Sample adding method for industrial analysis instrument

An industrial analysis and instrument technology, applied in the direction of instruments, analysis materials, etc., can solve the problems of inability to realize the measurement of incoming samples, low work efficiency, long waiting time, etc., to save waiting time, reduce labor intensity, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

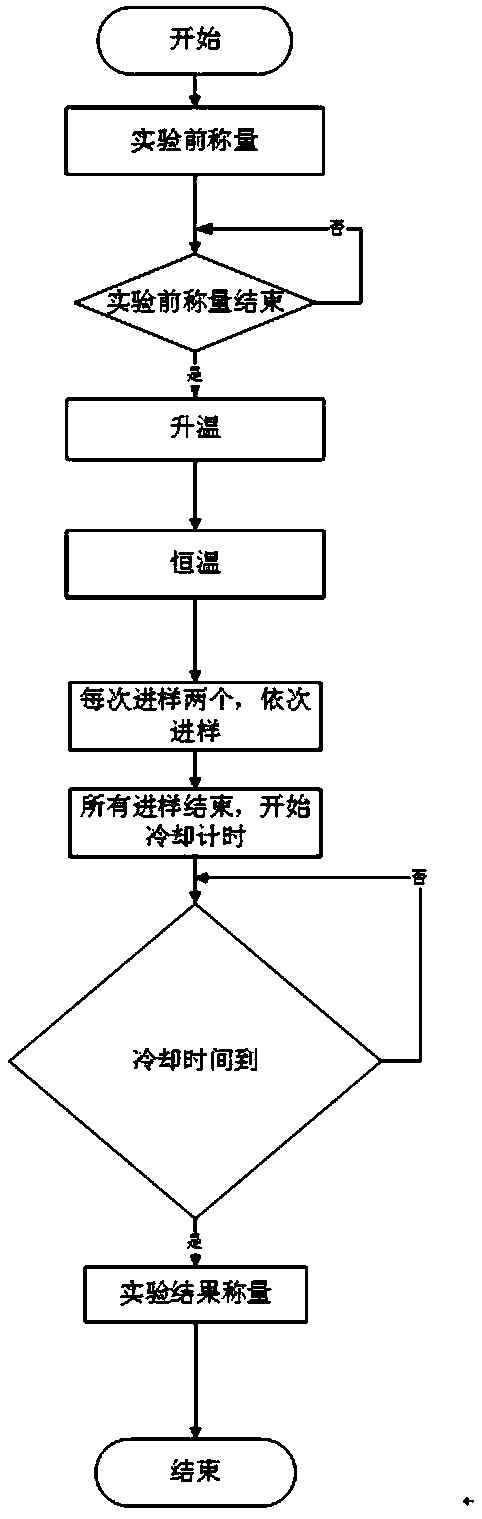

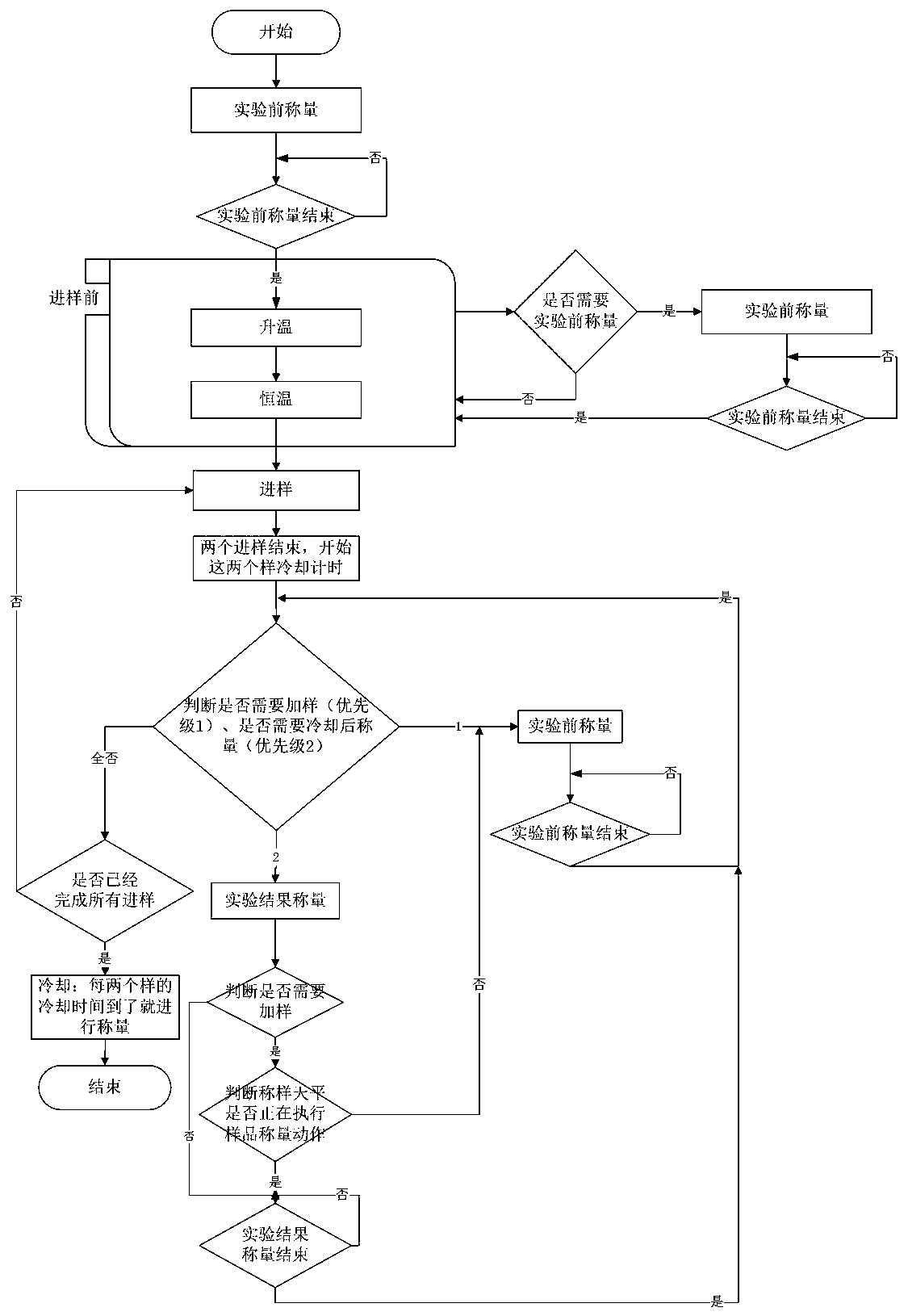

[0026] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

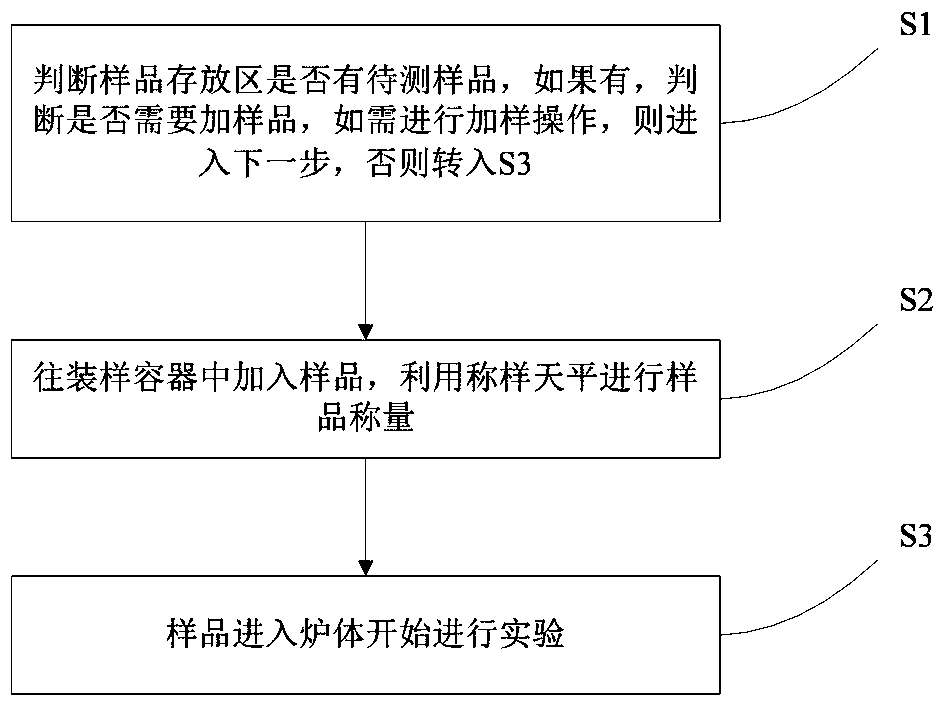

[0027] like figure 2 As shown, the sample adding method for industrial analytical instruments in this embodiment includes the following steps:

[0028] S1. When the instrument enters the heating or constant temperature stage, judge whether there is a sample to be tested in the sample storage area. If so, judge whether it is necessary to add a sample. If the sample adding operation is required, go to the next step, otherwise go to S3;

[0029] S2. Add the sample into the sample container, and use the sample balance to weigh the sample;

[0030] S3, the sample enters the furnace body to start the experiment.

[0031] The sample adding method for industrial analytical instruments provided by the present invention can automatically determine whether there is a sample in the sample storage area, as long as the current state is not in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com