Vertical thrust sliding bearing anti-shock device

A thrust sliding bearing and anti-vibration device technology, applied in bearing assembly, rotating bearing, rigid support of bearing components, etc., can solve the problems of insufficient instantaneous rigidity, large displacement deformation, small structural damping, etc., to ensure safe operation, The effect of small displacement deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

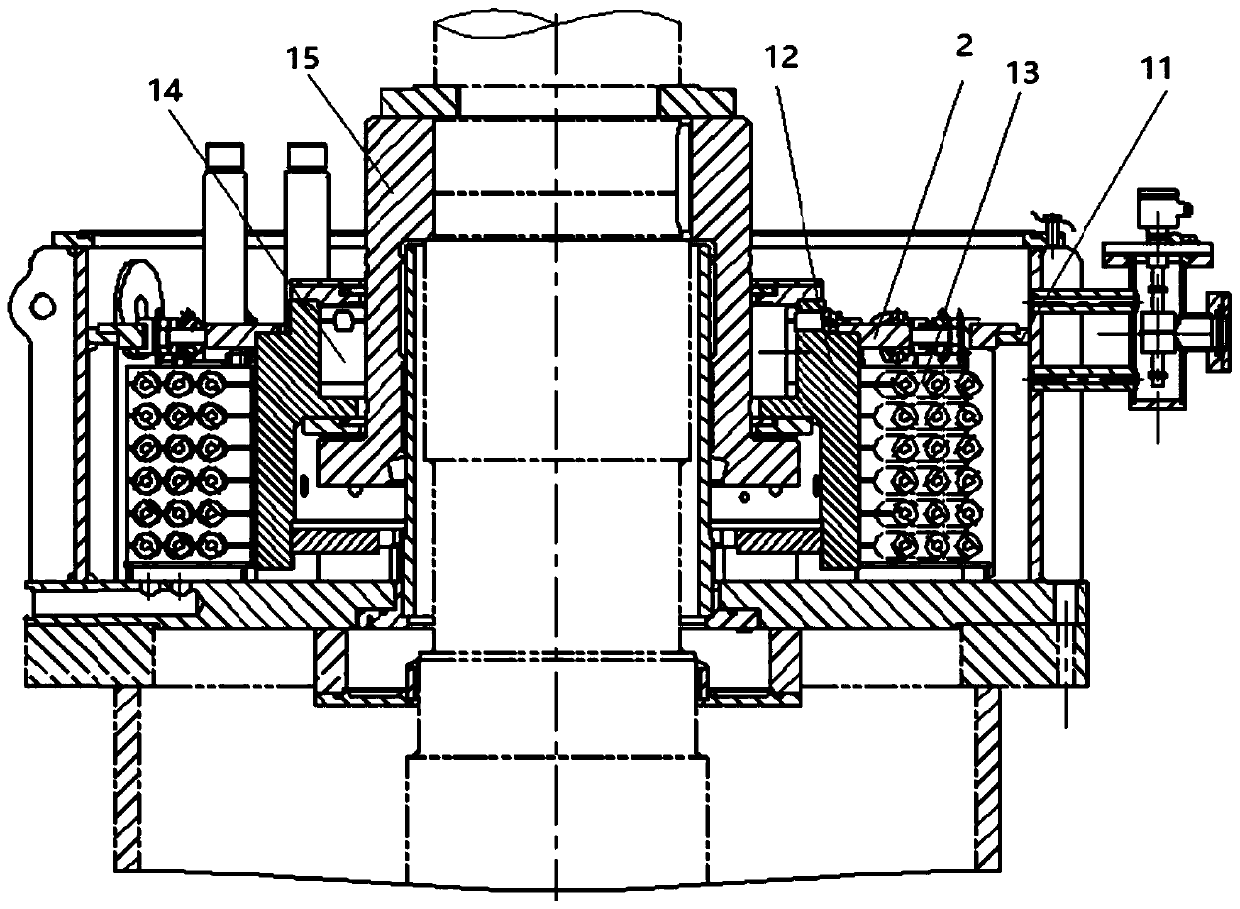

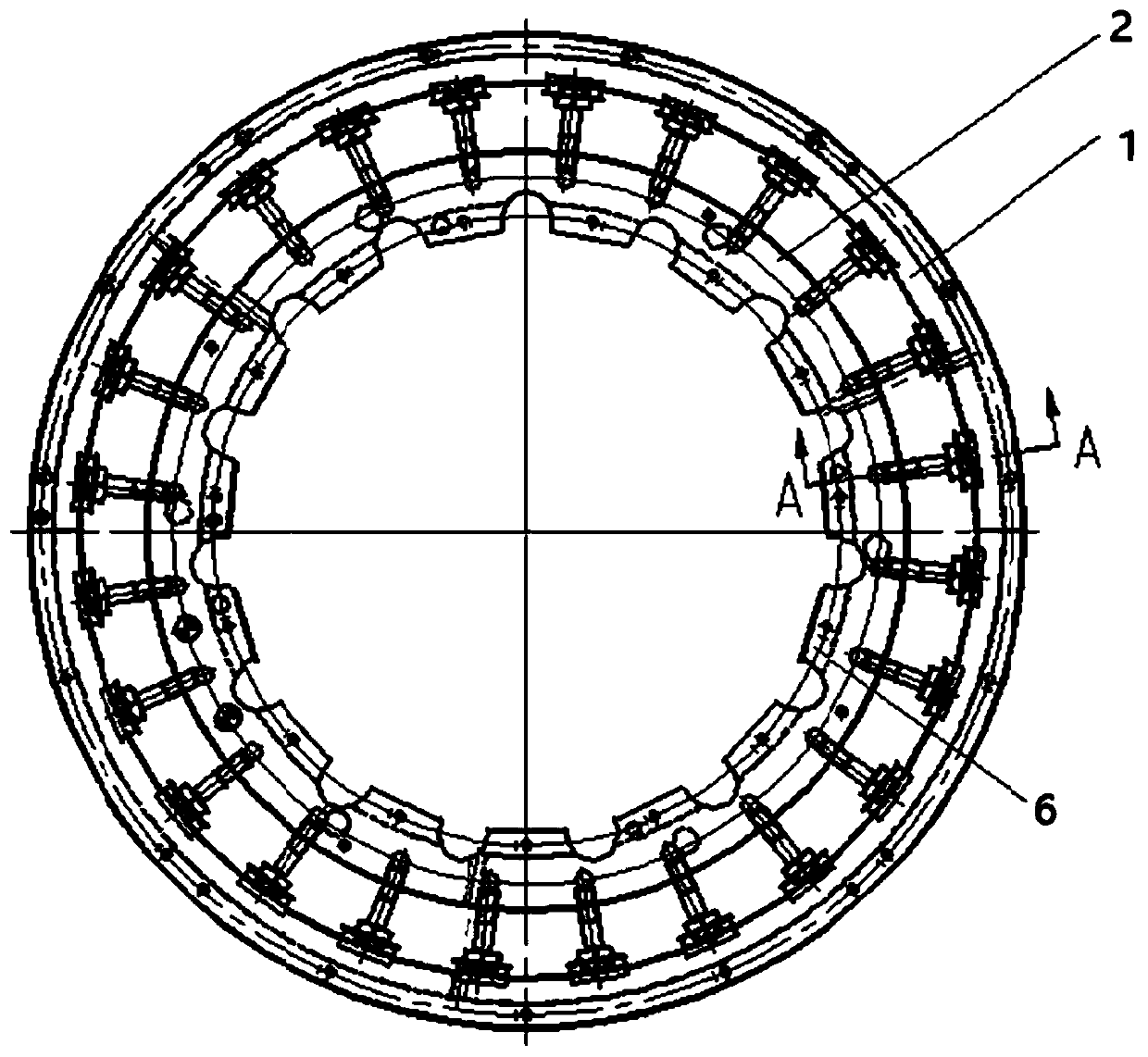

[0031] Figure 1 to Figure 3 It shows the first embodiment of the anti-seismic device of the vertical thrust sliding bearing of the present invention. The bearing structure includes a shell, a guide seat, a cooler, a guide shoe, a thrust head and an anti-seismic device. Outside the tile, cooler, thrust head and anti-seismic device, the shell is surrounded by an oil tank. The thrust head is set on the rotor, the guide seat is set outside the thrust head, the guide shoe is located between the thrust head and the guide seat, and the cooler is set outside the guide seat.

[0032] In this embodiment, the anti-seismic device is provided with a mounting stop and an oil hole, and a buffer part is provided at the contact between the anti-seismic device and the guide seat. , the cooler is located in the lower tank.

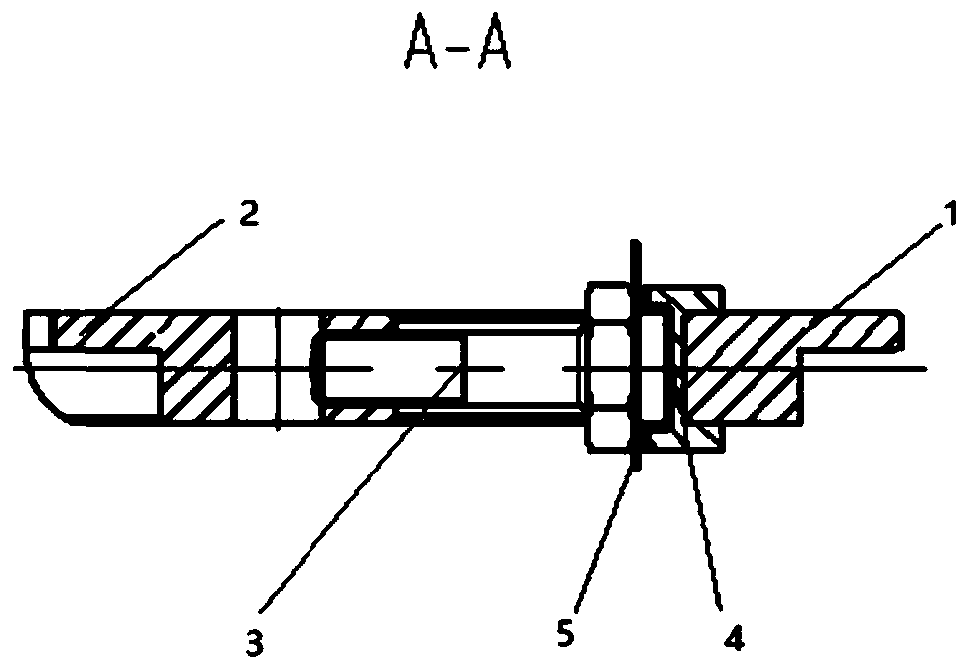

[0033] In this embodiment, the anti-seismic device includes an inner ring, an outer ring, and bolts. There are multiple bolts, which are evenly distributed along the circ...

Embodiment 2

[0041] Figure 4 to Figure 6 The second embodiment of the anti-seismic device of the vertical thrust sliding bearing of the present invention is shown. The difference between this embodiment and Embodiment 1 is that the anti-seismic device is a circular anti-vibration plate, and there are multiple oil holes on the anti-vibration plate. The oil holes are distributed along the circumference, and the installation notches are arranged at the outer and inner circumferential ends of the anti-vibration plate. The anti-seismic plate is provided with a circular mounting hole, and the mounting hole is provided with multiple give way slots to ensure product installation and easy and compact disassembly.

[0042] In this embodiment, the anti-seismic plate is provided with an oil hole, and the hot oil part of the lubricating oil flows through the oil hole of the anti-vibration plate and then flows through the cooler to ensure that the cooler and the hot oil are fully contacted and exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com