An Improved Structure of the End Cover of a Reaction Calorimeter

A technology of reaction volume and reaction vessel, which is applied in the field of improving the structure of the end cap of a reaction calorimeter, can solve the problems of affecting the accurate measurement of calorimetric experiments, difficulty in calorimetry of heat loss at the end cap, and inability to eliminate temperature gradients, etc. Heat storage effect, maintaining heat storage effect, effect of stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

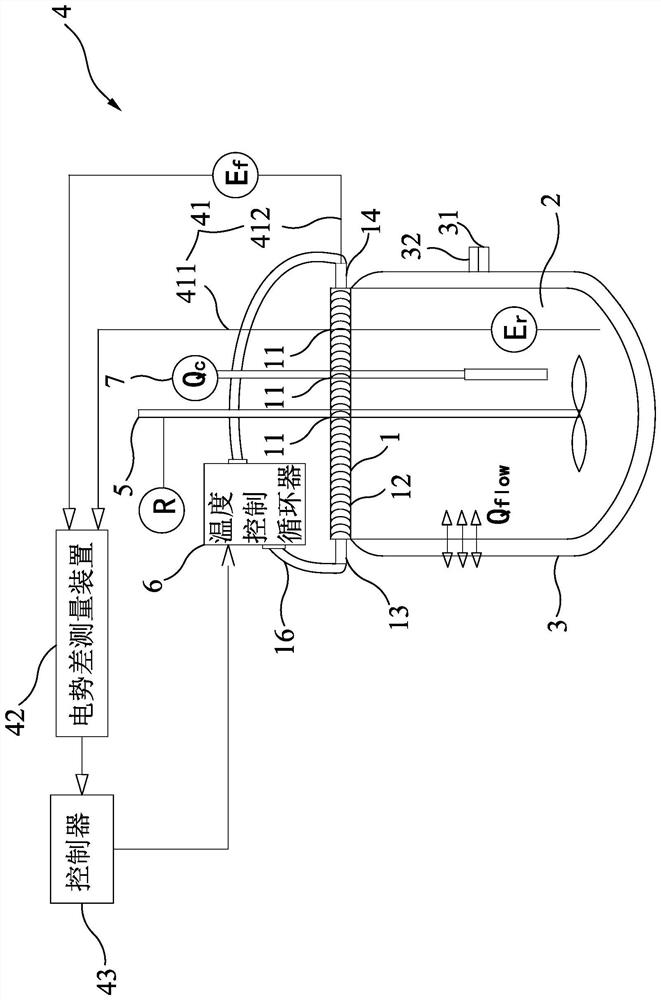

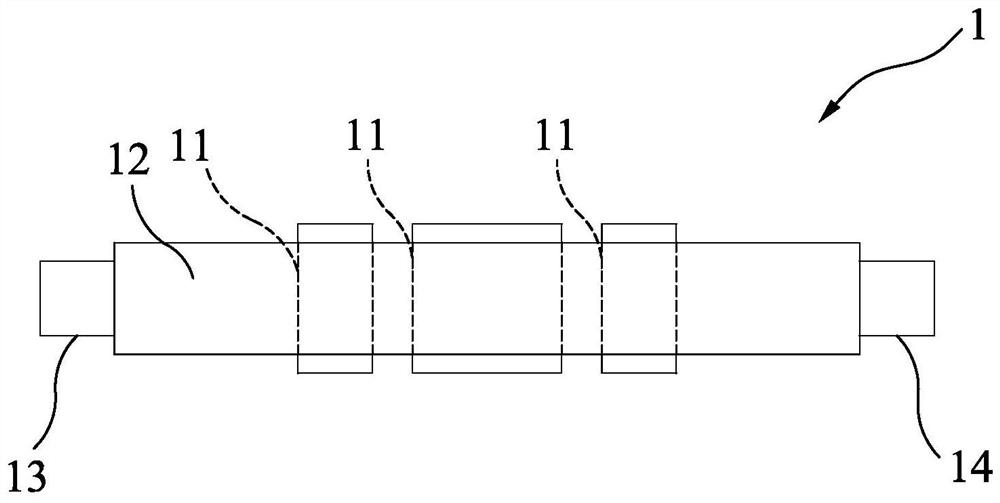

[0039] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. For those of ordinary skill in the art, other drawings can also be obtained according to these drawings without paying creative labor. Please refer to Figure 2 to Figure 6 .

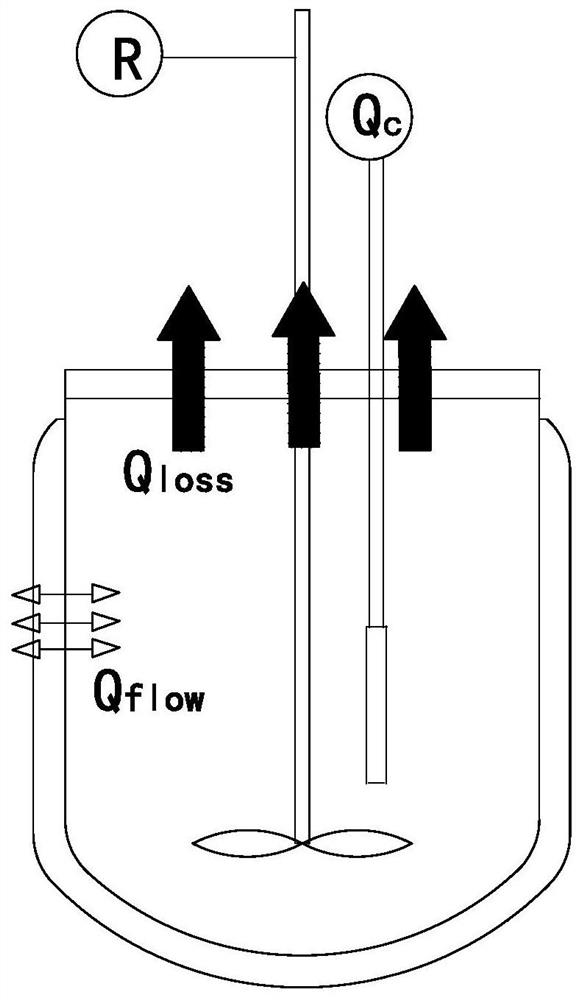

[0040]An improved structure of an end cover of a reaction calorimeter, comprising an end cover 1, a reaction vessel 2, a jacket 3, a temperature difference monitoring device 4, a stirrer 5, a temperature control circulator 6 and a heater 7, and the jacket 3 sets Connected to the outside of the reaction vessel 2, the temperature difference monitoring device 4 is used to measure the temperature difference between the inside of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap