Glass edge polishing control method

一种控制方法、玻璃磨边的技术,应用在适用于磨削工件边缘的机床、磨床、制造工具等方向,能够解决无法进行倒角处理、玻璃碎屑乱飞乱溅、影响打磨质量等问题,达到防止打磨效果不佳的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

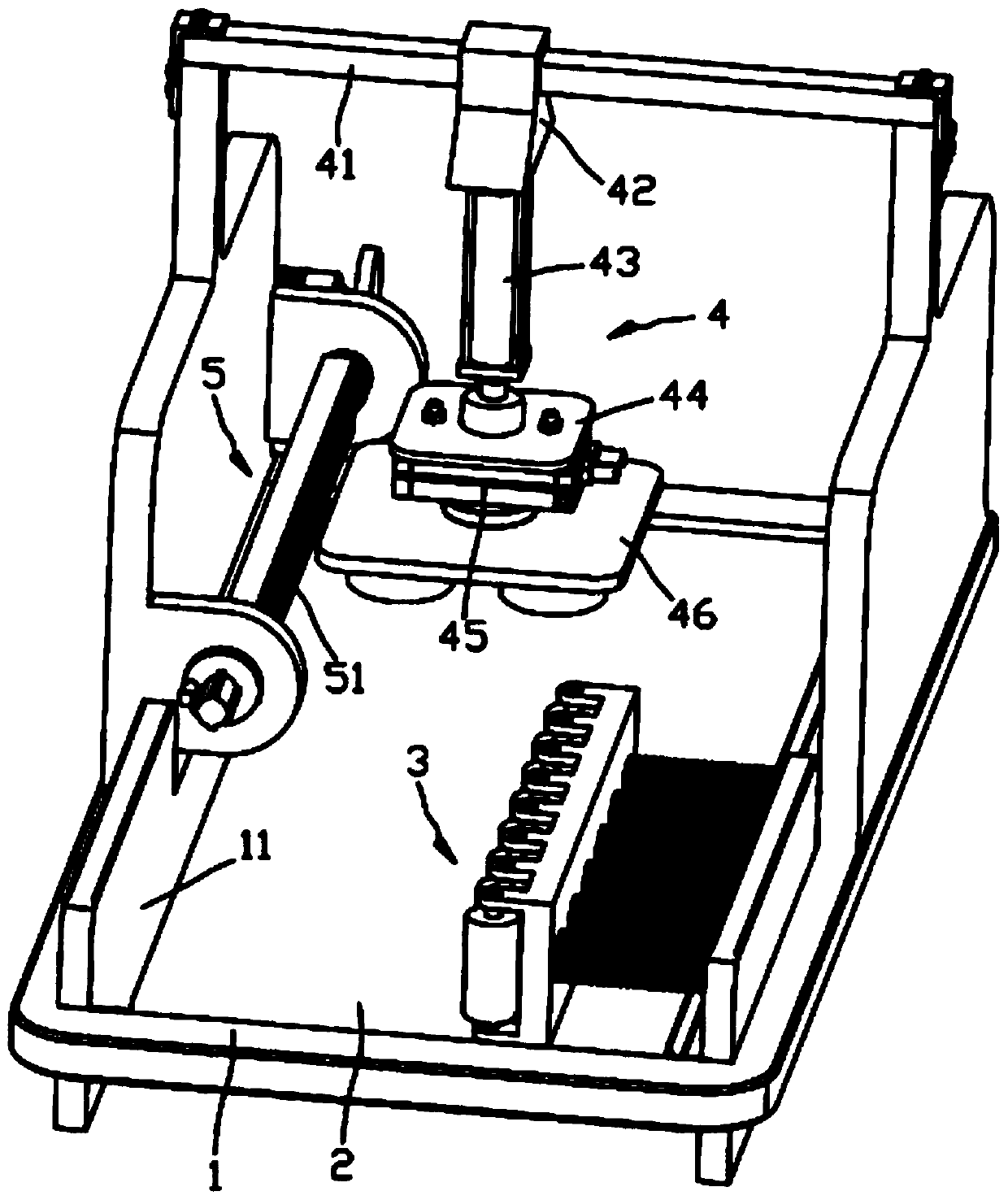

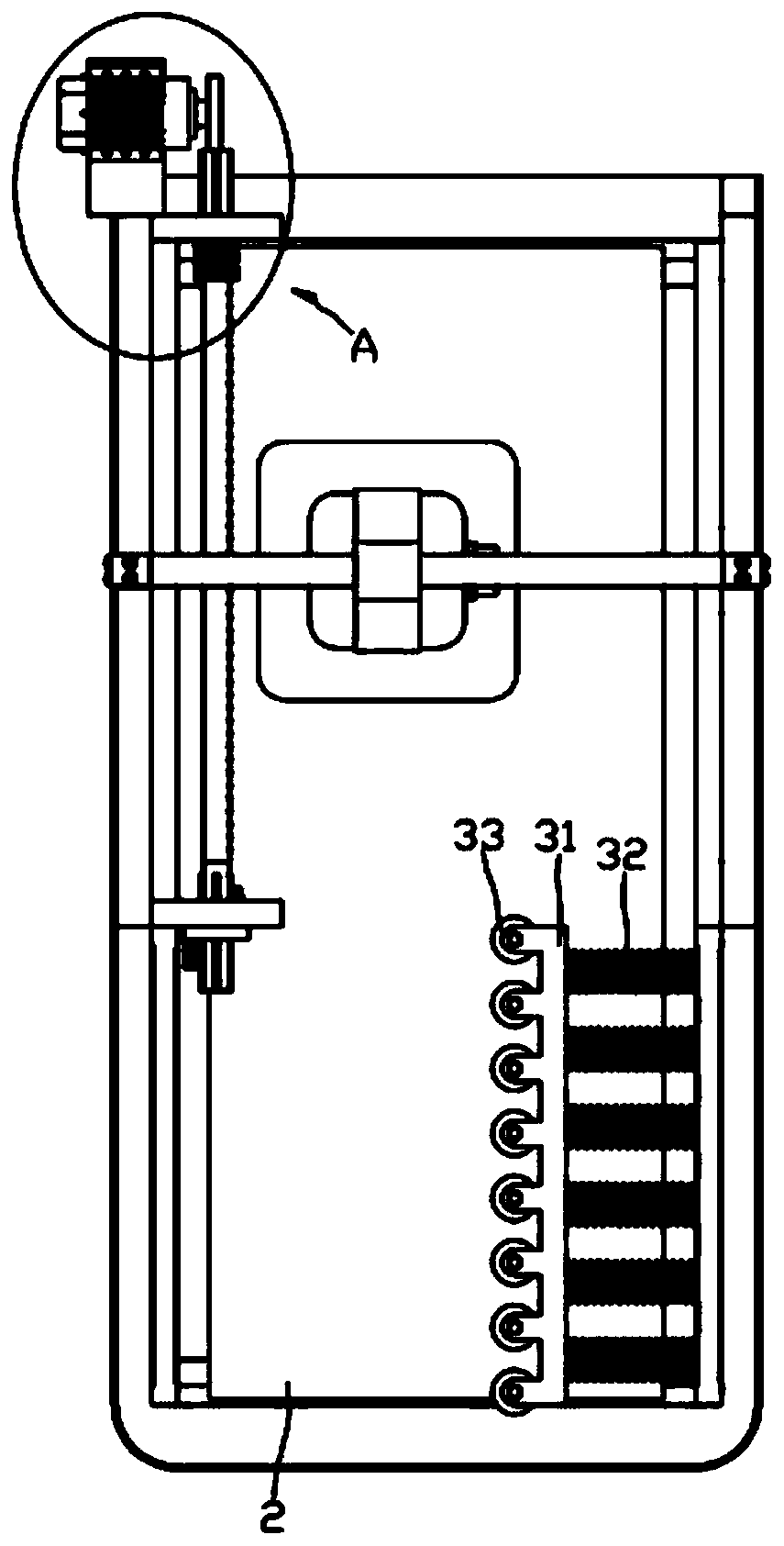

[0024] See Figure 1 to Figure 5 , The present invention provides a technical solution:

[0025] A glass edging device includes a support frame 1, a conveyor belt 2, a limit mechanism 3, a glass fixing mechanism 4, and a polishing mechanism 5, wherein:

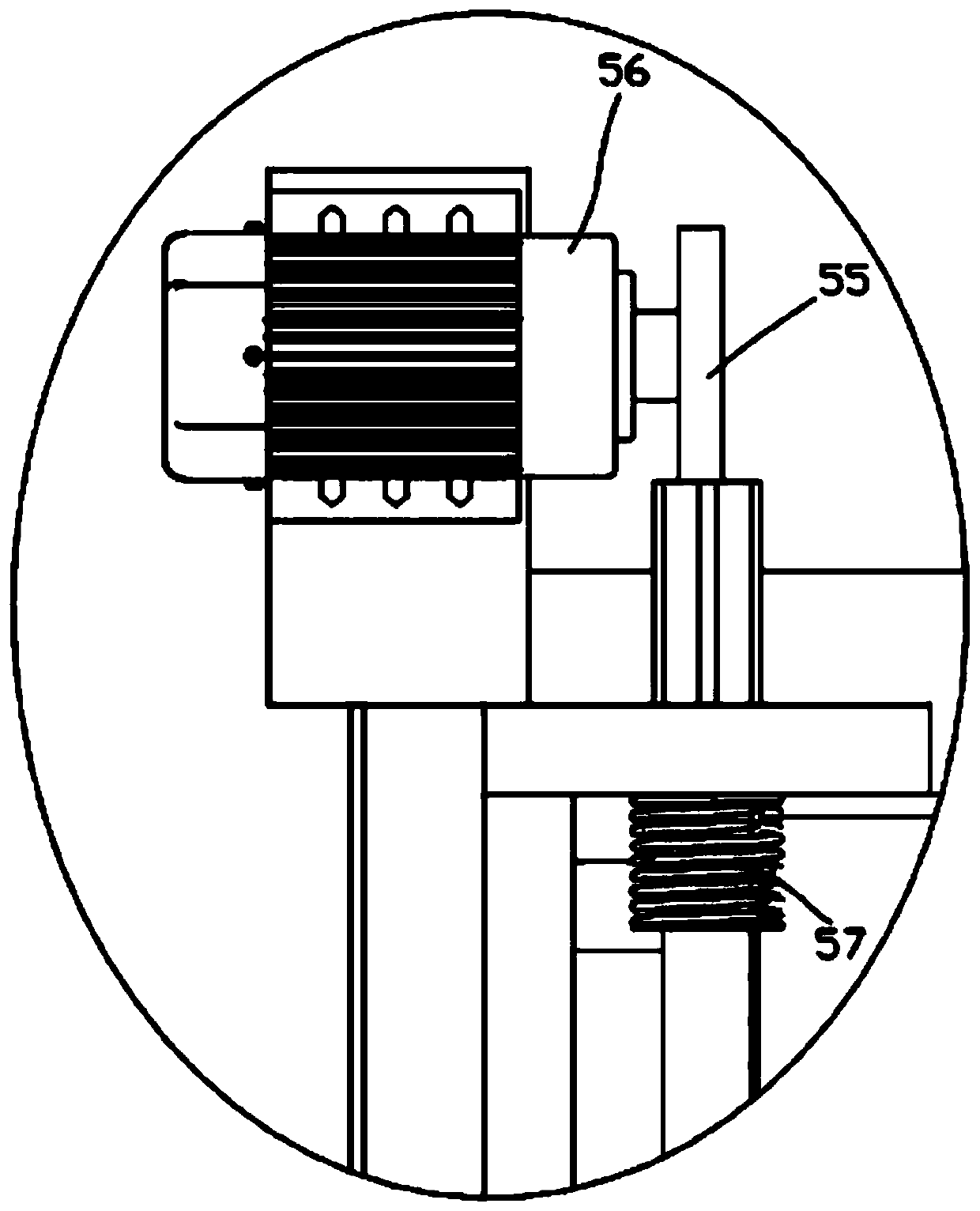

[0026] One end of the support frame 1 is provided with a baffle 11, and the side of the support frame 1 is provided with a semicircular ring 111 and a circular hole 112. Among them, there are three circular holes 112. The angle between the line of the center point and the line of the center point of the circular hole 112 on the upper and lower sides and the center point of the semicircular ring 111 is 45 degrees respectively, and when the ejector rod 53 is fitted in the upper and lower circles In the hole 112, the angle between the file 51 and the glass edge is forty-five degrees, and when the ejector rod 53 fits in the circular hole 112 in the middle position, the file 51 is parallel to the glass edge, and the two sides of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com