A three-degree-of-freedom low-frequency vibration test device

A low-frequency vibration and test device technology, used in vibration testing, measuring devices, and testing of machine/structural components, etc., can solve the problems of low operating frequency and large thrust, and achieve the effect of convenient real-time operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the embodiment, specific structure and working principle of the present invention will be described with reference to the drawings and specific embodiments.

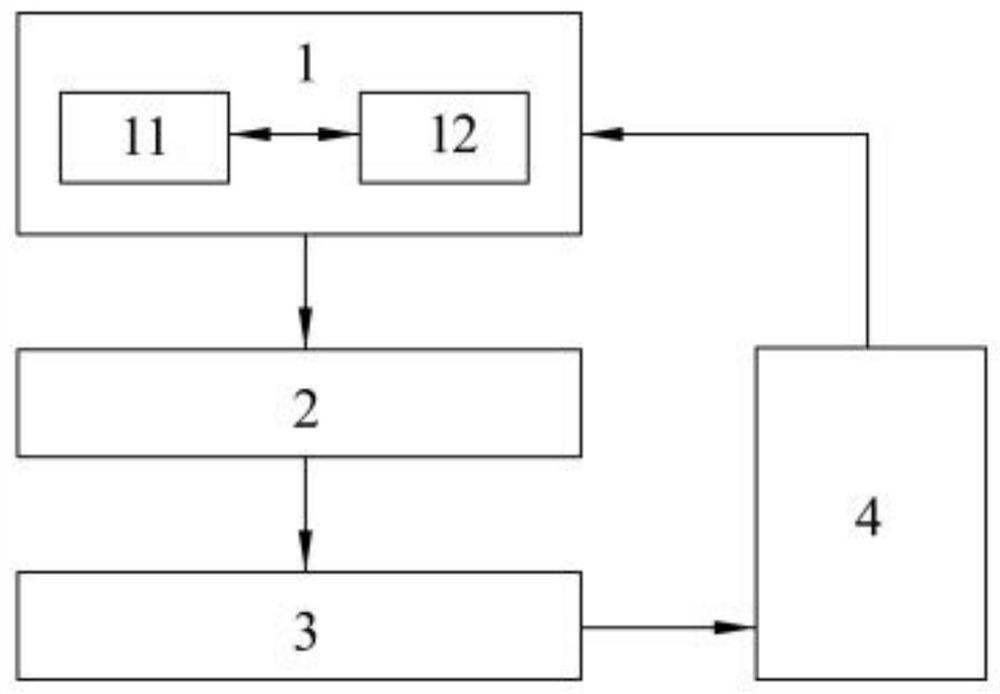

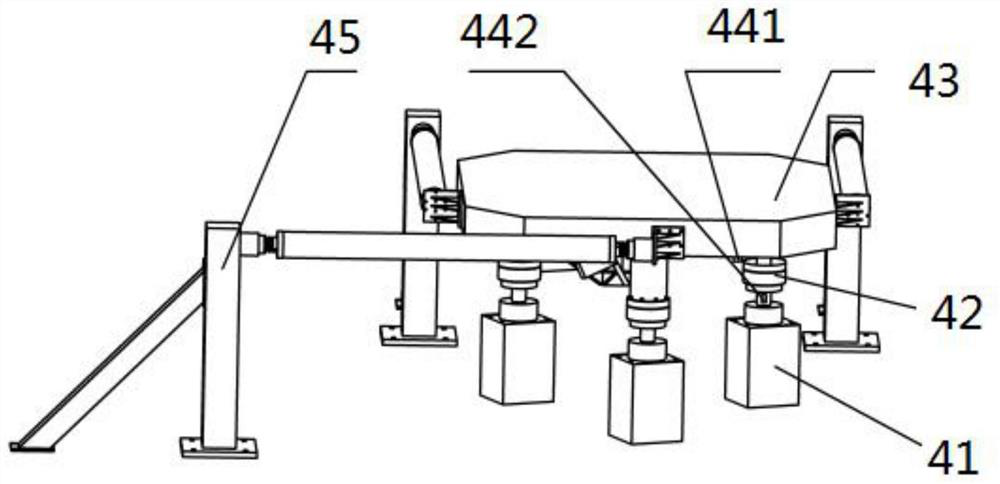

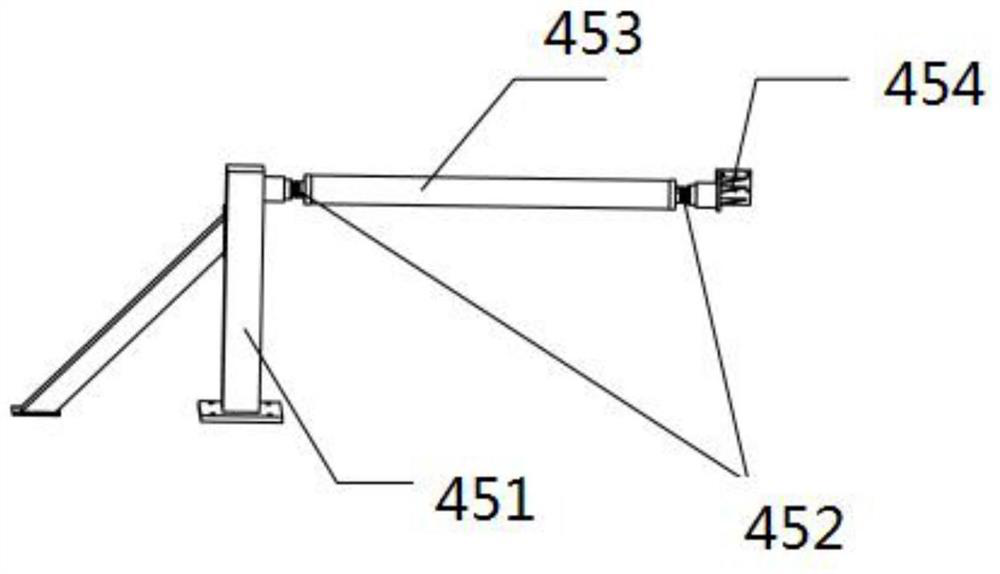

[0025] like figure 1 Shown is a three-degree-of-freedom low-frequency vibration test device according to an embodiment of the present invention, which includes a control system 1 , a power amplifier system 2 , a hydraulic system 3 and a vibration platform 4 .

[0026] The driving voltage signal generated by the control system 1 is input to the hydraulic system 3 after passing through the power amplifier system 2, and the hydraulic system 3 is connected to the vibration platform 4 to make the vibration platform 4 vibrate, and at the same time, the response on the vibration plane 4 is fed back to the control system 1, thereby realizing vibration control .

[0027] Preferably, the control system 1 includes a MIMO controller 11 and a servo controller 12 . The MIMO controller 11 communicates with the ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com