Hot air welding machine and working method and using method thereof

A hot-air welding and hot-melting technology, applied in the field of plastic lamination and hot-melting, can solve the problems of easy generation of bright edges around welding and easy diffusion of welding heat. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

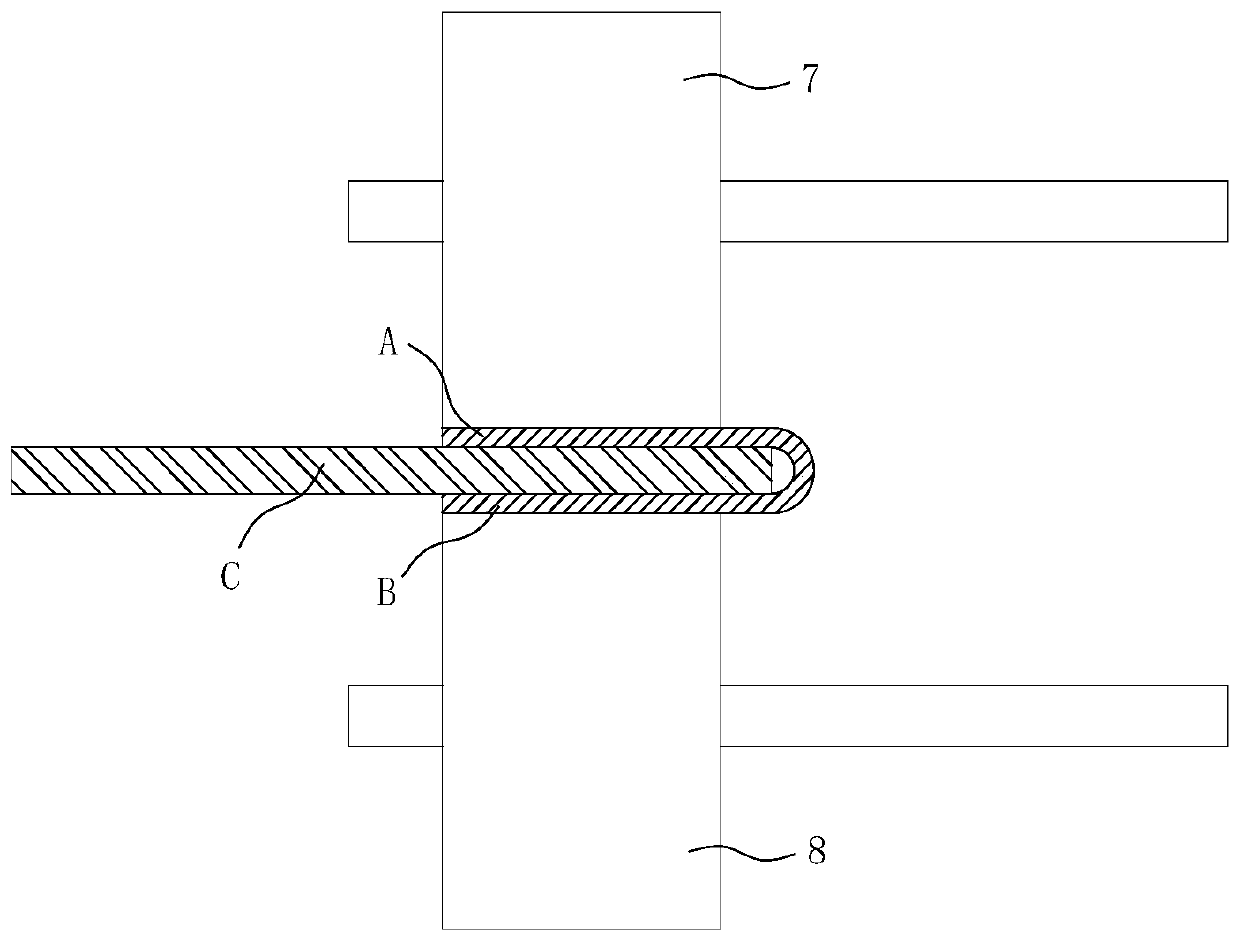

[0087] like figure 2 and Figure 14 As shown, the hot air welding machine of this embodiment includes a frame on which a pressurizing mechanism and a metal conduction hot-melting mechanism are arranged. The metal conductive hot-melt mechanism is suitable for hot-melting the laminated brushed cloth C and the upper and lower edge bands at the entrance of the pressurizing mechanism. The pressurizing mechanism is suitable for pressurizing, welding and transporting the hot-melted drawing cloth C and the upper and lower edging belts. The internal heat is conducted through the metal conduction hot-melt mechanism, and the hot-melt brushed cloth C and the upper and lower edge bands are then pressurized and welded by the pressurizing mechanism. Avoid hot air heat diffusion, not easy to cause material wrinkle deformation, no bright edges around welding, improve welding quality.

[0088] Specifically, such as Figure 4 As shown, the metal conduction hot-melt mechanism includes two bl...

Embodiment 2

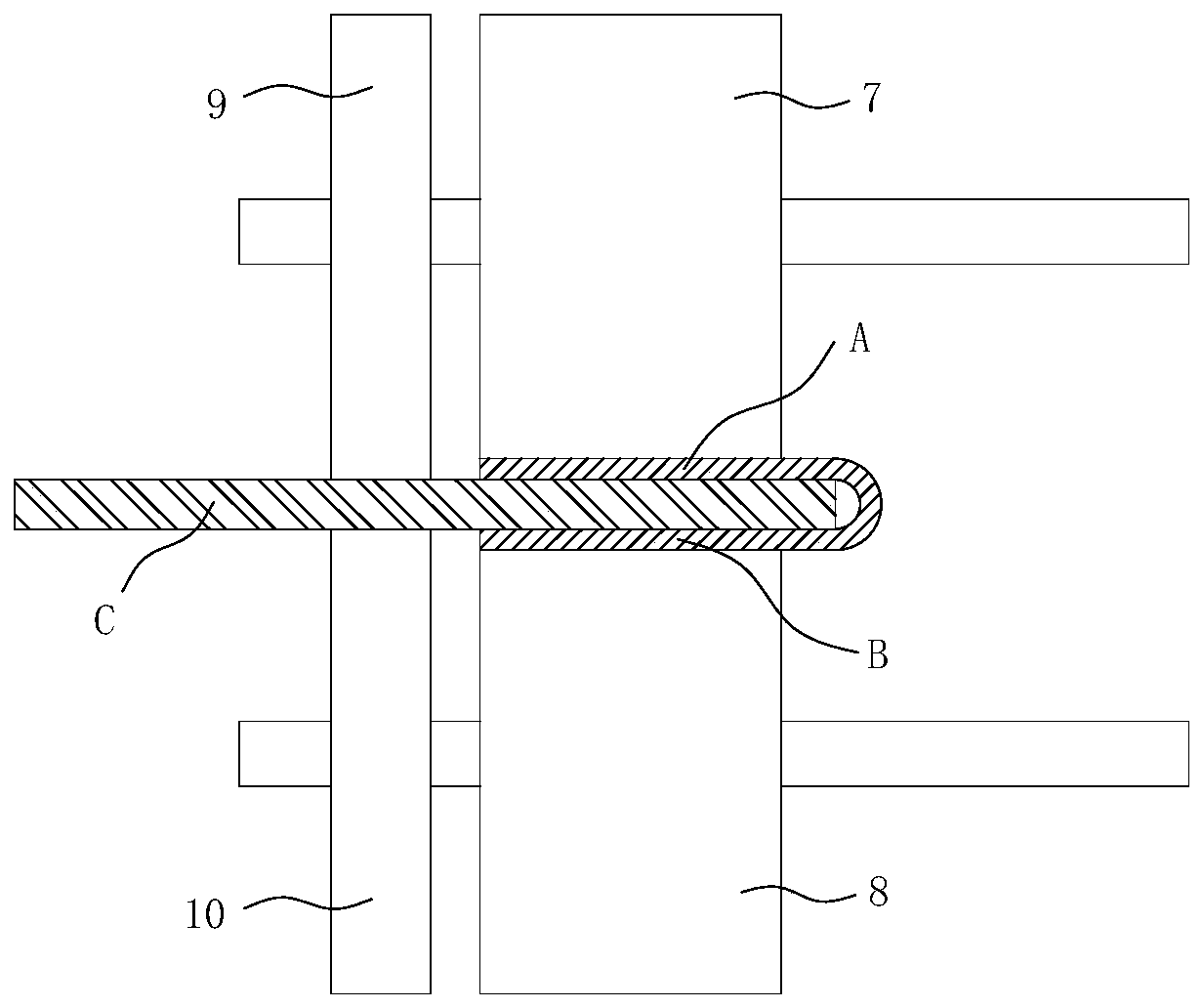

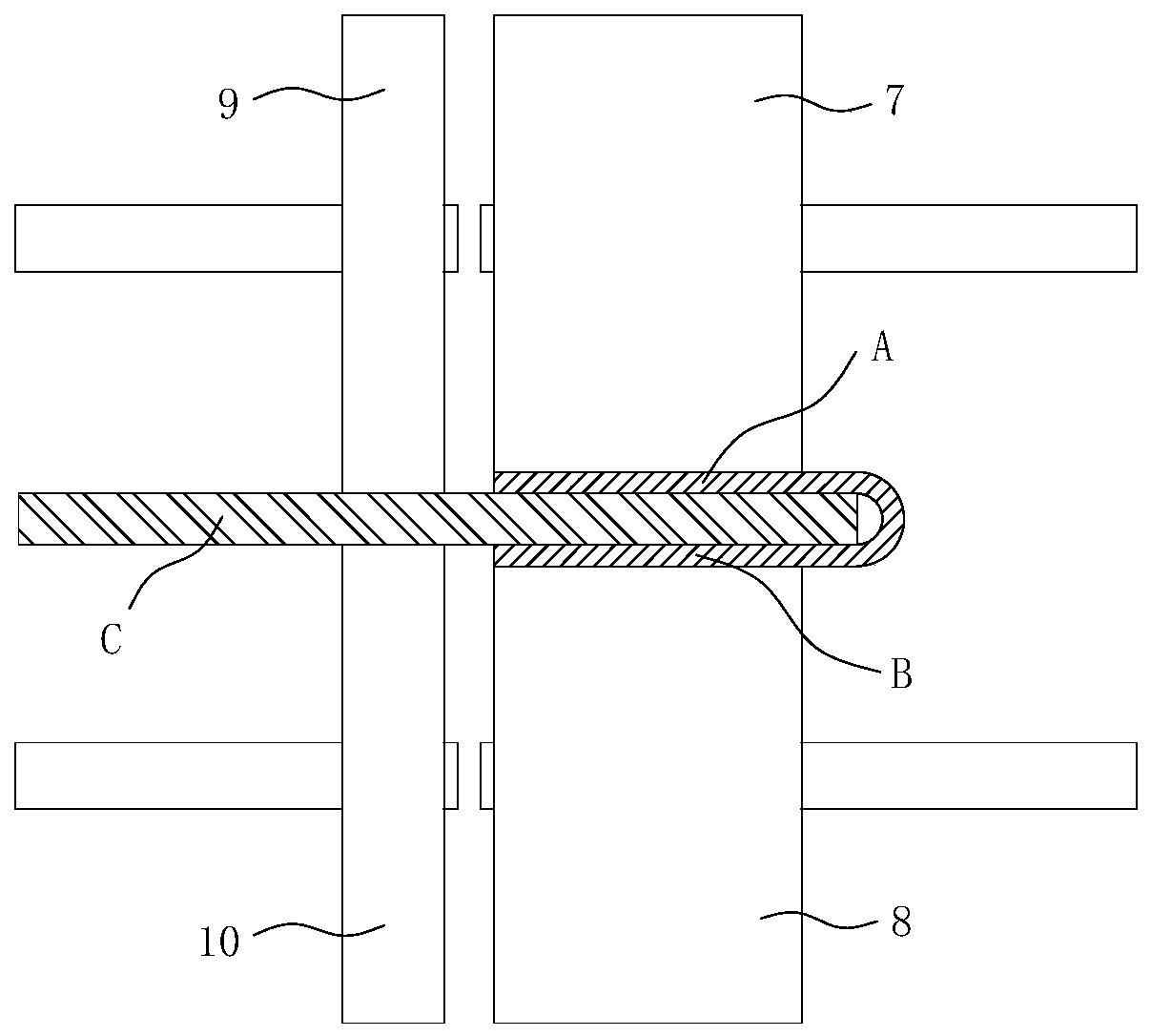

[0105] like image 3 , Figure 8 and Figure 15 As shown, the present invention provides another alternative embodiment of the press mechanism.

[0106] The difference from Example 1 is:

[0107] The pressurizing mechanism is a two-wheel set different-axis pressurization mechanism, and the double-wheel set different-axis pressurization mechanism includes upper and lower belt pulleys which are set to rotate synchronously. The outer section of the brushed cloth and the lower edge belt C are pressure welded and conveyed. The double-wheel group cross-axis pressurizing mechanism also includes upper and lower material wheels which are set to rotate synchronously, and the upper and lower material wheels are suitable for pressurizing, welding and transporting the inner section of the brushed cloth passing through. The lower pulley 8 and the upper pulley 7 have a synchronous rotation speed V1, and the lower material wheel 10 and the upper material wheel 9 have a synchronous rotation ...

Embodiment 3

[0114] like Figures 2 to 15 As shown, on the basis of the first or second embodiment, the third embodiment provides a working method of the hot air welding machine, which is implemented by using the hot air welding machine of the first or second embodiment.

[0115] The rolled edging tape is unwound through the tape unwinding reel 25, and then guided and drawn by the guide column 28. The edging tape passes through the auxiliary guide block 23 and is guided into a V shape, and the V-shaped edging tape passes through the guide block 22 and is guided into a V shape. After the U shape, it is laminated with brushed cloth.

[0116] The air heated by the outside penetrates into the hot air cavity 3 from the air inlet end 4 of the blower heat wedge, and is discharged through the air outlet end 5, forming a thermal cycle. During the circulating operation of the hot air, the heat of the hot air is conducted to the welding part 1 of the blowing hot wedge, so that the welding part 1 hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com