Novel cross bar fixing support of hanging net

A technology for fixing brackets and beams, applied in the application, poultry industry, poultry cages or houses, etc., to avoid easy rust, avoid welding process, and improve the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

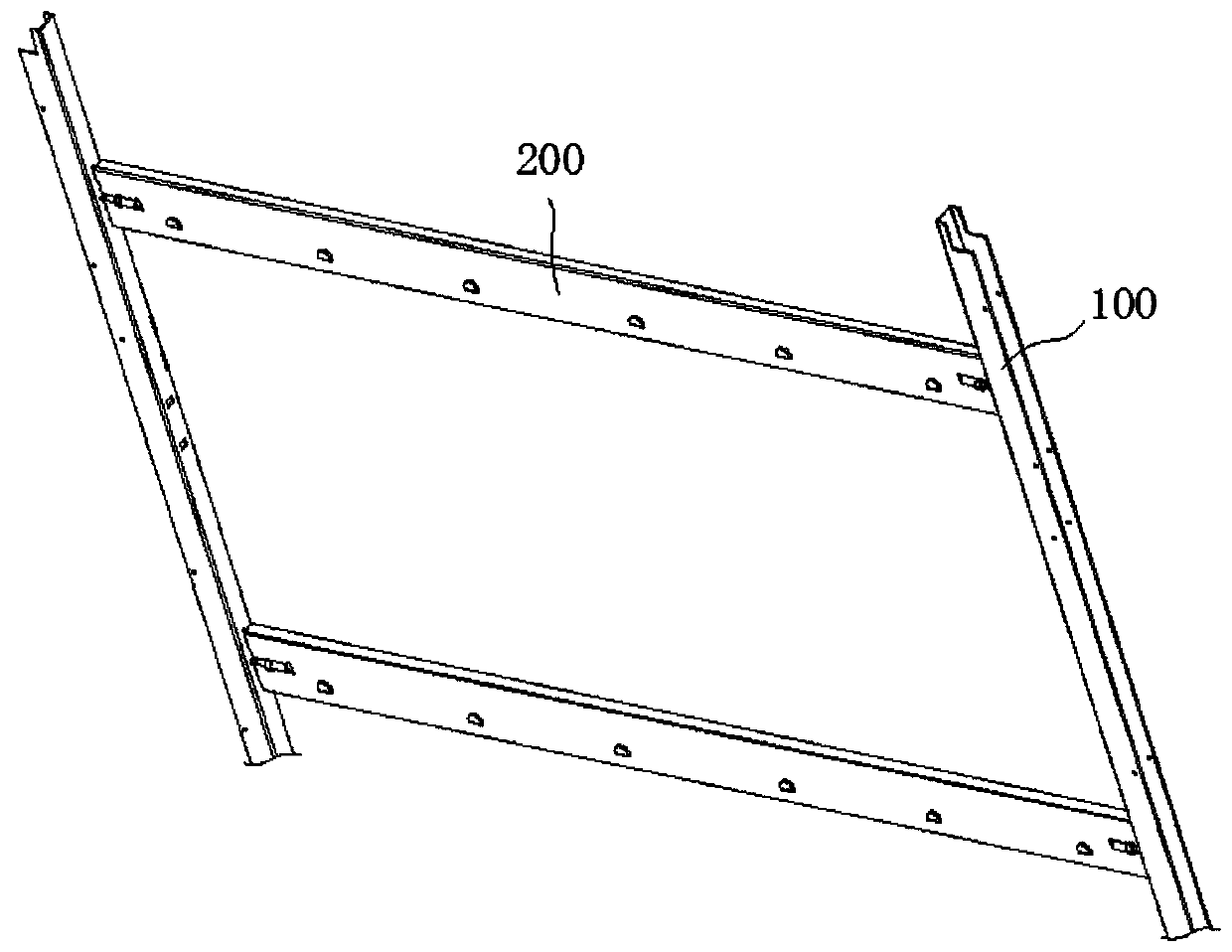

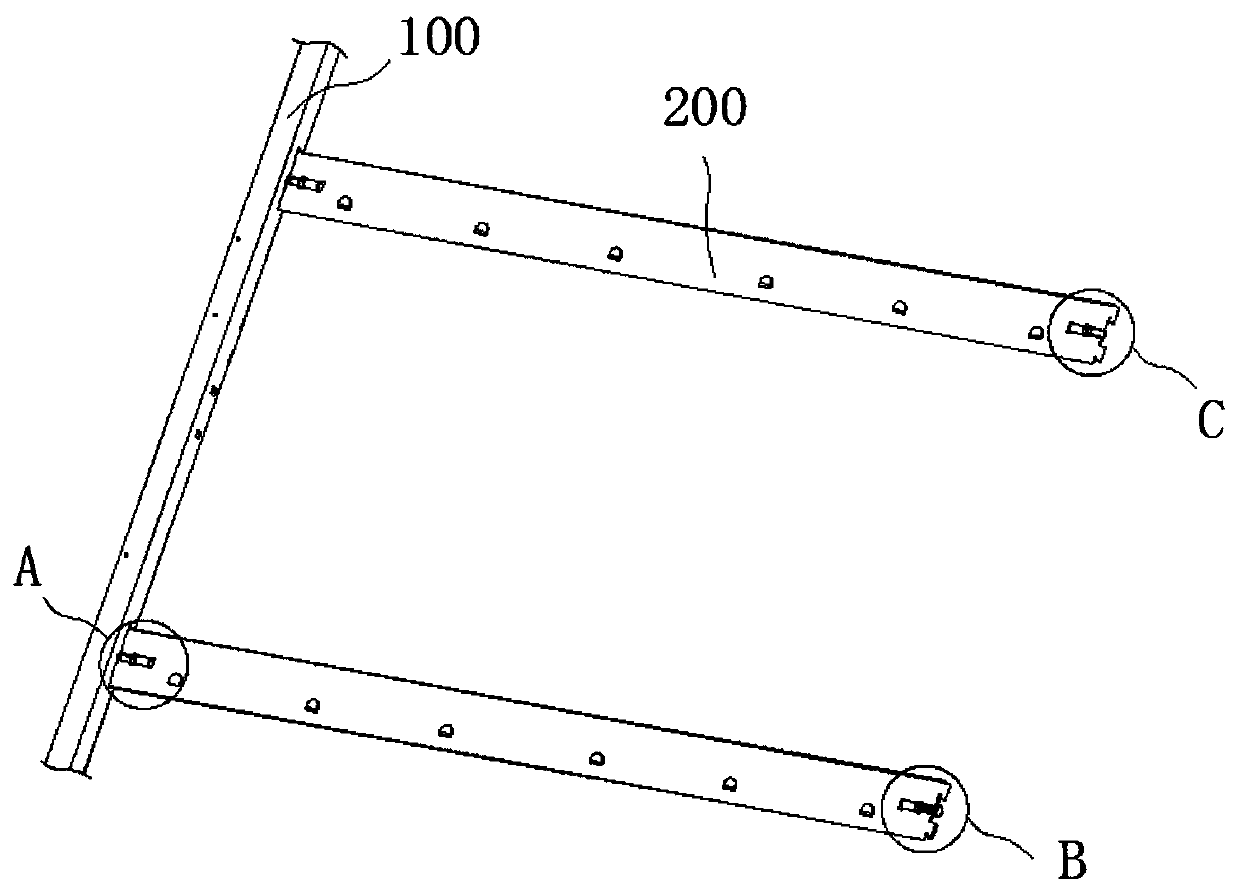

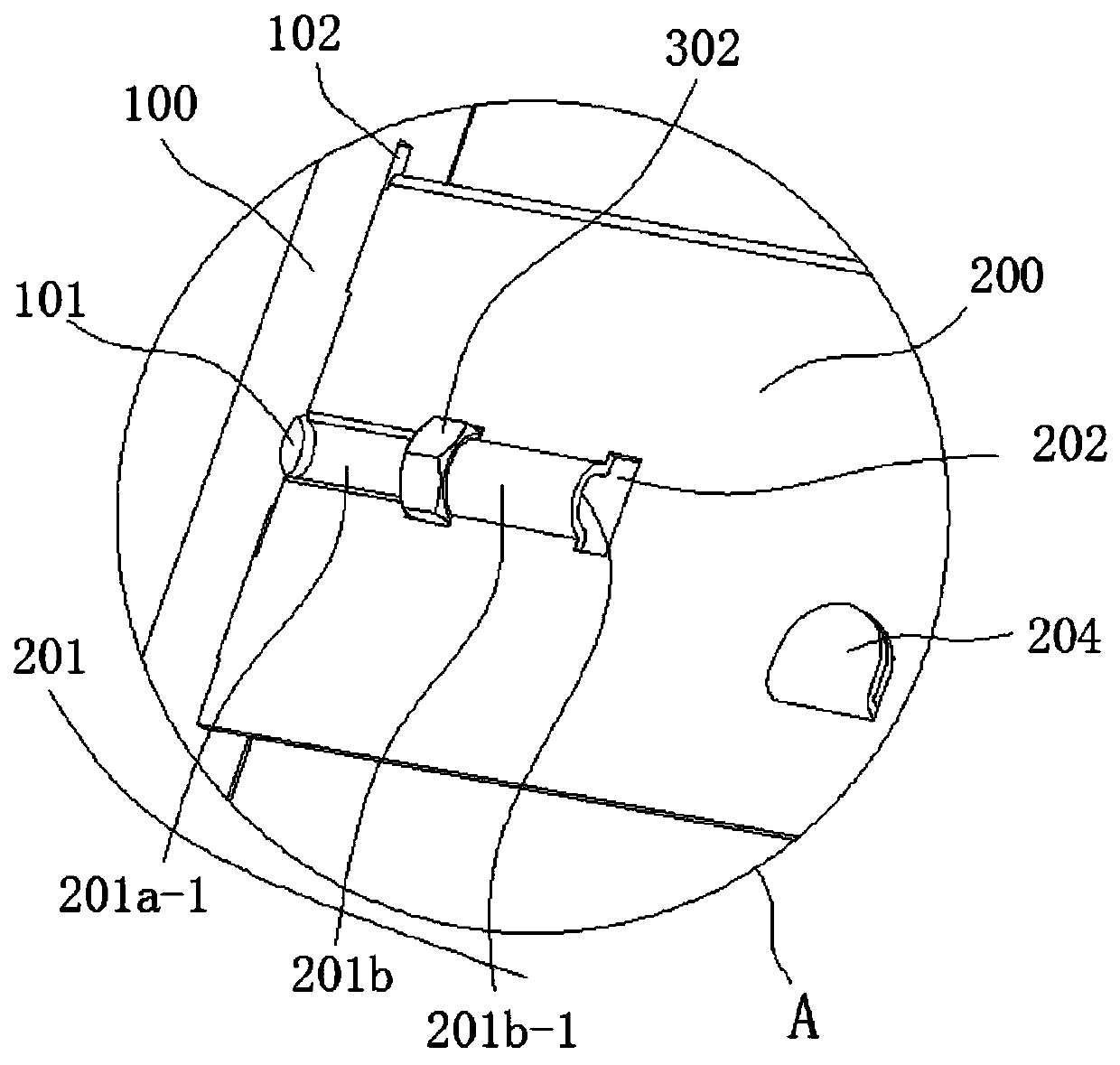

[0026] see figure 1 Or 6, the support is composed of two vertical longitudinal bars 100 and a plurality of cross beams 200, similar to a ladder, the two longitudinal bars 100 are parallel to each other, the cross beam 200 is perpendicular to the longitudinal bars 100 and the two ends of the cross beam 200 are respectively connected to two The longitudinal bars 100 are connected, the cross beam 200 is a rectangular steel plate structure, and the longitudinal bar 100 is a steel structure with a U-shaped cross section processed by steel plates.

[0027] see Figure 6-7 , the outer surface of the crossbeam 200 is provided with a hook 204, the hook 204 is used to hang the cage of the poultry, it should be noted that the hook 204 is formed by the stamping process of the crossbeam 200, in order to form the hook 204, the inside of the crossbeam 200 forms a stamping groove 204 a , the hook 204 formed by stamping has better durability than the hook 204 welded on the beam 200 , and the ...

Embodiment 2

[0039] In the above embodiment, the beam 200 is subjected to a large thrust, and the direction of the thrust is from the opening direction of the positive groove 201a-1 to the opening direction of the reverse groove 201b-1, and the effect of the force is to make the bolt 301 move away from the positive The opening direction of the groove 201a-1 or the reverse groove 201b-1 moves, especially when the distance between the positive concave ring 201a and the reverse concave ring 201b is too large, the position where the crossbeam 200 contacts the longitudinal bar 100 will slide, thereby The bolt 301 may rotate with the nut 302 as the axis due to the force and directly break away from between the positive concave ring 201a and the reverse concave ring 201b, thus causing the phenomenon that the beam 200 and the vertical rod 100 are not fixed stably. The above problems In this embodiment, a hanging plate 203 is added at one end of the beam 200, and the hanging plate 203 is clamped wit...

Embodiment 3

[0052] Such as Figure 4-6 , in the above-mentioned embodiment, when the longitudinal bar 100 moves away from the cross beam 200, the bolt 301 plays the main role of connecting and fixing, but if things go on like this, the bolt 301 is easy to rotate relative to the nut 302, thus causing the gap between the cross beam 200 and the longitudinal bar 100 In order to solve the above problem, the hanging plate 203 is arranged in an L-shape in this embodiment, and the L-shaped hanging plate 203 is divided into a fixed end 203a and an extension end 203b. The fixed end 203a is a rectangular steel plate structure, and the fixed end 203a is fixed to one end of the crossbeam 200, the extension end 203b is fixed to one side of the fixed end 203a, and there is a gap between the side of the extension end 203b close to the crossbeam 200 and the crossbeam 200, the narrowest part of the gap The width of the beam is the same as the thickness of the steel plate of the longitudinal bar 100, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com