Crimping machine for power engineering

A technology of electric power engineering and crimping machine, which is applied to circuits, connections, electrical components, etc., can solve the problems of poor crimping effect and inconvenient movement of the crimping machine, and achieves increased stability, convenient movement, and improved extrusion effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

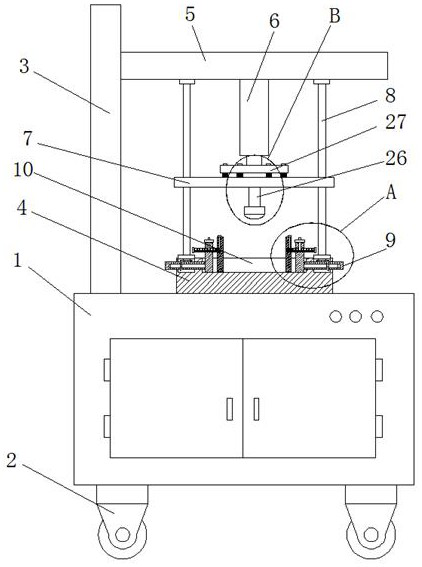

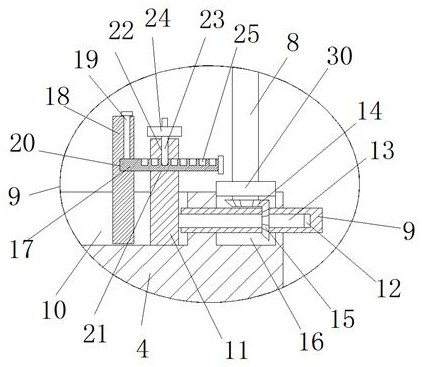

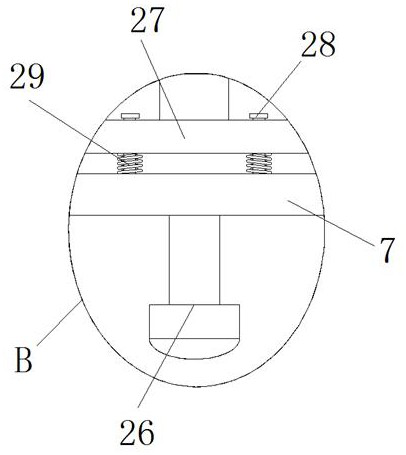

[0030]ReferFigure 1-6, The power engineering crimp, including the body 1, the bottom of the body 1 is fixedly connected to four universal wheel 2, the top of the body 1 is fixedly mounted, and the longitudinal plate 3 is fixed, and the longitudinal plate 3 is fixedly connected with the horizontal plate 5, the horizontal The bottom of the plate 5 is fixedly connected to the hydraulic cylinder 6, and the output shaft of the hydraulic cylinder 6 is fixedly connected to the cushioning mechanism, and the connection plate 7 is fixed to the buffer mechanism, the top of the body 1 is fixedly connected to the processing plate 4, the top of the processing plate 4 The bottom end of the two screws 8 is mounted, and the top end of the two screw bars 8 is rotated from the bottom of the cross plate 5, and the connecting plate 7 is threaded with the two screws 8, and the top of the processing plate 4 is opened. 10. Sliding in the processing tank 10 is mounted with two moving plates 11, and the two ...

Embodiment 2

[0033]ReferFigure 1-6, Power engineering crimping machine, including the body 1, the bottom of the body 1 is fixed by the screw 2 universal wheel 2, and the vertical plate 3 is fixed to the top of the body 1, and the longitudinal plate 3 is fixed by the screw. The plate 5, the bottom of the cross plate 5 is fixed to the hydraulic cylinder 6 by the screw, and the output shaft of the hydraulic cylinder 6 is fixedly connected to the buffer mechanism through the screw, and the buffer mechanism is fixedly connected to the connecting plate 7, the top of the body 1 is passed through the screw. Fixed, the processing plate 4 is fixed, and the top of the processing plate 4 is rotated and mounted with the bottom end of the two screw rods 8, and the top end of the two screw bars 8 is rotated from the bottom of the cross plate 5, the connecting plate 7 and two screw bars 8. The thread is connected, and the machining plate 10 is opened, and the machining tank 10 is slidably mounted with two movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com