Surface cleaning treatment device for cotton cloth production

A technology for surface cleaning and processing equipment, applied in the cleaning method using tools, the cleaning method using liquid, mechanical cleaning, etc., can solve problems such as affecting the beauty of cotton cloth, reducing the quality of cotton cloth, etc., to ensure quality, improve production efficiency, guarantee The effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

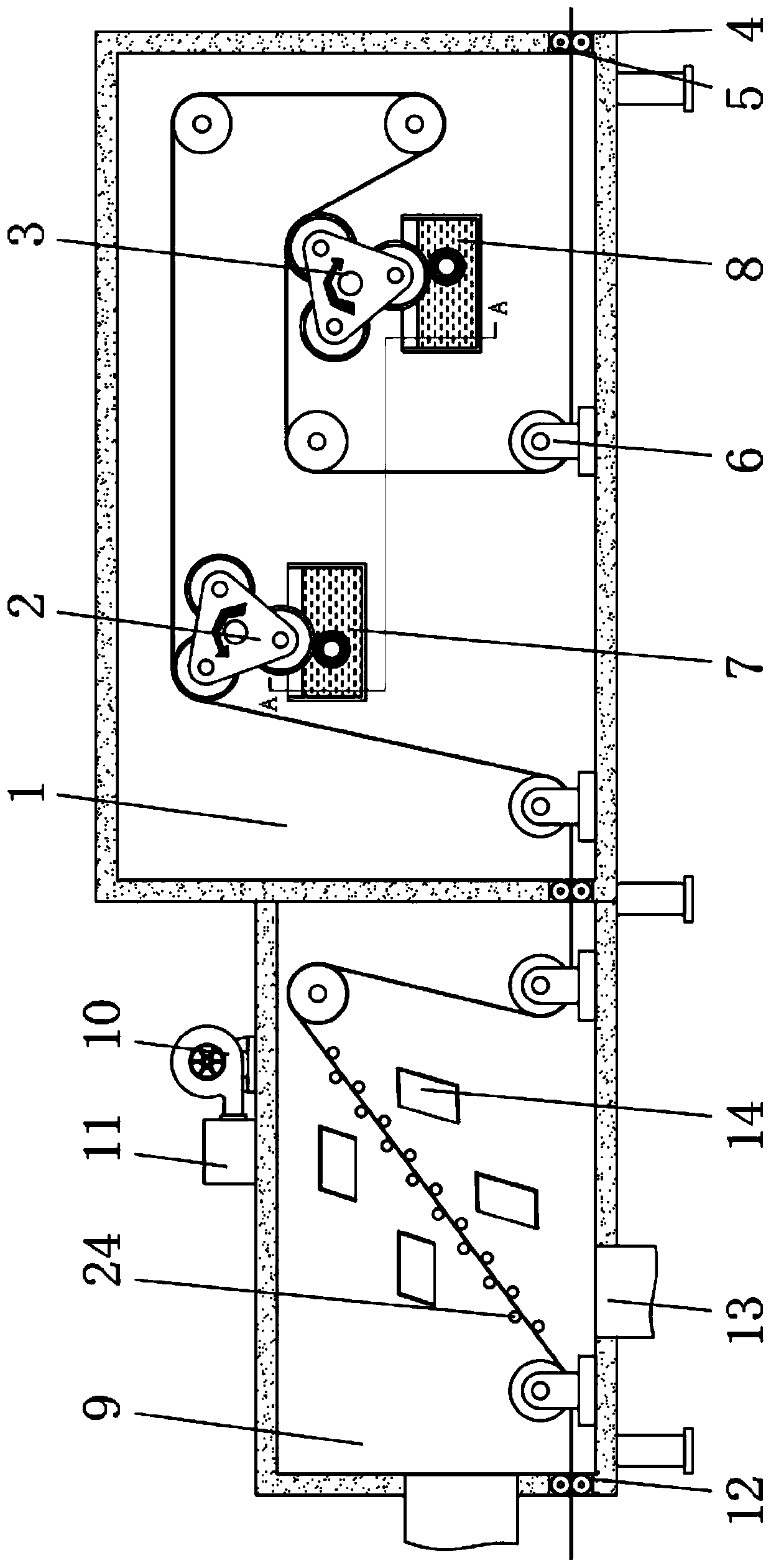

[0031] Embodiment one, with reference to figure 1 and Figure 5 , a kind of surface cleaning treatment equipment for cotton cloth production, comprising wool sticking room 1 dust removal room 9, the side of sticking wool room 1 is provided with dust removal room 9, and the top of dust removal room 9 is provided with blower 10 and air pipe 11, blower 10 and wind The pipe 11 is connected, and the air pipe 11 extends to the inside of the dust removal chamber to communicate with the blowing pipe 14. The bottom surface and the side of the dust removal chamber 9 are provided with a suction port 13, and one side of the dust removal chamber 9 is provided with a feed port 12 below the suction port 13. And feed port 12 one side is provided with and is positioned at dedusting chamber 9 inside and is provided with support bar 24, and sticking wool chamber 1 inside is respectively provided with the first sticking hair group 2, the second sticking wool group 3 and turning roller 6, and the ...

Embodiment 2

[0032] Embodiment two, refer to figure 1 , the supporting rods 24 are provided with a plurality, and the plurality of supporting rods 24 are arranged obliquely, and a plurality of blowing pipes 14 are symmetrically distributed on both sides of the supporting rods 24 arranged obliquely, and the inside of the dust removal chamber 9 is provided with a plurality of supporting rods 24. On the one hand, it can scrape off the larger sticky cotton wool, and on the other hand, it can play an auxiliary role in fixing the cotton cloth, which is conducive to blowing off the dust and other sundries adhered to the surface of the cotton cloth by the blowing pipe 14.

Embodiment 3

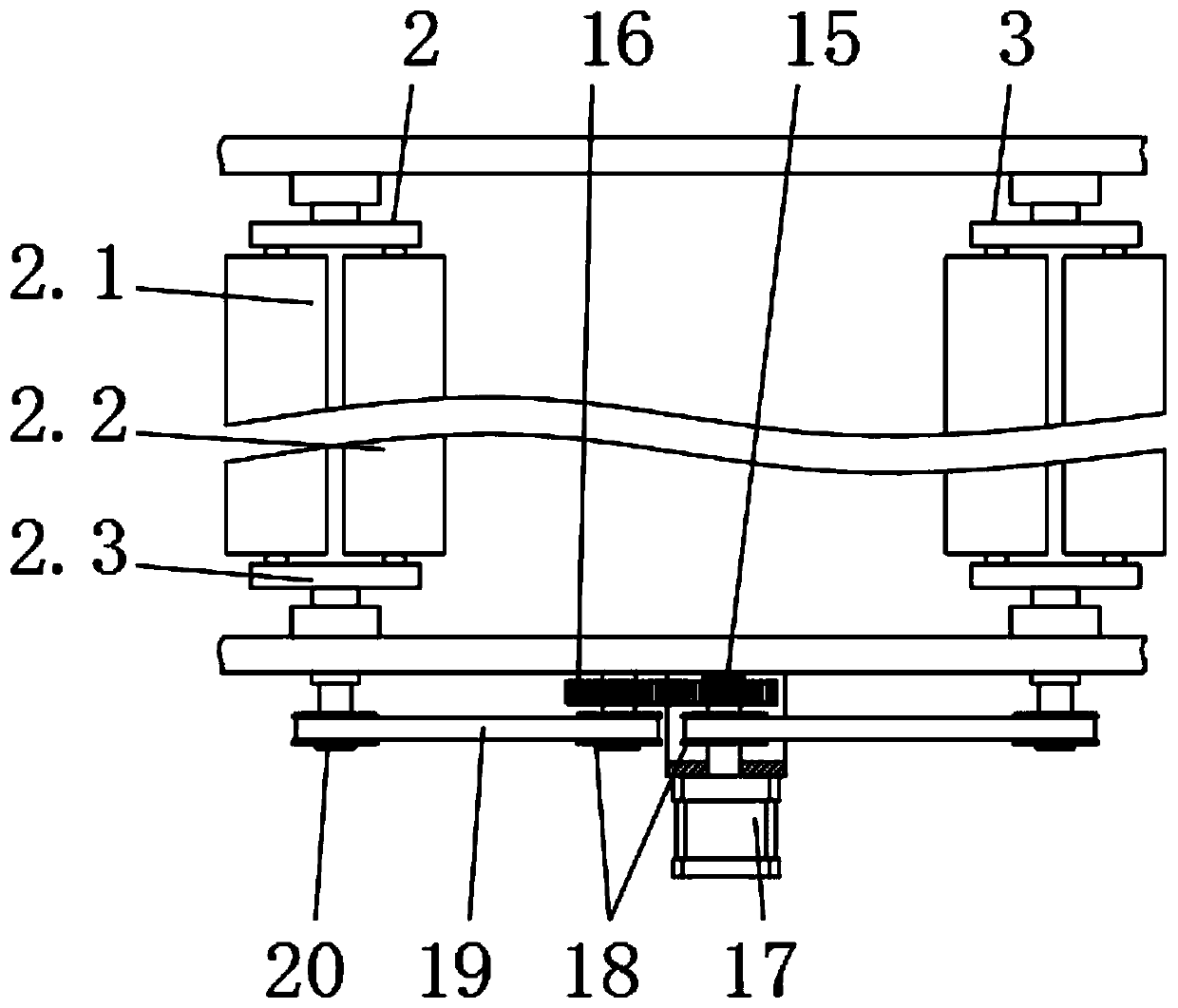

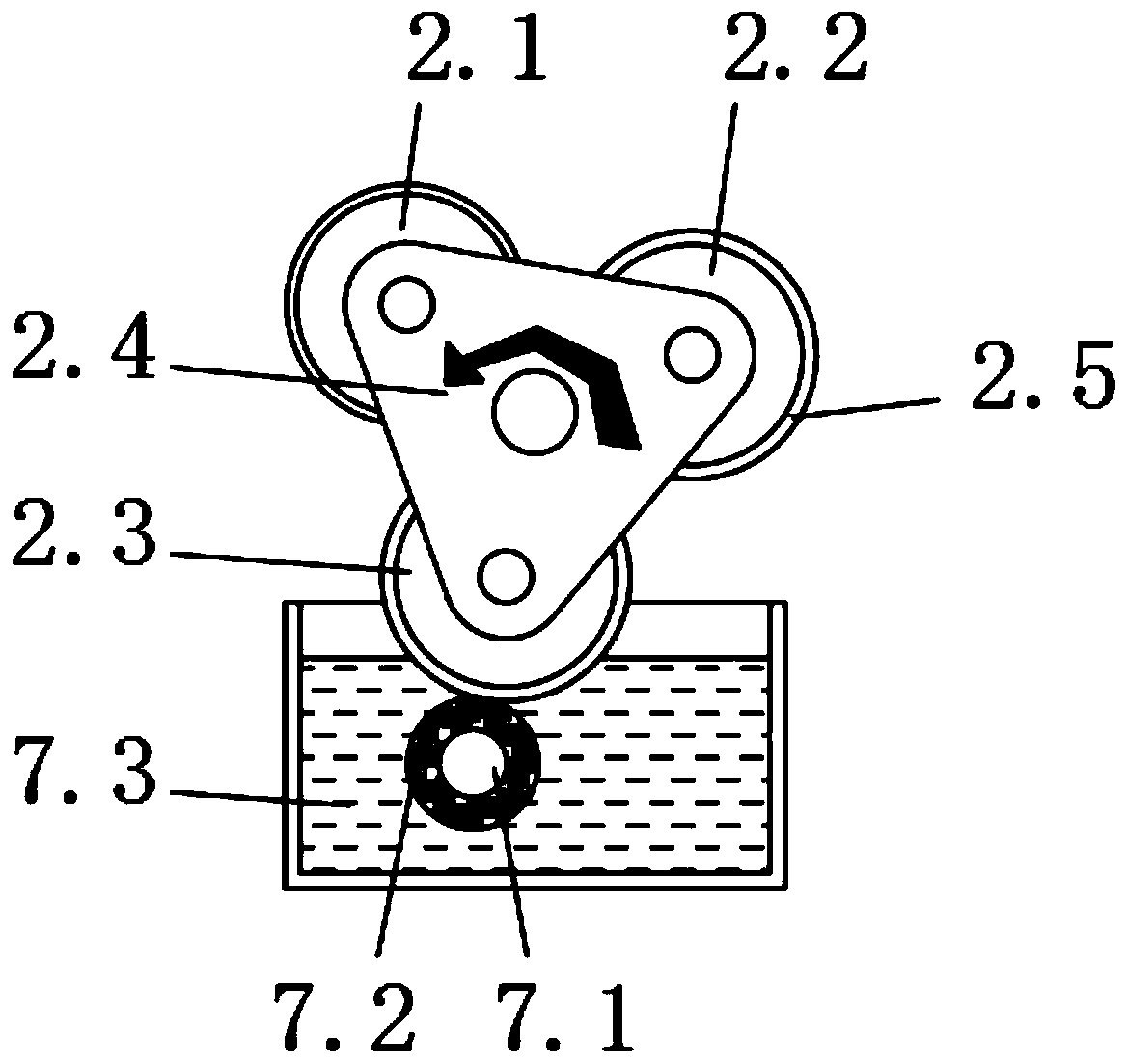

[0033] Embodiment three, refer to Figure 1-3 , the first wool sticking group 2 and the second wool sticking group 3 are composed of the same first wool sticking roller 2.1, second wool sticking roller 2.2, third wool sticking roller 2.3, support plate 2.4, and glue layer 2.5, And the first hair-sticking group 2 and the second hair-sticking group 3 are all installed inside the hair-sticking chamber 1 through the bearing seat, and one end of the first hair-sticking group 2 and the second hair-sticking group 3 extends to the outside of the hair-sticking chamber 1 respectively from the The driving pulley 20 is connected, and the driven pulley 20 side is connected with the driving pulley 18 by sticking the hair belt 19. The driving pulley 18 is provided with two altogether, and the two driving pulleys 18 are respectively connected to the corresponding driving pulley. Gear 15, driven gear 16 keys are connected, and driving gear 15, driven gear 16 meshes are connected, and driving g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com