Motor control system and control method thereof

A motor control and motor drive technology, applied in control systems, DC motor speed/torque control, excitation or armature current control, etc., and can solve problems such as difficulty in sampling back EMF

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

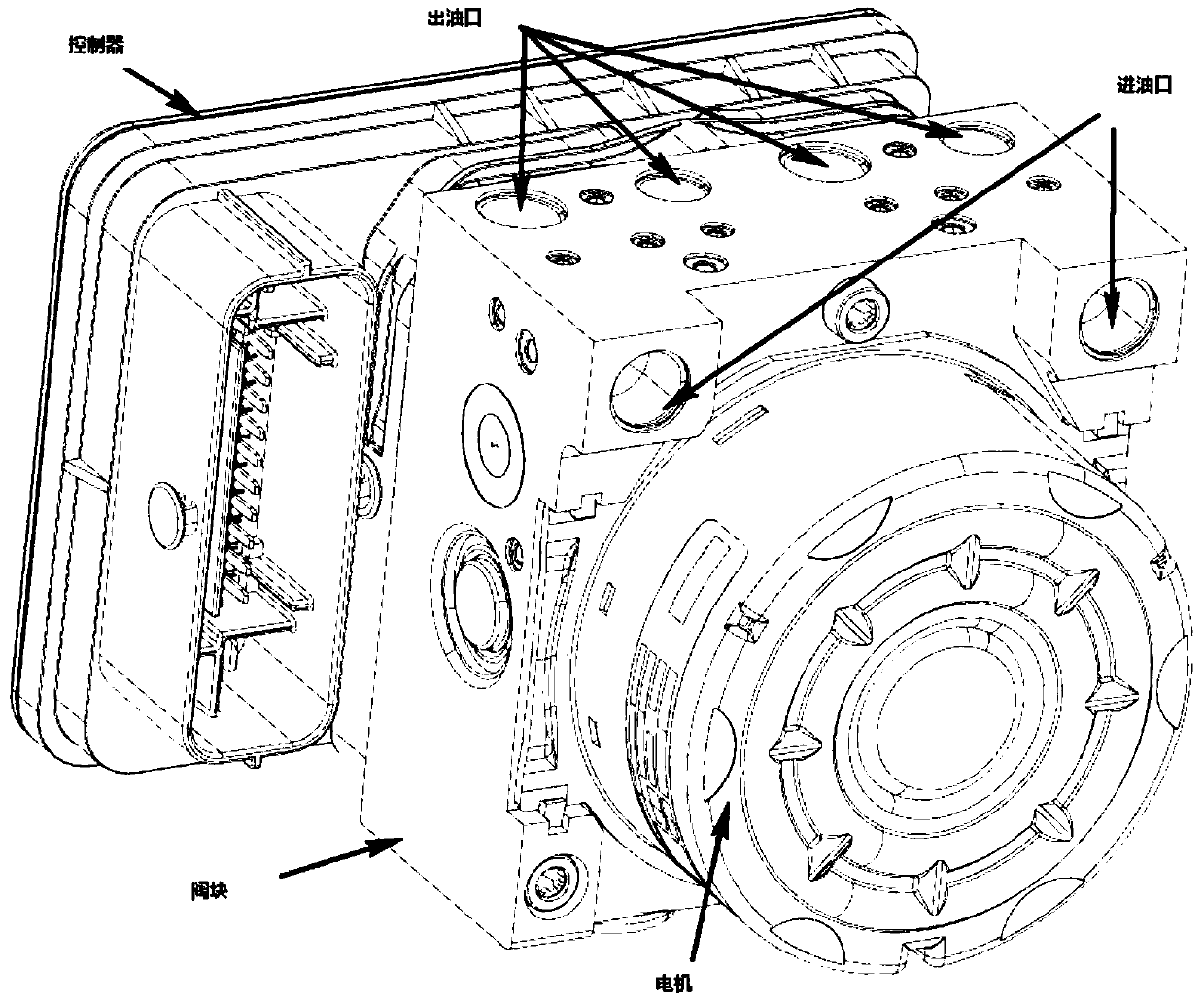

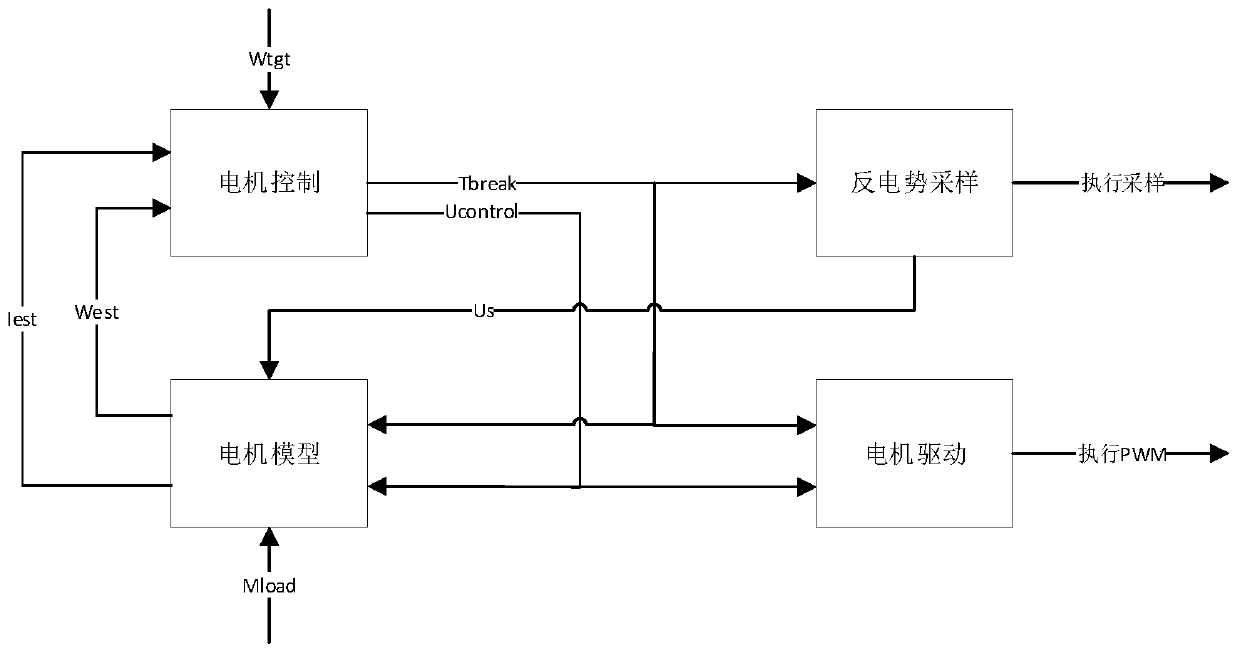

[0074] refer to image 3 As shown, the first embodiment of the motor control system provided by the present invention includes:

[0075] A motor drive module, which is adapted to output the motor drive voltage according to the motor control voltage output by the motor model module and the sampling time;

[0076] A motor model module, which is suitable for calculating the required motor control voltage and sampling interruption time according to the actual speed of the motor and the actual current of the motor;

[0077] And, it is suitable for calculating and obtaining the actual motor speed and motor actual current according to the motor control voltage, load torque and motor sampling back EMF;

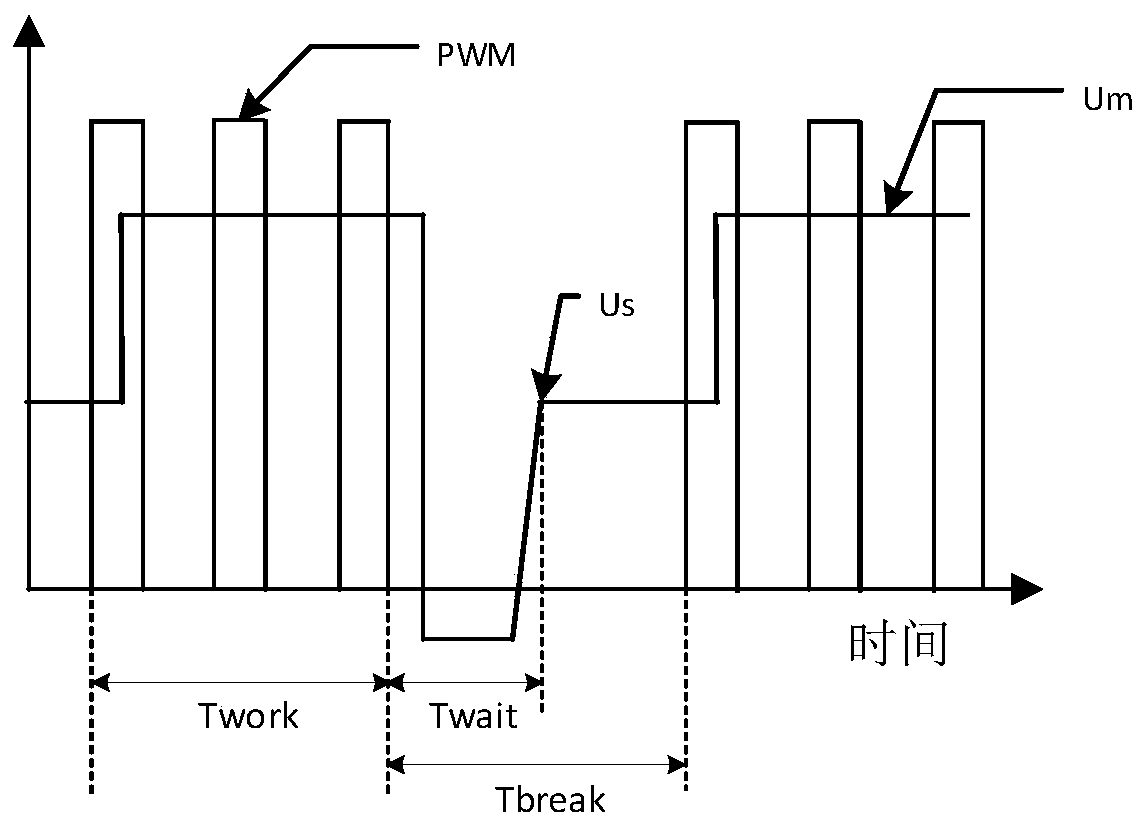

[0078] The motor control module is suitable for outputting a back EMF sampling interrupt signal to the motor drive module and the back EMF sampling module every Twork+Tbreak time. When receiving the back EMF sampling interrupt signal, the motor drive module stops outputting the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com