Waste silk curling collection device of automatic doffer

A technology of automatic doffing and collecting device, which is applied in textile and papermaking, complete sets of equipment for the production of artificial threads, cutting of textile materials, etc. Avoid normal operation detection, reduce the amount of flying silk, and ensure the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

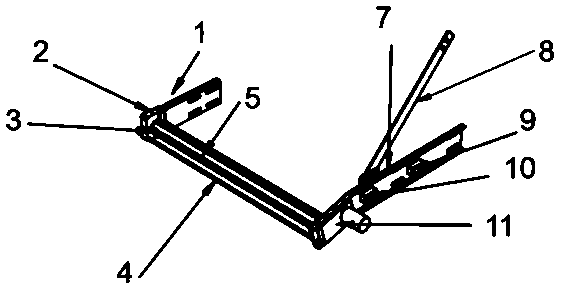

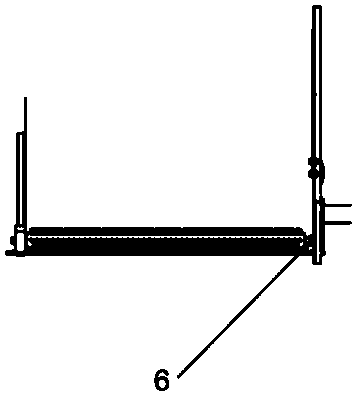

[0022] In this embodiment, the brackets are the left bracket (1) and the right bracket (7), the number is two, the material is aluminum, and the left and right brackets are properly connected by a fixed screw (4), and the distance is 590mm; the brush roller (5) is driven by the speed reducer (11) through the rotating mechanism to work; the support rod (8) is detachably connected to the outside of the right bracket (7), the number is 1, mainly To strengthen the support; the rotating mechanism adopts a bearing rotating mechanism, which includes a bearing seat (2) and a built-in bearing (3) installed on the top of the left bracket (1); the brush roller (5) is fixed on the rotating shaft and The ferrule (6) installed on the right bracket; the material of the brush implanted in the brush roller body is iron wire.

Embodiment 2

[0024] In this embodiment, the brackets are the left bracket (1) and the right bracket (7), the number is two, the material is steel, and the left and right brackets are properly connected by a fixed screw (4), and the distance is 590mm The brush roller (5) is driven by the speed reducer (11) through the rotating mechanism to rotate; the support rod (8) is detachably connected to the inner side of the right bracket (7), and the number is two, mainly Strengthen the role of support; the rotating mechanism adopts a bearing rotating mechanism, which includes a bearing seat (2) and a built-in bearing (3) installed on the top of the left bracket (1); the brush roller (5) is fixed on the rotating shaft and installed The ferrule (6) on the right bracket; the brush material implanted in the brush roller body is nylon.

[0025] Reference figure 1 As shown, when the automatic doffing machine is running, the motor switch (10) of the collecting device is activated. The motor is used as the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com