Low-back-pressure rotary compressor, corresponding oil return pressure drop control method and air conditioner

A rotary compressor and compressor technology, applied in the fields of low back pressure rotary compressors and air conditioners, to overcome ineffective lubrication, reduce refrigerant leakage, and ensure sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

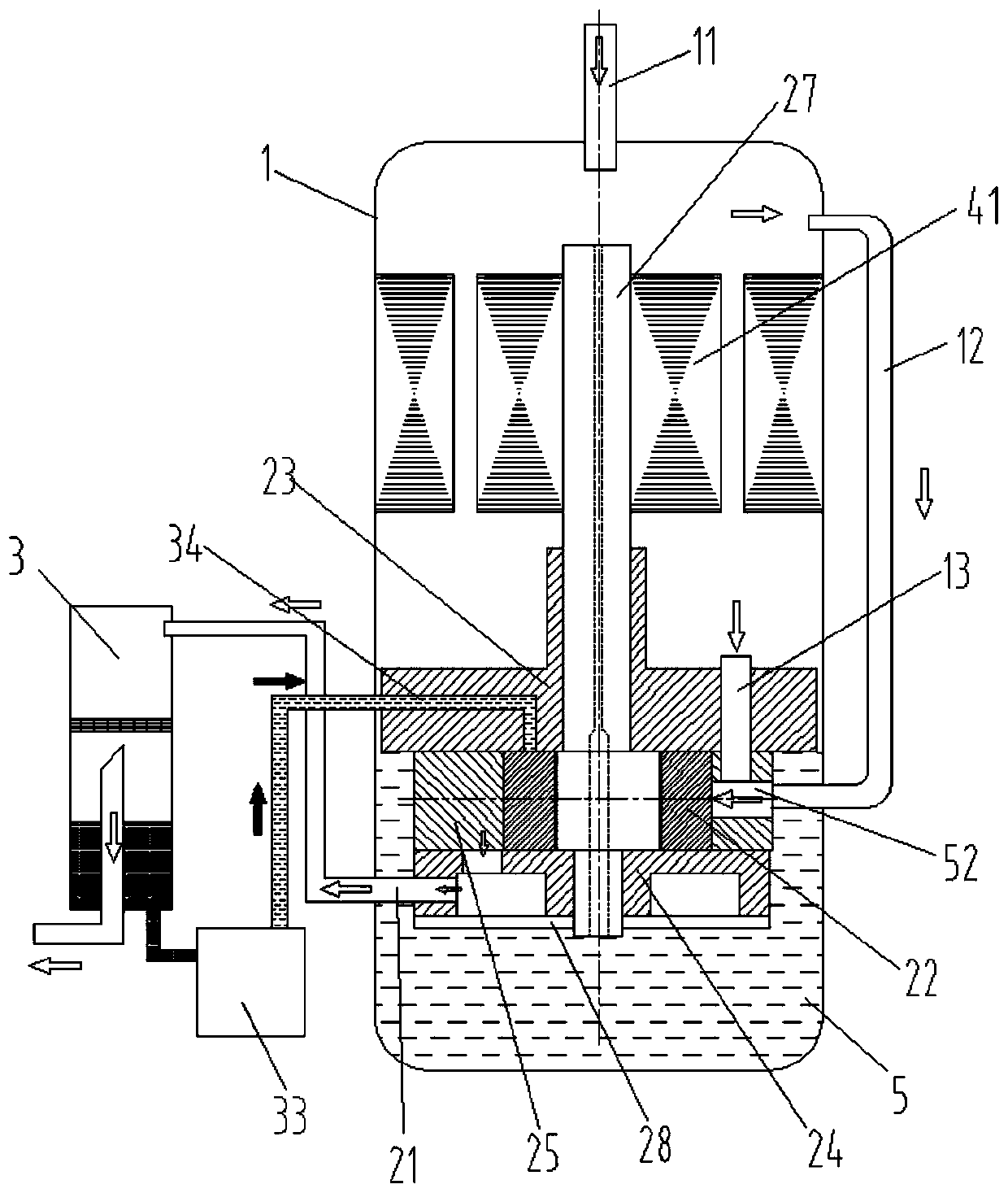

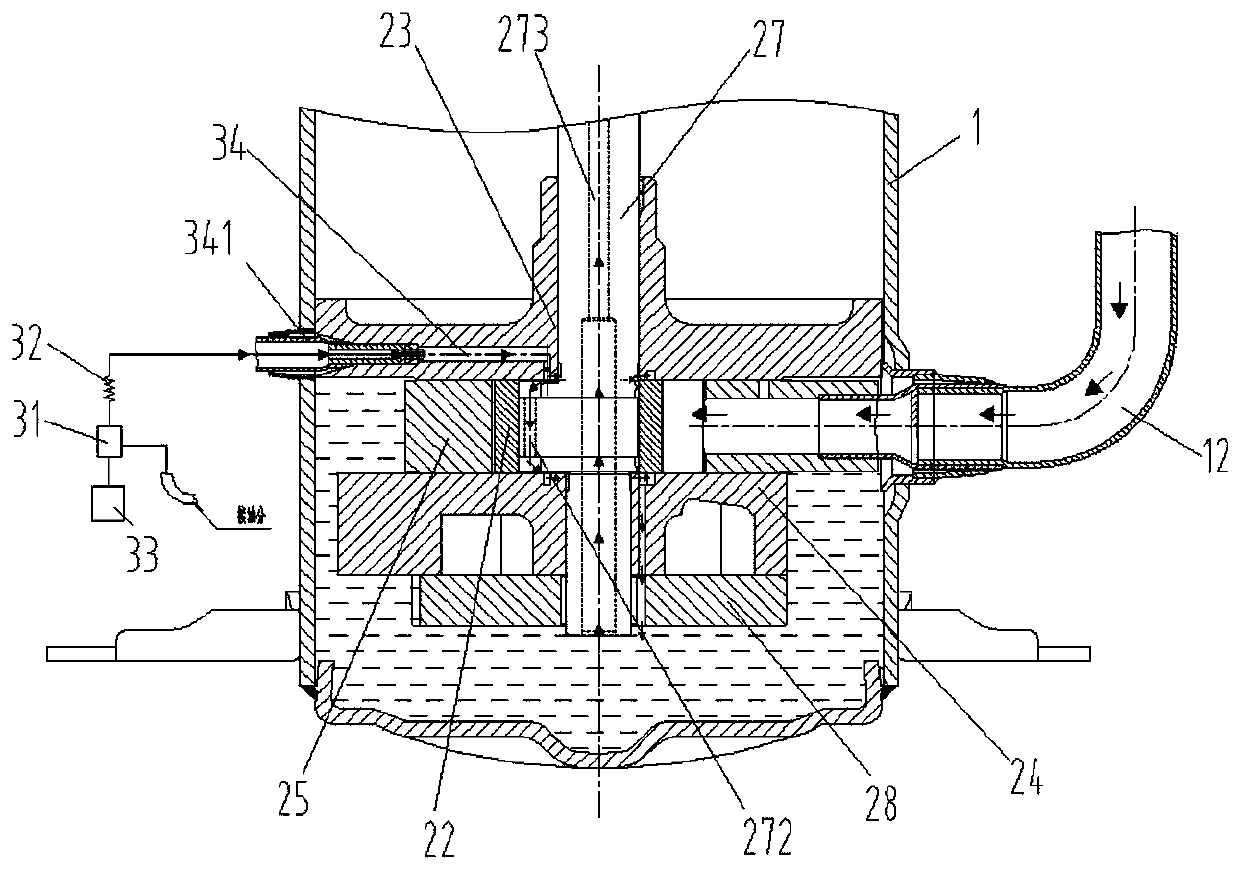

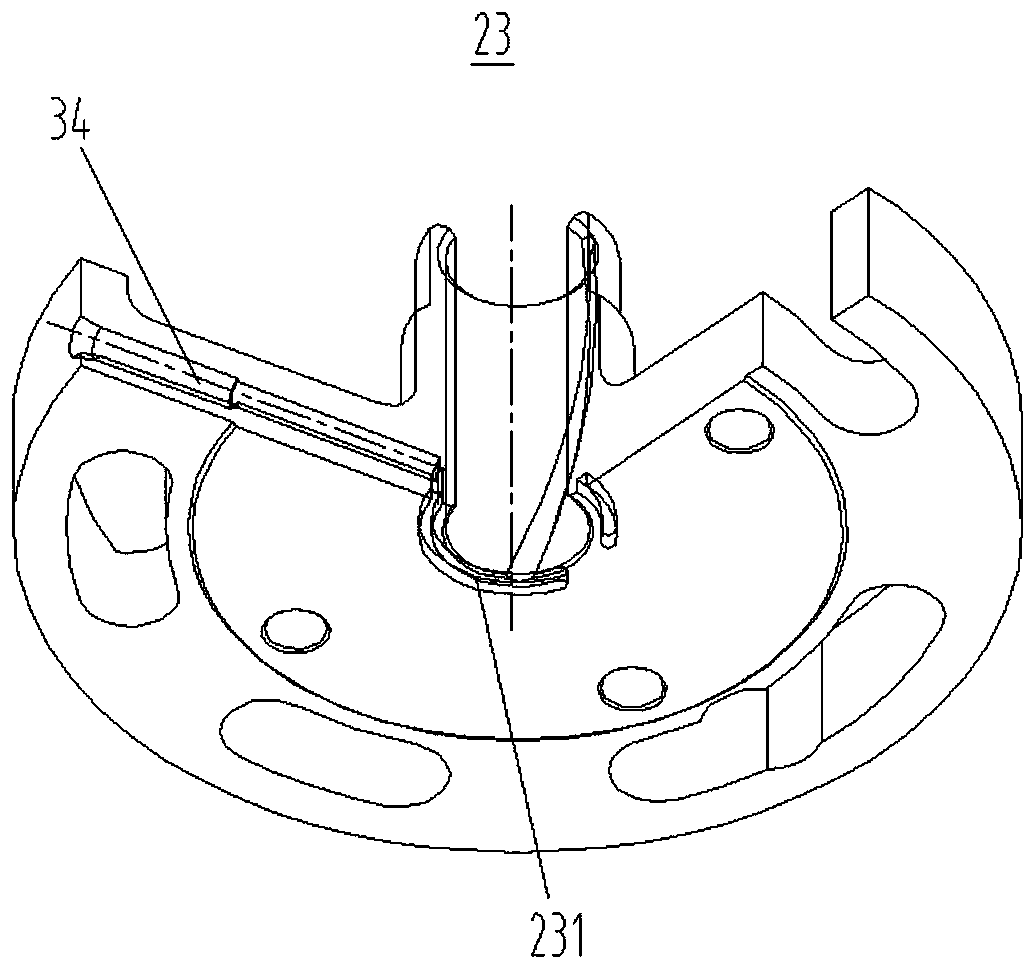

[0044] see in conjunction Figure 1 to Figure 9 As shown, according to the embodiment of the present invention, a low back pressure rotary compressor is provided, including a casing 1, a pump assembly inside the casing 1, an oil separator 3, and a motor assembly, and the motor The assembly is used to drive the operation of the pump body assembly to form periodic suction, compression and exhaust operations for the refrigerant flow. The oil separator 3 communicates with the exhaust port 21 of the pump body assembly. The oil separator 3 separates the lubricating oil in the refrigerant airflow discharged from the pump body assembly and collects it at its oil collection part to reduce the oil content in the system (to ensure the application system, such as the lubricating oil in the air conditioner system) low circulation rate), and also includes an oil return lubrication pipeline, the oil return lubrication pipeline is between the oil collection part of the oil separator 3 and at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com