External tapping equipment for annular part of wooden furniture

A wooden furniture and circular technology, which is applied in wood processing equipment, manufacturing tools, forming/shaping machines, etc., can solve the problems of inconvenient control and fixation, time-consuming and laborious, difficult to control chiseled radian, etc., to achieve perfect manufacturability and work efficiency Improve and solve the effect of fixed problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of external tapping equipment for ring-shaped parts of wooden furniture, such as figure 1 As shown, it includes a support frame 1, a first connecting frame 2, a power unit 3, a reduction motor 4, a first pulley 5, a flat belt 6, a cutting device 7, a base 8, a first guide rail 9, a first guide sleeve 10, The second connecting frame 11, the rotating device 12, the fixed plate 13, the gear plate 14 and the fixing device 15, the first connecting frame 2 is provided on the right side of the left arm of the support frame 1 top, and the power unit is arranged between the first connecting frame 2 two arms 3. A reduction motor 4 is provided on the left side of the upper part of the support frame 1. The reduction motor 4 is located on the right side of the left arm of the support frame 1. The reduction motor 4 is provided with a first pulley 5, and a Flat belt 6, a cutting device 7 is provided in the middle of the first connecting frame 2, and the cutting device 7 is in c...

Embodiment 2

[0032] A kind of external tapping equipment for ring-shaped parts of wooden furniture, such as Figure 2-7 as shown,

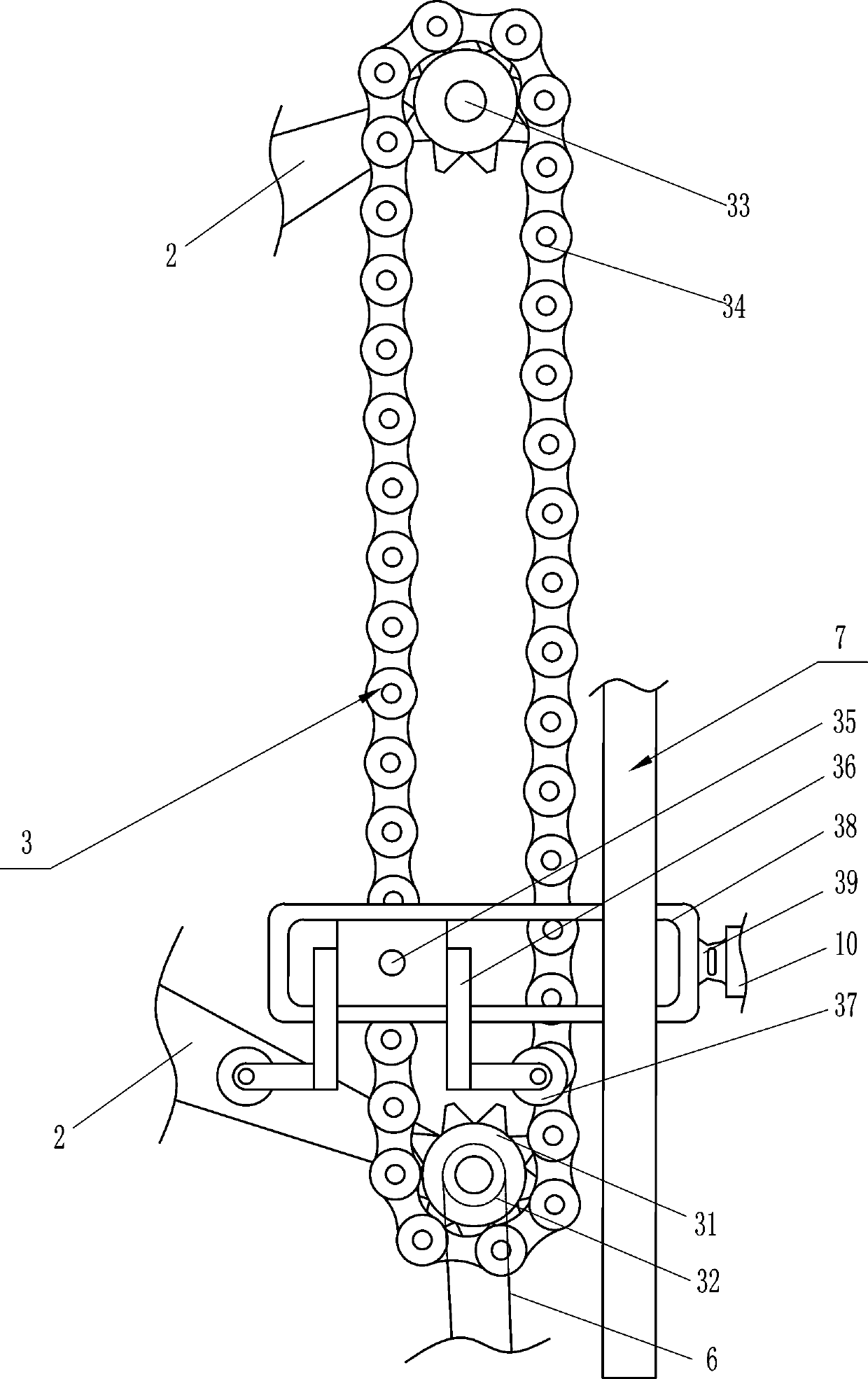

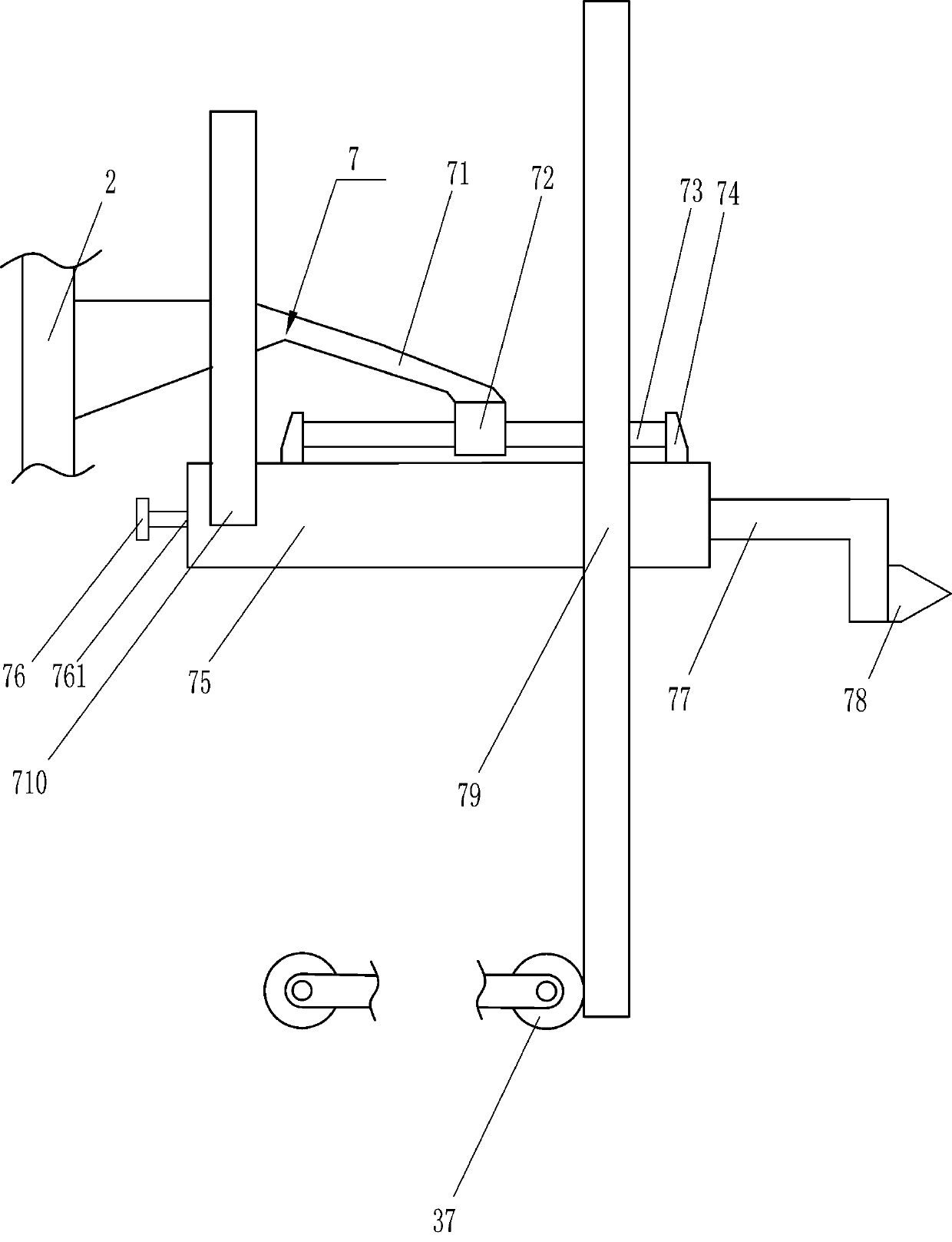

[0033] By the power unit 3 described in embodiment 1, such as figure 2 As shown, the power unit 3 includes a first gear 31, a second pulley 32, a second gear 33, a chain 34, an insert 35, a third connecting frame 36, a roller 37, an annular frame 38 and a first connecting plate 39, specifically for:

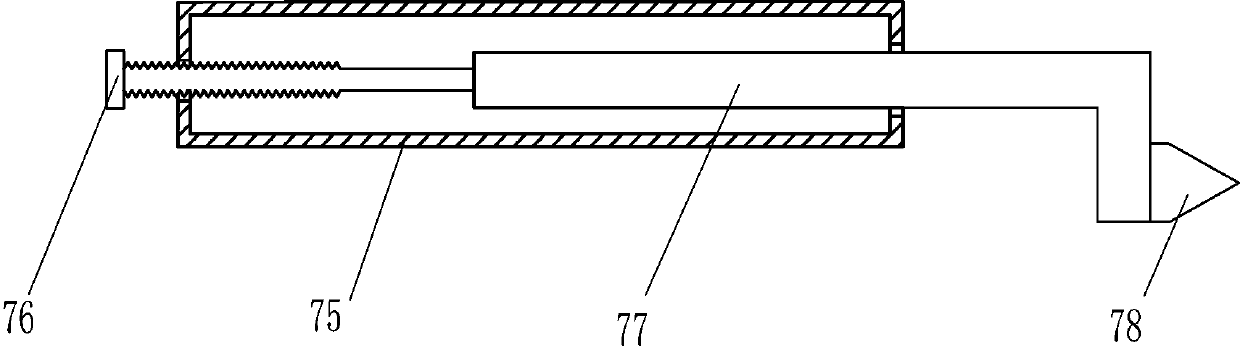

[0034] The lower side of the first connecting frame 2 is rotatably provided with a first gear 31, the first gear 31 is provided with a second pulley 32, the second pulley 32 cooperates with the flat belt 6, and the upper side of the first connecting frame 2 is provided with a second gear 33. A chain 34 is wound between the second gear 33 and the first gear 31. The chain 34 meshes with the first gear 31 and the second gear 33. The chain 34 is rotatably provided with an insert 35, and the insert 35 is symmetrically arranged on both sides. There is a third conne...

Embodiment 3

[0046] A kind of external tapping equipment for ring-shaped parts of wooden furniture, such as Figure 8 As shown, a debris collection box 16 is also included, and the debris collection box 16 is placed at the upper middle groove of the support frame 1 .

[0047] When the ring block is processed, the cutting knife 78 contacts the ring block and begins to generate chips, which fall into the chip collection box 16 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com