High-precision oil cooling machine and control method

An oil-cooled, high-precision technology, applied in refrigerators, cooling fluid circulation devices, compressors, etc., can solve problems such as insufficient energy saving and high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

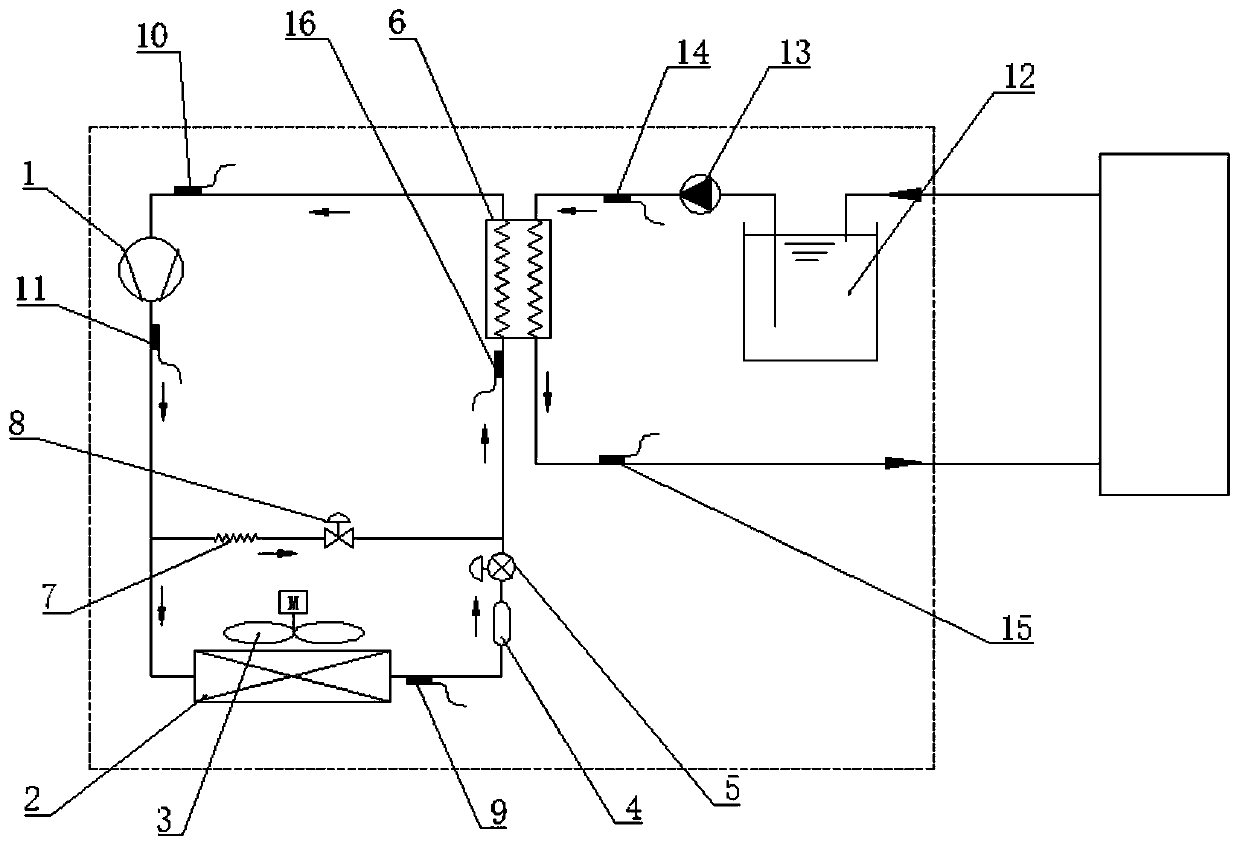

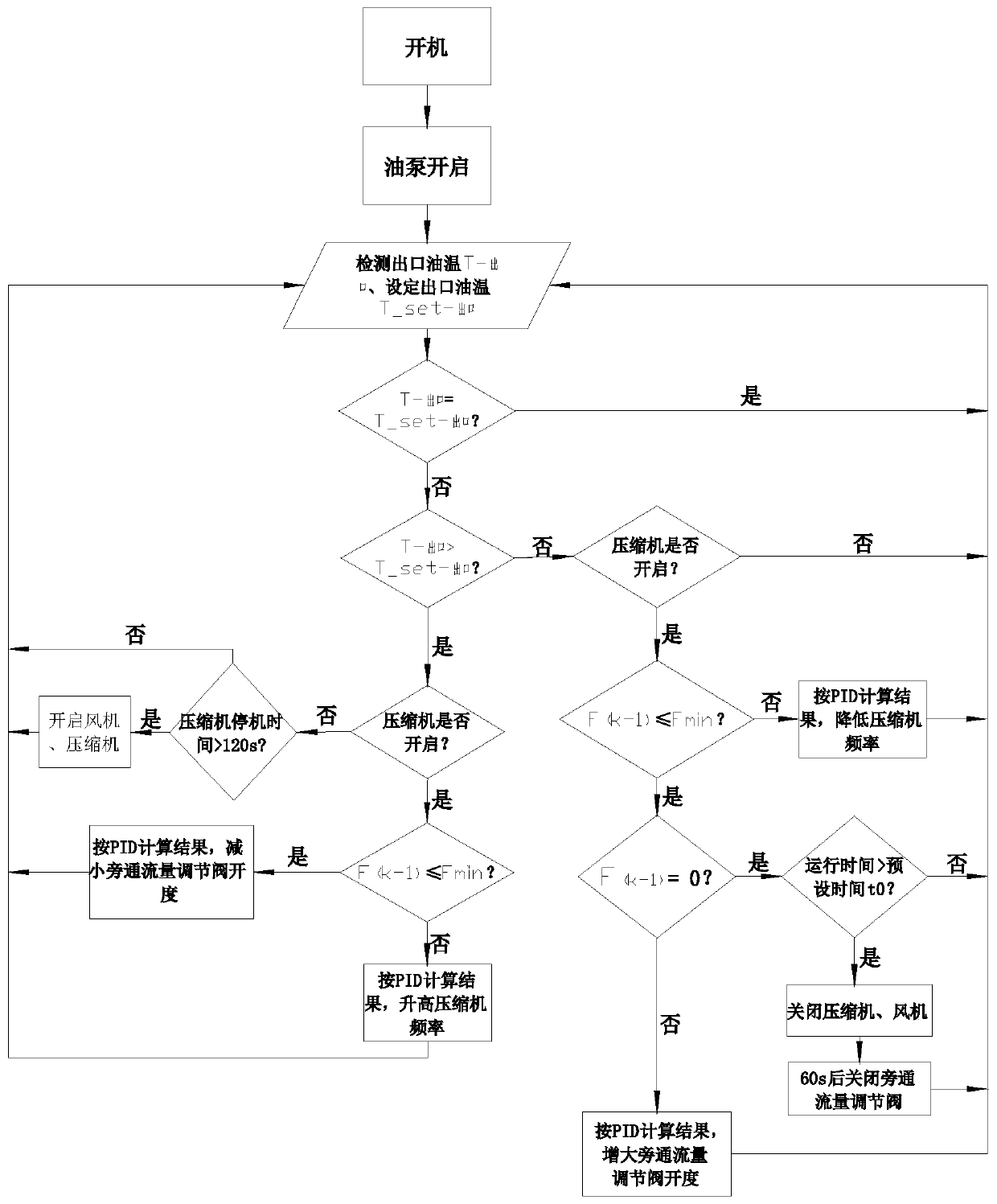

[0071] see Figure 1-Figure 2 , the high-precision oil cooler of the present invention includes a refrigeration system and a circulating oil circuit system, wherein,

[0072] The refrigeration system includes a main flow system and a side branch flow system, wherein,

[0073] The main flow system includes an inverter compressor 1, a condenser 2, a fan 3, a filter 4, an electronic expansion valve 5, and an evaporator 6, wherein the suction end of the inverter compressor 1 is connected to the evaporator 6 The outlet port is connected, and the exhaust port is connected with the inlet port of the condenser 2; the fan 3 is arranged on the condenser 2, and the outlet port of the condenser 2 is connected with the inlet port of the filter 4; The outlet end of the filter 4 communicates with the inlet end of the electronic expansion valve 5, and the outlet end of the electronic expansion valve 5 communicates with the inlet end of the evaporator 6;

[0074] The bypass flow system inclu...

Embodiment 2

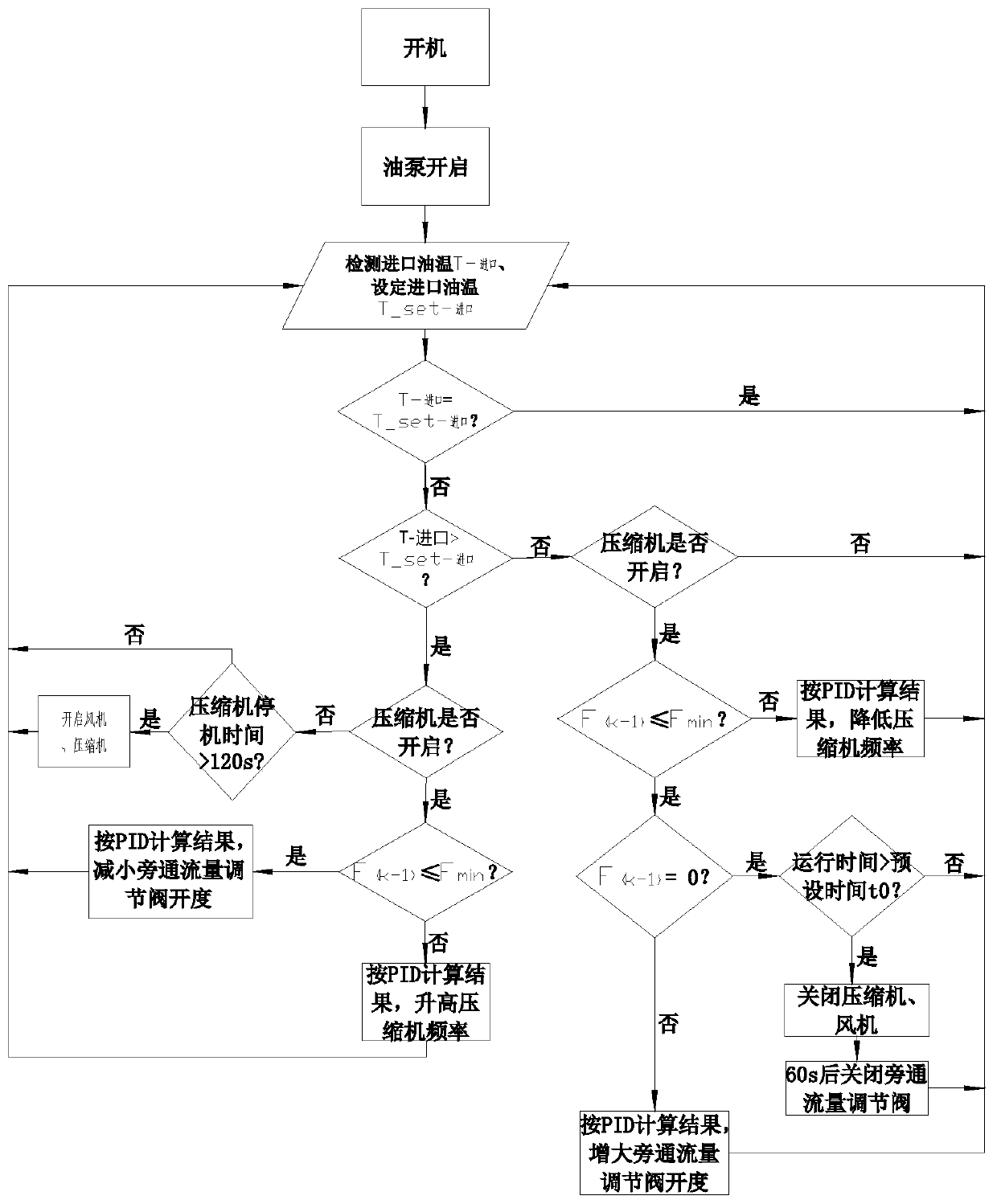

[0116] see image 3 The difference between this embodiment and Embodiment 1 is that the control method of the high-precision oil cooler of the present invention is applied in the inlet oil temperature control mode, the frequency control of the inverter compressor 1 and the opening of the bypass flow regulating valve 8 Degree control is carried out according to the following steps (for details, see image 3 ):

[0117] (T1) The oil pump 13 is turned on, and the inlet oil temperature T is detected -进口 , set the inlet oil temperature T _set-进口 , when the inlet oil temperature reaches the set target temperature, namely T -进口 =T _set-进口 ; then keep the current state;

[0118] (T2) When the inlet oil temperature is lower than the set target temperature, that is, T -进口 _set-进口 ; If the variable frequency compressor 1 is not turned on, keep the current state;

[0119] (T3) When the inlet oil temperature is lower than the set target temperature, that is, T -进口 _set-进口 ;

[012...

Embodiment 3

[0128] The difference between this embodiment and Embodiment 1 is that in step (4) of the control method of the high-precision oil cooler of the present invention, the maximum opening degree E of the bypass flow regulating valve 8 is fully opened max (that is, 500B) is used as the inverter compressor 1 frequency 0Hz control, and 0B when the bypass flow regulating valve 8 is fully closed is used as F min (i.e. 20HZ) control; set E max (ie 500B) According to the flow curve of the bypass flow regulating valve 8, the opening is determined according to the equal flow; 0-E max Among other opening parameters with inverter compressor 1F min The frequency parameters between -0Hz correspond in turn; as shown in the following table:

[0129]

[0130] The remaining steps are completed with reference to Example 1.

[0131] This embodiment aims at bypassing the flow regulating valve 8 with a non-linear flow curve, so that its change is close to linear, which is more conducive to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com