An earphone membrane with gradient rigidity and its manufacturing method

A production method and technology of earphone film, which are applied in the directions of earphone manufacturing/assembly, earpiece/earphone accessories, diaphragm structure, etc., can solve the problems of affecting sound quality, difficult response speed, and high manufacturing cost, and achieve production cost saving and wide frequency response range. , the effect of sound quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

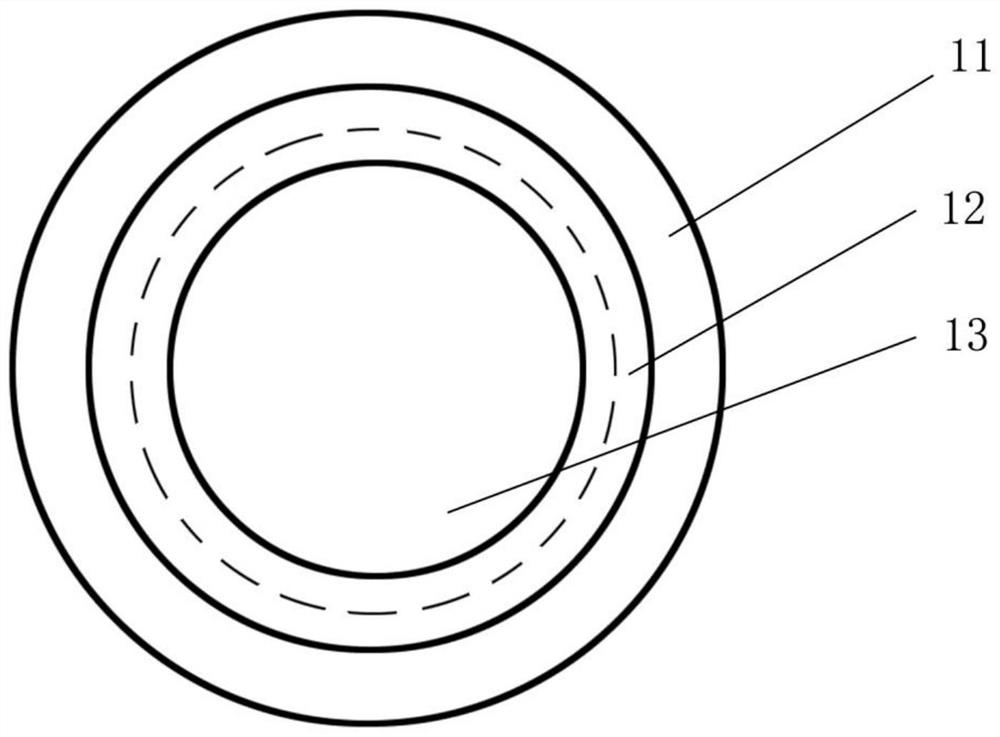

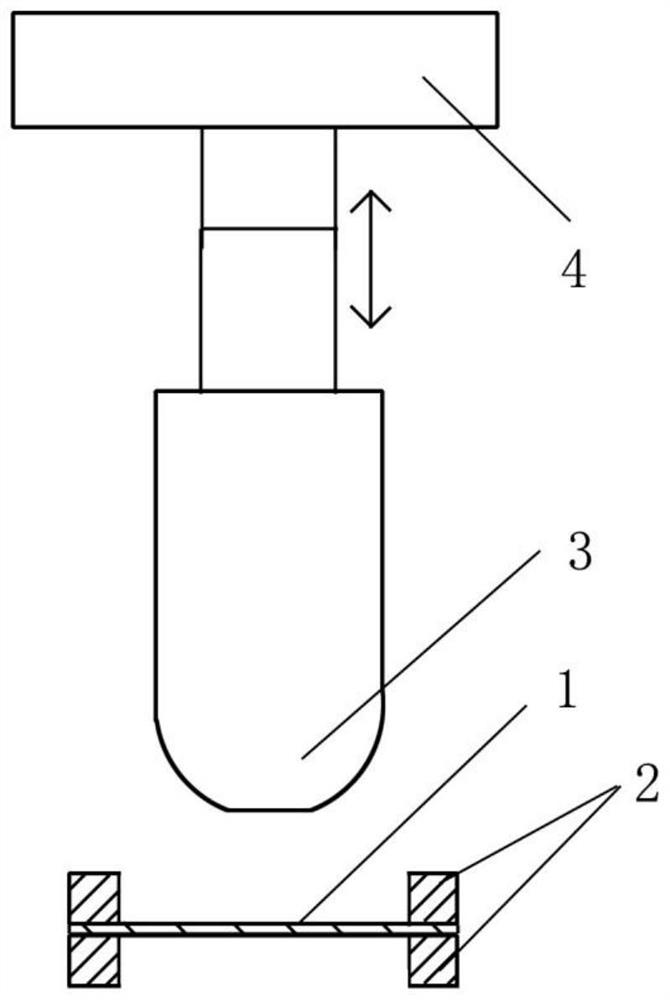

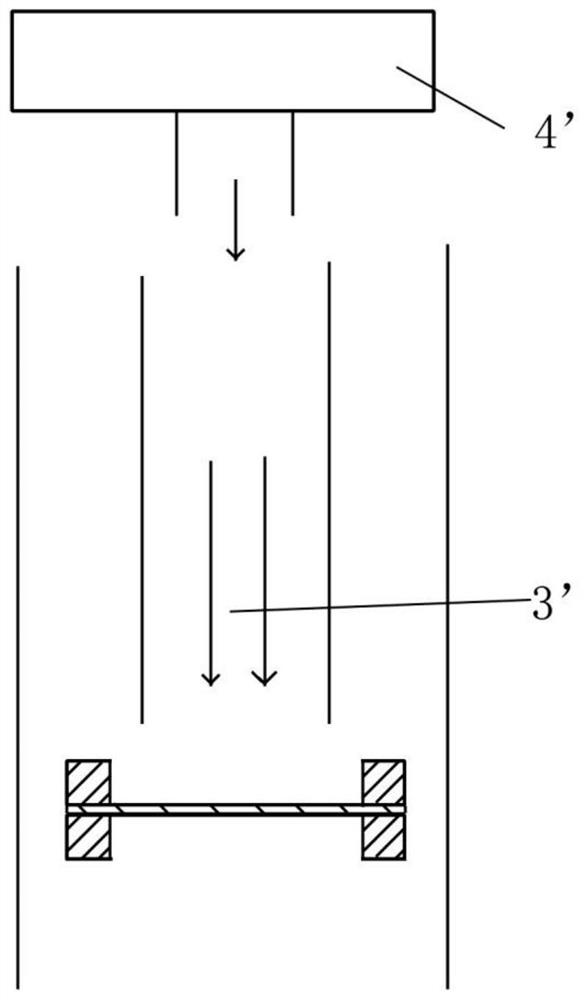

[0018] Such as Figure 1 to Figure 3 As shown, a kind of earphone membrane with gradual rigidity, the key is that the membrane body of the earphone membrane is made of a polymer compound material as the base material, the earphone membrane is circular, and the earphone membrane includes sequentially ring-shaped sleeves The outer ring part 11, the gradual change part 12 and the central part 13, take the rigidity of the film substrate as the reference stiffness, and the rigidity of the gradual change part is from the outer to the inner stiffness, and gradually transitions from the reference stiffness to the lowest stiffness, and then transitions to the reference stiffness, The rigidity of the outer ring portion and the central portion is equal to the rigidity of the material base material. The width of the outer ring part is 1 mm to 2.5 mm, the width of the transition part is 15% to 45% of the diameter of the earphone membrane, and the central part is connected to the center of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com