Steel box girder tied arch bridge structure

A technology for tied arch bridges and steel box girders, which is applied in the field of steel box girder tied arch bridges, and can solve the problems of reduced service life, inability to alleviate the vibration and impact energy of tied arch bridges, and large damage at the joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

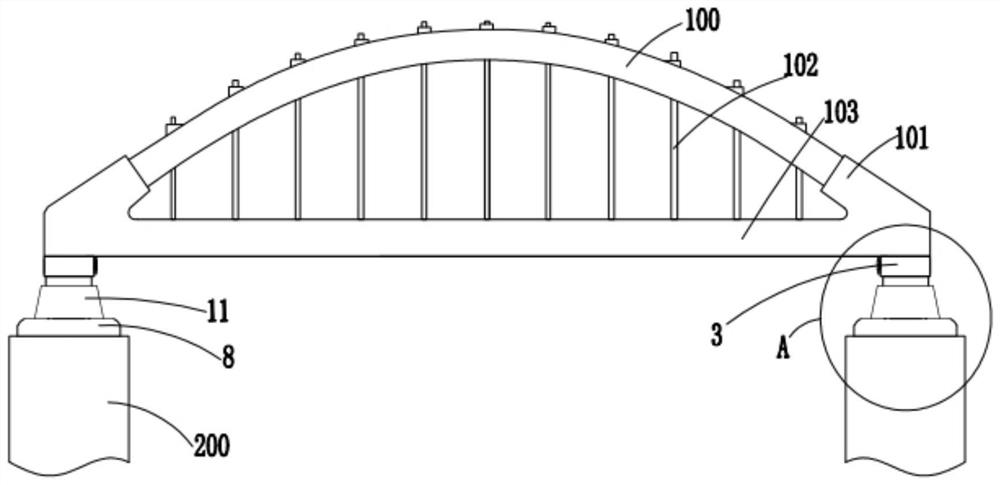

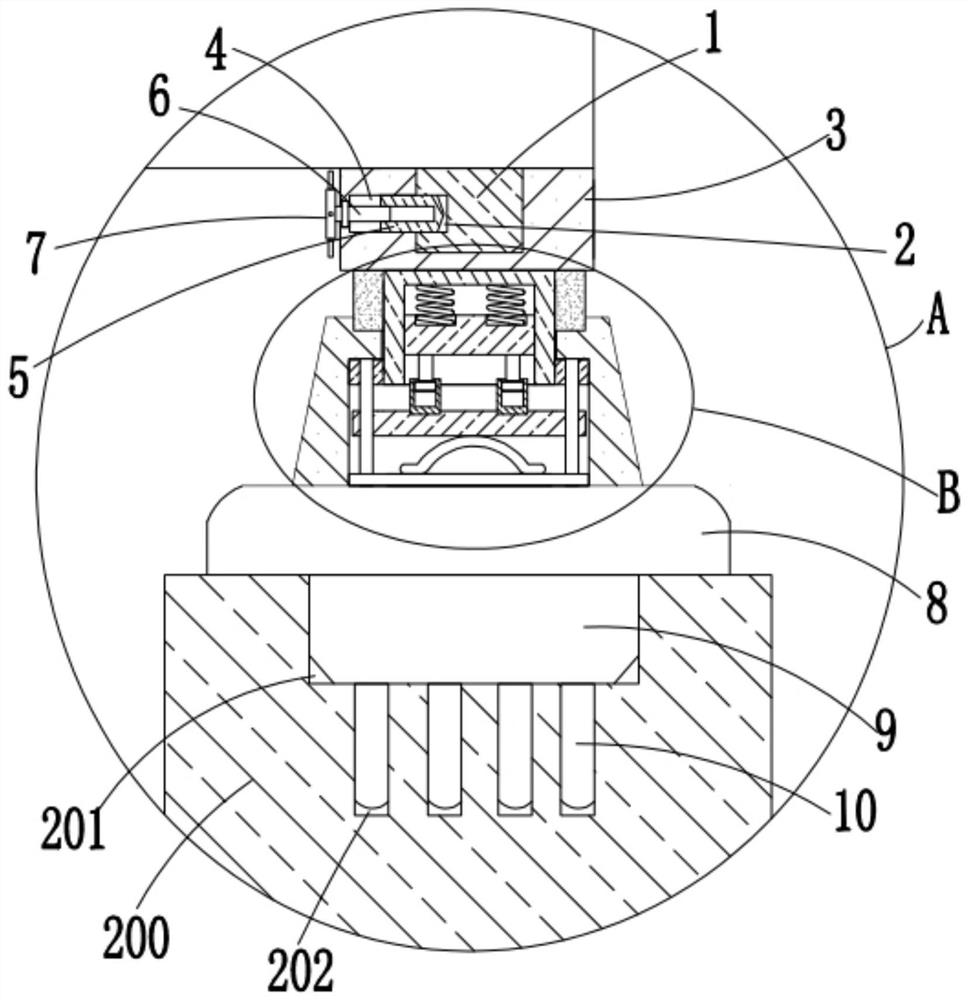

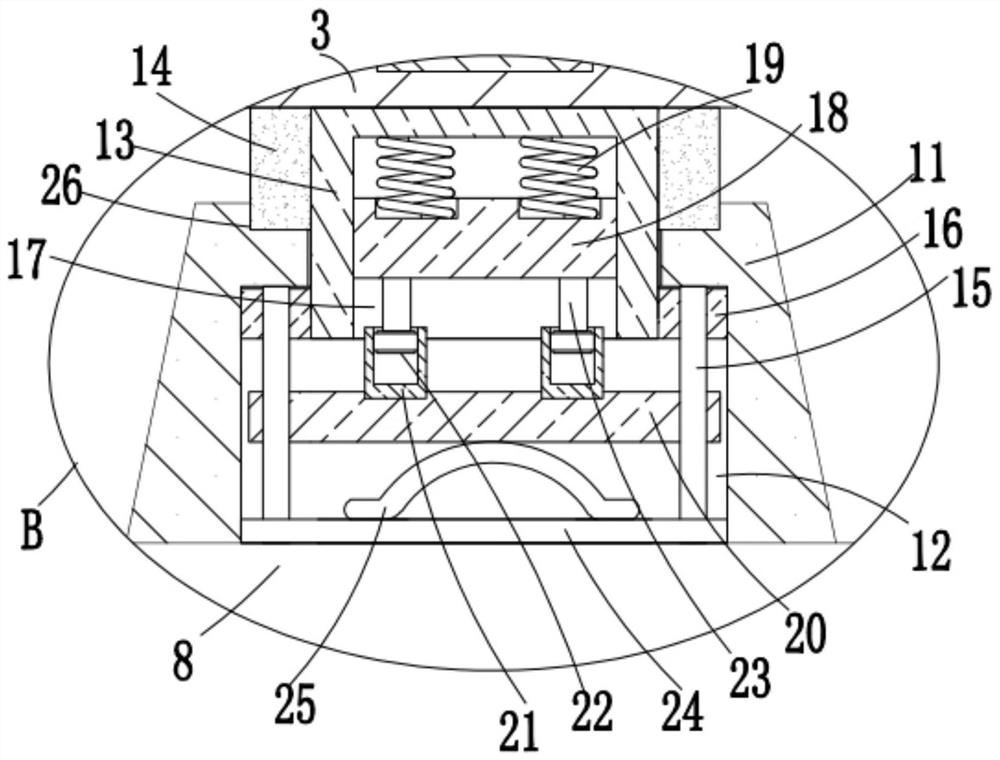

[0026] refer to Figure 1-4 , the present embodiment proposes a steel box girder tied-bar arch bridge structure, which includes an arch bridge structure body and support piers 200 respectively arranged below the four corners of the arch bridge structure body. Two arch rings 100, and a plurality of suspenders 102 arranged between the arch ring 100 and the tie beam 103, two arch feet 101 are uniformly arranged on both sides of the top of the tie beam 103, and the arch feet 101 and the corresponding arch rings The bottom end of 100 is fixedly connected, and the top of the support pier 200 is provided with a first slot 201, and the bottom inner wall of the first slot 201 is provided with a plurality of second slots 202, and the bottom four corners of the tie beam 103 are fixedly connected with Rectangular deck 1, two rectangular decks 1 opposite to each other are provided with a rectangular slot 2 on the side close to each other, and a quick-connect mechanism is arranged between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com