Rotational multi-degree-of-freedom motion generation platform

A technology with degrees of freedom and motion, applied in the direction of non-electric variable control, mechanical oscillation control, instruments, etc., can solve the problems of inconvenient driving force and driving force control and adjustment, inability to meet precise control output vibration, complex structure installation, etc., to achieve The effect of simple structure, light weight and high driving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

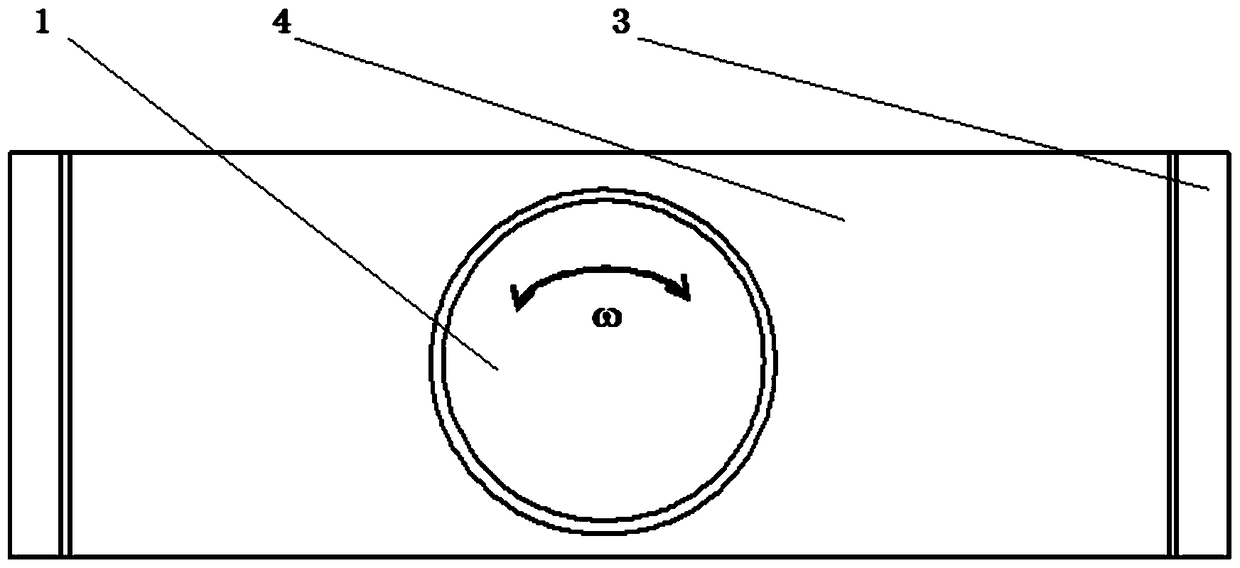

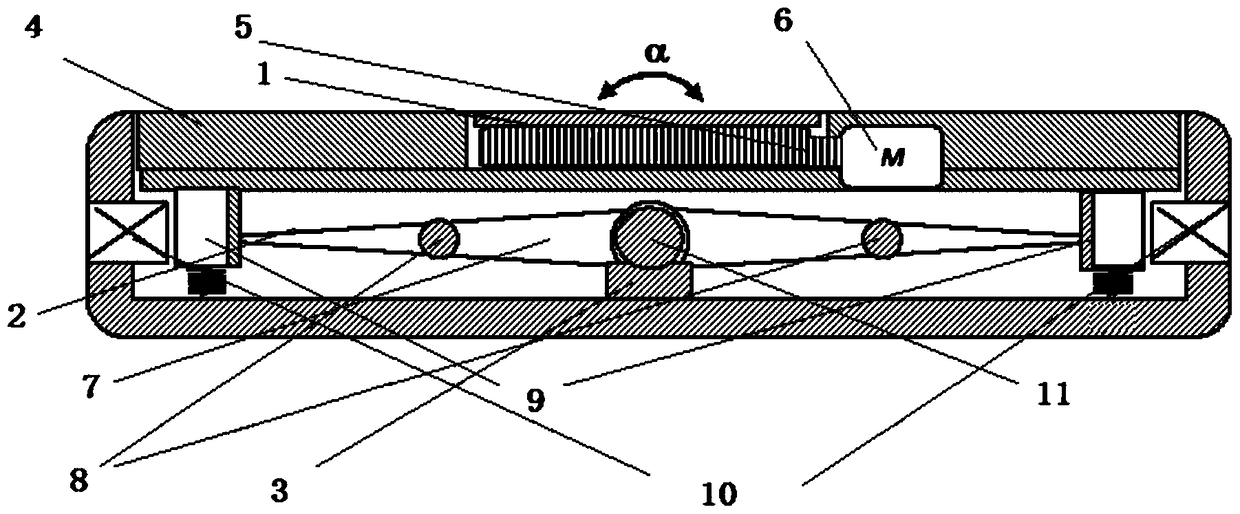

[0048] Such as figure 1 As shown, this embodiment provides a swinging multi-degree-of-freedom motion generation platform, including: a structural frame body, a cover structure, a rotating component, a transmission component, and a swing component; the cover structure is arranged on the top of the structural frame body , and form a structural shell with the structural frame body; the rotating parts and transmission parts are respectively embedded in the cover structure; the swinging parts are arranged inside the structural shell; wherein:

[0049] The rotating part is drivingly connected with the transmission part;

[0050] Such as figure 2 with image 3 As shown, the swinging part includes a set of magnetic force generating parts and electromagnetic direct drive parts, a swing beam and a swing beam supporting part; a magnetic control loop is formed between the magnetic field force generating part and the electromagnetic direct drive part, and the electromagnetic direct driv...

Embodiment 2

[0073] Embodiment 2 is a modification example of Embodiment 1.

[0074] Such as Figure 4 As shown, on the basis of embodiment 1, the present embodiment differs from embodiment 1 in that:

[0075] The magnetic field force generation part and the electromagnetic direct drive part are multiple groups, and the magnetic field force generation part in the multi-group magnetic field force generation part and the electromagnetic direct drive part is installed on the structural frame body, and the multi-group magnetic field force generation part and the electromagnetic direct drive part Corresponding to the magnetic field force generating part in the driving connection is connected on the swing beam.

Embodiment 3

[0077] Embodiment 3 is a modification example of Embodiment 1.

[0078] On the basis of embodiment 1, this embodiment differs from embodiment 1 in that:

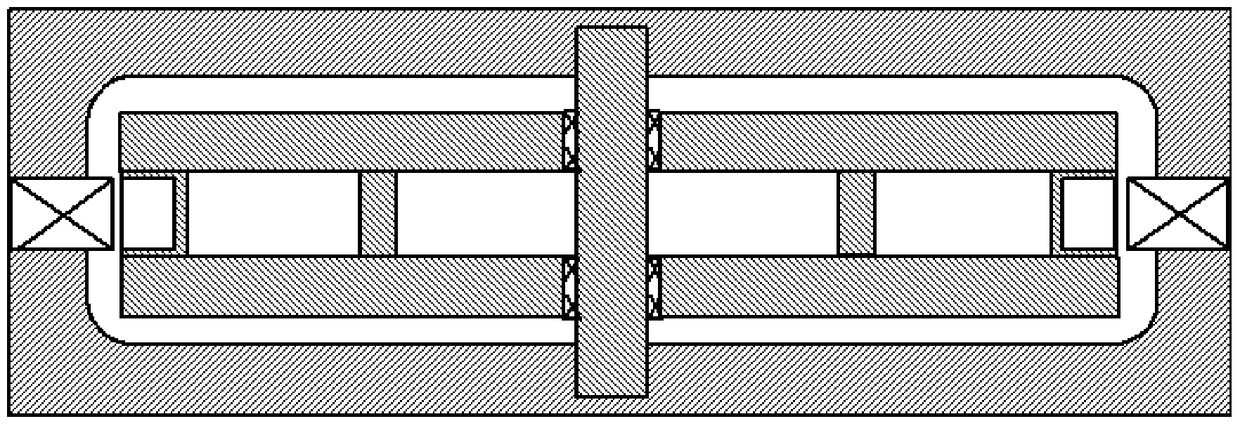

[0079] The swing supporting part adopts ball bearings, such as Figure 5 with Image 6 As shown, the ball bearing can rotate in both directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com