Piling method of sheet pile retaining structure and hanger type pile hammer

A technology of enclosure structure and pile driving hammer, which is applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of increasing construction cost, affecting construction efficiency, unable to complete the construction of steel sheet piles with various pile types, and achieving improved The effect of load strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Embodiments of the present invention will be described in detail below.

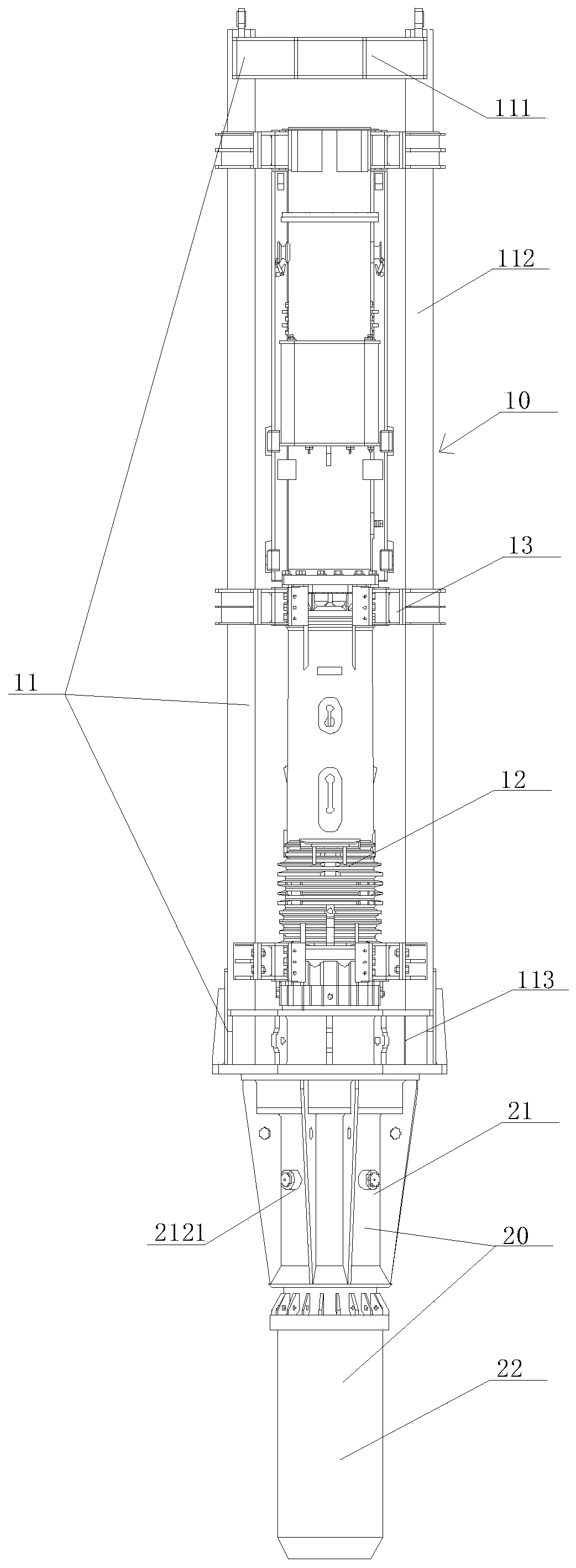

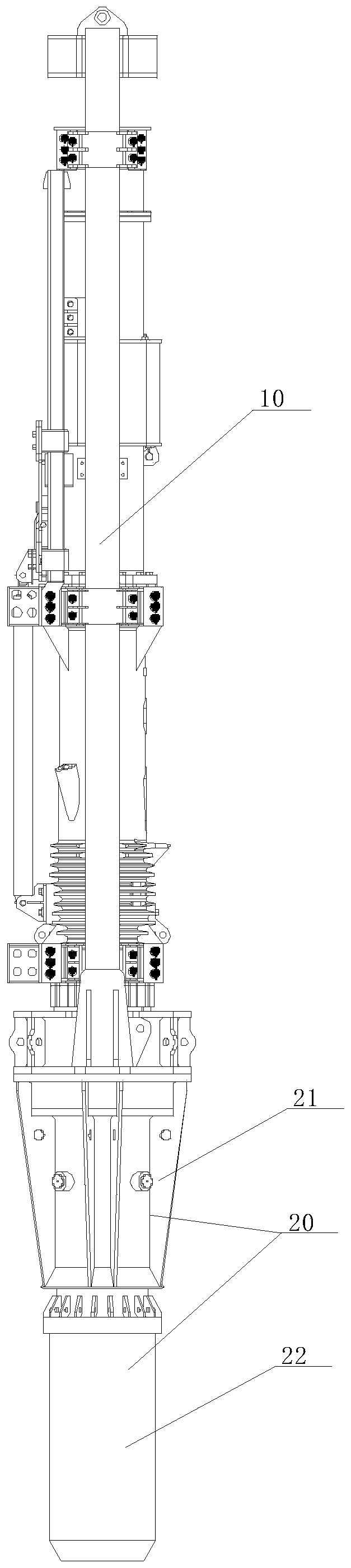

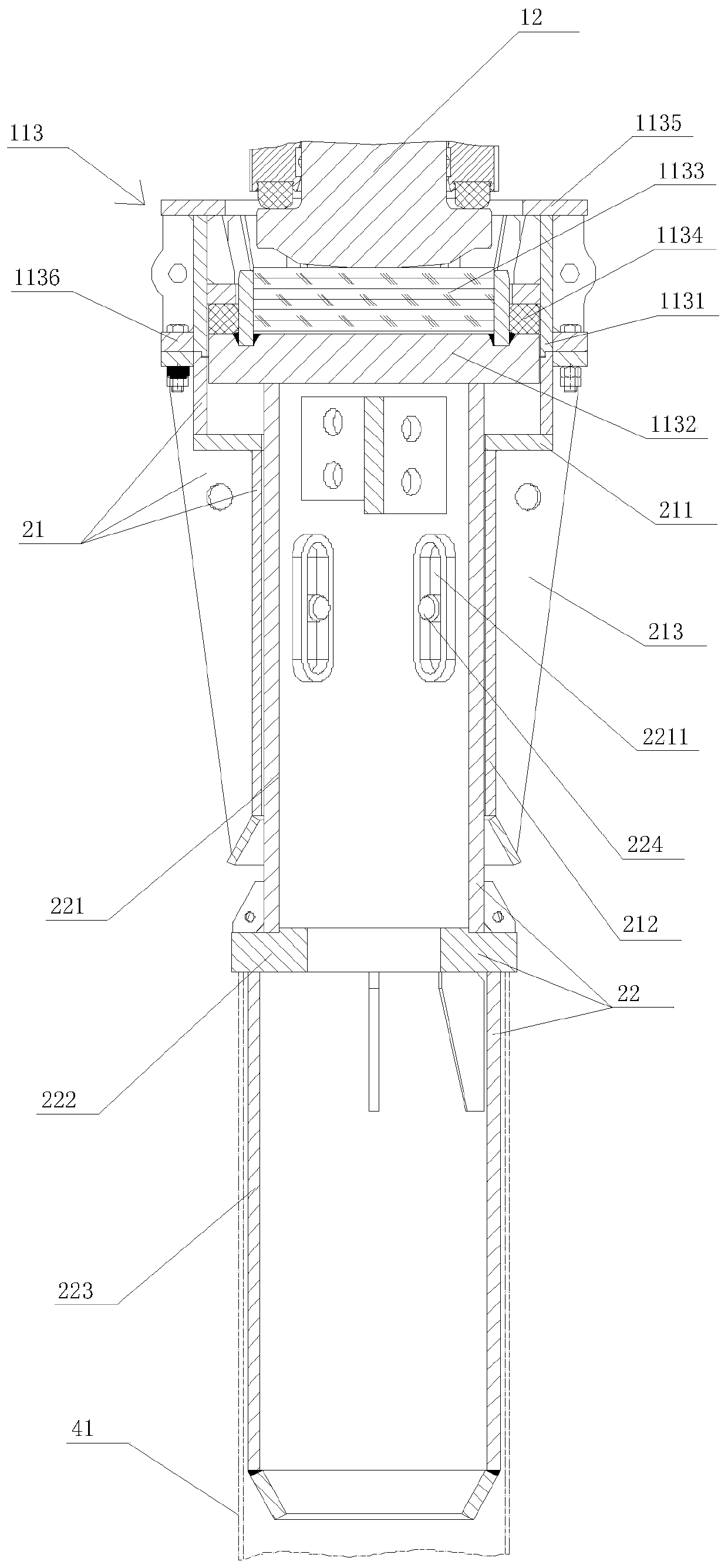

[0063] refer to Figure 1 to Figure 12 , the pile driving method of the sheet pile enclosure structure of the hanger type piling hammer provided by the present invention is suitable for the sheet pile enclosure construction of various pile type combinations, and can increase the load strength of the sheet pile structure of various pile type combinations , which includes the following steps:

[0064] Set a plurality of target sheet piles, the sheet piles include a plurality of steel pipe locking piles 41 and / or a plurality of steel plate locking piles 42, and the two sides of the steel pipe locking piles 41 and the steel plate locking piles 42 are respectively provided with toothed locks ;

[0065] At least one hanger-type piling hammer is set, and the hanger-type piling hammer includes a pile hammer 10 and a plurality of lower pile caps, each lower pile cap is interchangeably connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com