A glass edging device

A glass edging and glass technology, which is applied to the grinding drive device, machine tools suitable for grinding workpiece edges, grinding machines, etc. problem, to achieve the effect of preventing poor grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

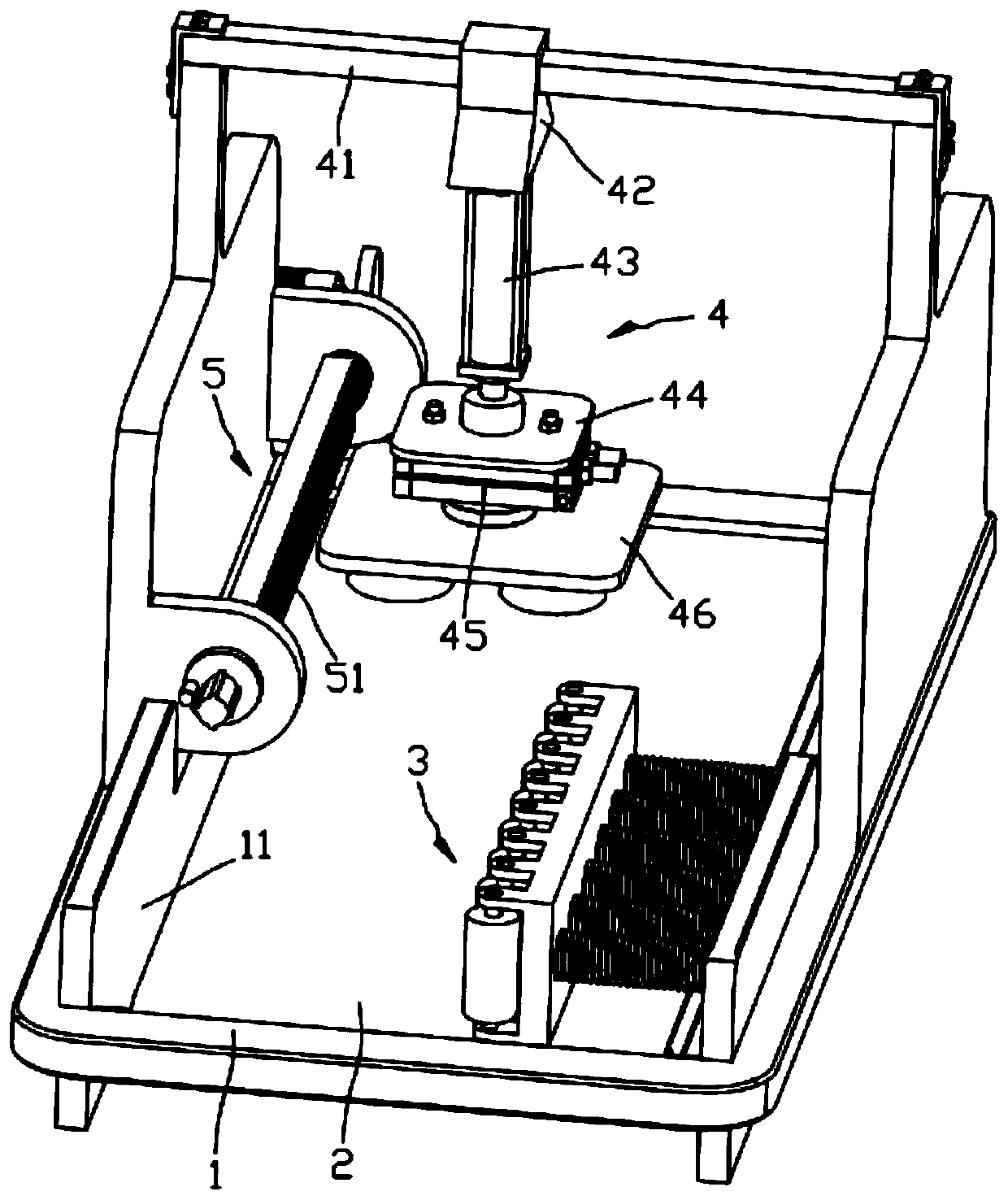

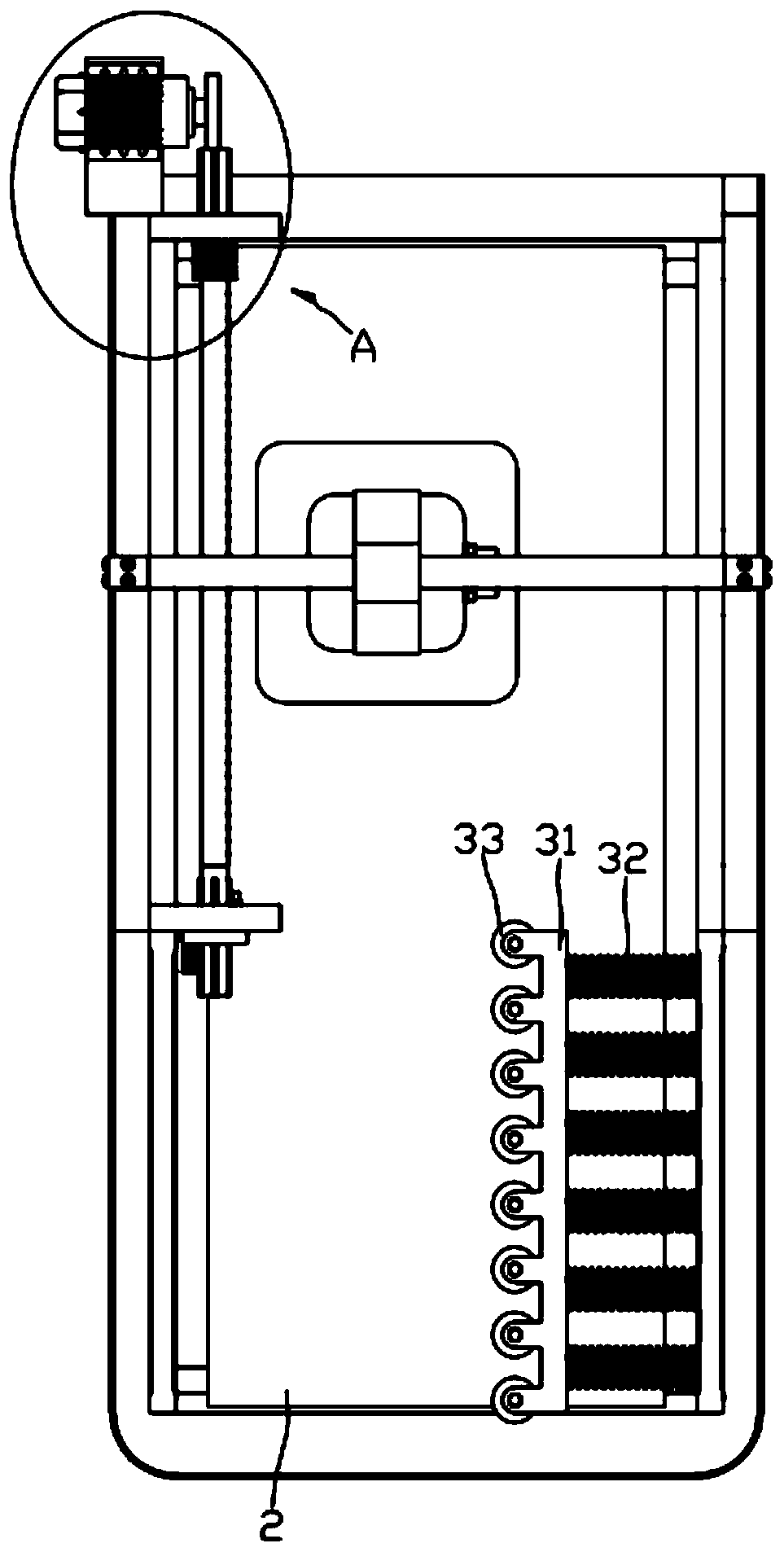

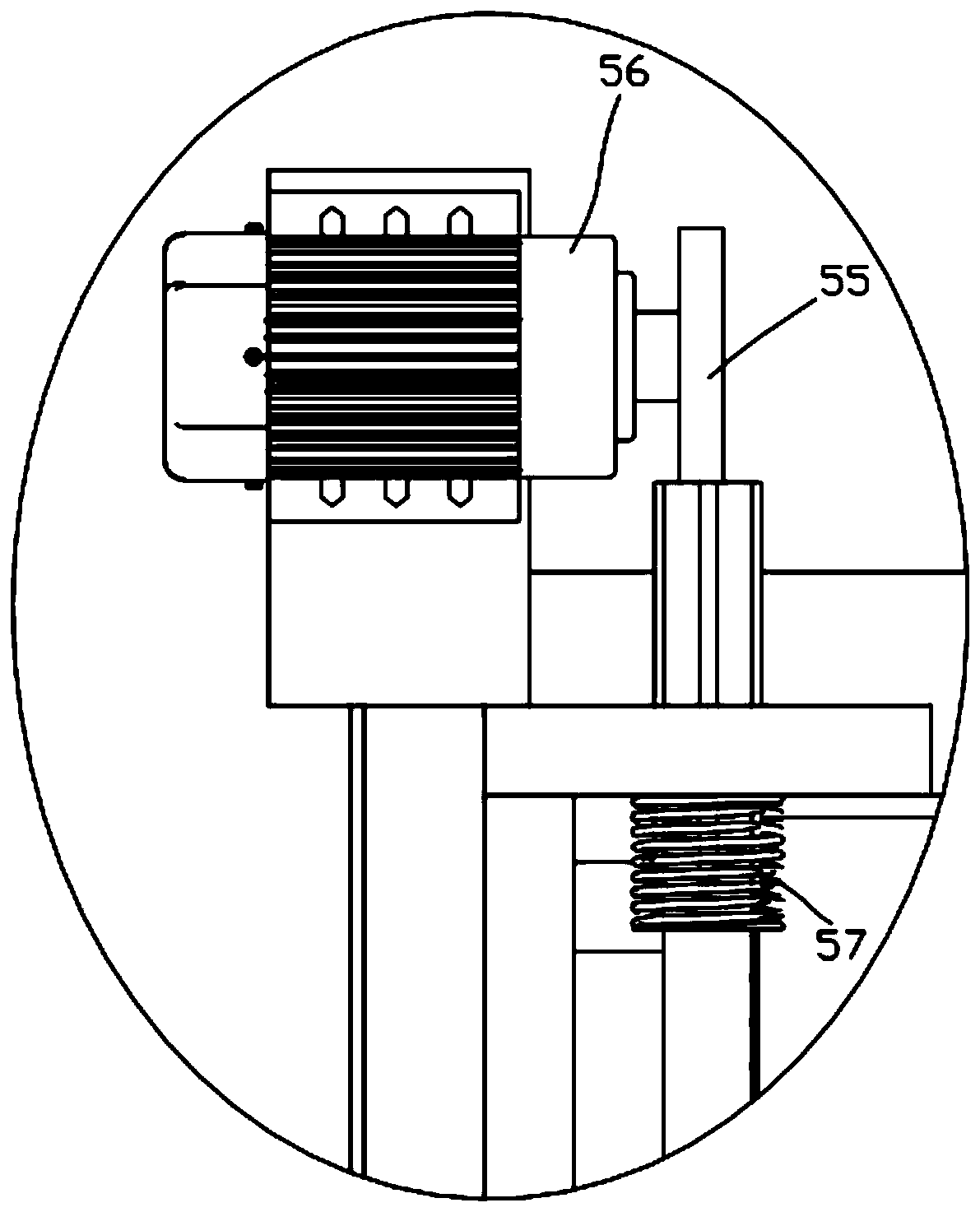

[0024] see Figure 1 to Figure 5 , the present invention provides a technical solution:

[0025] A glass edging device, including a support frame 1, a conveyor belt 2, a limit mechanism 3, a glass fixing mechanism 4 and a grinding mechanism 5, wherein:

[0026] One end of the support frame 1 is provided with a baffle plate 11, and the side of the support frame 1 is provided with a semi-circular ring 111 and a circular hole 112, wherein there are three circular holes 112, and the central point of the circular hole 112 in the middle is connected with the semi-circular ring 111. The included angle between the connection line of the center point and the connection line between the center point of the circular hole 112 and the center point of the semi-circular ring 111 located on the upper and lower sides is respectively 45 degrees. When inside the hole 112, the angle between the file 51 and the glass edge is 45 degrees, and when the push rod 53 fits in the middle hole 112, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com