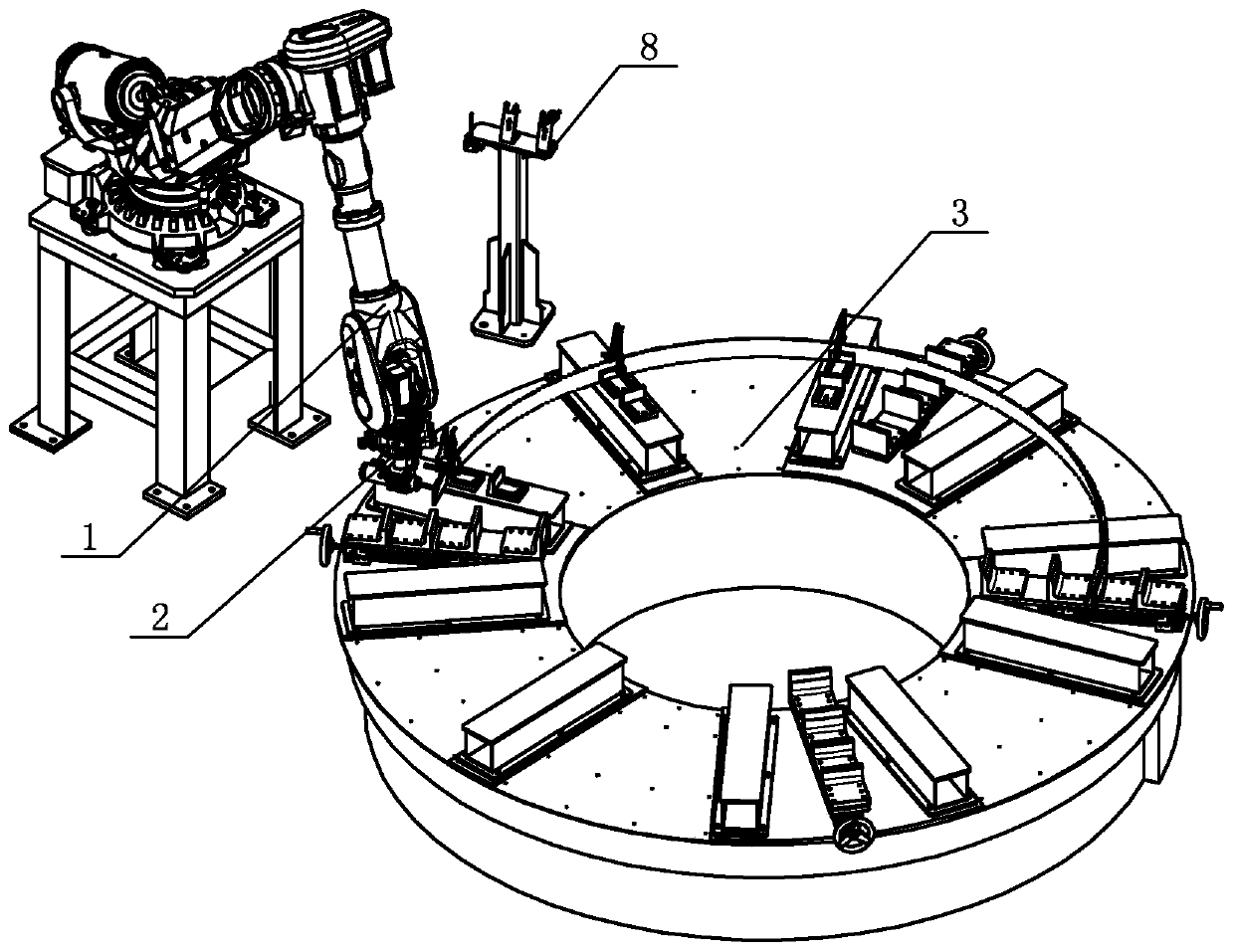

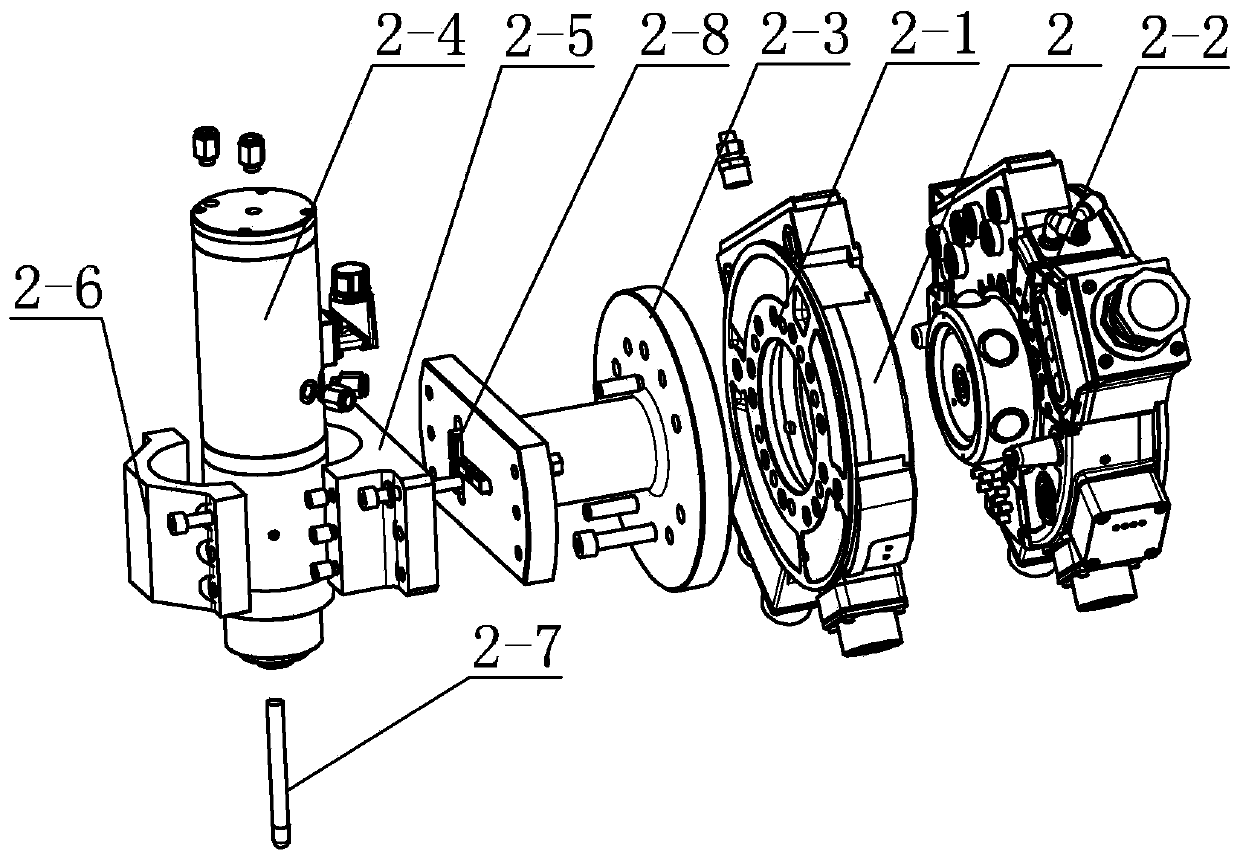

[0019] Specific implementation mode one: combine Figure 1-Figure 7 Describe this embodiment, a bevel processing device for thin plate parts described in this embodiment, it includes a mechanical arm 1, it also includes a processing mechanism 2, a clamping and fixing mechanism 3 and a tool changer assembly 8, the processing mechanism 2 Including the movable end of the quick change block 2-1, the fixed end of the quick change block 2-2, the adapter seat 2-3, the electric spindle 2-4, the electric spindle fixed seat 2-5, the compression cover plate 2-6 and the milling cutter 2-7, the output end of the mechanical arm 1 is fixedly connected to the fixed end 2-2 of the quick change block, the fixed end 2-2 of the quick change block is pneumatically locked with the movable end 2-1 of the quick change block, and the adapter seat 2-3 One end of the quick-change block is fixedly connected with the movable end 2-1, the electric spindle fixing seat 2-5 is fixedly installed on the other e...

specific Embodiment approach 2

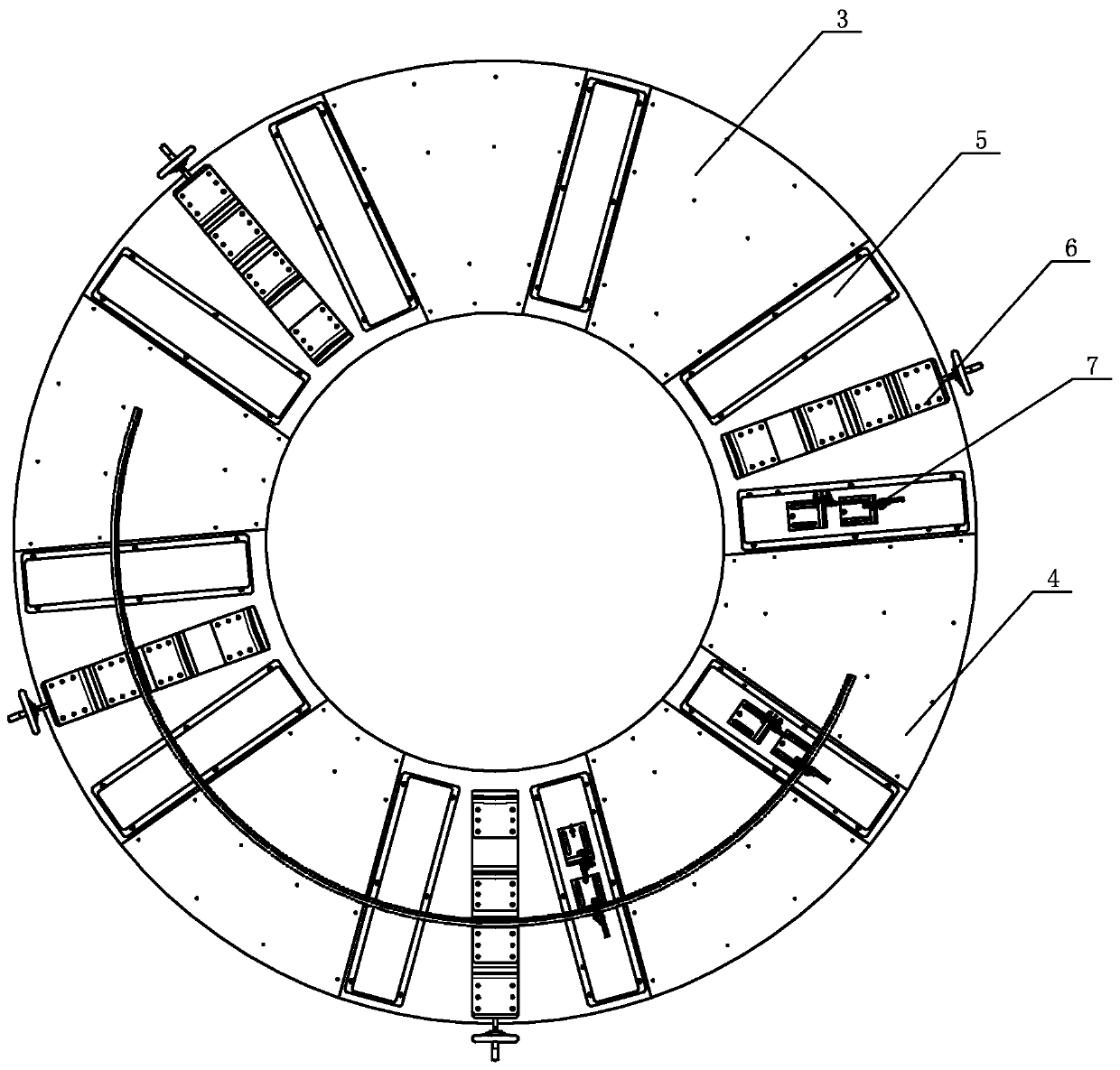

[0024] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, a bevel processing device for thin plate parts described in this embodiment, the clamping and fixing mechanism 3 includes a work plate 4, a plurality of support limit frames 6, a plurality of support frames 5 and multiple sets of support clips Tightening assembly 7; the work disk 4 is an annular disk body, a plurality of support frames 5 are fixedly installed on the upper end surface of the work disk 4, and a plurality of support limit frames 6 are installed on the upper end surface of the work disk 4, and each group of support clamping assemblies 7 Fixedly installed on a support frame 5, the center line of each support frame 5 along the length direction passes through the center of the work disk 4, and the center line of each support limit frame 6 passes through the center of the work disk 4 along the length direction. , in the present embodiment, the number of groups of sup...

specific Embodiment approach 3

[0025] Specific implementation mode three: combination figure 1 and figure 2 This embodiment will be described. In the bevel processing device for thin plate parts described in this embodiment, the plurality of support frames 5 are rectangular frames, and the upper surfaces of the plurality of support frames 5 are planes. The thin-walled plate workpiece is supported by the upper surface of the support frame 5 to ensure that the bottom end surface of the thin-walled plate is even and the accuracy of workpiece processing is ensured. Other methods are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com