High-protection-level explosive-proof transmission encoder assembly

An encoder and high protection technology, applied in the field of encoder components, can solve the problems of high cost, complex structure, poor coaxiality guarantee, etc., and achieve the effect of improving the explosion-proof level and the protection level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

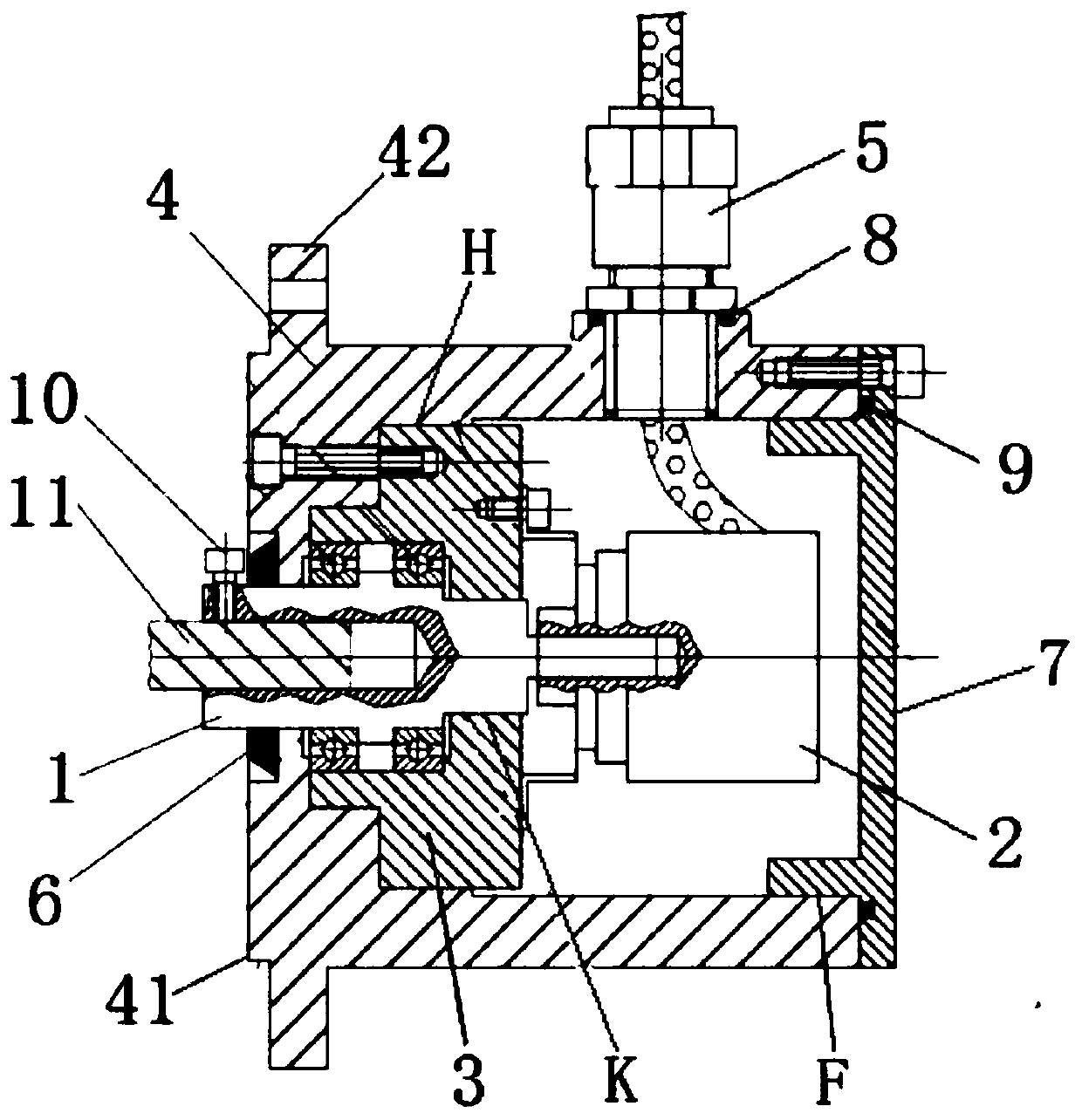

[0013] Embodiment 1: as figure 1 As shown, an encoder assembly of a flameproof transmission with a high protection level includes a transition shaft 1, an encoder 2, a transition sleeve 3, a housing 4 and a flameproof sealing locking joint 5;

[0014] The encoder 2 and the transition bushing 3 are arranged in the housing 4, and the housing 4 is processed with a threaded hole, and the threaded hole on the housing 4 is provided with a flameproof sealing locking joint 5, and the flameproof sealing locking joint 5 is connected with the housing The wires on the encoder 2 pass through the flameproof sealing locking joint 5 to the outside of the housing 4, the transition sleeve 3 and the housing 4 are fixedly connected, and the inside of the housing 4 and the transition sleeve 3 There is a first mating surface H between them, the gap between the first mating surface H of the housing 4 and the first mating surface H of the transition sleeve 3 is 0-0.104mm, and the length of the first ...

Embodiment 2

[0019] Embodiment 2: as figure 1 As shown, the difference between this embodiment and Embodiment 1 is: the side of the transition shaft 1 on the housing 4 in this embodiment is processed with a connecting flange 42, and the connecting flange 42 is provided with a connecting flange 42. The flange 42 is concentric with the positioning boss 41 . The positioning boss 41 is used to ensure that the connection hole 11 is coaxial with the external motor shaft, so as to ensure that the installation accuracy meets the requirements.

Embodiment 3

[0020] Embodiment 3: as figure 1 As shown, the difference between this embodiment and Embodiment 1 is that a sealing groove is processed on the circumference of the threaded hole on the casing 4 in this embodiment, and a first sealing ring 8 is arranged on the sealing groove, and the explosion-proof sealing lock The tight joint 5 is screwed into the thread of the casing 4, and is sealingly engaged with the first sealing ring 8 on the sealing groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com