Multifunctional integrated ship stern support device

A support device, multi-functional technology, applied in the field of ships, can solve problems such as eccentric load, and achieve the effect of high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and examples.

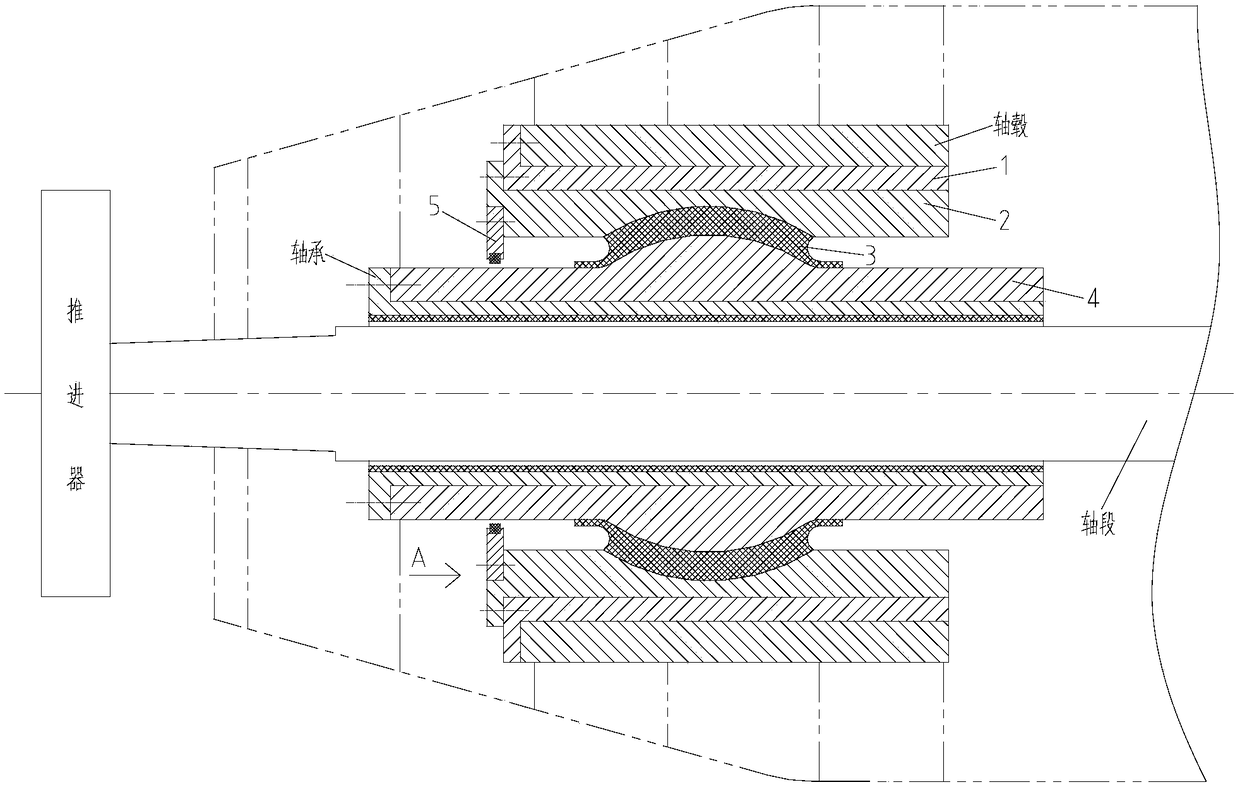

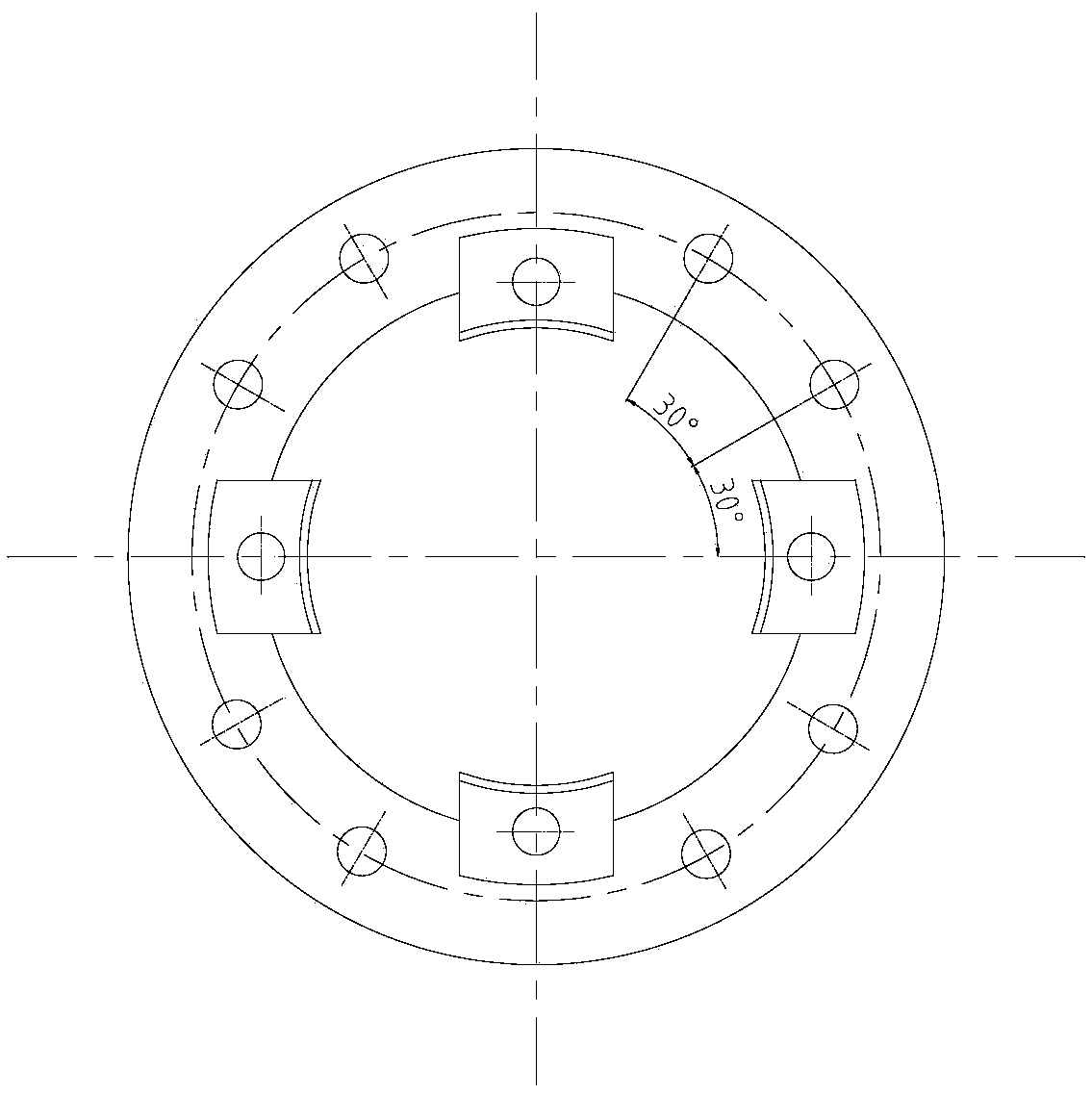

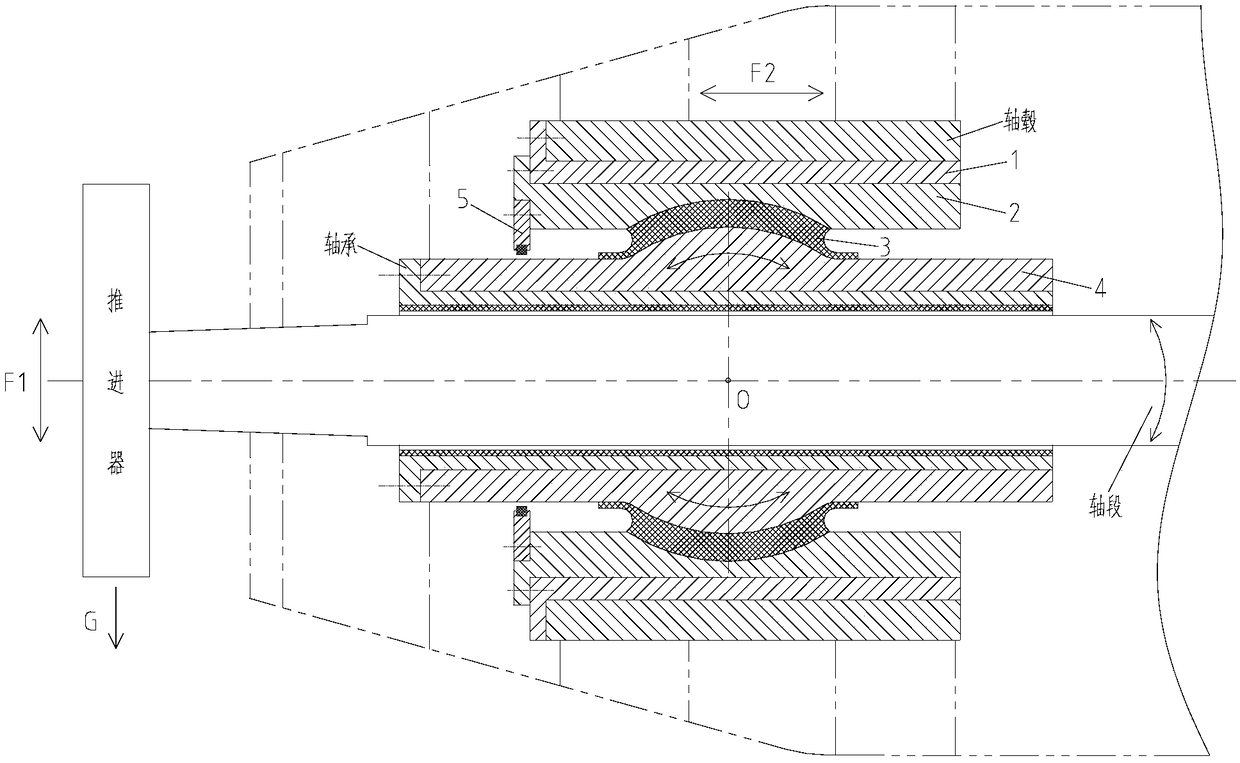

[0022] The invention provides a multifunctional integrated ship stern support device, such as figure 1 As shown, it includes a centering ring 1, an outer rigid damping layer, an elastic body 3, an inner rigid damping layer and a limiter 5. Both the outer rigid damping layer and the inner rigid damping layer are made of alloy, which are the outer damping alloy 2 and the inner damping alloy 4 respectively. The damping loss factor of the damping alloy is lower than that of rubber and is higher than that of rubber. Compared with the damping loss factor of ordinary steel.

[0023] The centering ring 1 is connected to the shaft hub through the end face flange, the outer layer of vibration-damping alloy 2 and the inner layer of vibration-damping alloy 4 are fixedly connected to the centering ring 1 and the bearing respectively through bolts, and the middle of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com