A waste can collection device used in the production of pop cans

A collection device and pop can technology, applied in the manufacture of tools, presses, etc., can solve the problems of wasting manpower and electricity, and achieve the effects of saving materials, reducing power consumption, and expanding the scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

[0035] In the prior art, due to the limitation of the height of the load-bearing system and the briquetting system, the distance between the main pipe and the ground is very large, so the fan on the main pipe must use a powerful fan to suck the waste cans and aluminum through the suction pipe. In the main pipeline, a lot of electricity is wasted; in the prior art, the waste cans and aluminum scrap are usually pushed to the feed inlet manually to suck the waste cans and scrap aluminum into the main pipeline, which wastes manual operation costs.

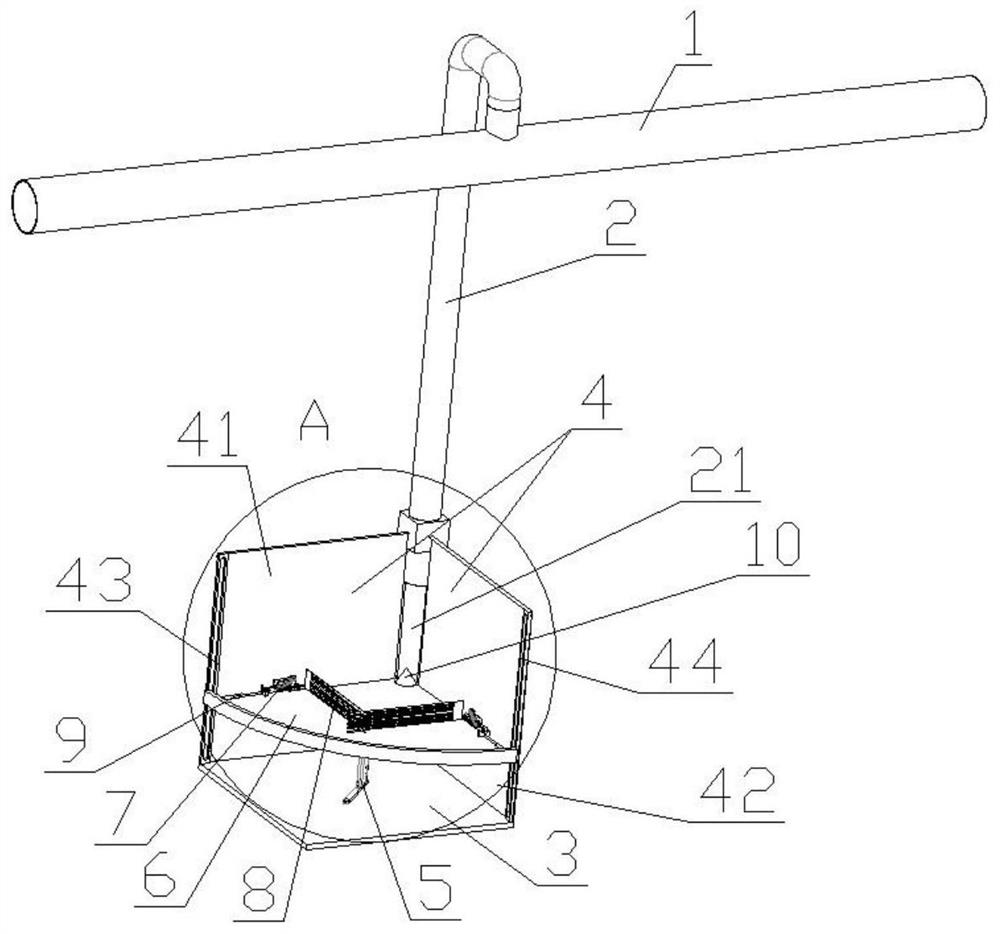

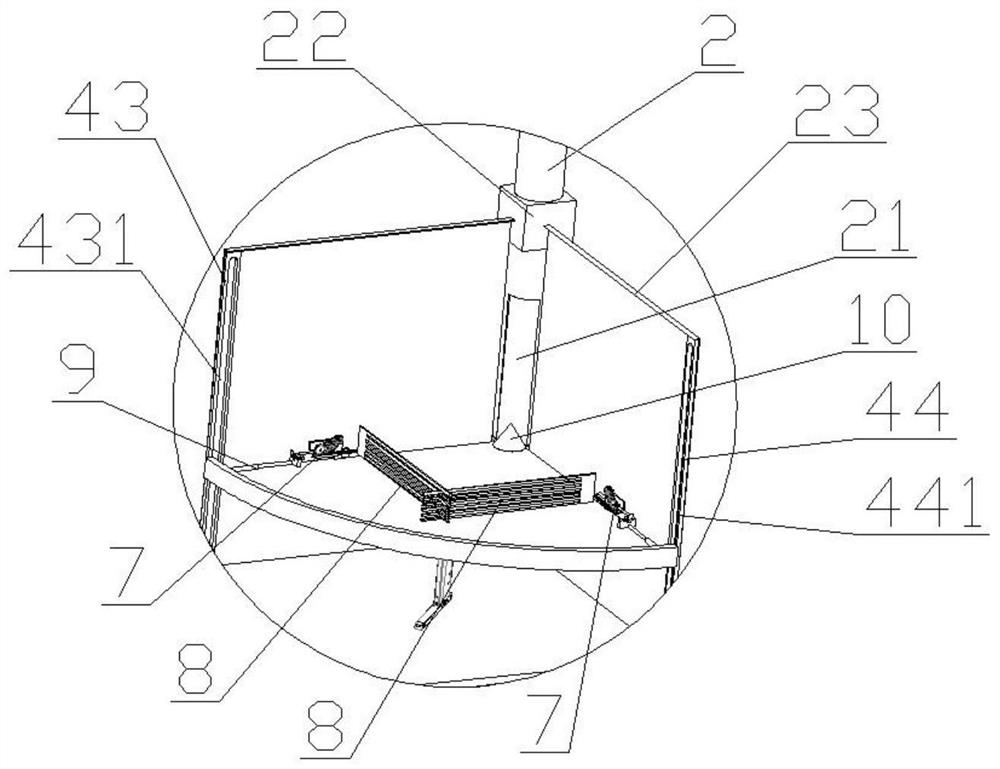

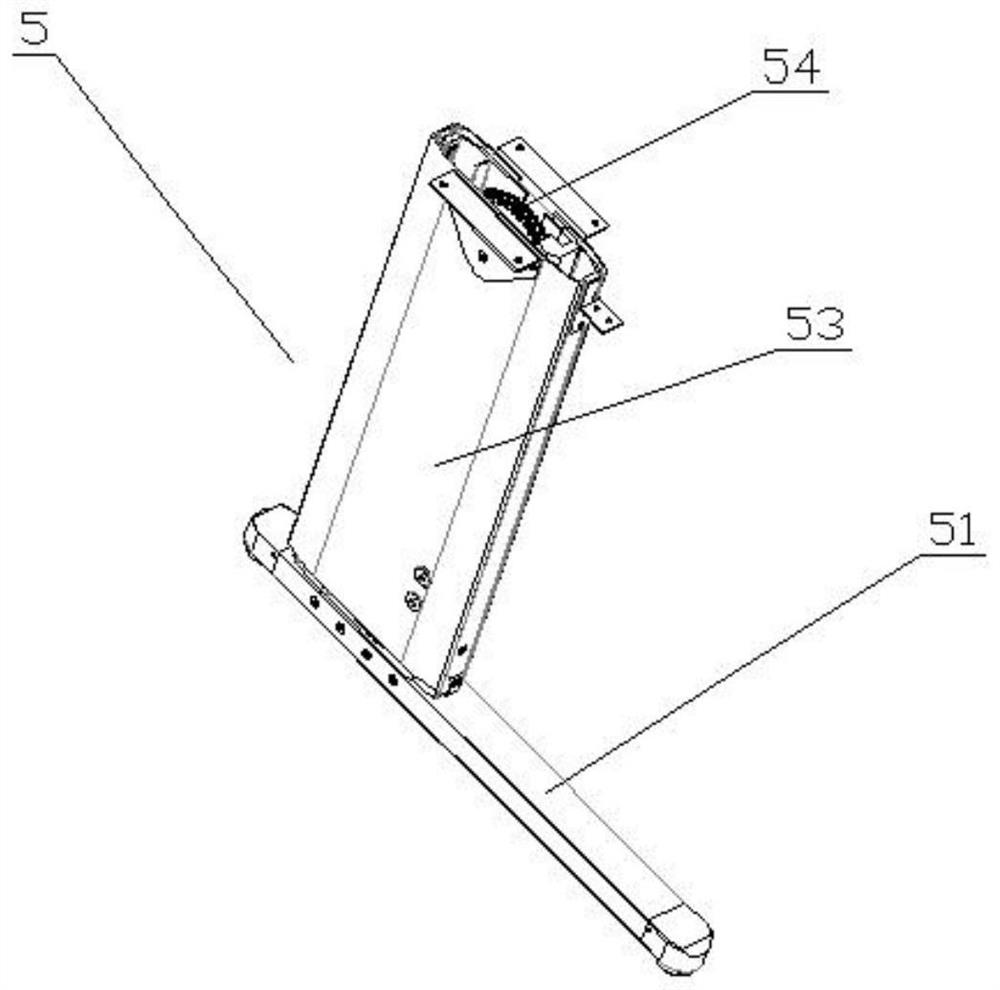

[0036] Based on solving the above two problems, the technical solution of the present invention has been adopted, see figure 1 Summary of the invention: the present invention is a kind of waste can collection device used in the production of pop cans, comprising a main pipe 1 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com