High-strength spring washer color zinc barrel plating production line and machining process

A spring washer, high-strength technology, applied in lighting and heating equipment, drying solid materials without heating, drying solid materials, etc., can solve problems such as troublesome processing technology, low degree of grease and rust, product surface residue, etc. Achieve the effects of simplifying the processing process, facilitating galvanizing processing, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. The following description of at least one exemplary embodiment is merely illustrative in nature and in no way taken as limiting the invention, its application or uses.

[0038]To keep the following description of the embodiments of the present invention clear and concise, detailed descriptions of known functions and known components are omitted from the present invention.

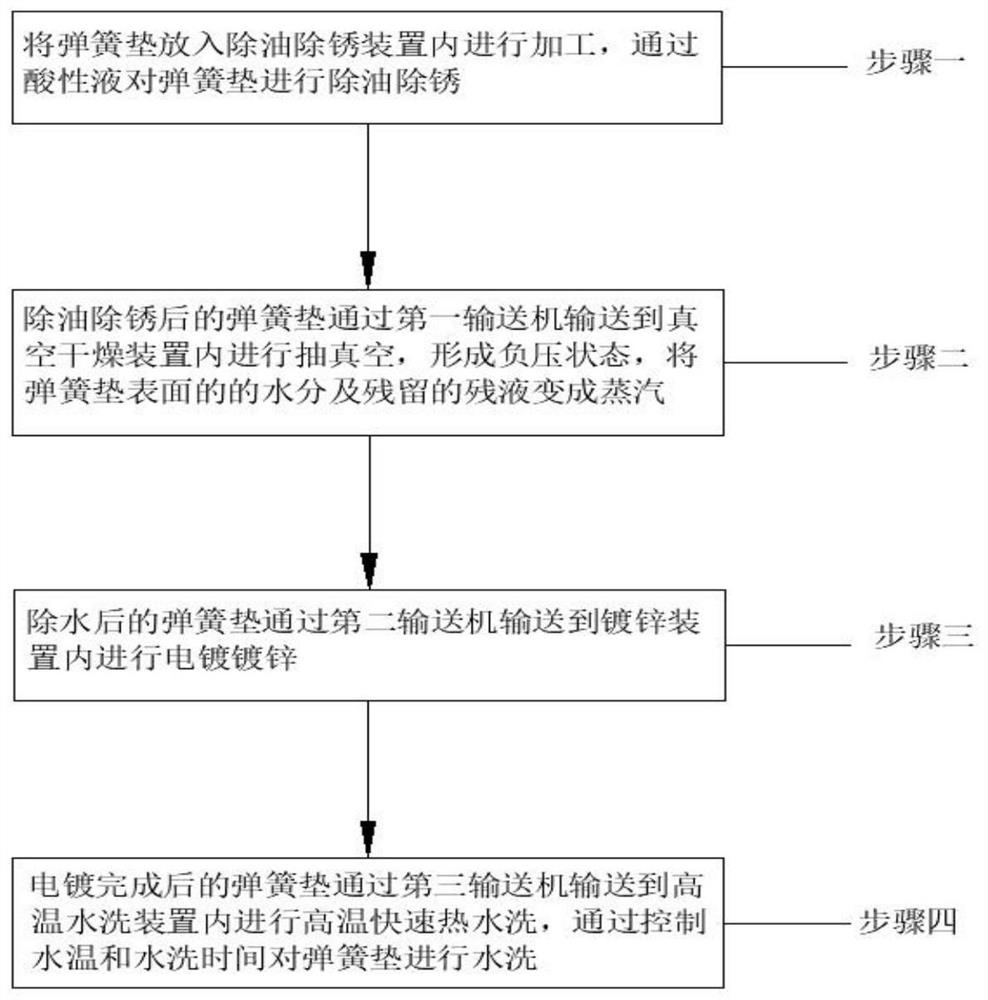

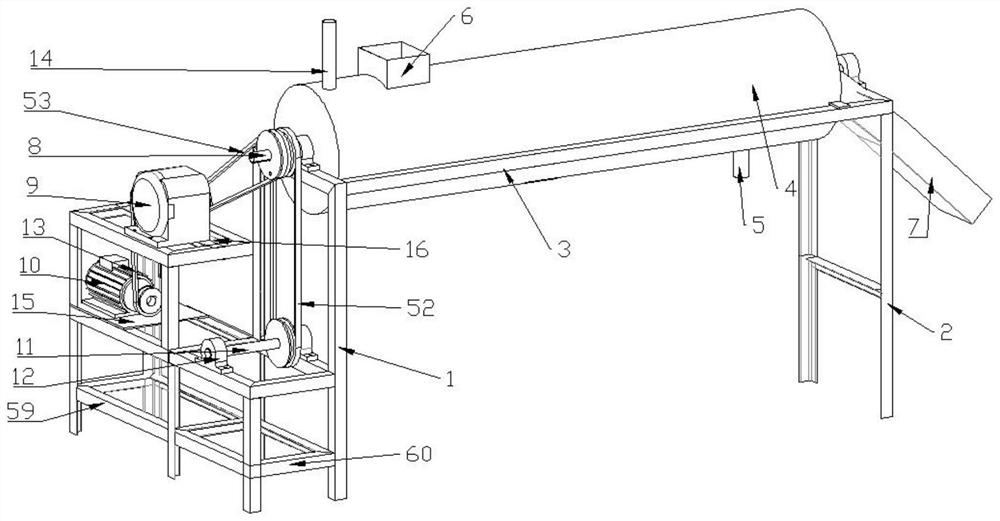

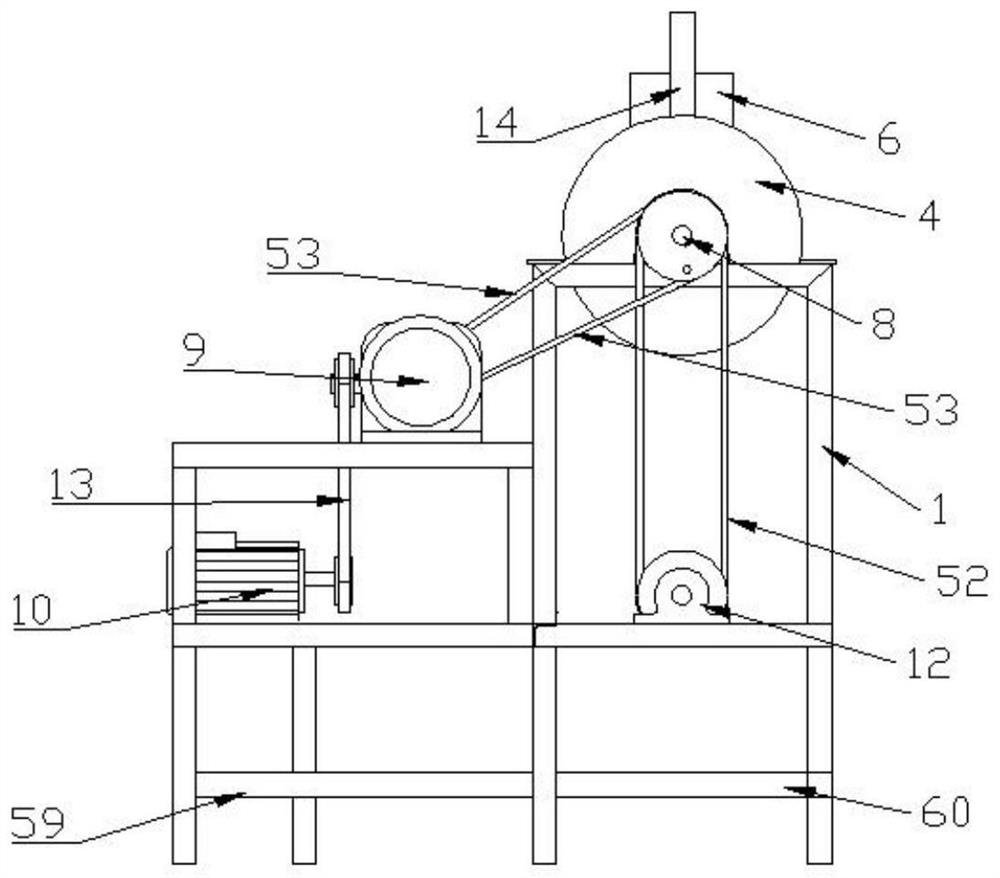

[0039] see Figure 1-11 As shown, in this embodiment, a high-strength spring washer color zinc barrel plating production line and processing technology are provided, including: a first conveyor is provided on one side of the oil and rust removal device, and a vacuum is provided on one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com