Cotton and linen fabric color fixation technology for luggage bags

A technology of cotton and linen fabrics, which is applied in the field of color fixing process of cotton and linen fabrics for bags and bags, can solve the problems of color fading and color fading of cotton and linen fabrics, and achieve the effects of convenient operation, reduced color fading, and improved color fixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

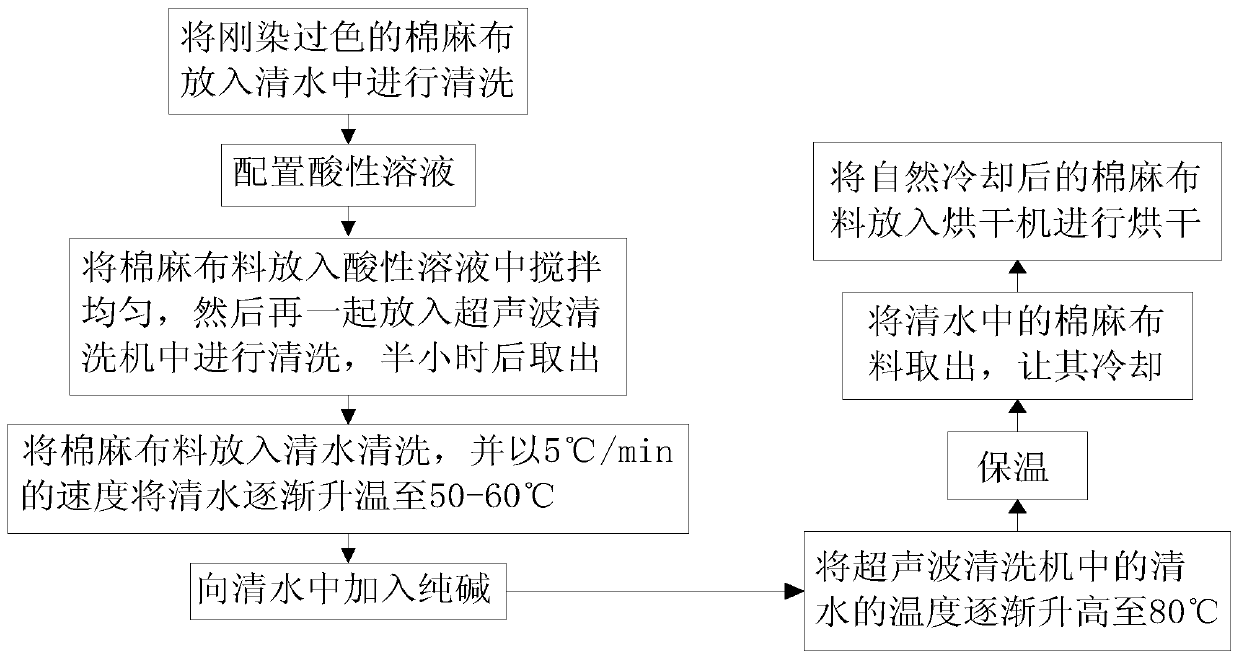

[0029] Such as figure 1 Shown, a kind of process for fixing color of cotton and linen cloth for bag cloth bag, this process comprises the following steps:

[0030] 1. Put the newly dyed cotton and linen cloth into clean water at 35°C for cleaning, and clean the undyed pigment;

[0031] 2. Configure a colorless dilute acetic acid solution with a concentration of 1%.

[0032] 3. Put the cotton and linen cloth cleaned in step 1 into the acid solution in step 2 and use wooden sticks to switch clockwise and counterclockwise in turn to stir the cotton and linen cloth and acid solution evenly, and then put the cotton and linen cloth and acidic solution Put the solution together into the ultrasonic cleaning machine for cleaning, and take out the cotton and linen cloth after half an hour;

[0033] 4. Put the cotton and linen cloth taken out in step 3 into clean water for cleaning. During the cleaning process, gradually raise the temperature of the clean water to 50°C at a speed of 2 ...

Embodiment 2

[0039] Such as figure 1 Shown, a kind of process for fixing color of cotton and linen cloth for bag cloth bag, this process comprises the following steps:

[0040] 1. Put the newly dyed cotton and linen cloth into clean water at 40°C for cleaning, and clean the undyed pigment;

[0041] 2. Configure a colorless dilute acetic acid solution with a concentration of 1.5%.

[0042] 3. Put the cotton and linen cloth cleaned in step 1 into the acid solution in step 2 and use wooden sticks to switch clockwise and counterclockwise in turn to stir the cotton and linen cloth and acid solution evenly, and then put the cotton and linen cloth and acidic solution Put the solution together into the ultrasonic cleaning machine for cleaning, and take out the cotton and linen cloth after half an hour;

[0043] 4. Put the cotton and linen cloth taken out in step 3 into clean water for cleaning. During the cleaning process, gradually raise the temperature of the clean water to 55°C at a speed of ...

Embodiment 3

[0050] Such as figure 1 Shown, a kind of process for fixing color of cotton and linen cloth for bag cloth bag, this process comprises the following steps:

[0051] 1. Put the newly dyed cotton and linen cloth into clean water at 45°C for cleaning, and clean the undyed pigment;

[0052] 2. Configure a colorless dilute acetic acid solution with a concentration of 2%.

[0053] 3. Put the cotton and linen cloth cleaned in step 1 into the acid solution in step 2 and use wooden sticks to switch clockwise and counterclockwise in turn to stir the cotton and linen cloth and acid solution evenly, and then put the cotton and linen cloth and acidic solution Put the solution together into the ultrasonic cleaning machine for cleaning, and take out the cotton and linen cloth after half an hour;

[0054] 4. Put the cotton and linen cloth taken out in step 3 into clean water for cleaning. During the cleaning process, gradually raise the temperature of the clean water to 60°C at a rate of 3°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com