Machine tool base mechanism of small engraving and milling machine

A technology of engraving machines and machine tools, which is applied to large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of no buffer mechanism, affect the stability of equipment, generate noise, etc., to achieve less difficulty in installation and adjustment, and improve the Processing stability and vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

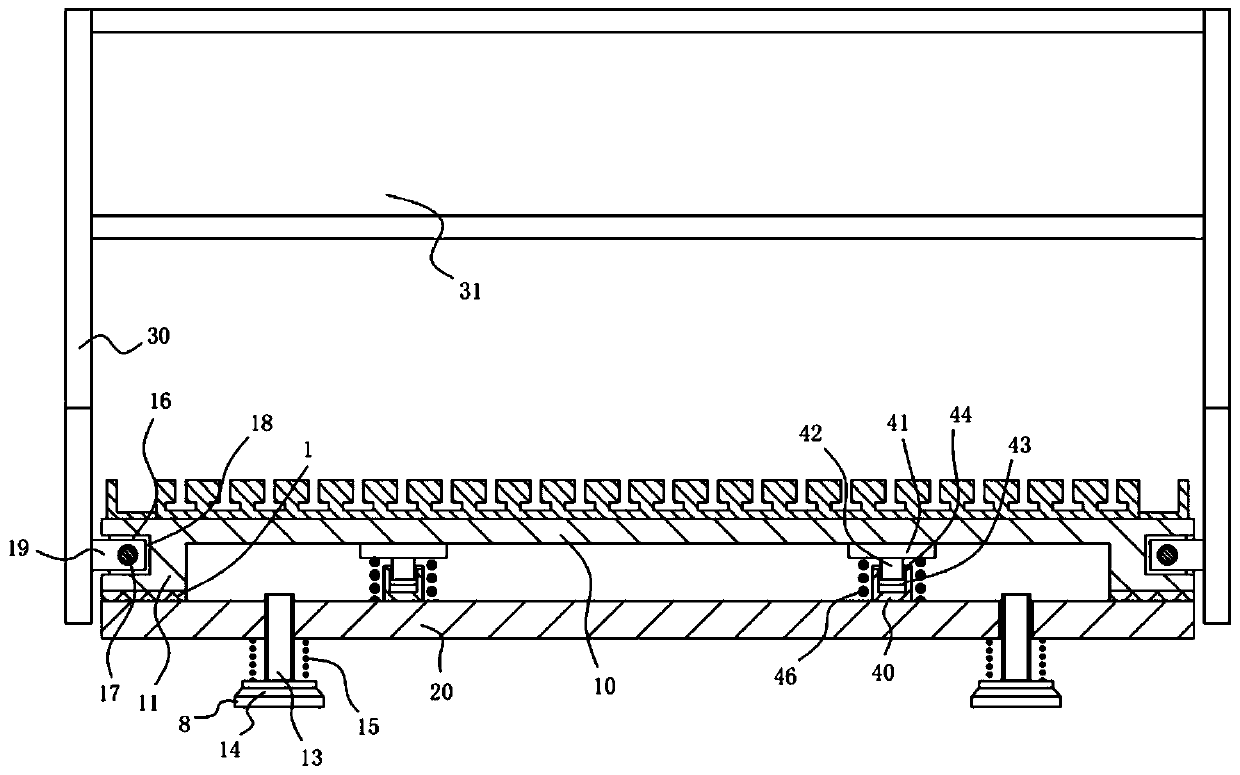

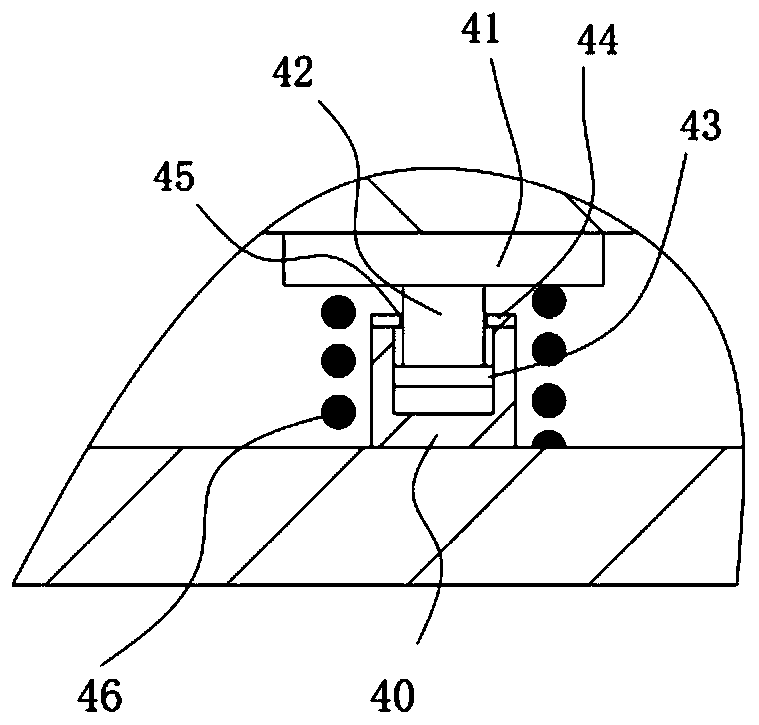

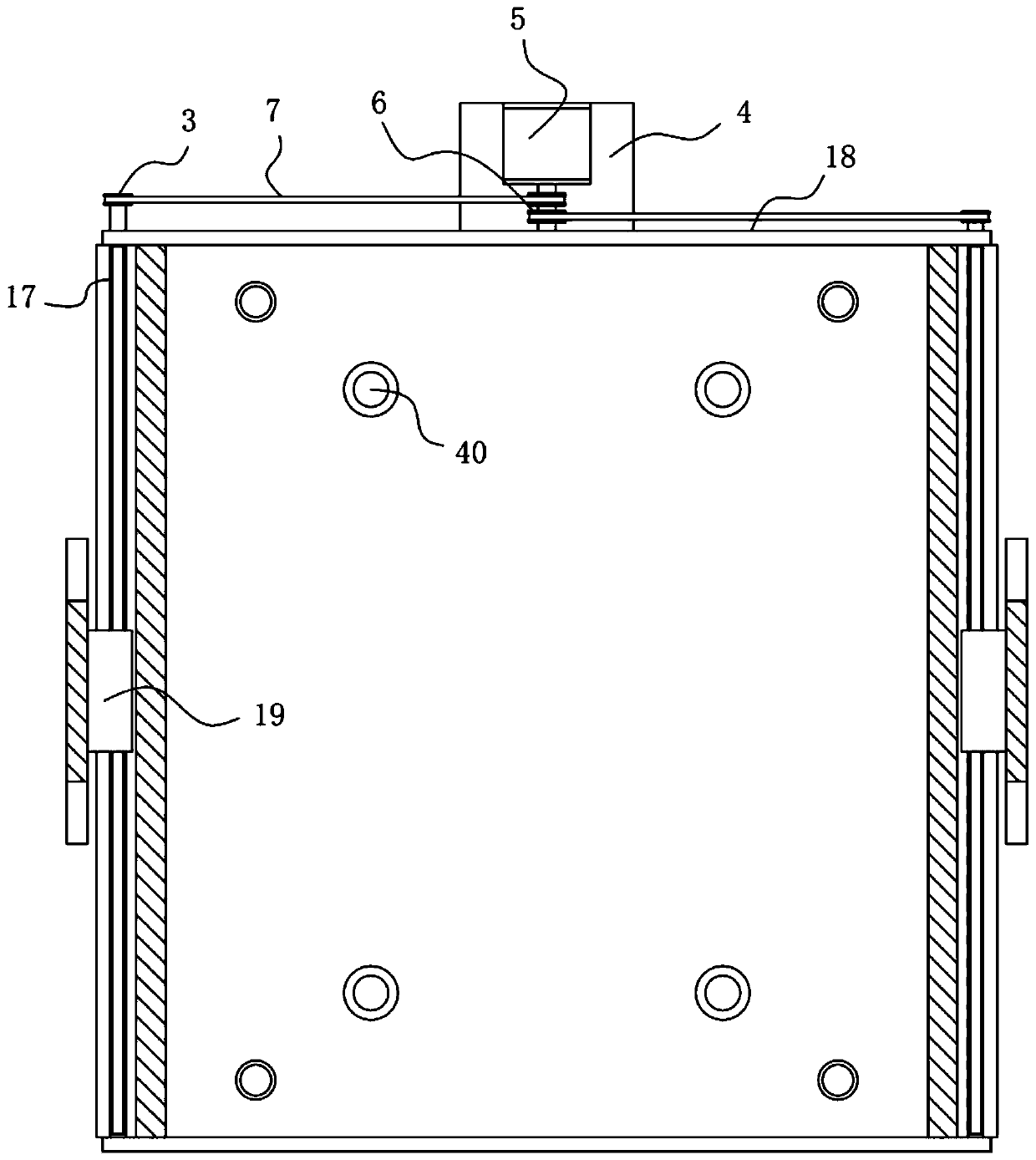

[0020] Example: see Figure 1 to Figure 3 As shown, a machine tool base mechanism of a small precision engraving machine includes a fixed mounting plate 10, the left and right sides of the bottom surface of the fixed mounting plate 10 are formed with downwardly extending extension blocks 11, and the lower buffer connecting plate 20 is in two extensions. Right below the block 11, the vertical screw 13 is screwed into the screw holes provided on the left and right sides of the front and rear of the lower buffer connecting plate 20, and the lower end of the vertical screw 13 extends out of the lower buffer connecting plate 20. The bottom end of the straight screw 13 is fixed with a lower fixed block 14, the buffer spring 15 is inserted and sleeved on the vertical screw 13, the bottom end of the buffer spring 15 is applied to the top surface of the lower fixed block 14, and the top end of the buffer spring 15 is applied to the lower buffer The bottom surface of the connecting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com