Device and method for aligning a train

A line and train calibration technology, which is applied in the field of train debugging, can solve the problems of difficulty in ensuring the accuracy of calibration results and consume a lot of manpower, material and financial resources, and achieve the effect of avoiding human participation, avoiding manpower, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

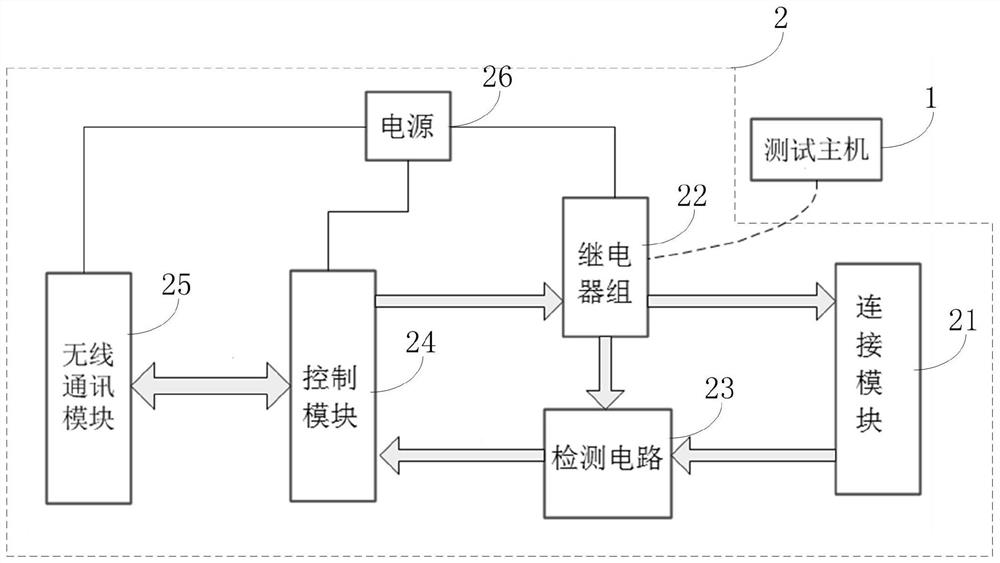

[0053] As an embodiment, the relay group 22 of the present invention includes 8 relays, which are respectively KA1, KA2, KA3, KA4, KA5, KA6, KA7 and KA8, and the 8 relays are respectively connected to the 8 outputs of the control module 24. end connection.

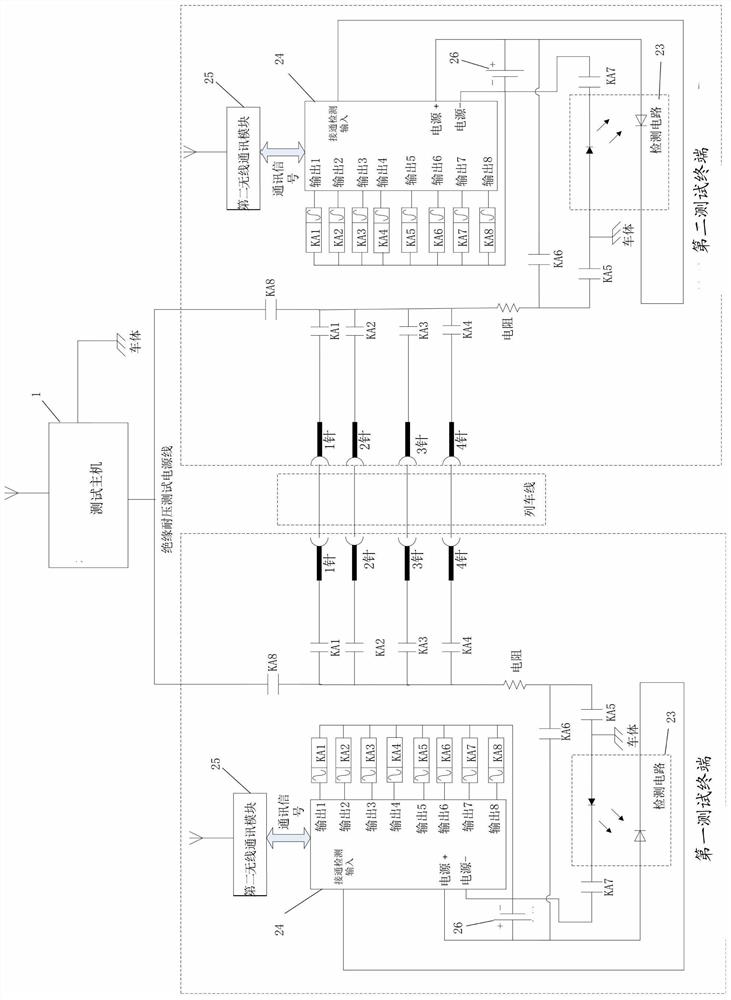

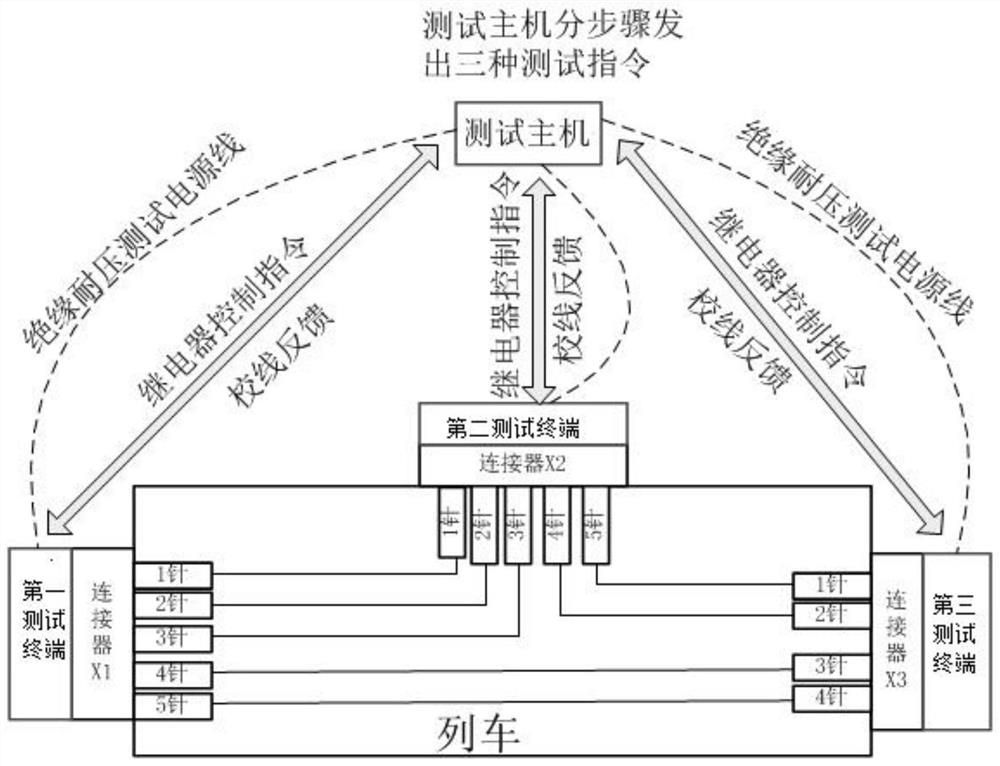

[0054] figure 2 It is a specific connection diagram between the test host 1 and the two test terminals 2 in the embodiment of the present invention, such as figure 2 As shown, in the line calibration mode, the test host 1 sends the first line calibration command to the first test terminal through the wireless communication module 25, and sends the second line calibration command to the second test terminal. The test terminals receive the first line calibration instruction through the wireless communication module 25, and all test terminals 2 first disconnect KA8. The first test terminal closes KA6 and KA7, and then closes KA1. The second test terminal closes KA1 after receiving the second calibration command, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com