Product quality prediction method and system in production and manufacturing process, medium and equipment

A product quality and manufacturing process technology, applied in the field of product quality prediction, can solve problems such as economic loss and slow speed, and achieve the effects of improving accuracy, controllable manufacturing process, and improving process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

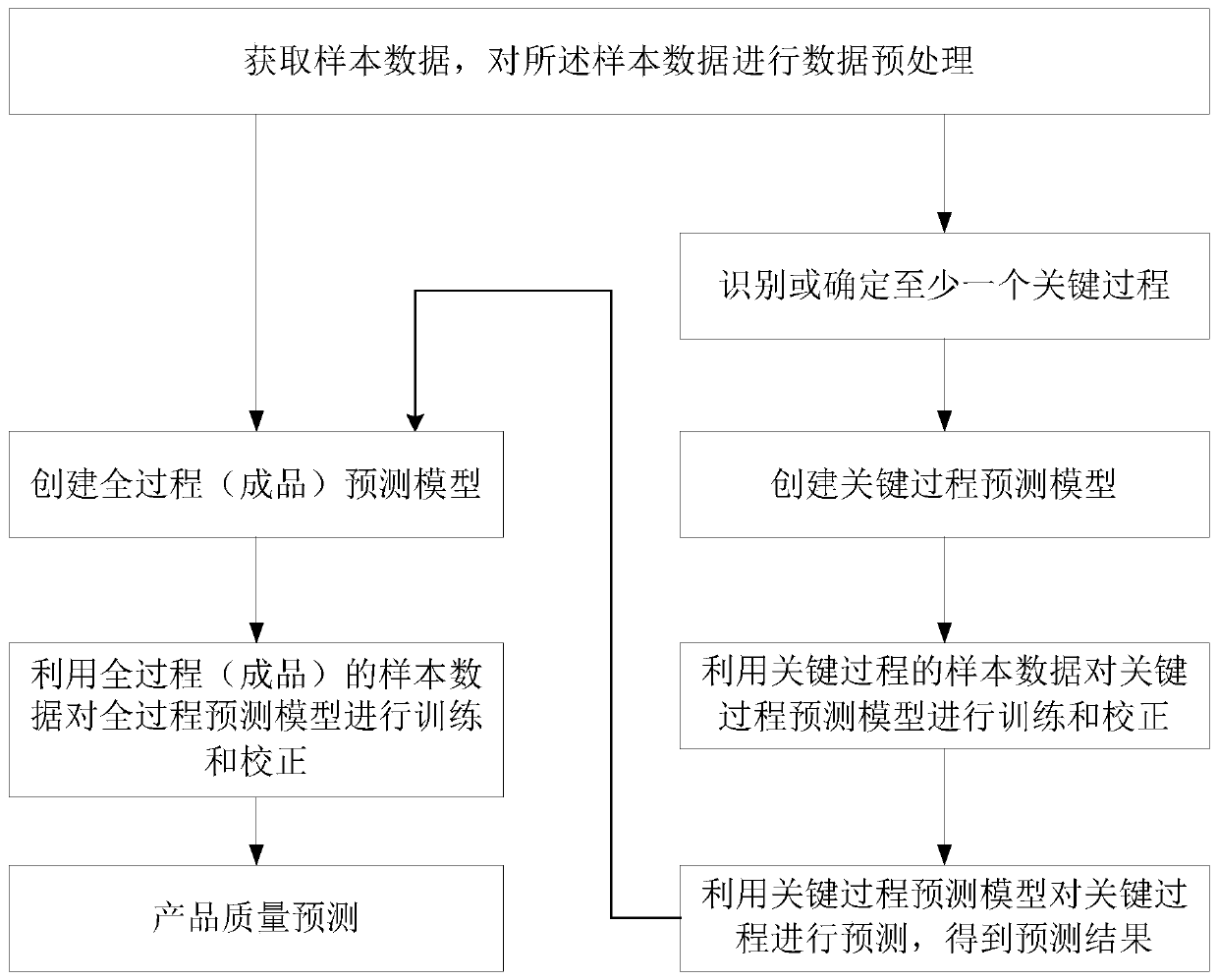

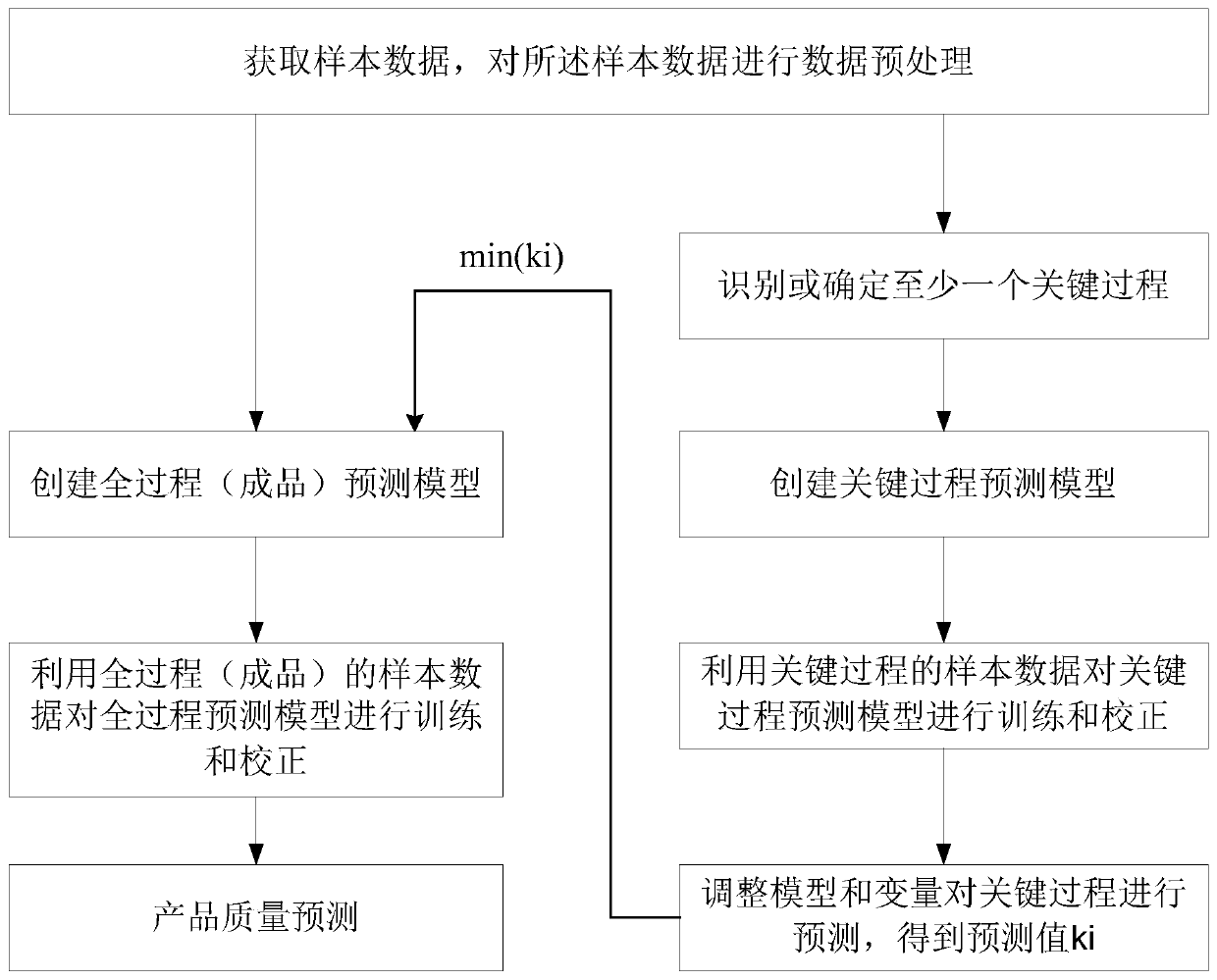

[0013] figure 1 A schematic flowchart of a method for predicting product quality in a manufacturing process provided by an embodiment of the present invention. Such as figure 1 As shown, the method includes:

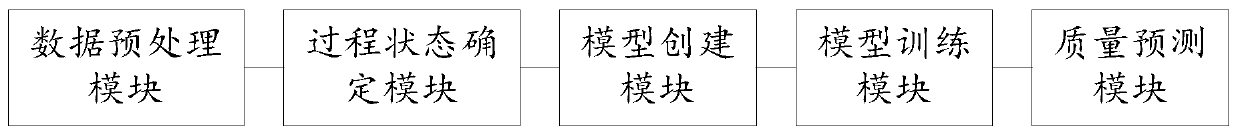

[0014] Obtain sample data, perform data preprocessing on the sample data; determine at least one key process in the whole process of manufacturing; create a corresponding key process prediction model for the at least one key process; use the sample data of the key process to analyze the key The process prediction model is trained and corrected; the key process prediction model is used to predict the key process, and the prediction result of the key process is obtained; the whole process prediction model of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com