Jet engine

A jet engine and air technology, applied in machine/engine, jet propulsion device, gas turbine device, etc., can solve the problem of jet engine weight, achieve the effect of good mixing and shorten the structure space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

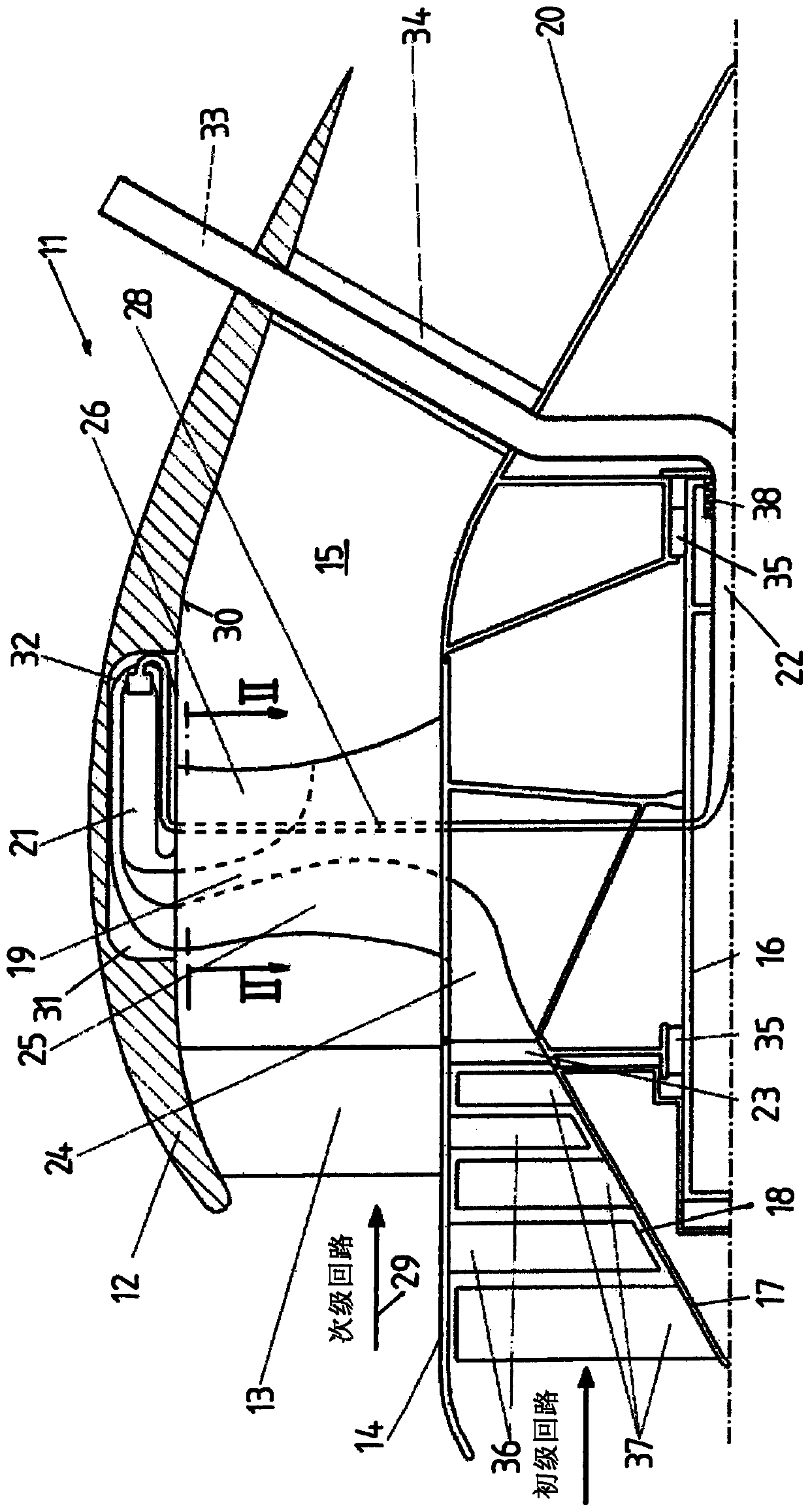

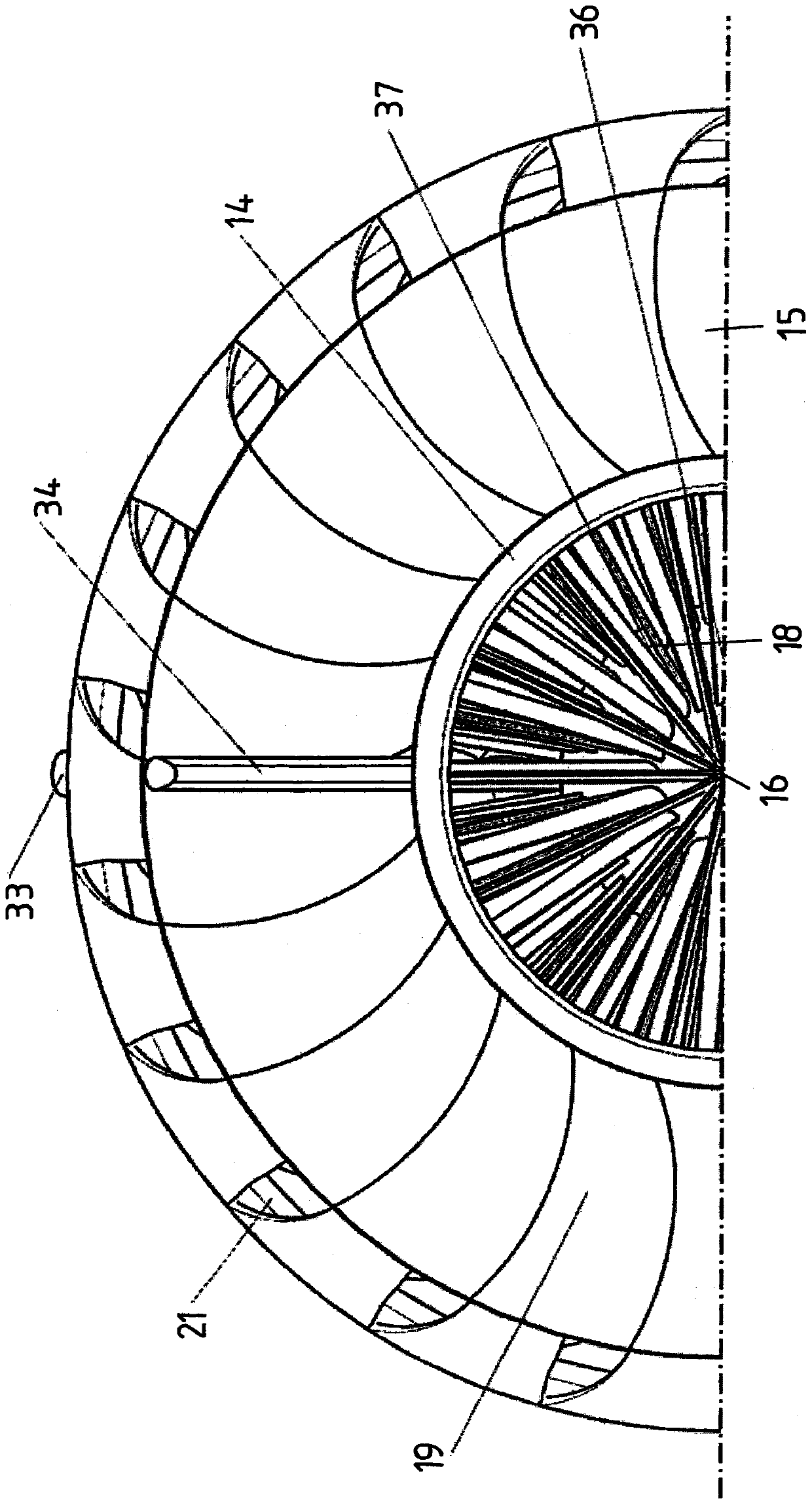

[0028] exist Figures 1 to 3 The jet engine shown exemplarily in has a stationary housing 11 comprising an outer housing wall 12 which is connected to an inner housing section 14 via radial supports 13 connect. Between the inner housing section 14 and the outer housing wall 12 there is an annular channel 15 in which the secondary flow is formed.

[0029] A spindle 16 is rotatably mounted in the inner housing section 14 . This main shaft 16 carries at its front end 17 an axial compressor 18 having a plurality of stages with stationary guide vanes 36 and blades 37 rotating with the main shaft.

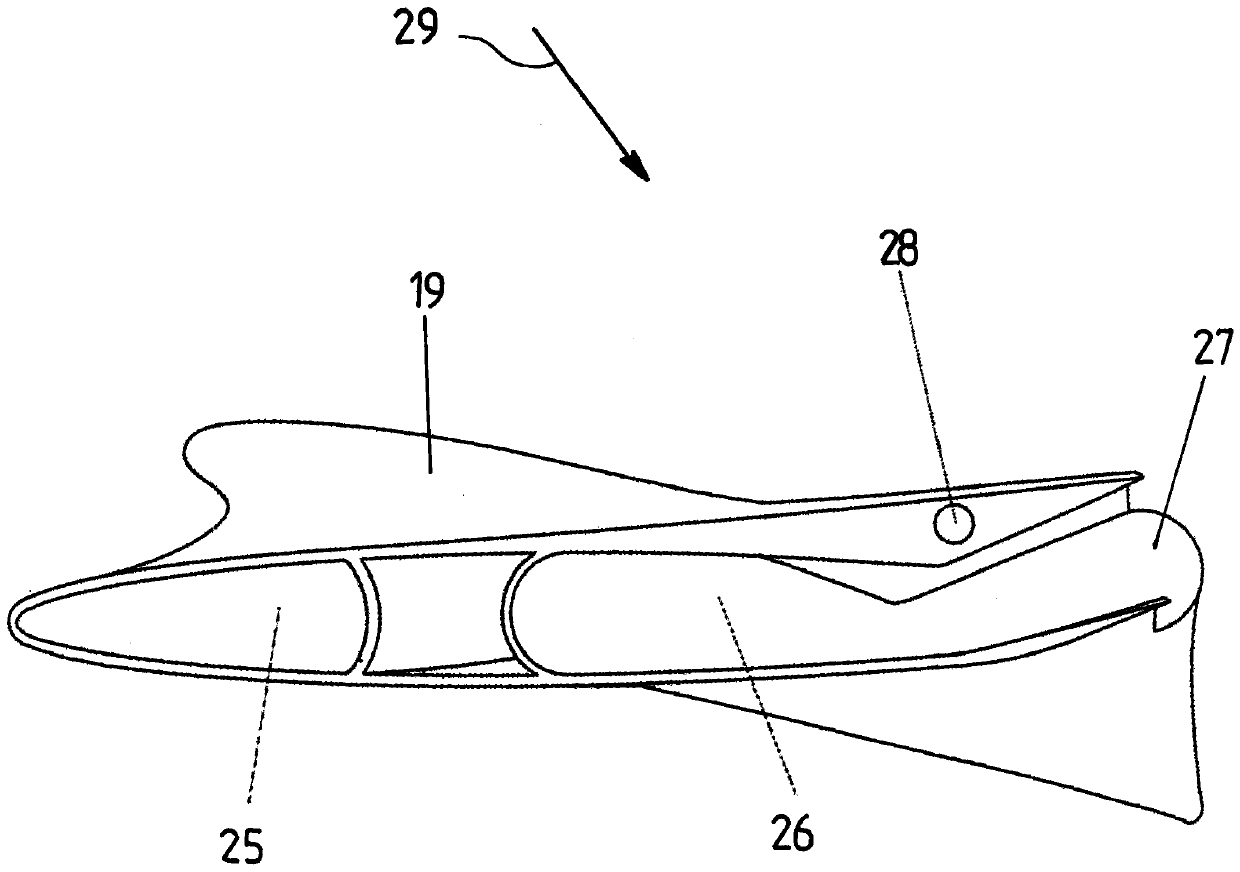

[0030] Furthermore, fan blades 19 of the fan are arranged on the main shaft 16 . Thus, the fan blades 19 turn in the same direction and at the same rotational speed as the compressor stages. In principle, gears or coaxial shafts can also be present in order to be able to achieve different directions of rotation or rotational speeds of the fan and compressor.

[0031] further back in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap