Combined Smart Carbon Skateboard Carrier Tool and Method of Operation Facilitating Two-way Scribing

A carbon slide, combined technology, used in manufacturing tools, workpiece clamping devices, workshop equipment, etc., can solve the problems of inaccurate and inconvenient straight lines, affecting the scribing efficiency, and increasing the processing cost, so as to improve the scribing efficiency. and accuracy, solve the effect of fixing incomprehension, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

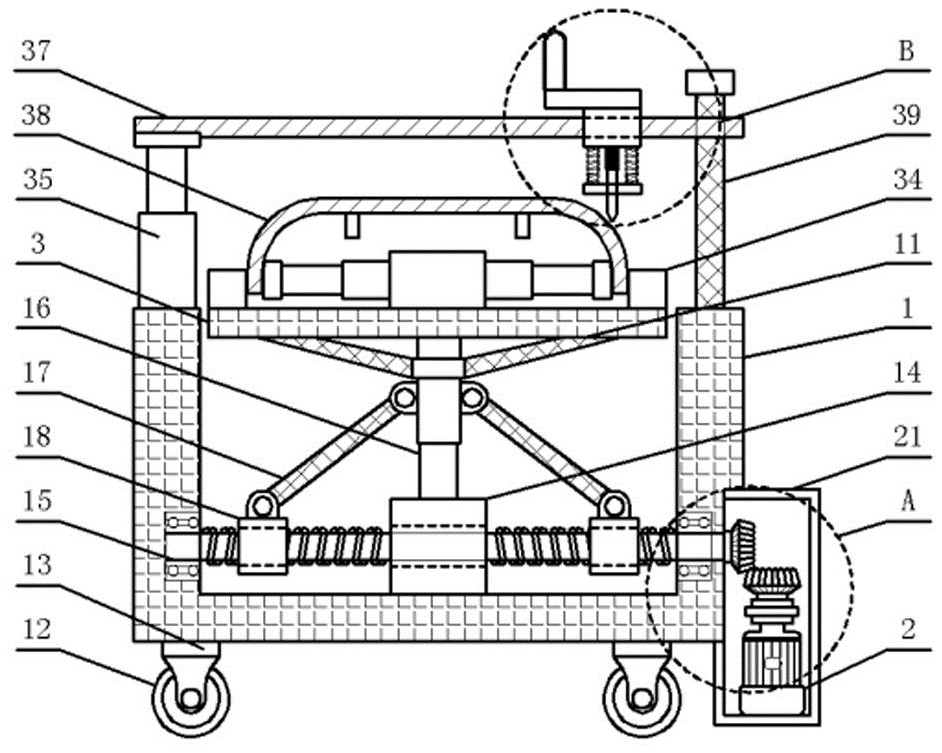

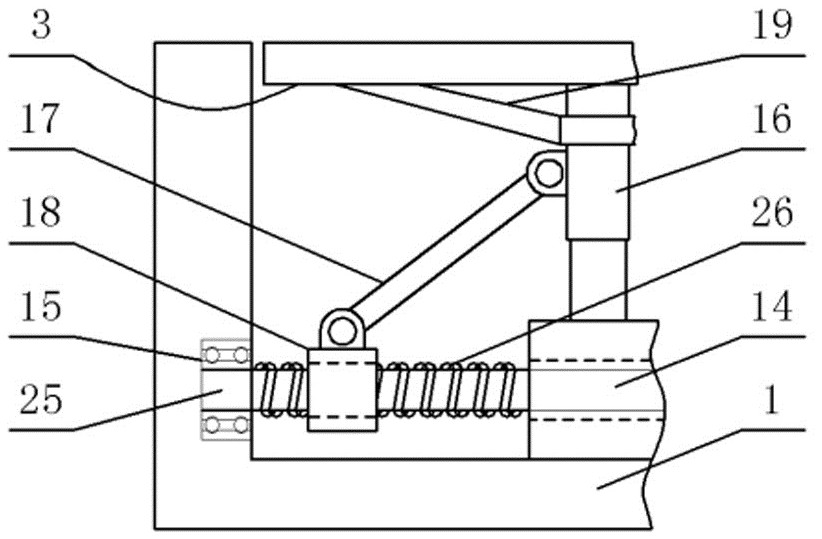

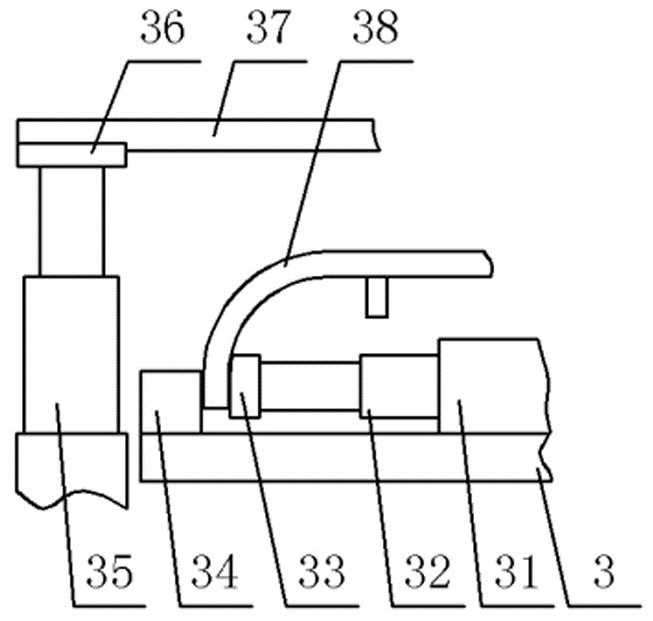

[0033] Example 1: see Figure 1-5 , a combined intelligent carbon skateboard bracket tool for two-way scribing, including a bottom plate 1, the bottom plate 1 is a U-shaped plate placed horizontally and laterally, a support block 14 is provided in the middle of the inner top surface of the bottom plate 1, and the bottom plate 1 The bottom of the right end face is provided with a vertically placed motor box 21 , the inner bottom of the motor box 21 is provided with a vertically upward motor 2 , and the motor 2 is movably connected with the support block 14 through a transmission mechanism; There is a horizontally placed lifting plate 3 directly above, and the bottom surface of the lifting plate 3 is movably connected to the top surface of the support block 14 through a link mechanism; The two bottom ends of the carbon sliding plate 38 are respectively fixed on both sides of the top surface of the lift plate 3 by clamping components; the top surface of the left side wall of the ...

Embodiment 2

[0040] Example 2: see Image 6 , in this embodiment, the present invention also proposes an operation method of a combined intelligent carbon skateboard bracket tool that is convenient for bidirectional scribing, including the following steps:

[0041] Step 1, the tail end of the motor 2 is electrically connected to the external power source through the motor wire, the tail end of the first telescopic cylinder 32 is electrically connected to the external power source through the first wire, and the tail end of the second telescopic cylinder 35 is electrically connected to the external power source through the second wire. sexual connection;

[0042] Step 2, the two bottom ends of the carbon slide plate 38 to be marked are respectively fixed on both sides of the top surface of the lift plate 3 through the clamping assembly; the two ends of the carbon slide plate 38 are placed on the inside of the two stoppers 34, and the two A telescopic cylinder 32 stretches at the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com