A device for manufacturing dripping glazed tile blanks

A technology for manufacturing devices and blanks, which is applied in the field of manufacturing devices for dripping glazed tile blanks, and can solve problems such as uneven thickness and affecting the quality of blanks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

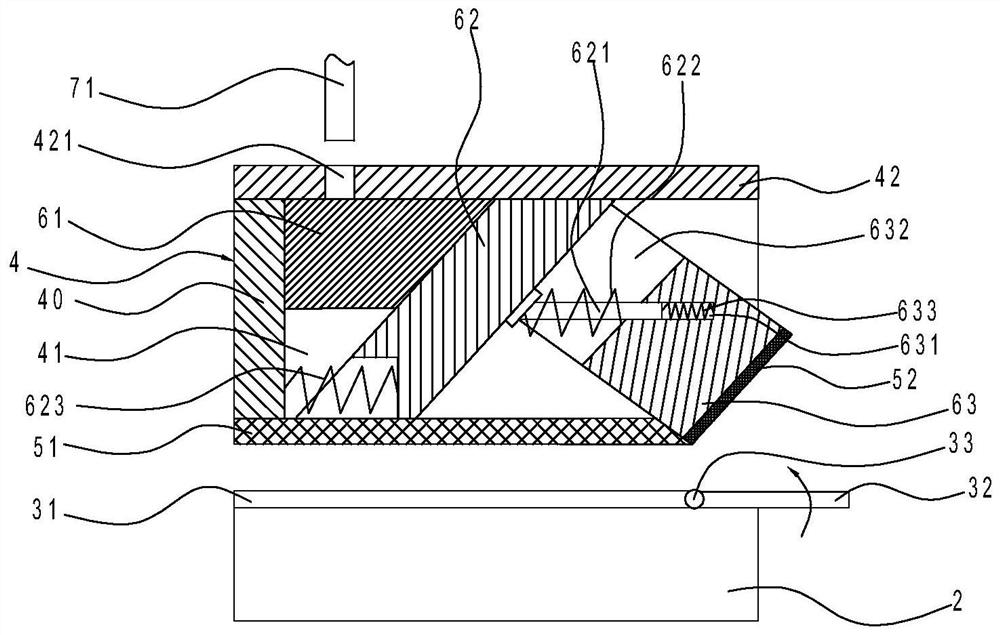

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0020] like Figures 2 to 8 As shown, the device for manufacturing dripping glazed tile blanks in this implementation includes a base 2, a tile body bottom mold 31, a tile bottom mold 32, a rotating shaft 33, a rotating motor 34, a top pressure seat 4, a plurality of guide posts 8, a plurality of Root limit column 83, pressure rod 72, pressure plate 7, upper spring 81, lower spring 82, vertical slider 61, middle slider 62, side slider 63, tile body top mold 51, tile top mold 52, return spring 623 transverse guide bar 621, transverse spring 622, hold down spring 633, cutter and cut off cylinder.

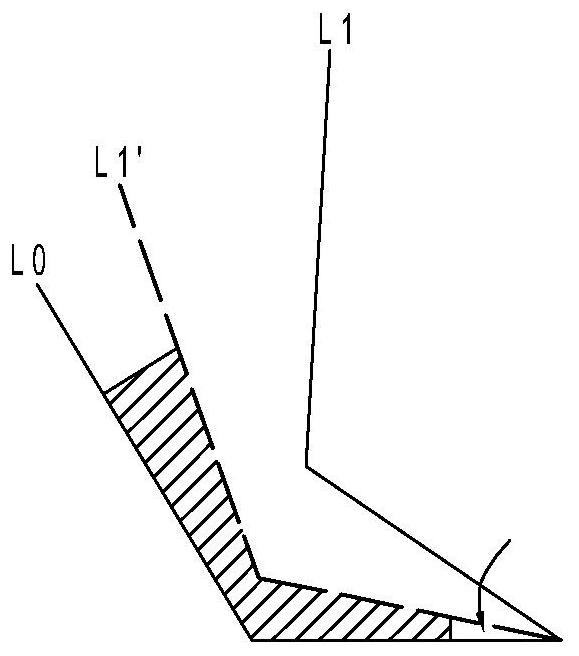

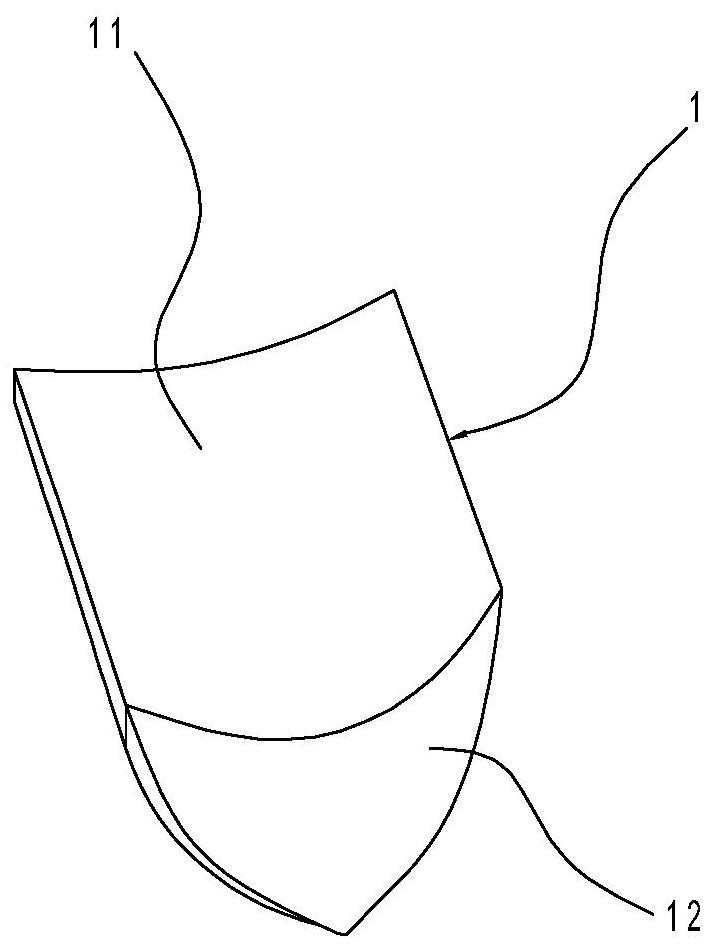

[0021] Among them, the tile body bottom mold 31 and the tile piece bottom mold 32 are arranged on the base 2, the tile body bottom mold 31 is used for forming the rough piece 1 tile body 11, and the tile piece bottom mold 32 is used for forming the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com