Welding device for cable breakage maintenance

A welding device and cable technology, which is applied in the field of welding devices for repairing cable fractures, can solve problems such as inability to repair cracks in the cable sheath, and achieve the effect of avoiding tilting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

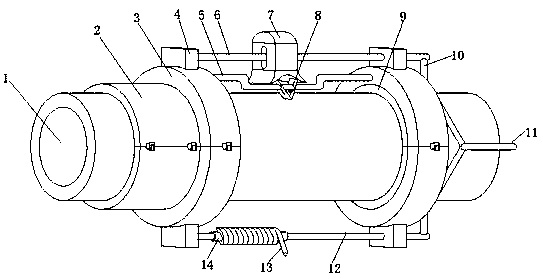

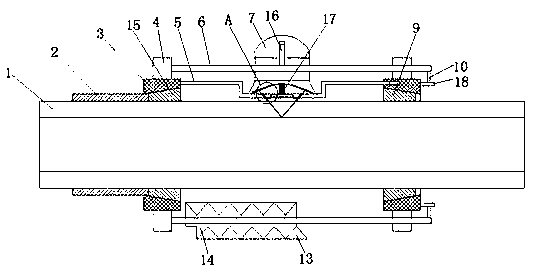

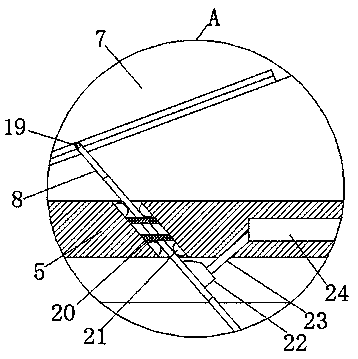

[0028] refer to Figure 1-4 , a welding device for repairing cable breakage, comprising a first rubber ring 9 and a second rubber ring 15 fixed on the outer wall of the cable 1, a handle 2 is bonded to one side of the second rubber ring 15, the first rubber ring 9 and the The outer wall of the second rubber ring 15 is provided with a fixed ring 3, and the top and bottom ends of the two fixed rings 3 are welded with a first fixed block 4, and one side of the first fixed block 4 is welded with a second fixed rod 6. The middle part of the two fixed rods 6 is provided with a second fixed block 7, and the bottom end of the second fixed block 7 is provided with two blades 8, and the middle part of the blade 8 is provided with a square through hole, and a first fixed block is provided between the two fixed rings 3. Fixed rod 5, the middle part of the first fixed rod 5 is provided with two openings, the first fixed rod 5 is provided with a guide rod 20 at the opening, and the guide ro...

Embodiment 2

[0038] refer to Figure 5-6 , a welding device for repairing cable fractures. Compared with Embodiment 1, in this embodiment, in order to increase the stability of the device, the inner wall of the fixed ring 3 is provided with two annular grooves, and the fixed ring 3 is provided between the two annular grooves. Inner wall is bonded with slideway 25, and the material of slideway 25 is iron, and the inside of slideway 25 is provided with magnetic ball 26, and magnetic ball 26 can be attracted together with slideway 25, avoids falling off, and the first rubber ring 9 and the second The outer wall of the rubber ring 15 is bonded with a fixed plate 27, and the outer wall of the fixed plate 27 is provided with two chutes, so that the magnetic ball 26 can slide inside the chute. little friction.

[0039] During use, after the handle 2, the fixed ring 3, the first rubber ring 9 and the second rubber ring 15 are installed on the outside of the cable 1 through buckles, the rotating r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com