8-shaped bearing disassembling device and disassembling method

A bearing dismounting device and figure-8 technology, which is applied to hand-held tools, manufacturing tools, etc., achieves the effects of high reliability, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

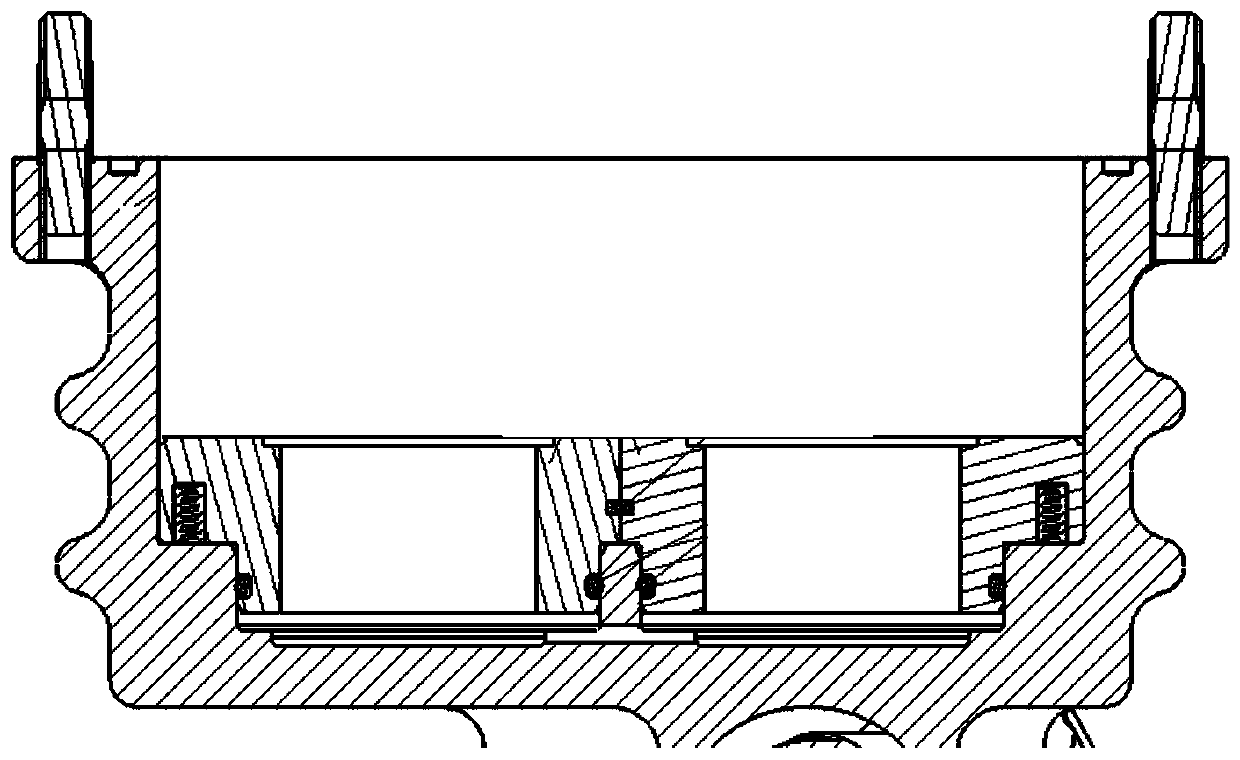

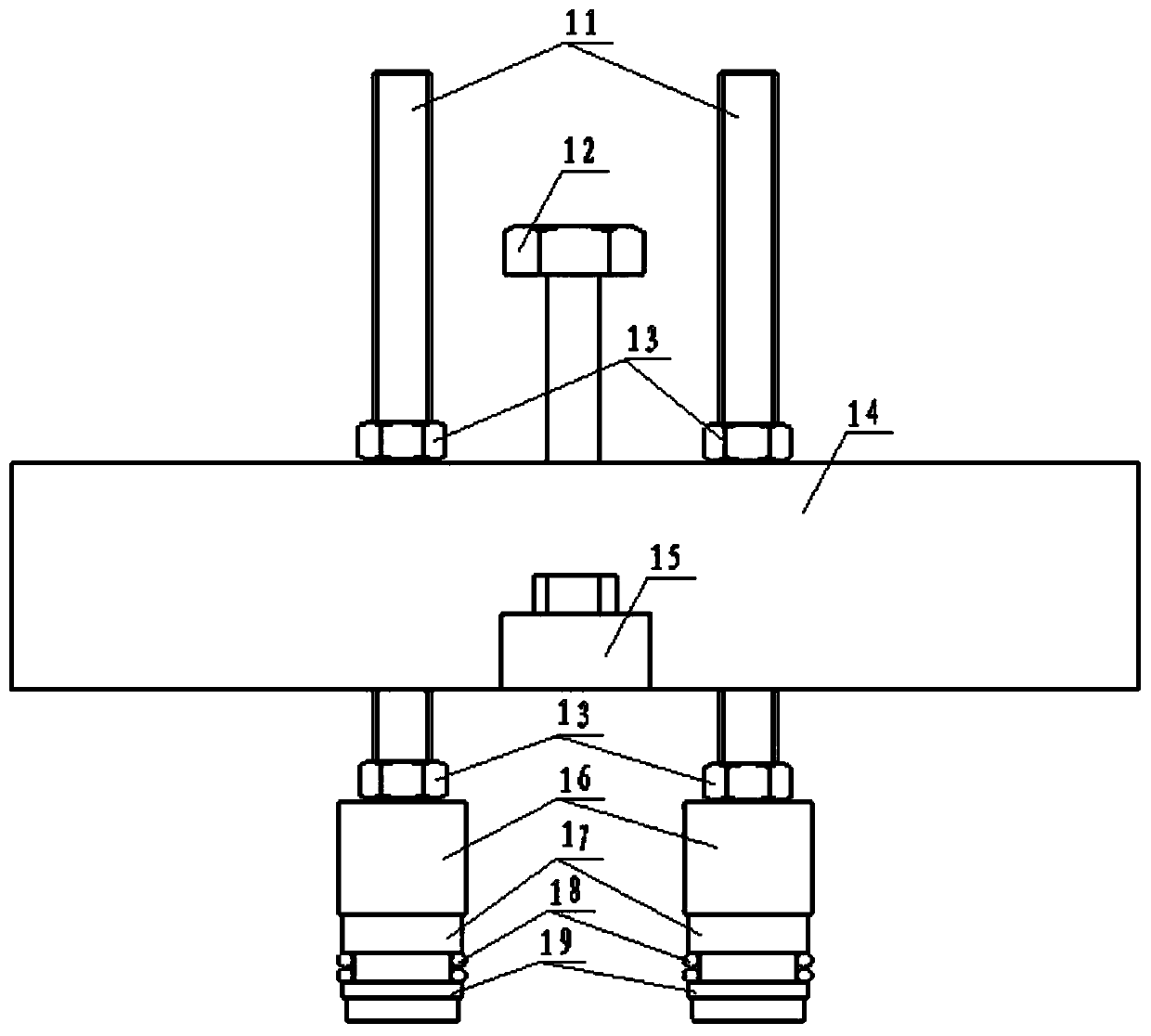

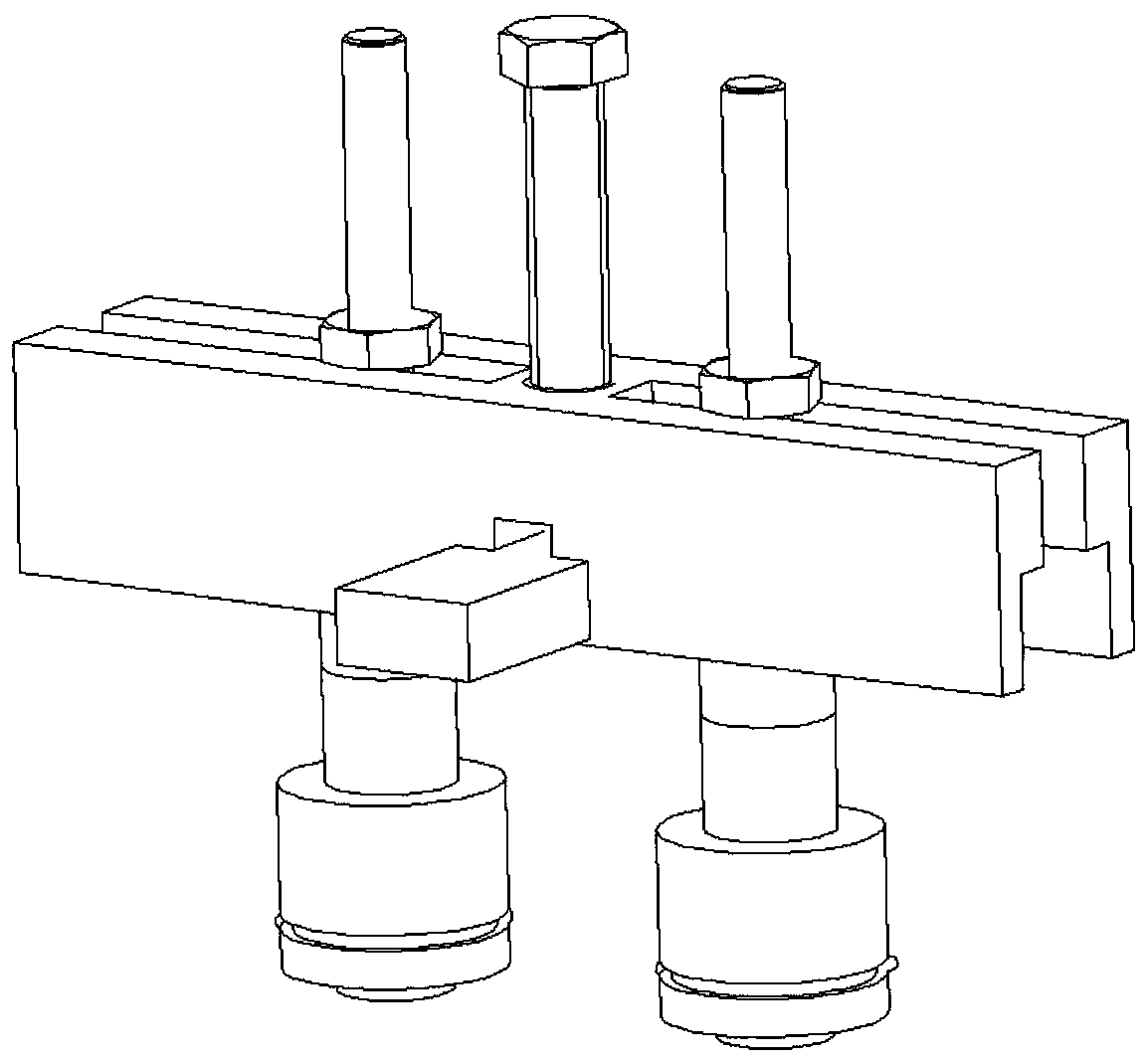

[0027] Such as figure 2 as well as image 3 , the present invention provides an 8-shaped bearing removal device, which includes two sets of threaded rod assemblies, an operating handle 12, a support frame 14 and a support base 15; each set of threaded rod assemblies includes a threaded rod 11, a force transmission nut, a compression Nut, guide sleeve 16, pressing plate 17, expansion ring 18 and briquetting block 19; There is a through groove on the support frame 14, and the support seat 15 runs through the through groove, so that the support frame 14 and the support seat 15 form the cross-overlapping of the upper and lower positions; There is a threaded through hole on the support frame 14, and the front part of the operating handle 12 is an externally threaded rod. The frame 14 and the support seat 15 move oppositely or backward in the axial direction; each threaded rod is sequentially equipped with a force transmission nut, a compression nut, a guide sleeve 16, a pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com