Multi-electrode gas shielded arc welding device for refining

A shielded arc, multi-electrode technology, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve the problems of poor wire arrangement and storage, gas shielded arc welding machine rollover, easy to shake, etc. Achieve easy subsequent use, reduce the difficulty of winding and laying out, and easy to store

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

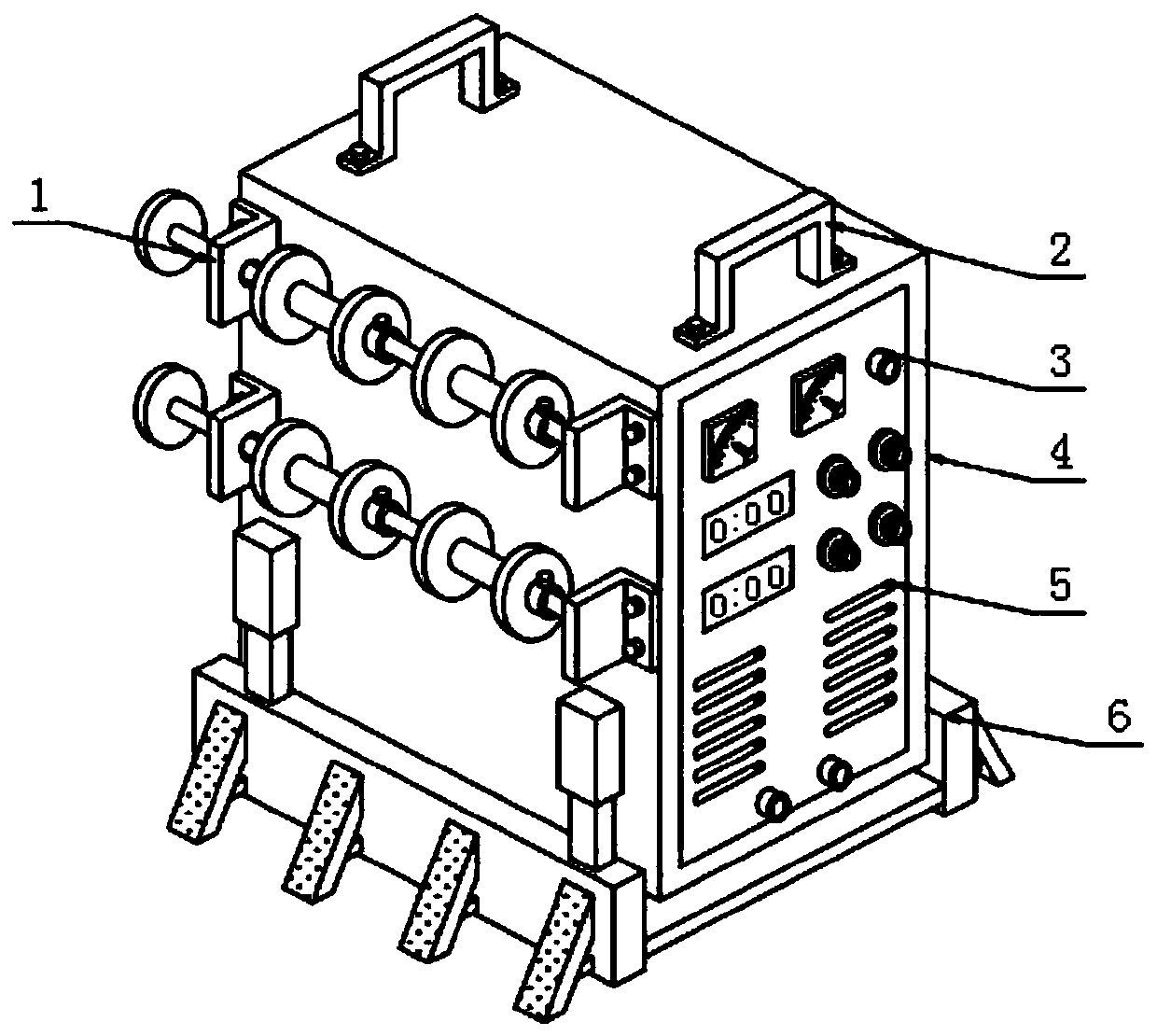

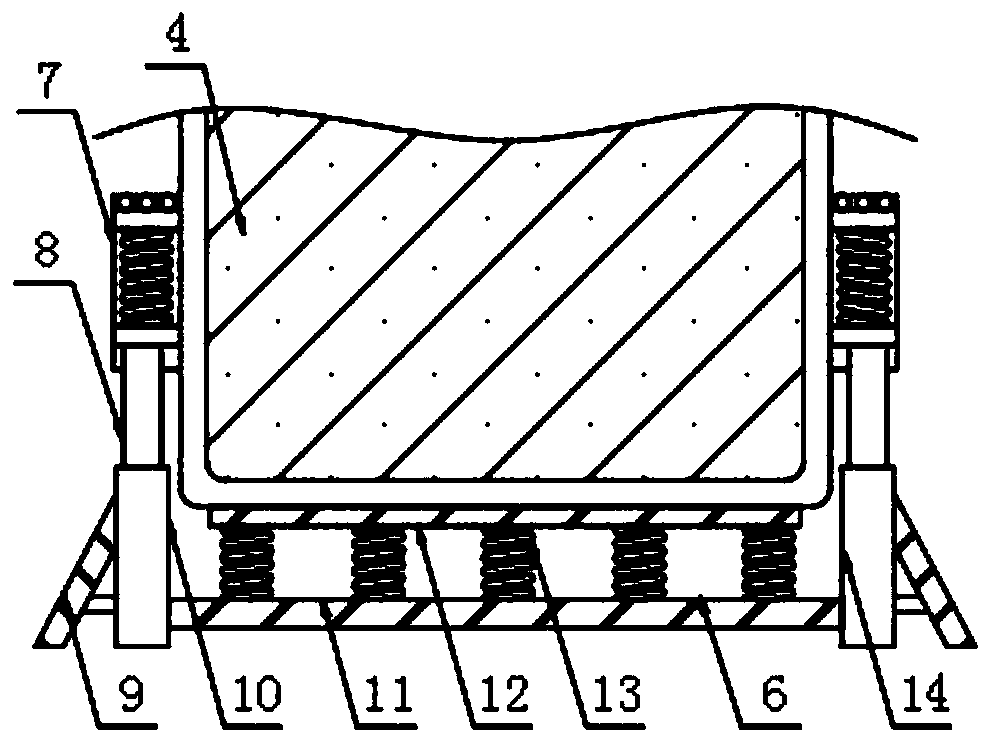

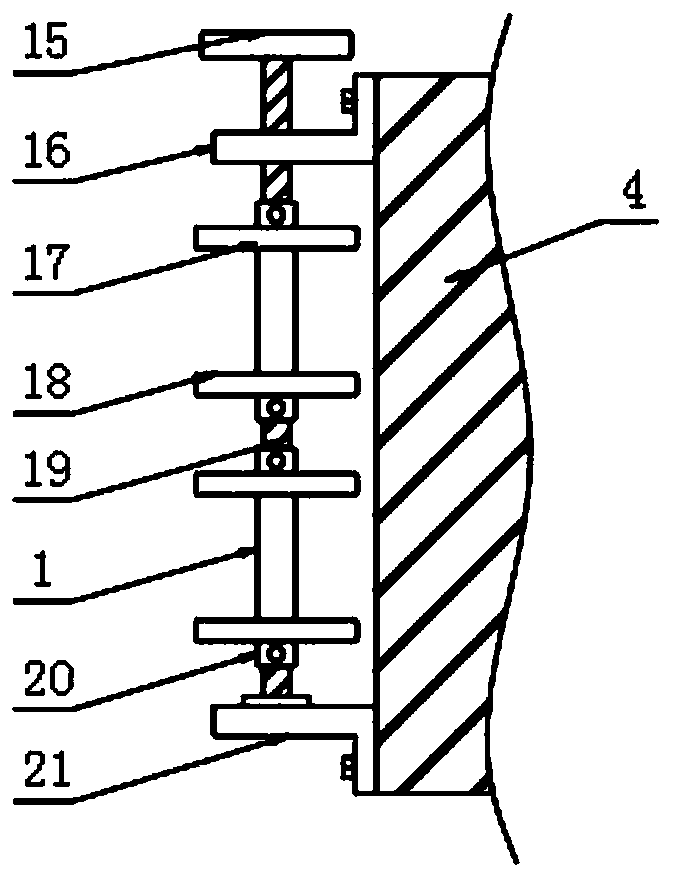

[0022] see Figure 1 to Figure 4 , in an embodiment of the present invention, a multi-electrode gas-shielded arc welding device for refining, comprising an arc welding machine main body 4, two handles 2 are sequentially fixed on the upper surface of the arc welding machine main body 4 from the front to the rear, and The front surface of the arc welding machine main body 4 is sequentially fixed with adjustment buttons 3 and provided with heat dissipation windows 5 from top to bottom, and both sides of the arc welding machine main body 4 are provided with a winding assembly 1, and the winding assembly 1 includes a rotating handle 15 , the first mounting frame 16, the first retaining ring 17, the second retaining ring 18, the rotating rod 19, the sleeve 20 and the second mounting frame 21, and one end of the rotating rod 19 is movably connected with the arc welding machine main body through a bearing. 4, the second mounting frame 21 on both sides, and the other end of the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com