Production spraying device based on building energy conservation plates

A technology of spraying device and building energy saving, applied in spraying device, spray booth and other directions, can solve the problems of difficulty in quickly adjusting the number of nozzles, fixed number of nozzles, limitation of spraying thickness, etc., to achieve good adjustable performance, improve spraying uniformity, Safe and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

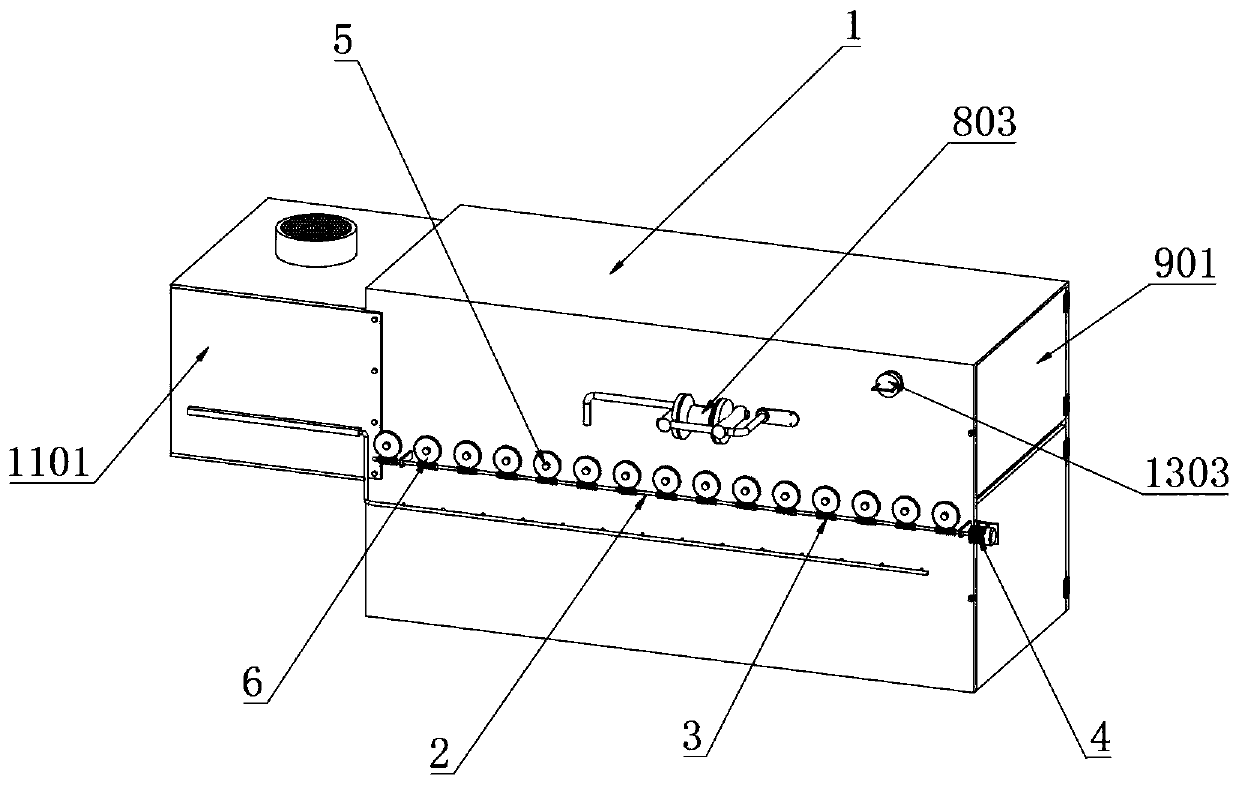

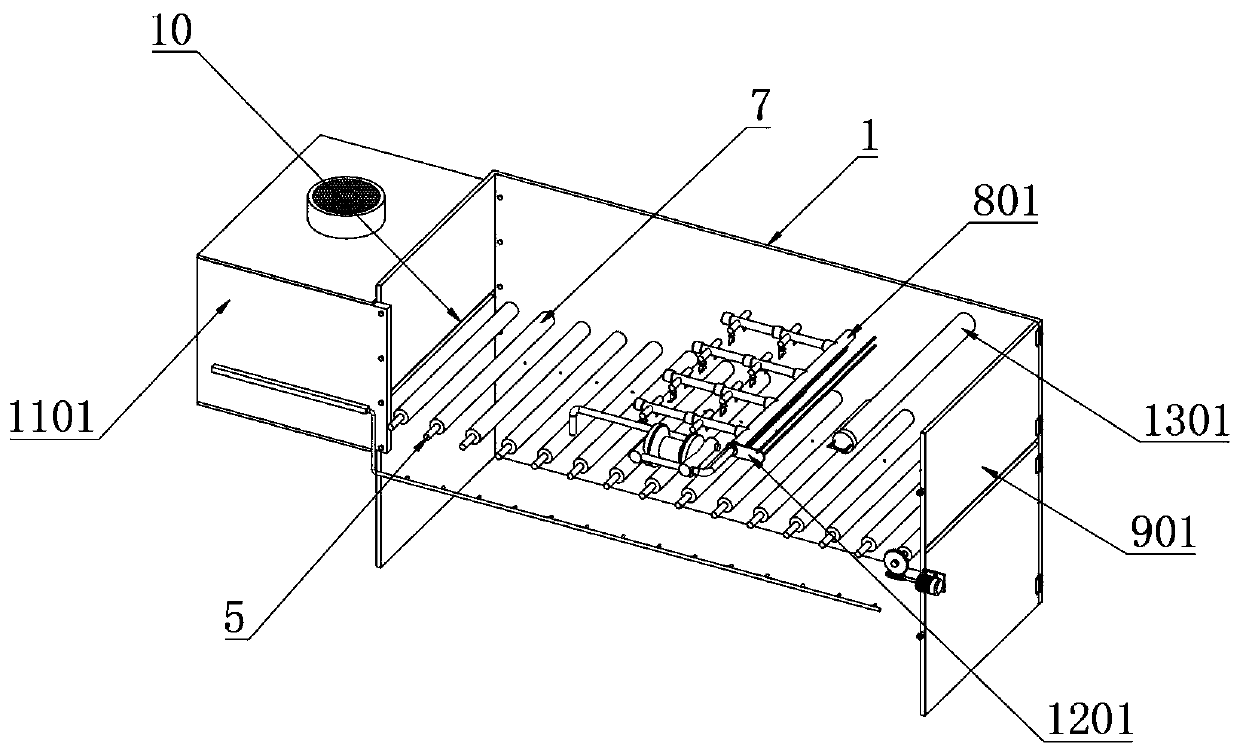

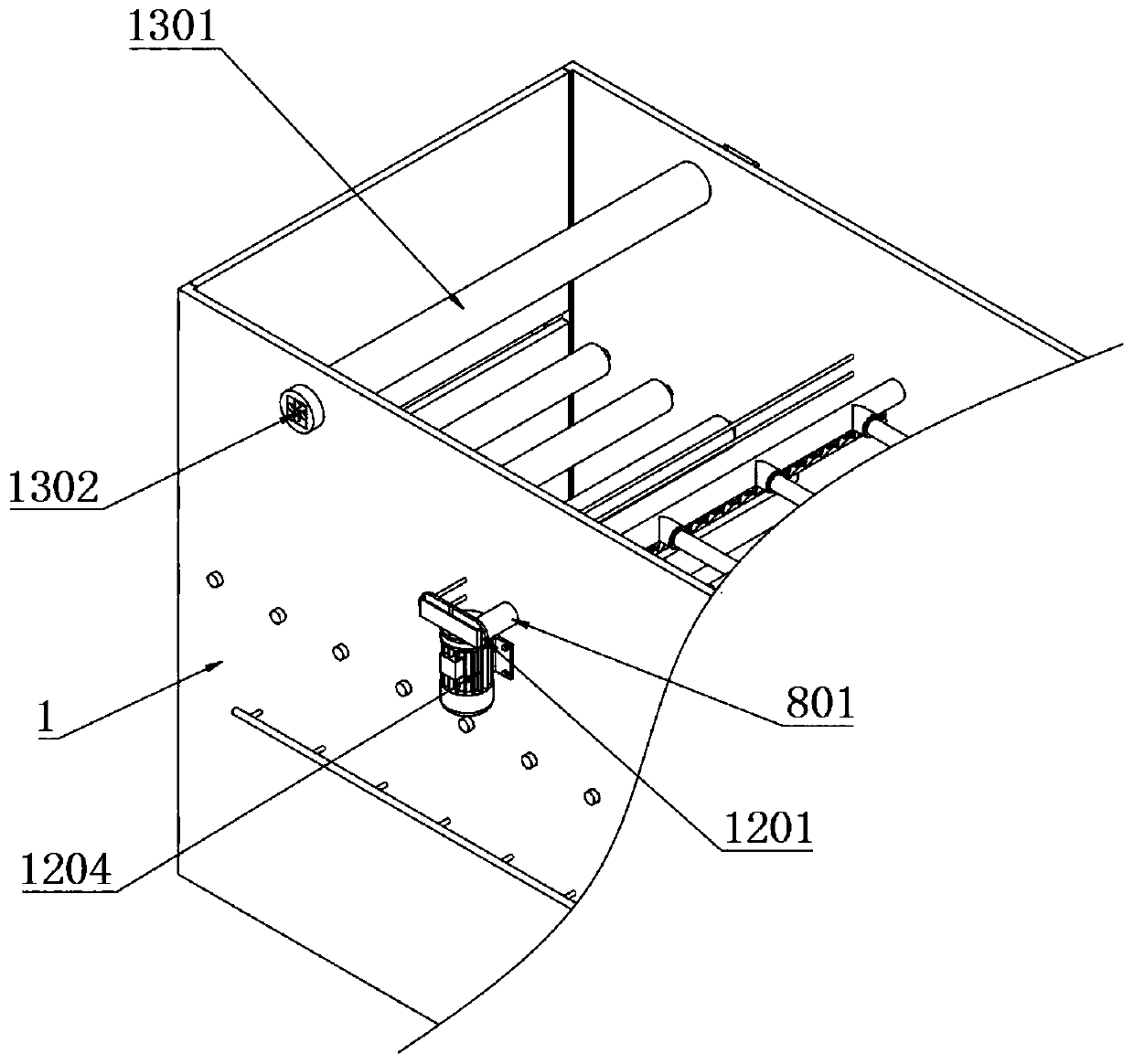

[0052] Example: such as Figure 1-11 As shown, the present invention provides a technical solution, a production spraying device based on building energy-saving panels, including a housing 1, the middle part of the front end of the housing 1 is connected to a drive shaft 2 through a shaft seat, and the outer surface of the drive shaft 2 is equidistantly socketed There are a number of worm sleeves 3, one end of the drive shaft 2 is connected with a drive motor 4, a number of installation shafts 5 are installed in the middle of the housing 1 corresponding to the position of the worm sleeve 3, and a worm gear 6 is socketed at one end of the installation shaft 5 corresponding to the position of the worm sleeve 3. The worm gear 6 is meshed with the worm sleeve 3 through teeth, so the rotation of the drive shaft 2 and the worm sleeve 3 can effectively drive the worm gear 6 to rotate, and the middle part of the installation shaft 5 is sleeved with a delivery sleeve 7;

[0053] A spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com