Spring damping mechanism with quick locking function

A vibration damping mechanism and functional technology, applied in the direction of spring/shock absorber, low internal friction spring, friction clamping detachable fasteners, etc., can solve the problem of random divergence and reliability affecting the optical axis and vibration damping direction and low service life, to avoid rigid connection, ensure stability, and delay impact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

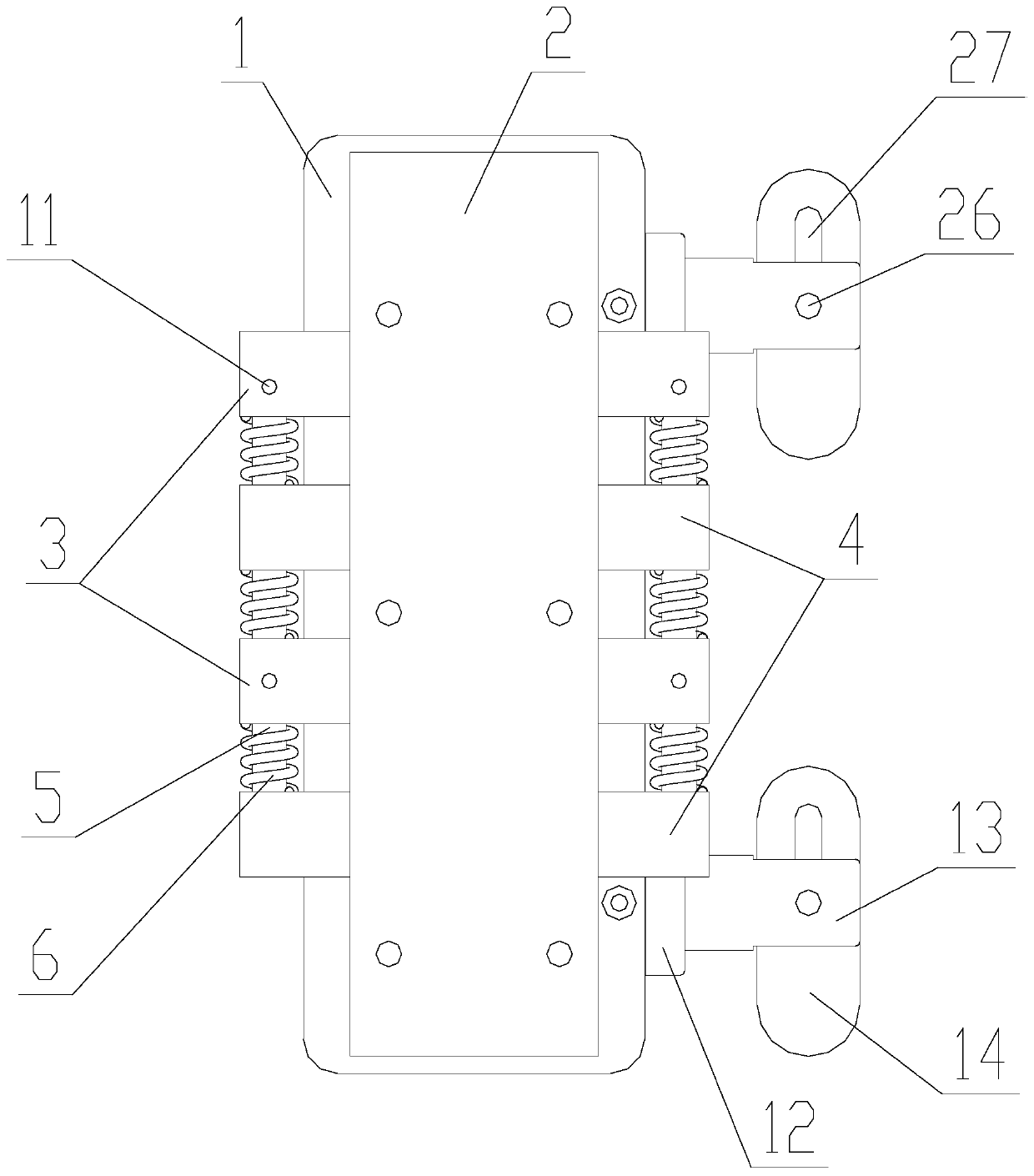

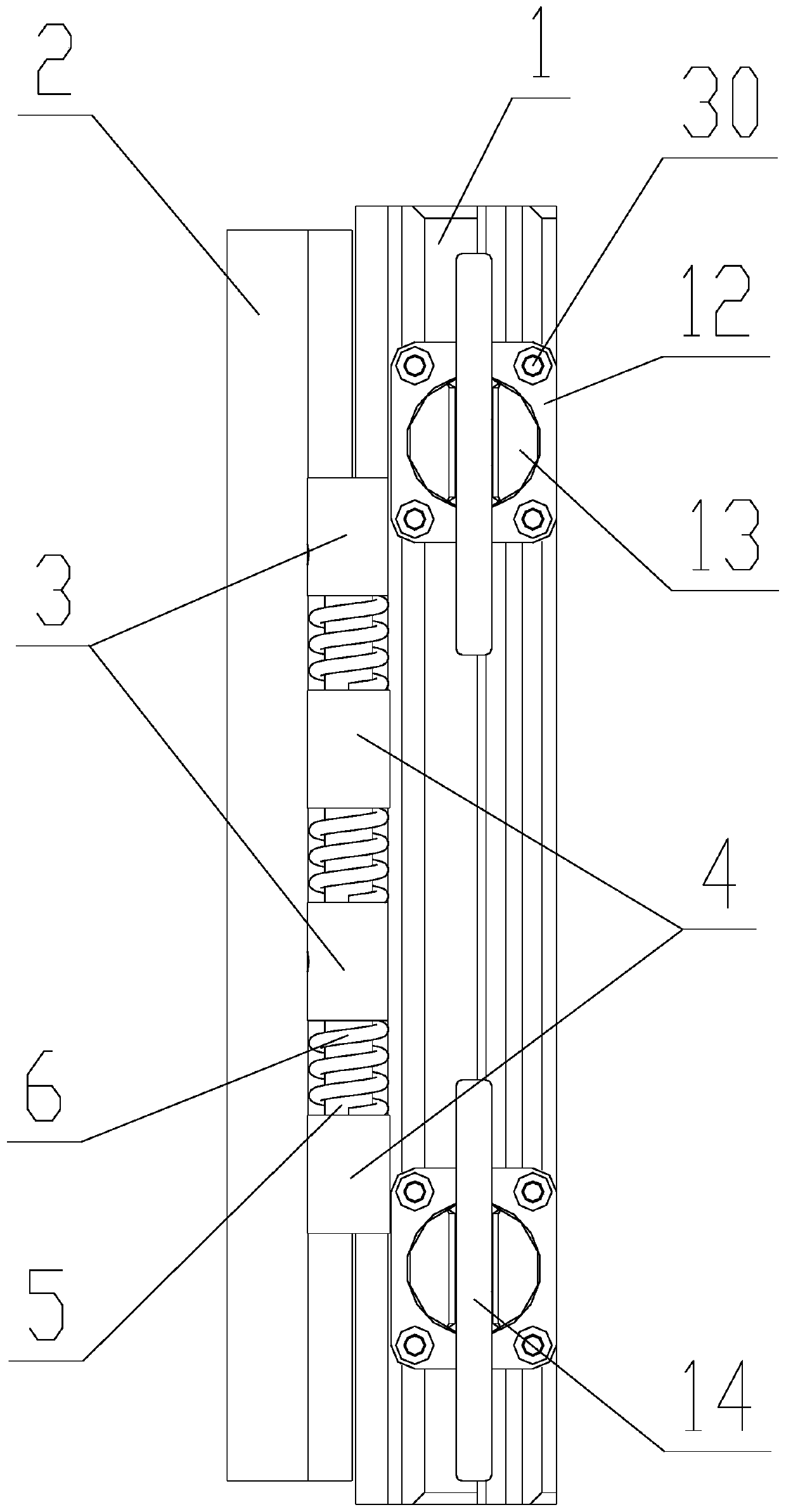

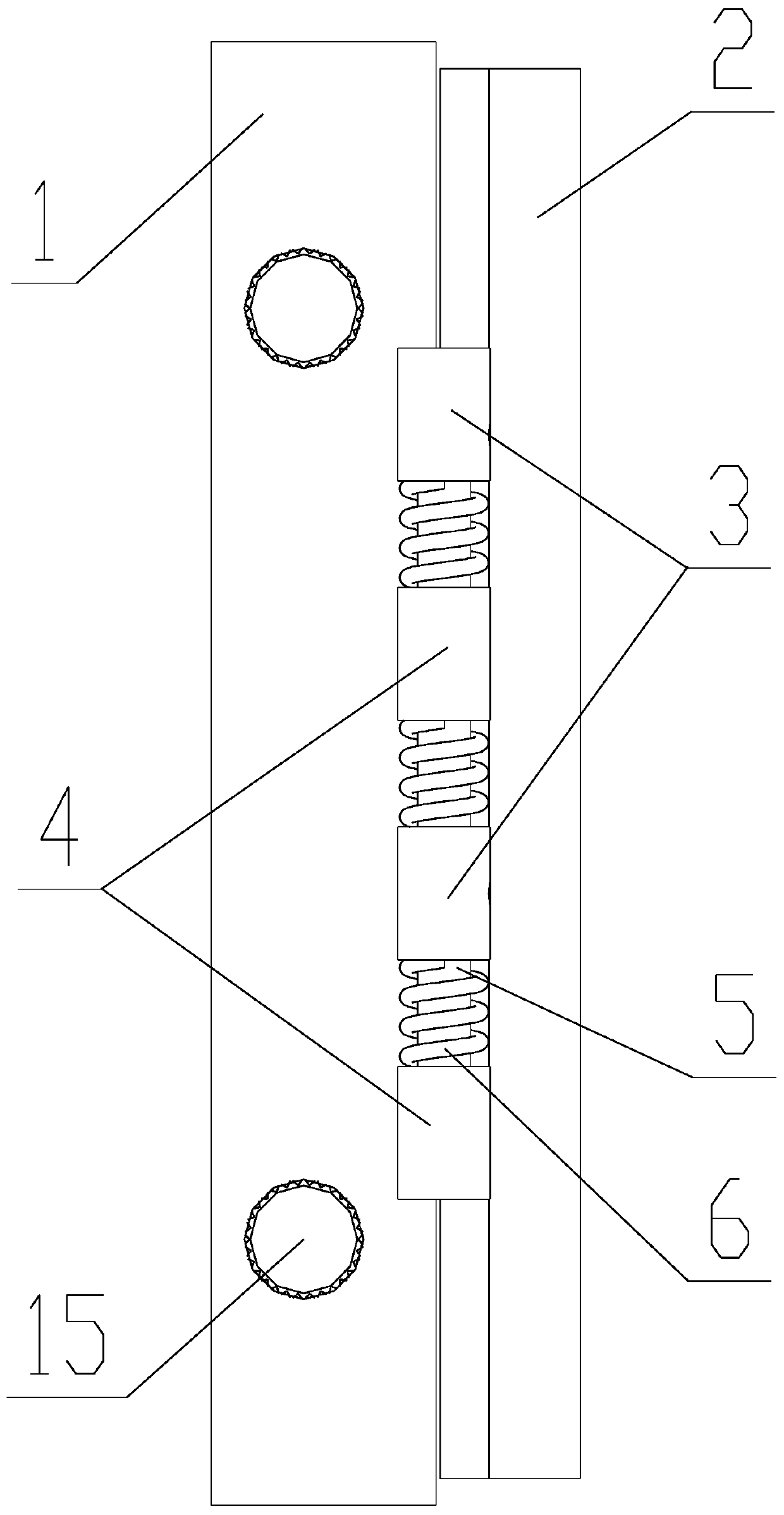

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0031] Such as Figure 1-7As shown, a spring damping mechanism with a fast locking function includes a base 1, a mounting base 2 and two guide rods 5, and two base guide rod supports 3 are fixedly connected to both sides of the base 1. Both sides of the mounting base 2 are fixedly connected with two mounting base guide rod bearings 4, the mounting base 2 is located on the top of the base 1, and one of the mounting base guide rod bearings 4 on each side Located between the two base guide rod supports 3 on the same side, each base guide rod support 3 is provided with a base guide rod support hole 9, each of the mount guide rod supports 4 There are mounting seat guide rod support holes 10 inside, the central axes of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com