Buckle bending device and method for angle support

A technology of angles and cuboids, applied in the field of bending devices for angle brackets, can solve problems such as lowering product processing efficiency, difficulty in dimensional accuracy, and difficulty in guaranteeing processing quality, and achieves improved processing efficiency and quality, strong promotion, and savings The effect of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better explain the present invention and facilitate understanding, the technical solutions and effects of the present invention will be described in detail below through specific implementation manners in conjunction with the accompanying drawings.

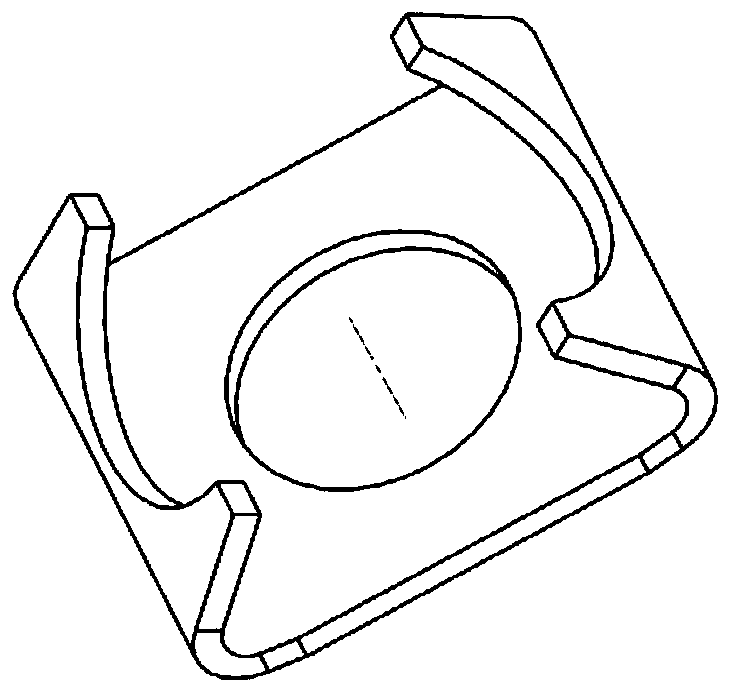

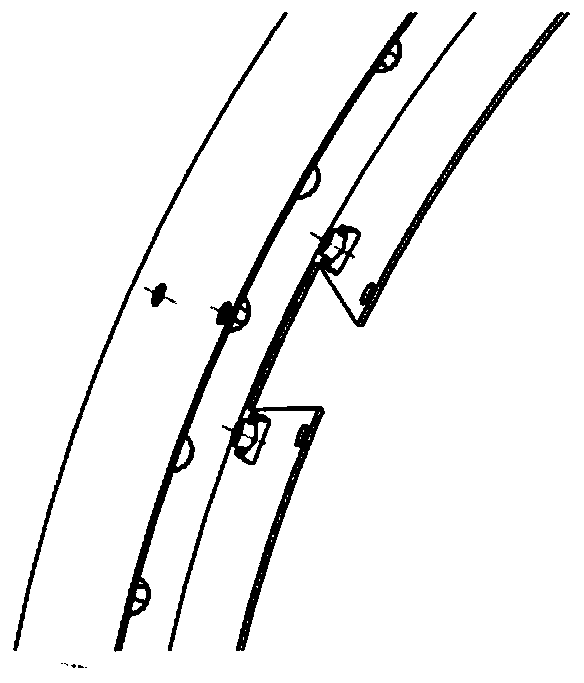

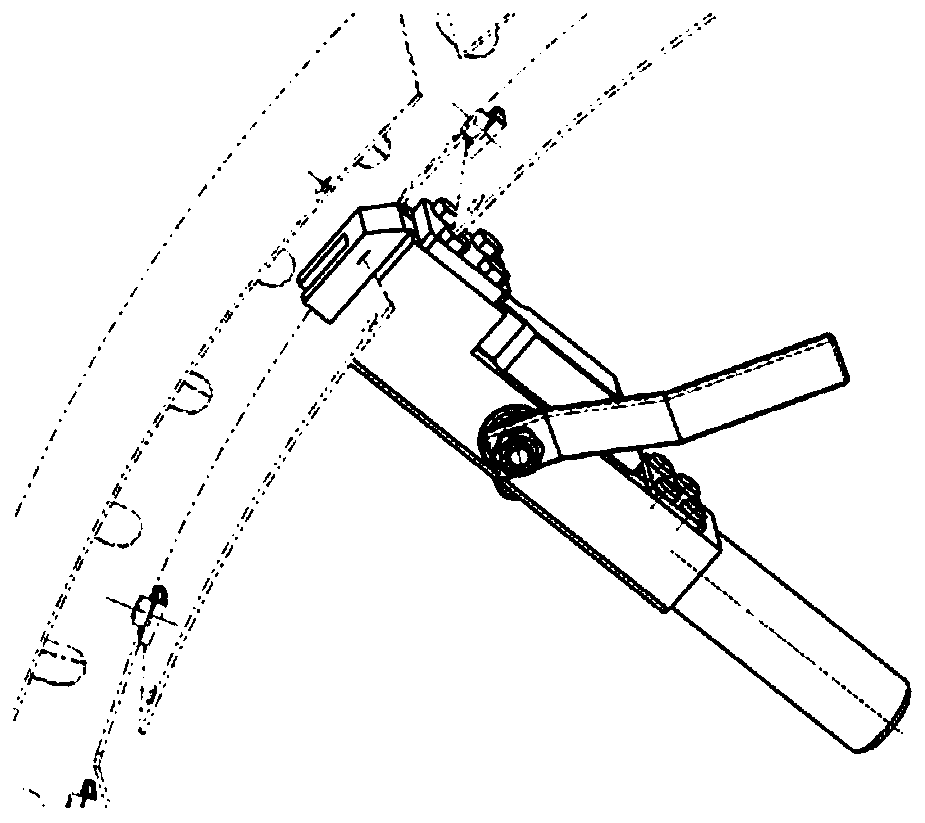

[0027] like Figure 4-7 As shown, a bending device for an angle bracket includes a positioning seat 1, a pressure plate 2, a cover plate 3, a cam 4, a handle 5, a mandrel 6, a bushing 7, and a cover plate 2 8. The main structure is a cuboid , with a guide groove, the top and bottom of the middle position of the guide groove are provided with mandrel 6 mounting holes; the outer contour of the cam 4 is composed of three arcs and a plane, a square hole is opened near the end of the arc, and the handle 5 is stepped It is a cuboid with a "U"-shaped hole near the end. The mandrel 6 passes through the "U"-shaped hole of the handle 5 and the square hole of the cam 4 to install it in the installation hole. The two ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com