Wavefront detection device and method for edge sub-mirror in spliced mirror

A technology of wavefront detection and sub-mirror, which is applied in the direction of measuring devices, machine/structural component testing, optical instrument testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

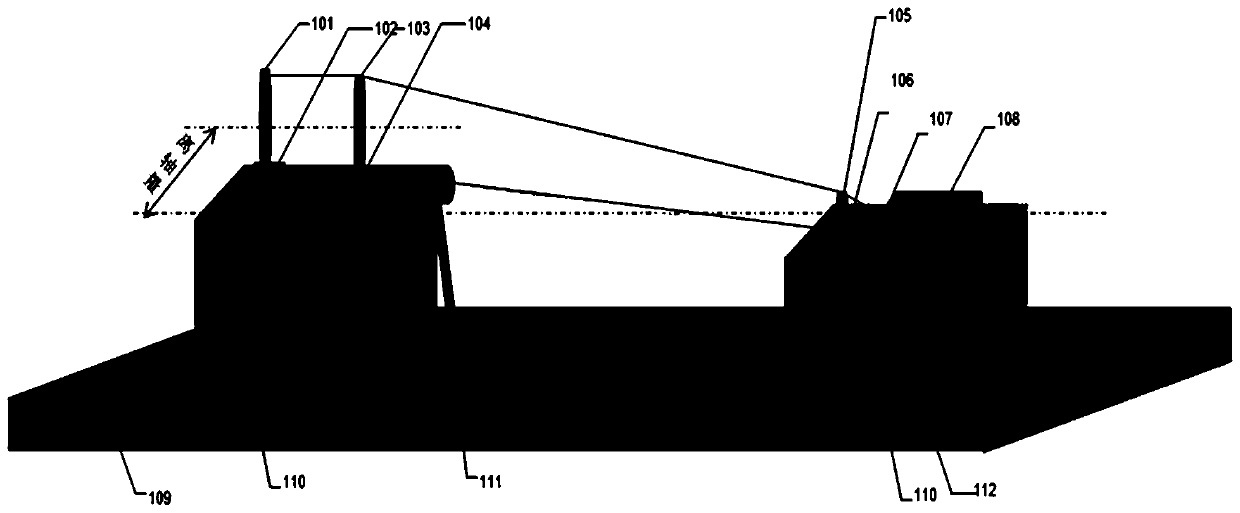

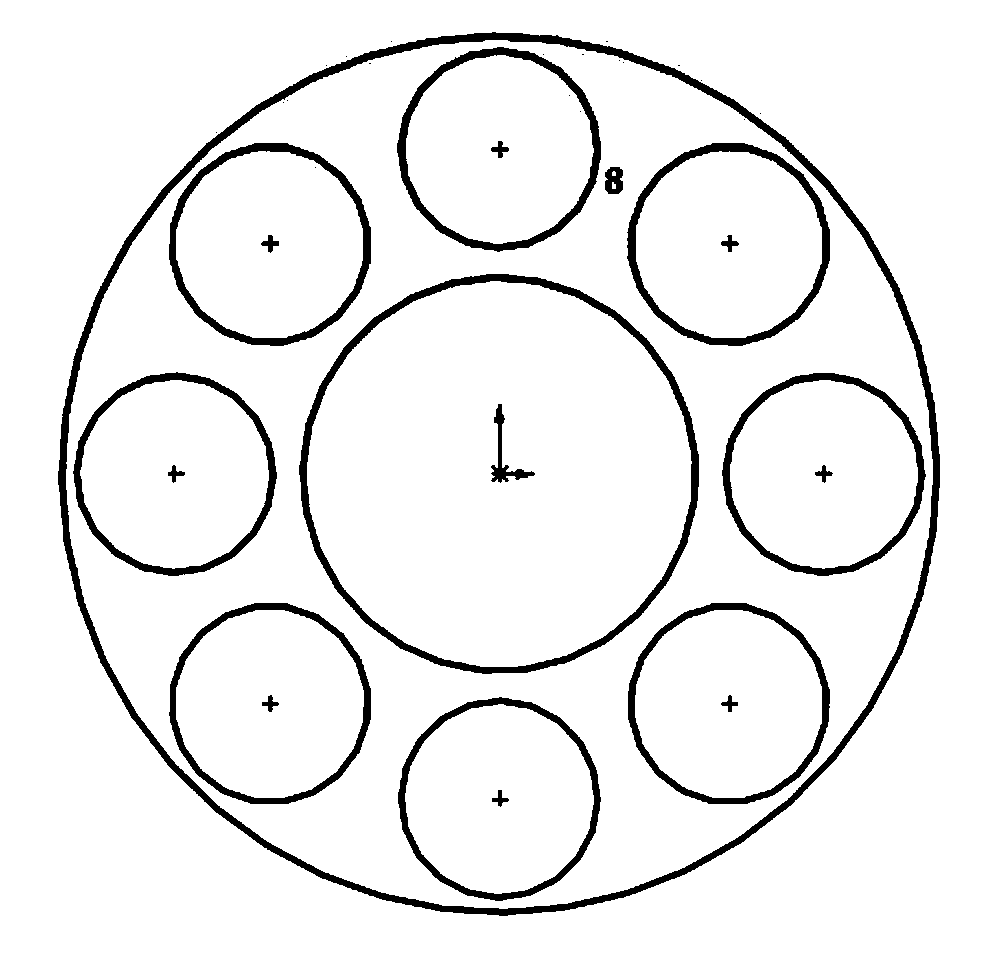

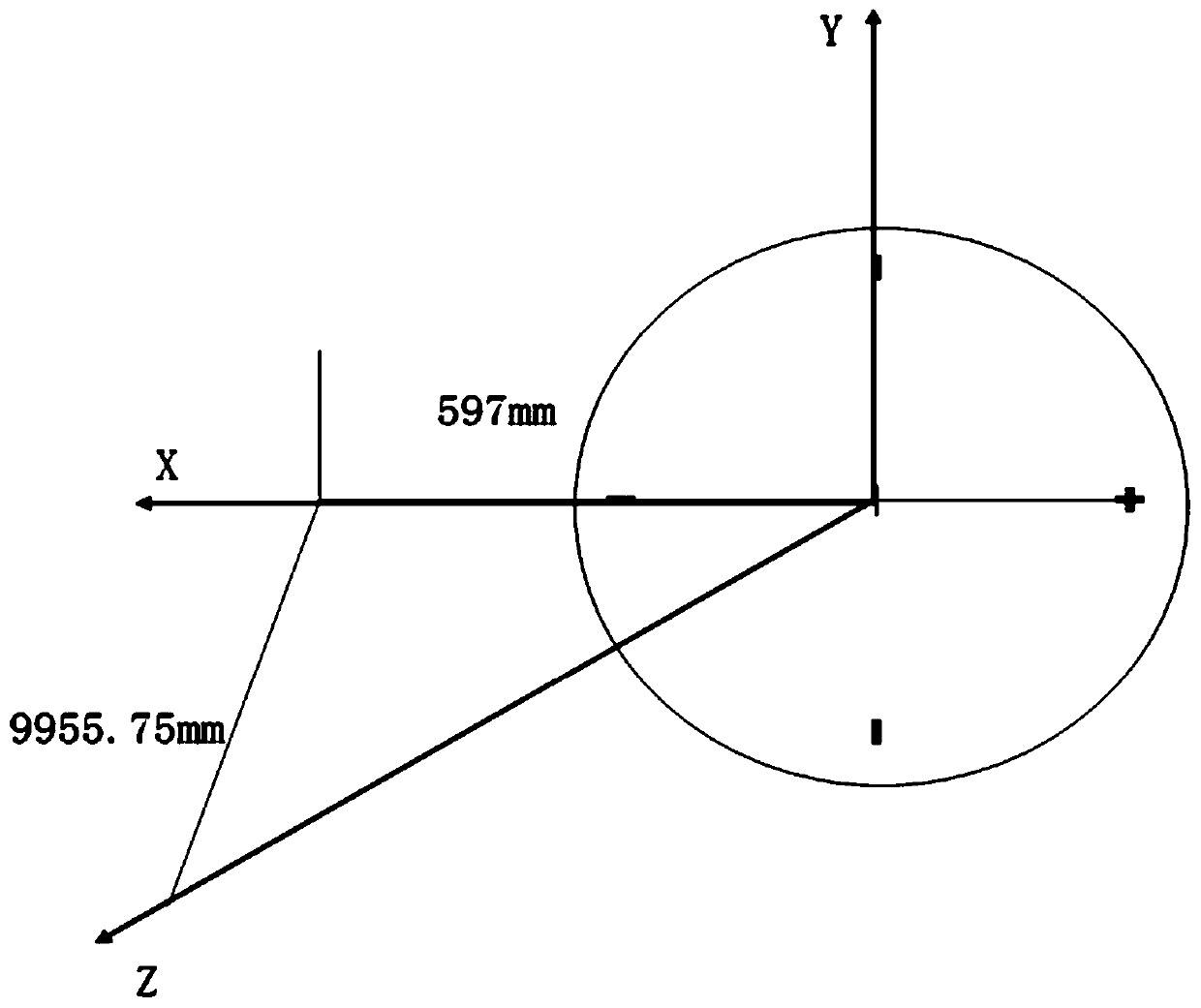

[0029] Such as figure 1 As shown, a wavefront detection device of the edge sub-mirror in the splicing mirror uses an interferometer and a laser tracker in combination, and uses a computational hologram to compensate for aberrations to detect the wavefront of the edge sub-mirror in the splicing mirror. The device includes a high-precision flat mirror 101, a lifting frame 102, a measured edge mirror 103, a tilt adjustment device 104, a calculation hologram 105, a small five-dimensional adjustment table 106, a standard lens 107, an interferometer 108, and a vibration isolation platform 109 , Five-dimensional adjustment table 110, laser tracker 111, target ball 112.

[0030] Wherein, the light emitted in the interferometer 108 passes through the standard lens 107, the calculation hologram 105, the measured edge sub-mirror 103, and is reflected on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com