Efficient goods sorting system

A high-efficiency, shelf technology, used in transportation, packaging, storage devices, etc., can solve the problems of high human resource occupancy, high sorting work intensity, low work efficiency, etc., to reduce the use of labor and reduce the time when items are vacant. , the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

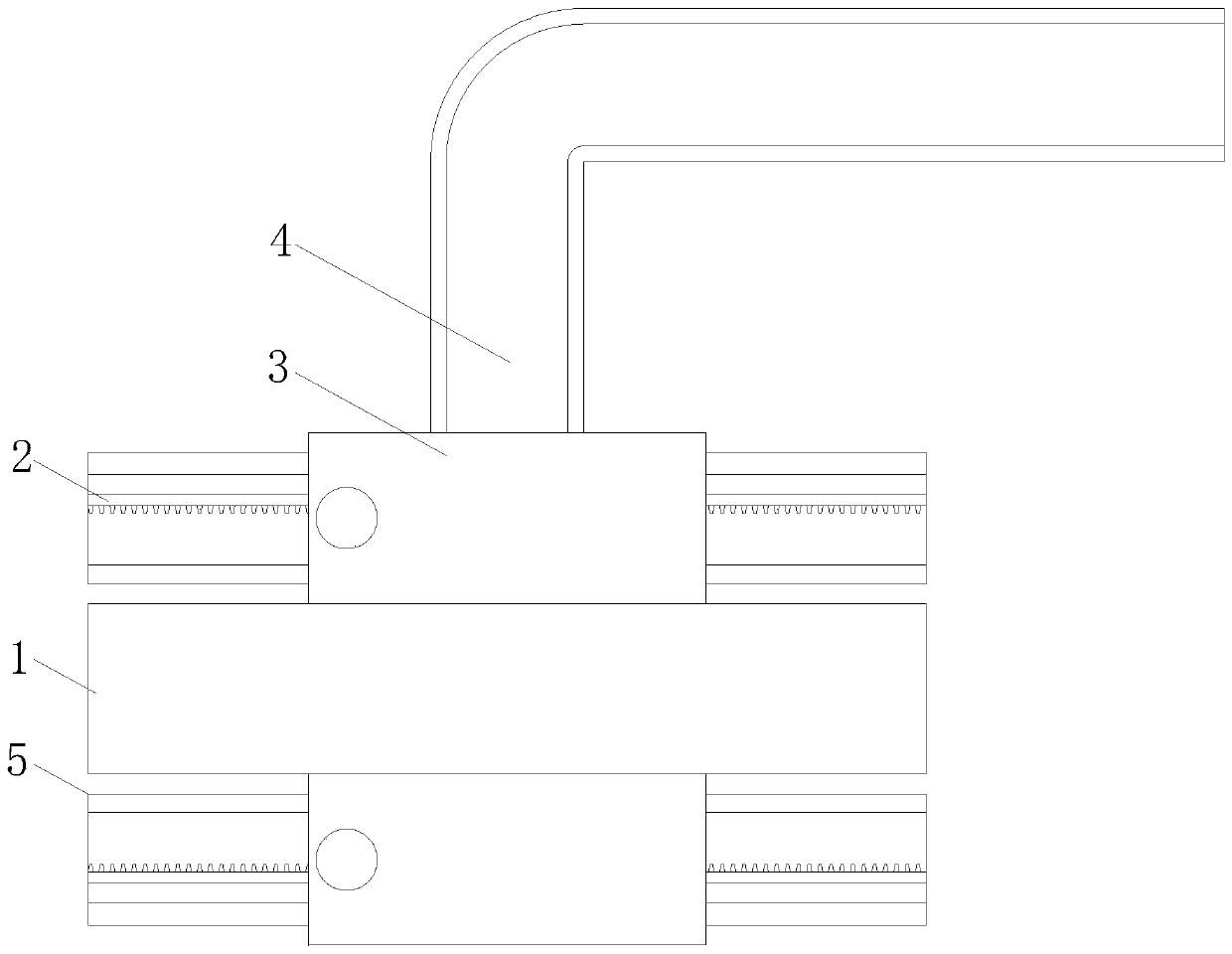

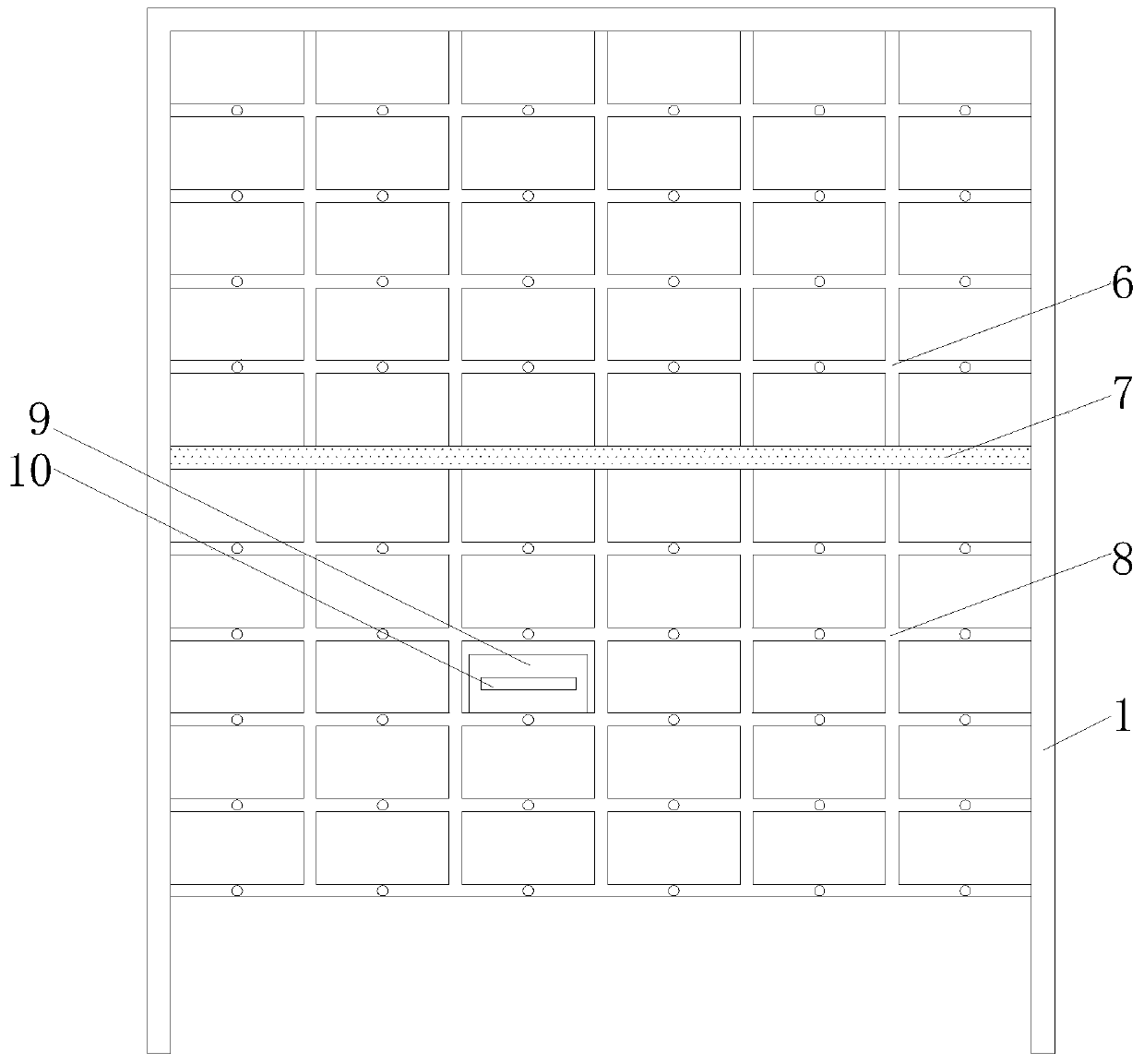

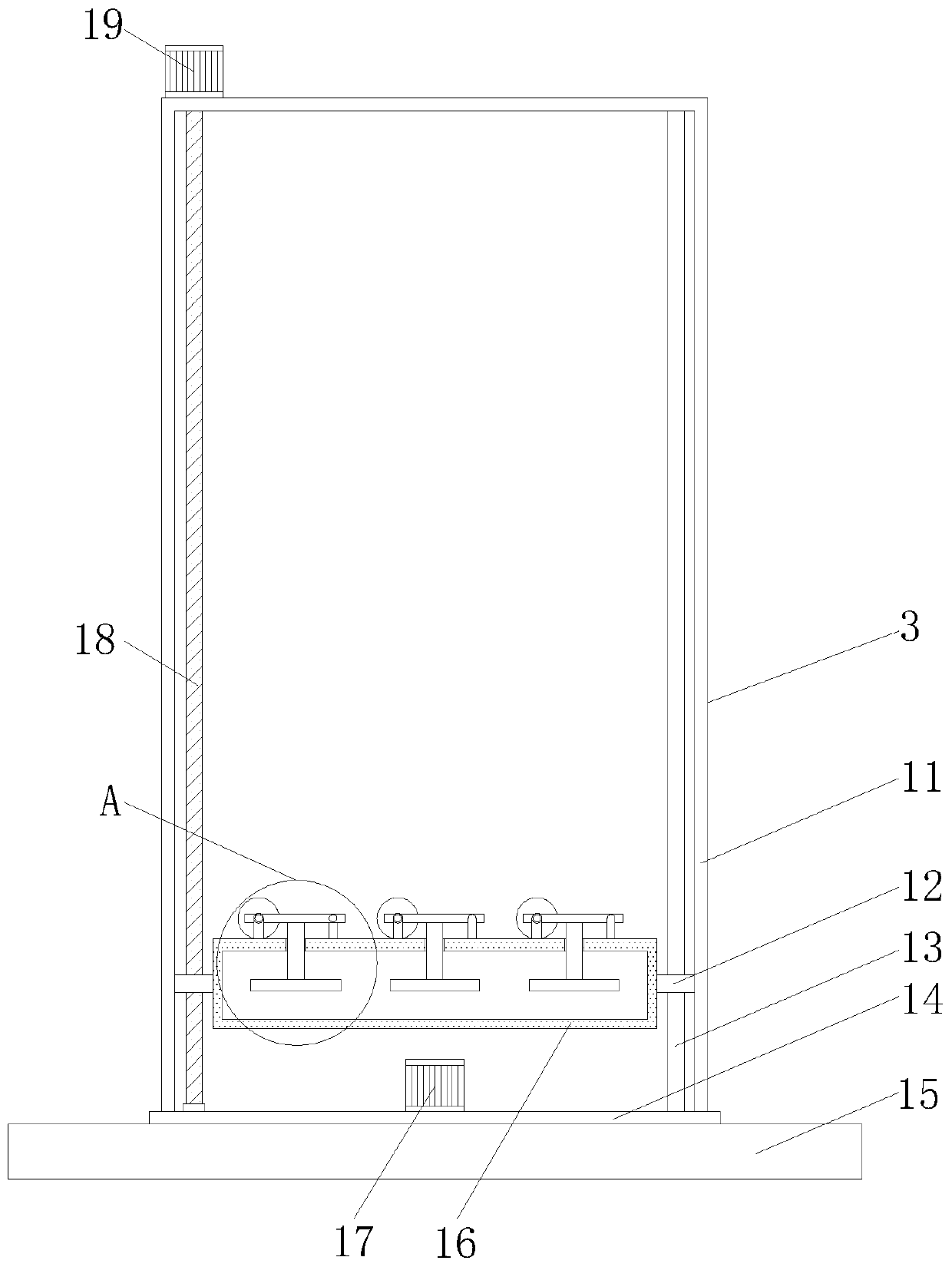

[0021] see Figure 1~4 , in an embodiment of the present invention, an efficient picking system includes an item rack 1, a first picking mechanism 3, a conveyor 4 and a controller. A picking rack 8 is fixedly installed inside the item rack 1, and the picking rack 8 passes through it The storage cavity provided on the top is placed with an article frame 9, and the front end surface and the rear end surface of the article frame 9 are fixedly equipped with magnet blocks 10. The first picking mechanism 3 includes a frame 15, and the frame 15 passes through the groove provided on its top. The rack 2 is fixedly installed, and the frame 15 is slidably connected with the mov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap