A preparation method and use of bamboo pulp fibers and bamboo extracts from bamboo

A bamboo pulp fiber and extract technology, which is applied in the direction of cellulose raw material pulping, fiber raw material processing, manufacturing tools, etc., can solve the problem of not fully realizing the value of bamboo resources, high waste and waste water treatment costs, and the existence of waste or waste water. and other problems, to achieve the effect of improving the pulping environment of bamboo pulp fiber, reducing pulping cost and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

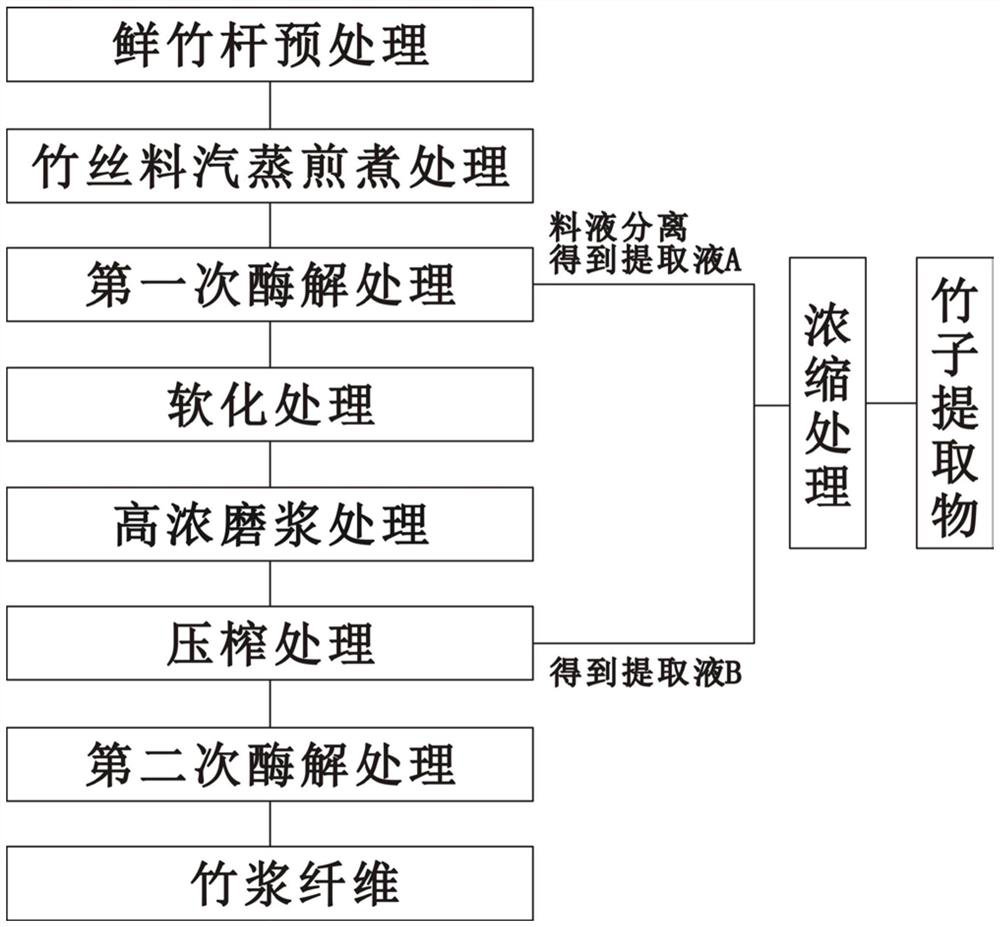

[0035] Such as figure 1 Shown, a kind of preparation method of producing bamboo pulp fiber and bamboo extract with bamboo, its method is as follows:

[0036] A, pretreatment of fresh bamboo stalks: collect fresh bamboo stalks of Grass plants that are 1 to 2 years old, and remove branches and leaves on the fresh bamboo stalks to form fresh bamboo stalk raw materials. Eliminate moth-eaten and spotted bamboo stalks for fresh bamboo stalks; transport the fresh bamboo stalk raw materials to the bamboo slice cutting machine through the belt conveyor and cut them into fresh bamboo slices. The length of each fresh bamboo slice is controlled at 40-120 mm; the fresh bamboo The bamboo chips are transported to the bamboo chip washing machine by the belt conveyor for washing, and the washed fresh bamboo chips are torn into fine bamboo silk materials, and the diameter of the bamboo silk materials is less than 2 mm.

[0037] B. Steaming and decocting treatment of bamboo silk material: send ...

Embodiment 2

[0044] Such as figure 1 Shown, a kind of preparation method of producing bamboo pulp fiber and bamboo extract with bamboo, its method is as follows:

[0045] A, fresh bamboo stalk pretreatment (corresponding figure 1 pretreatment of fresh bamboo stalks): collect fresh bamboo stalks of Gramineae plants that are 1 to 2 years old, and remove the branches and leaves on the fresh bamboo stalks to form fresh bamboo stalk raw materials. Eliminate moth-eaten and spotted bamboo stalks for fresh bamboo stalks; transport the fresh bamboo stalk raw materials to the bamboo slice cutting machine through the belt conveyor and cut them into fresh bamboo slices. The length of each fresh bamboo slice is controlled at 40-120 mm; the fresh bamboo The bamboo chips are transported to the bamboo chip washing machine by the belt conveyor for washing, and the washed fresh bamboo chips are torn into fine bamboo silk materials, and the diameter of the bamboo silk materials is less than 2 mm.

[0046] ...

Embodiment 3

[0060] Such as figure 1 Shown, a kind of preparation method of producing bamboo pulp fiber and bamboo extract with bamboo, its method is as follows:

[0061] A, pretreatment of fresh bamboo stalks: collect fresh bamboo stalks of Grass plants that are 1 to 2 years old, and remove branches and leaves on the fresh bamboo stalks to form fresh bamboo stalk raw materials. Eliminate moth-eaten and spotted bamboo stalks for fresh bamboo stalks; transport fresh bamboo stalk raw materials to bamboo slice cutting machine through belt conveyor and cut them into fresh bamboo slices, and the length of each fresh bamboo slice is controlled at 80-120 mm; The bamboo chips are transported to the bamboo chip washing machine by the belt conveyor for washing, and the washed fresh bamboo chips are sent to the tearing and kneading machine to be torn into fine bamboo silk materials, and the diameter of the bamboo silk materials is less than 2 mm.

[0062] B, steaming and decocting treatment of bambo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| dryness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com