Cylinder body mold suitable for multiple length specifications

A technology of specifications and cylinder blocks, applied in the field of cylinder block molds, can solve problems such as high cost and waste of resources, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

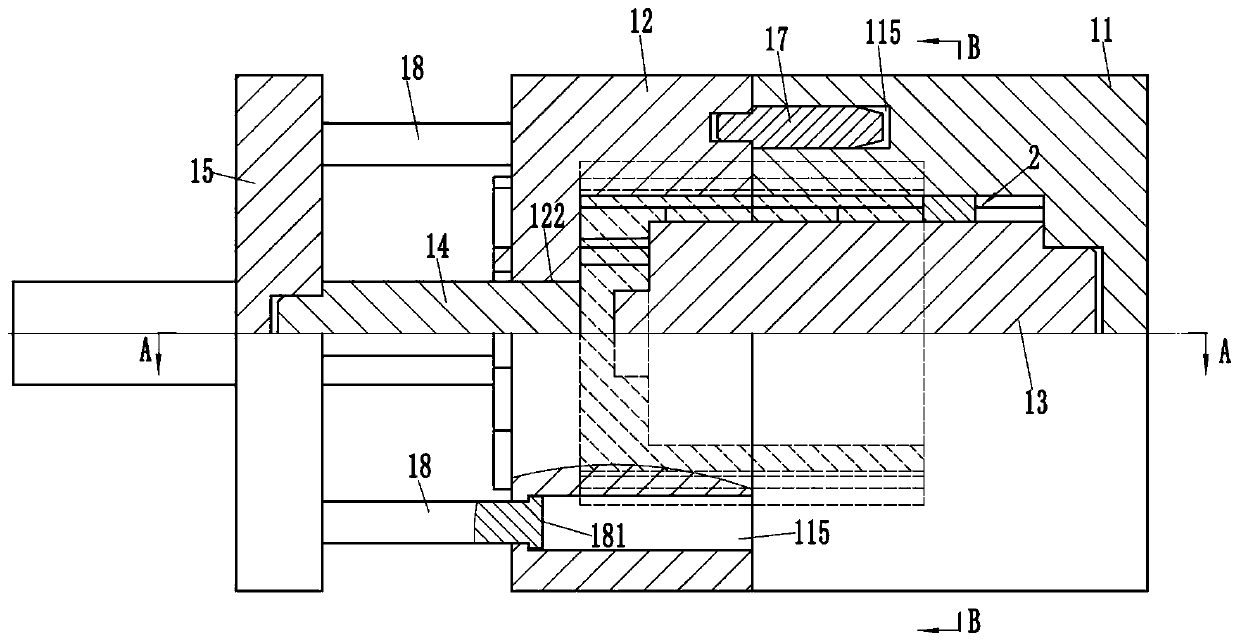

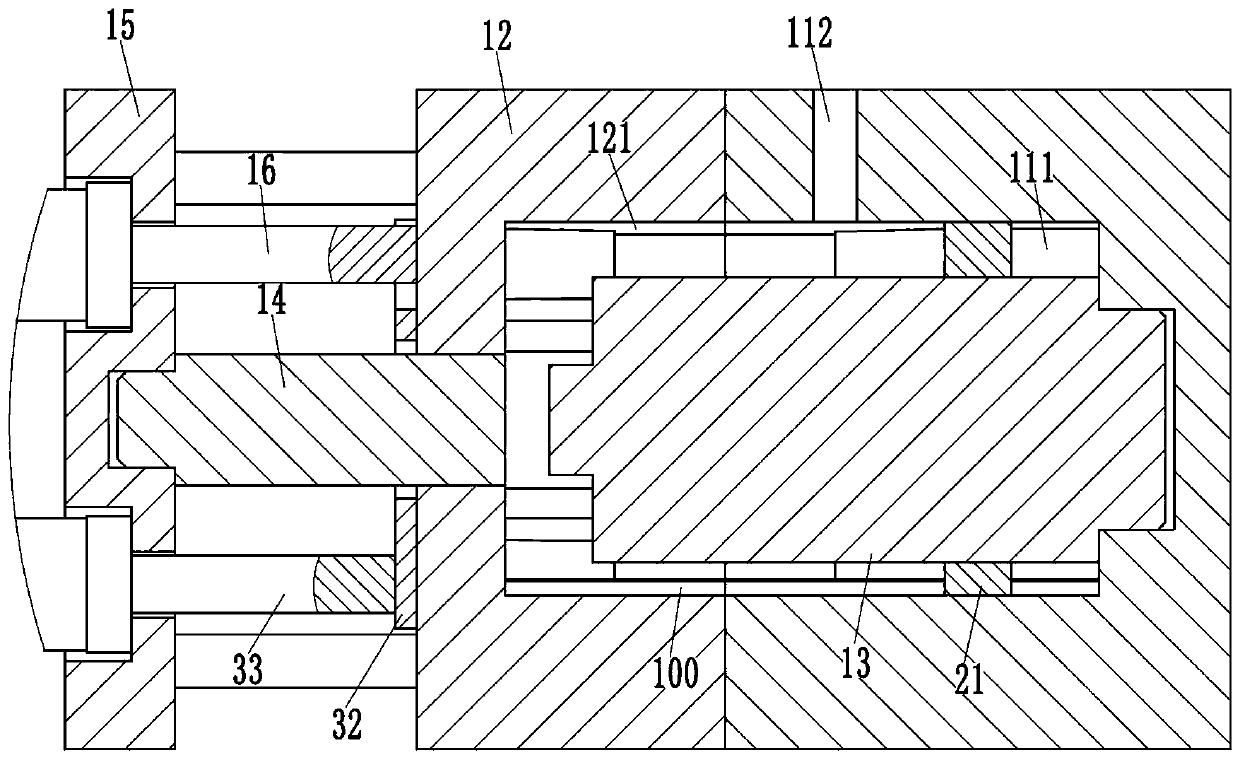

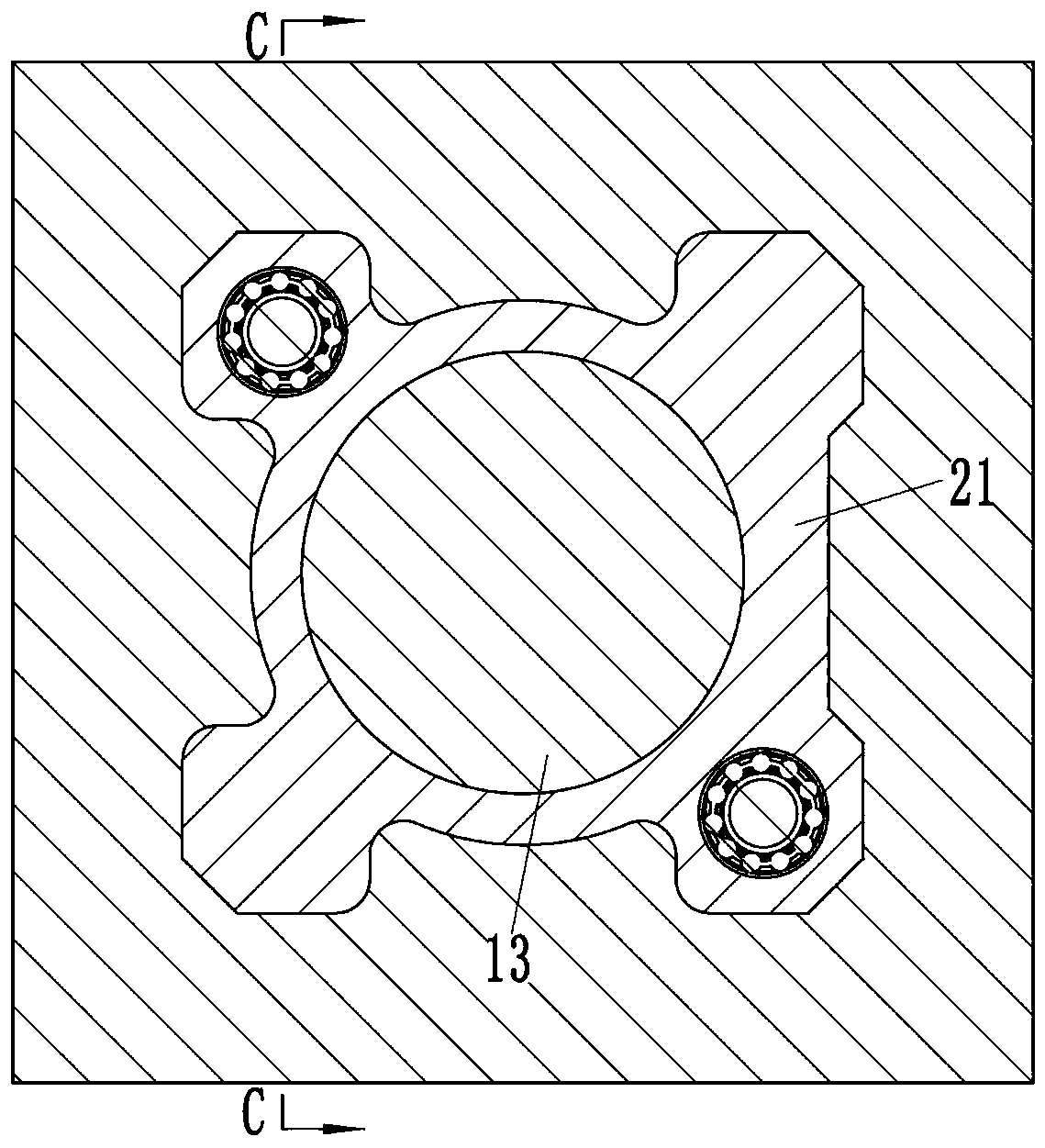

[0020] Examples, see e.g. Figure 1 to Figure 6 As shown, a cylinder mold suitable for a variety of length specifications includes a fixed mold 11 and a movable mold 12. The fixed mold 11 is formed with a first groove 111 with a left opening, and the first groove 111 is fixed with Forming mandrel 13 and adjustment assembly 2, the forming mandrel 13 is fixed on the right side wall of the first groove 111, the adjustment assembly 2 includes a left and right movable adjustment template sleeved on the outer wall of the forming mandrel 13 21. The contour of the outer wall of the adjustment template 21 is consistent with the contour of the inner wall of the first groove 111, and a feed port 112 communicating with the first groove 111 is formed on the side wall of the fixed mold 11; There is the second type groove 121 of opening on the right side, the size and shape of the cross section of the first type groove 111 and the second type groove 121 are consistent, the first type groove ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap