Bonding agent coating device

A coating device and adhesive technology, which is applied in the direction of devices and coatings for coating liquid on the surface, can solve the problems of uneven local coating of the adhesive, affect product quality, and affect normal use, etc. The effect of adhesive coating quality, labor cost saving and production efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] An adhesive coating device provided in an embodiment of the present invention is installed on an adhesive coating device for coating the adhesive.

[0059] The adhesive coating equipment includes a machine base (not shown in the accompanying drawings of this embodiment) and a moving device (not shown in the accompanying drawings of this embodiment), the mobile device is installed on the machine base and can move on the machine base For two-dimensional or three-dimensional movement, the adhesive coating device is installed on the mobile device and can move together with the mobile device, wherein:

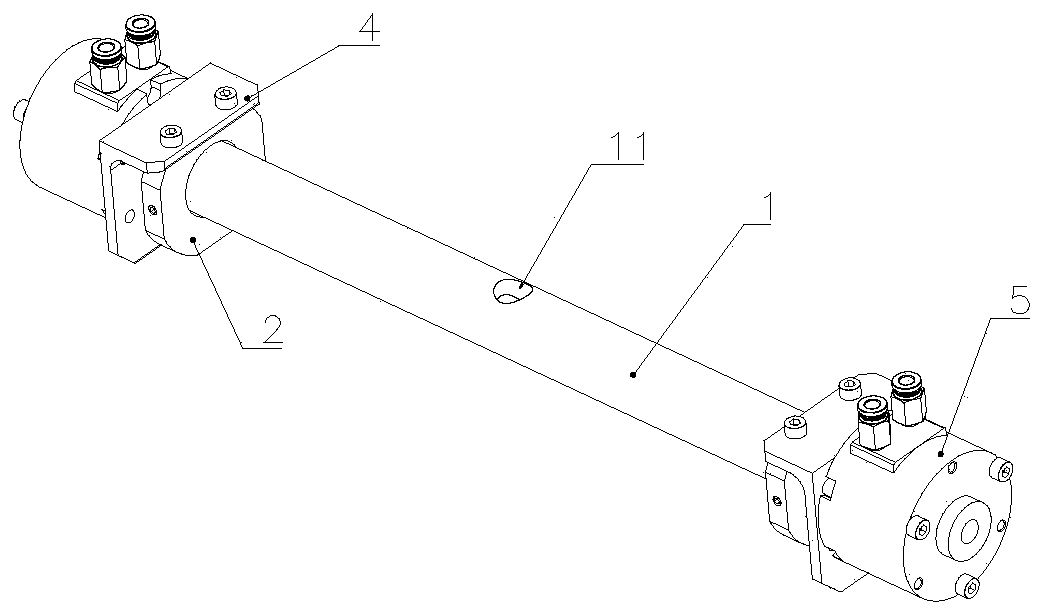

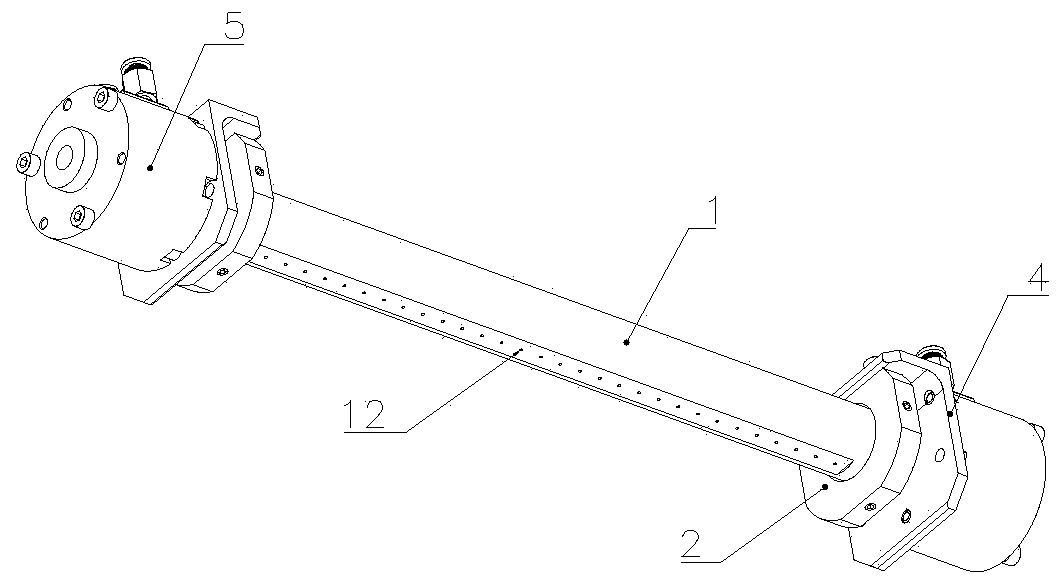

[0060] An adhesive coating device provided by an embodiment of the present invention is as figure 1 A schematic top view of a three-dimensional structure of an adhesive coating device provided in an embodiment of the present invention, figure 2 A schematic bottom view of a three-dimensional structure of an adhesive coating device provided in an embodiment of the present inv...

Embodiment 2

[0079] This embodiment is a further improvement and perfection of the adhesive coating device provided in the first embodiment. In this embodiment, for the sake of brevity, the same technical features and connection relationships as those described in Embodiment 1 will not be repeated here.

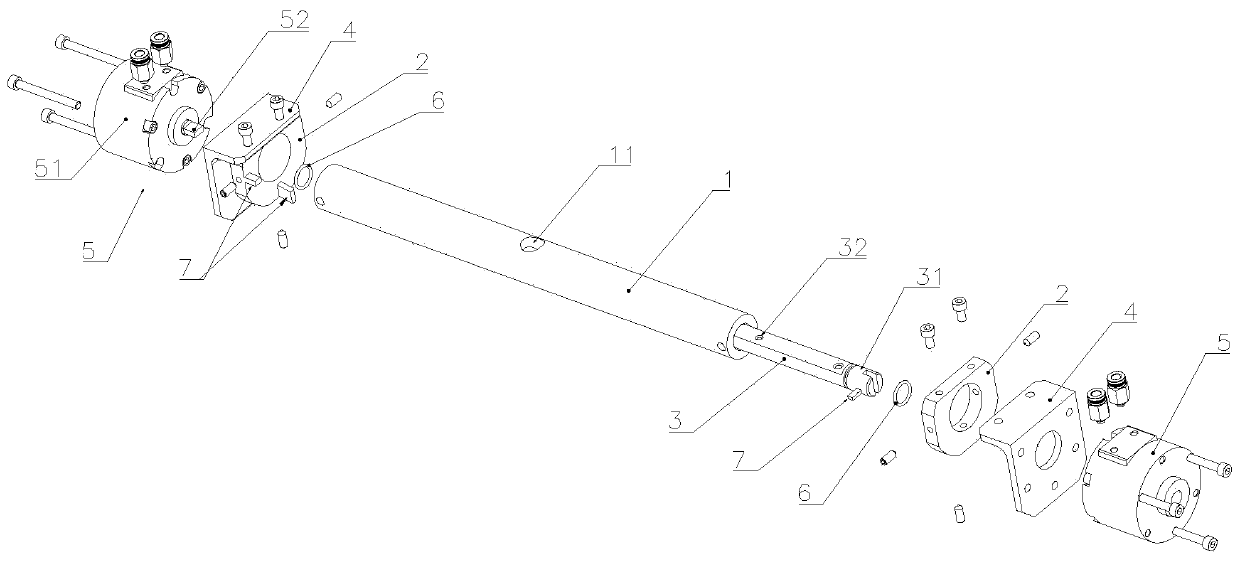

[0080] Such as image 3 The three-dimensional structure decomposition diagram of an adhesive coating device provided in the embodiment of the present invention is shown in the following diagram:

[0081] In this embodiment, on the basis of not changing the basic structure of the adhesive coating device provided in Embodiment 1, further, a sealing ring 6 is provided at the end 31 of the switch shaft 3, and the two ends of the switch shaft 3 are sealed with the glue application pipe 1. Ring 6 for sealing fit.

[0082] In this way, the sealing effect between the rubber tube 1 and the end 31 of the switch shaft 3 can be further improved.

[0083] The sealing ring 6 is preferably made of fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com