Patents

Literature

33results about How to "Achieve self-stabilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Constant support

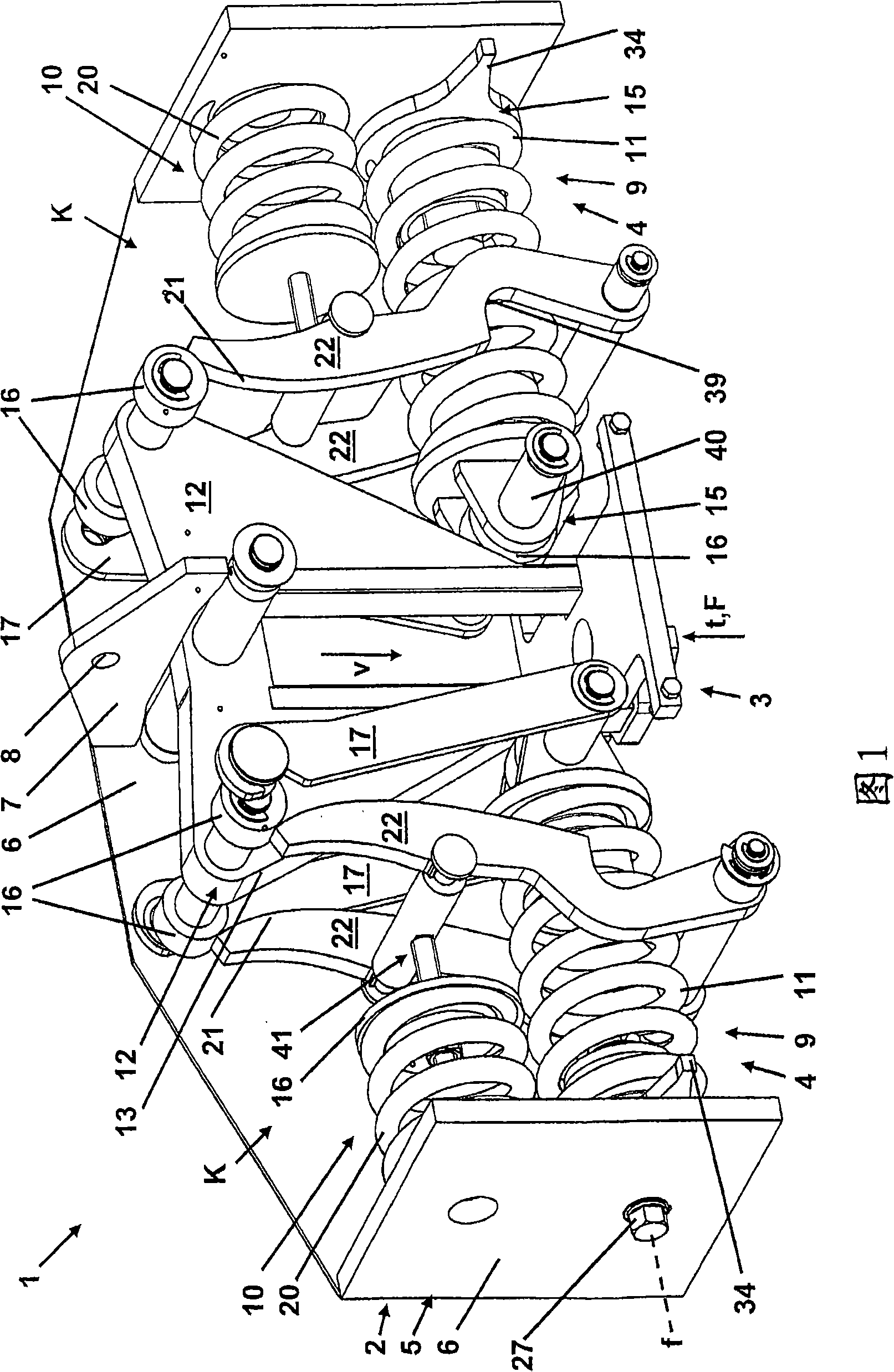

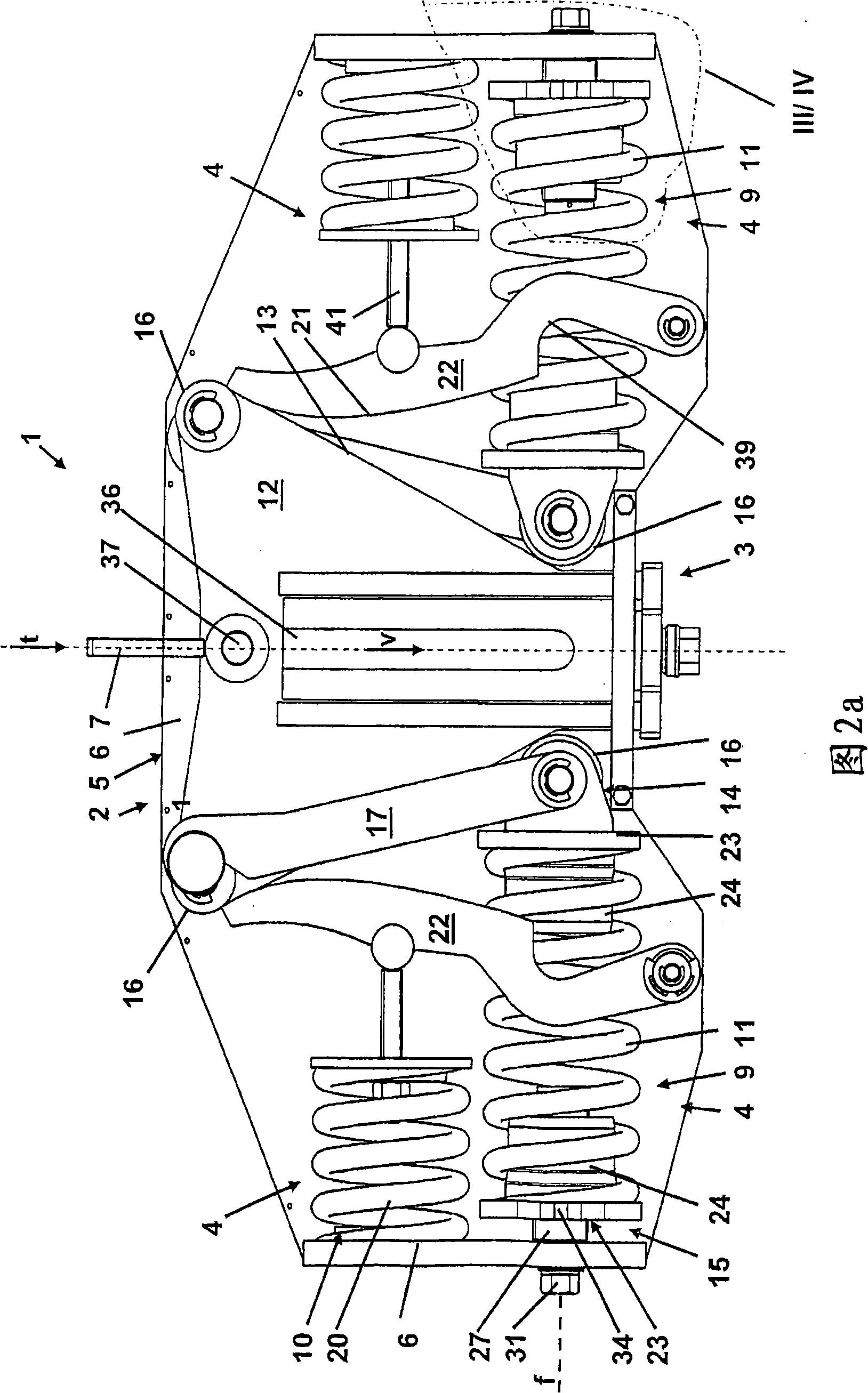

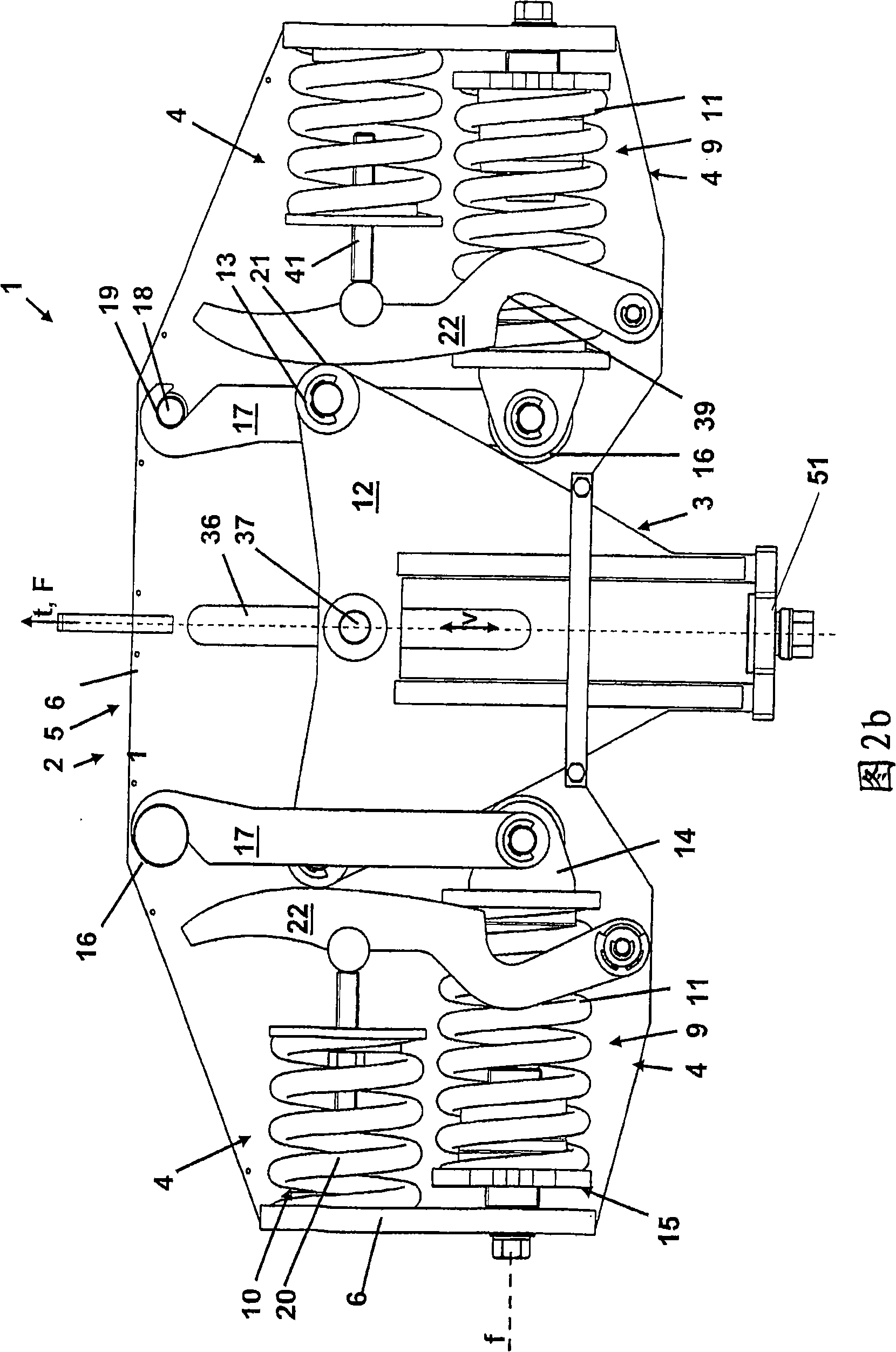

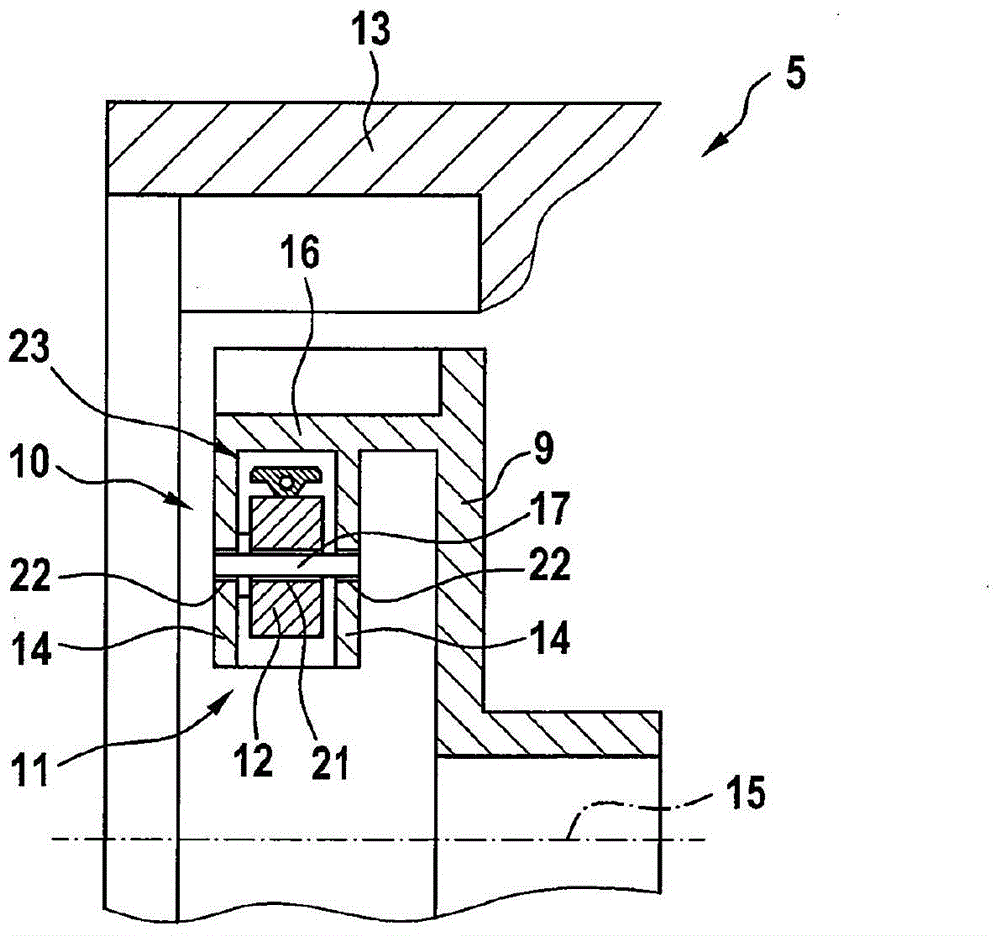

ActiveCN101273226AReduce the height of the structureIncrease the length of the leverPipe supportsShaft liningMechanical engineeringSpring system

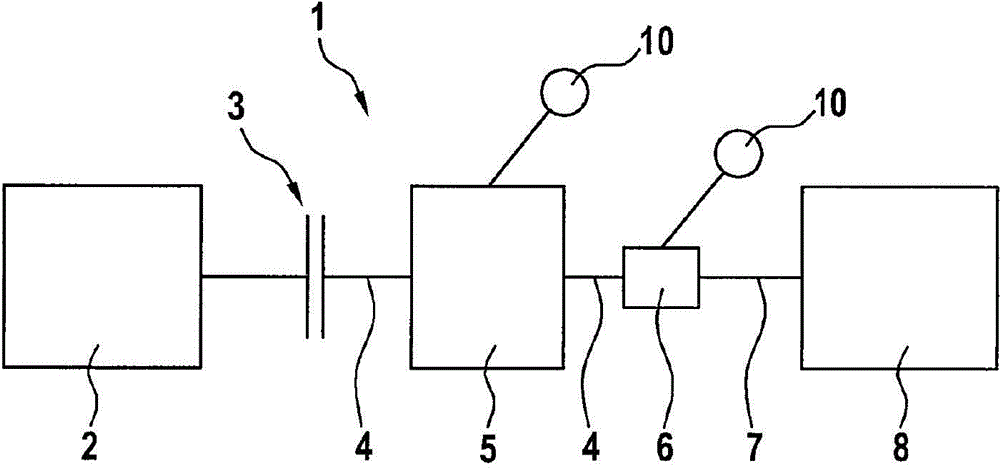

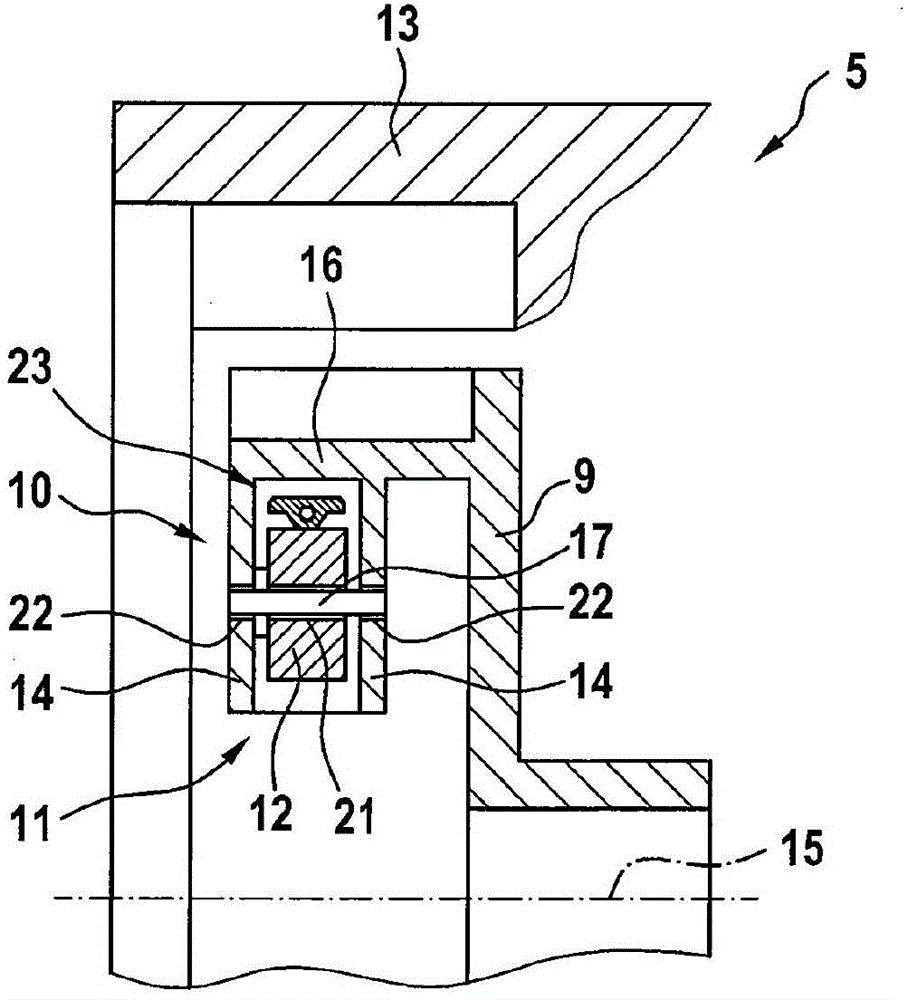

The invention relates to a constant support (1) for moving loads, especially pipelines and similar. Said constant support (1) comprises a fastening part (2), a load-bearing part (3), and a spring system (4) which is located between the fastening part (2) and the load-bearing part (3) to generate a constant bearing strength. The spring system (4) is provided with a main spring assembly (9) absorbing the load and a device (K) for compensating changing pressures of the main spring assembly (9).

Owner:LISEGA GMBH

Medicated health care kidney-nourishing wine

InactiveCN101204491AAchieve self-stabilizationImprove kidney functionDigestive systemAlcoholic beverage preparationBoschniakiaRHODIOLA ROSEA ROOT

The invention relates to medicinal liquor for kidney invigorating and health protection which belongs to traditional Chinese medicinal health protection liquor. The invention provides medicinal liquor with a better effect of kidney invigorating and health protection.The invention is immersed and made by the following pure grain liquor under atmospheric temperature of which weight percentage of ingredients are as foolows: 100-130g of curculigo orchioides, 110-135g of desertliving cistanche, 10-30g of Russian boschniakia, 50-70g of chiretta, 10-30g of Chinese caterpillar fungus, 5-20g of rhodiola rosea, 20-40g of fruit of Chinese wolfberry, 15-35g of dioscorea root, 10-35g of songaria cynomorium herb, 25-40g of ginseng and 15-35g of white poria.

Owner:刘森

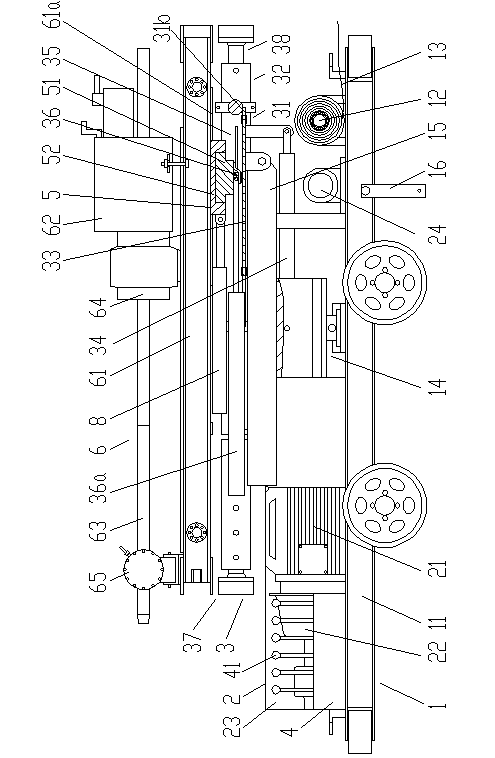

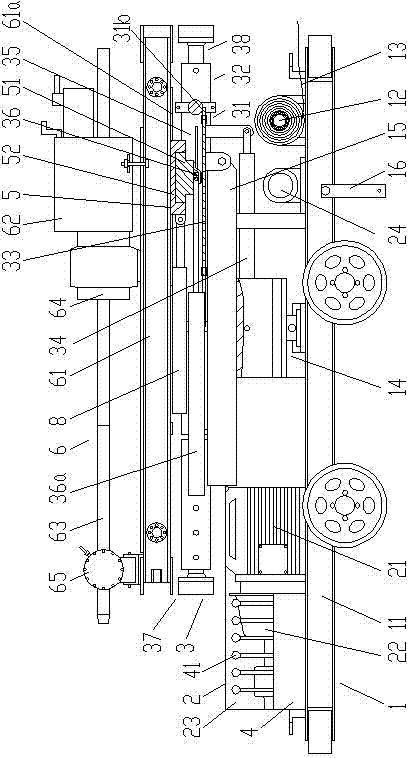

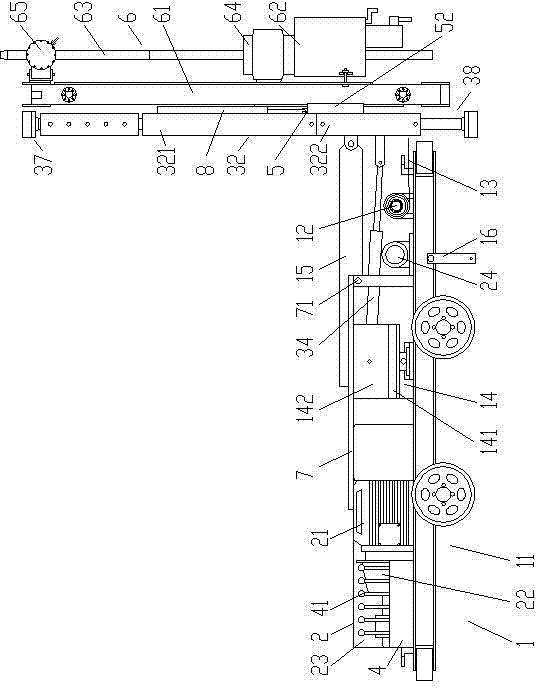

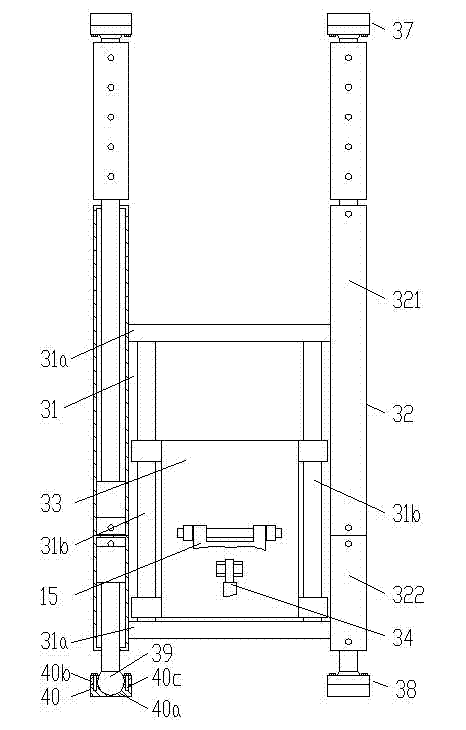

Wheel type truck-mounted drilling rig

The invention discloses a wheel type truck-mounted drilling rig which is characterized in that a movable frame with a drilling device is disposed on a body, the body comprises a mining flatbed truck and a hydraulic winch, a support seat is disposed on the mining flatbed truck, a support beam which is used for allowing the movable frame to be horizontal is disposed on the support seat, a guide rail clamp is further disposed on the mining flatbed truck, the movable frame comprises a #-shaped frame, two ends of the two crossbeams of the #-shaped frame are fixedly connected with main support oil cylinders, two longitudinal beams of the #-shaped frame forms two parallel guide rails which are in slide fit with a movable support, the movable support is hinged to the outer end of the support beam, a vertical oil cylinder which is used for allowing the movable frame to be vertical is connected between the movable support and the support seat, an n-shaped frame is fixedly connected between cylinder bodies the two main support oil cylinders, and a drilling rig turn plate is disposed between the n-shaped frame and the drilling device. The wheel type truck-mounted drilling rig has the advantages that the wheel type truck-mounted drilling rig can be moved in a tunnel without damaging sleepers, the drilling rig is good in rigidity, and drilling hole positions can be adjusted conveniently.

Owner:重庆市能源投资集团科技有限责任公司 +1

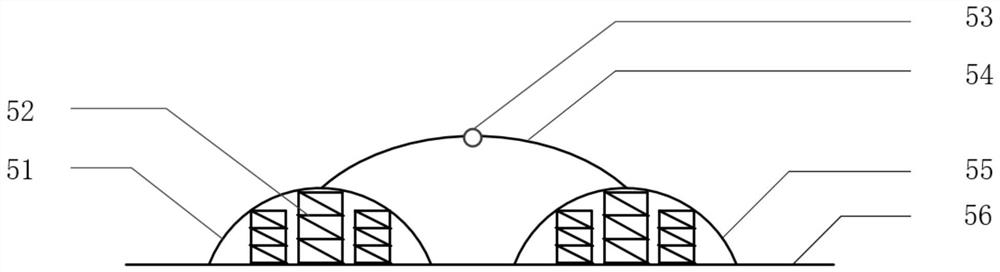

Suspended rail transit apparatus and magnetoelectric hybrid levitation rail system therein

ActiveCN109094422AReduce vibrationLow mechanical wear and electric heat lossSliding/levitation railway systemsRailway transportAutomotive engineeringDistance sensors

A suspended rail transit apparatus and a magnetoelectric hybrid suspension rail system therein, comprising a control unit, a track and a vehicle-mounted magnetoelectric rail. The vehicle-mounted magnet rail comprises at least two arrays of vehicle-mounted permanent magnets arranged along the running direction of the car, electromagnets and a distance sensor; The rail comprises a rail permanent magnet array, wherein the rail permanent magnet array and the vehicle-mounted permanent magnet array are staggered at intervals, and the rail and the vehicle-mounted magnetoelectric rail are self-stabilized through mutually exclusive magnetic poles. The rail comprises a rail permanent magnet array, a rail permanent magnet array and a vehicle-mounted permanent magnet array. At the same time, the distance sensor, the control unit and the electromagnet form a closed loop control system, wherein the control unit controls the magnitude of the excitation current in the electromagnet through the data ofthe distance sensor so that the excitation current excitation magnetic field keeps the permanent magnet array of the road rail from contacting with the permanent magnet array of the vehicle to realize hovering. The hovering rigidity of the invention is large, the road rail and the vehicle-mounted magnetoelectric rail constitute a self-stable system, and the vibration is small when the road rail and the magnetoelectric rail are loaded.

Owner:江西永磁磁浮科技有限责任公司

Medicated health-caring wine

InactiveCN101204492AAchieve self-stabilizationImprove kidney functionDigestive systemAlcoholic beverage preparationForest yamAdditive ingredient

The invention belongs to traditional Chinese medicinal health protection liquor. The invention provides medicinal liquor with a better effect of kidney invigorating and health protection. The invention is immersed and made by the following pure grain liquor under atmospheric temperature of which weight percentage of ingredients are as follows: 110-130g of curculigo orchioides, 110-135g of desertliving cistanche, 10-30g of Russian boschniakia, 50-70g of angelica, 10-30g of chinese caterpillar fungus, 5-15g of rhodiola root, 20-40g of fruit of Chinese wolfberry, 15-40g of chinese yam, 15-35g of medicinal cyathula root, 10-30g of dried tangerine peel, 20-40g of ginseng,10-30g of white poria, 20-40g of songaria cynomorium herb, 10-20g of caesalpinia, 20-40g of fruit of Chinese magnoliavine and 20-40g of liquorice.

Owner:刘森

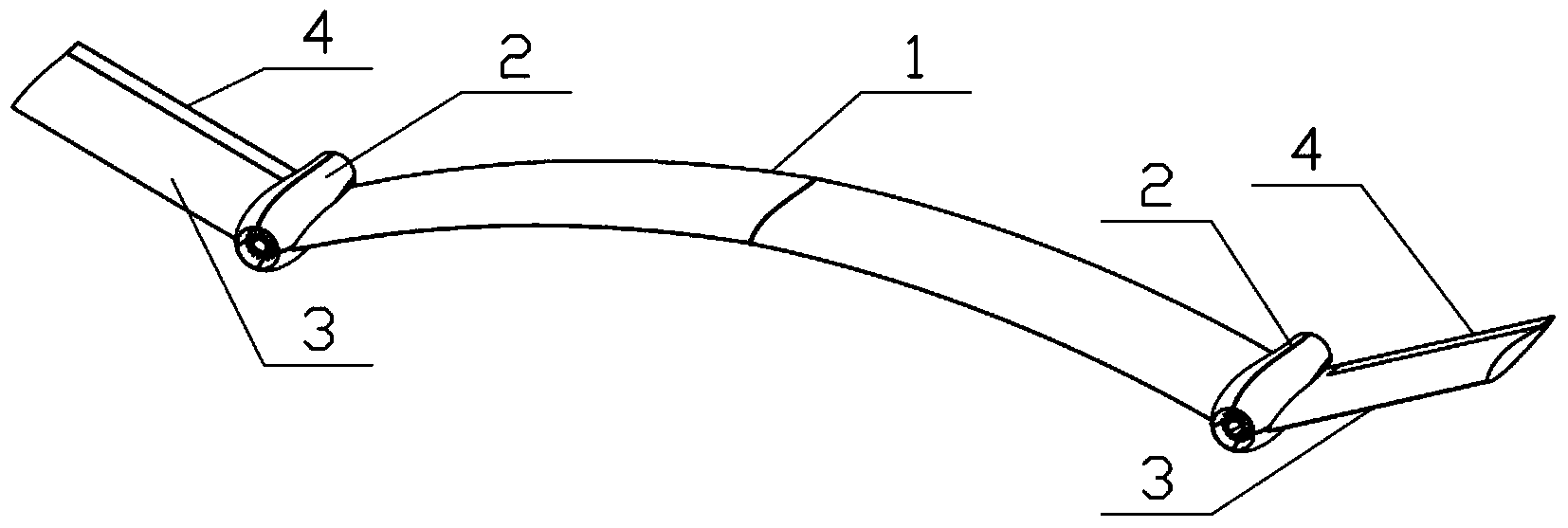

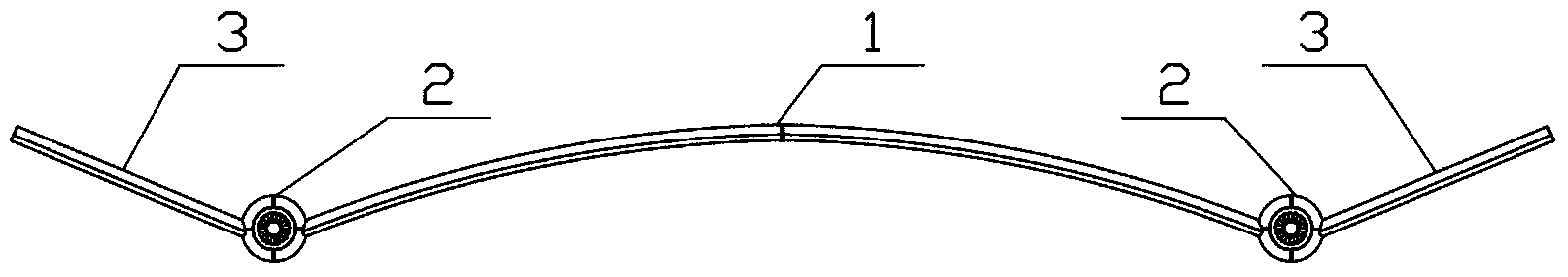

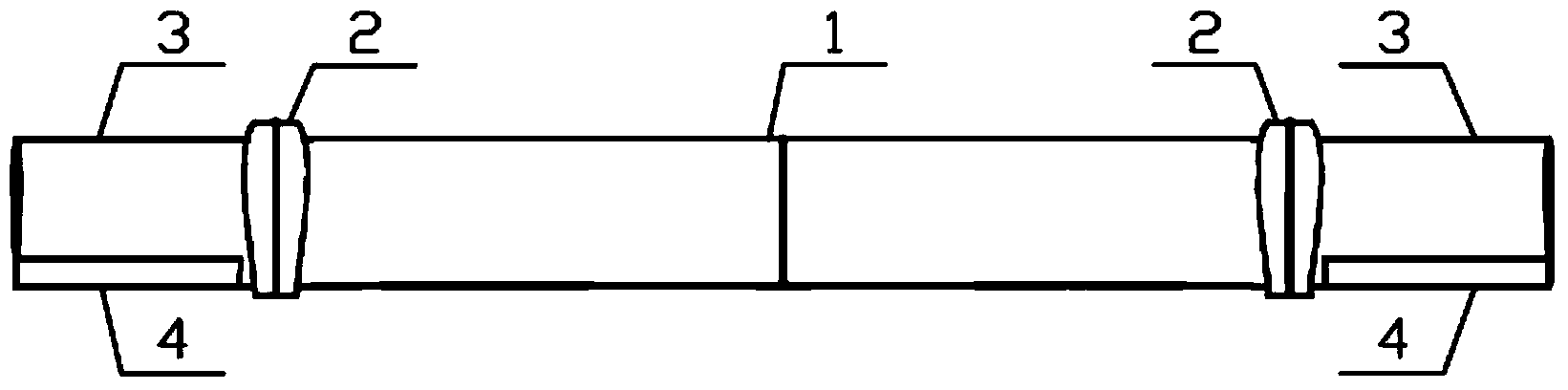

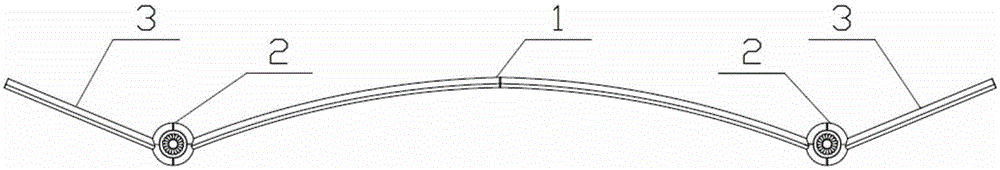

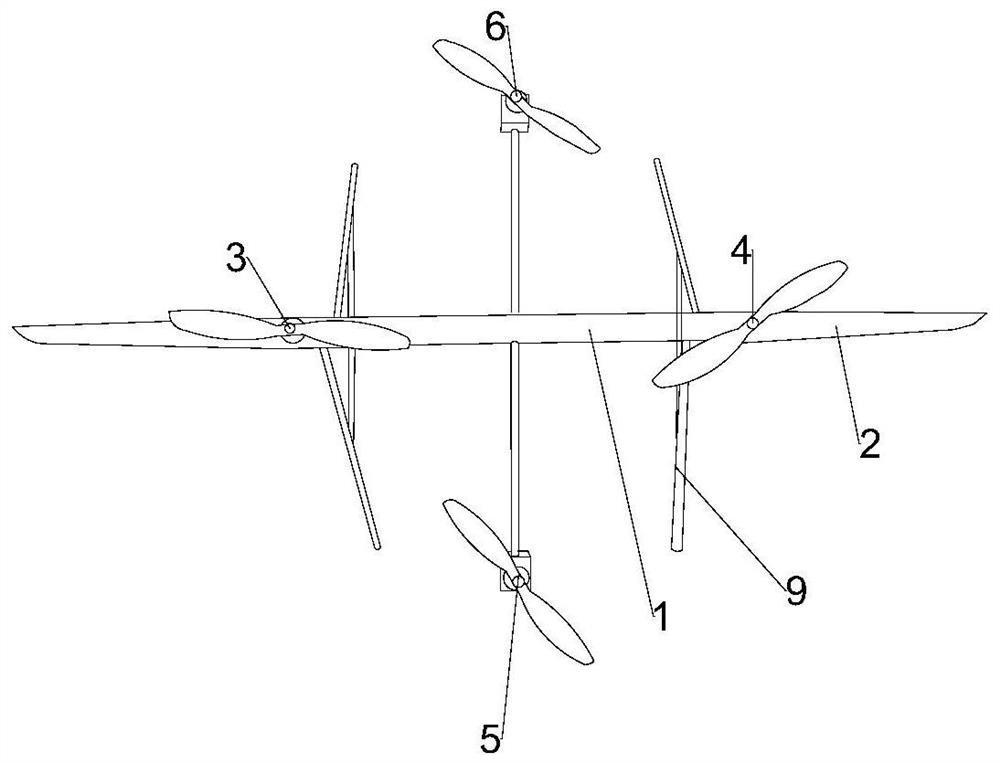

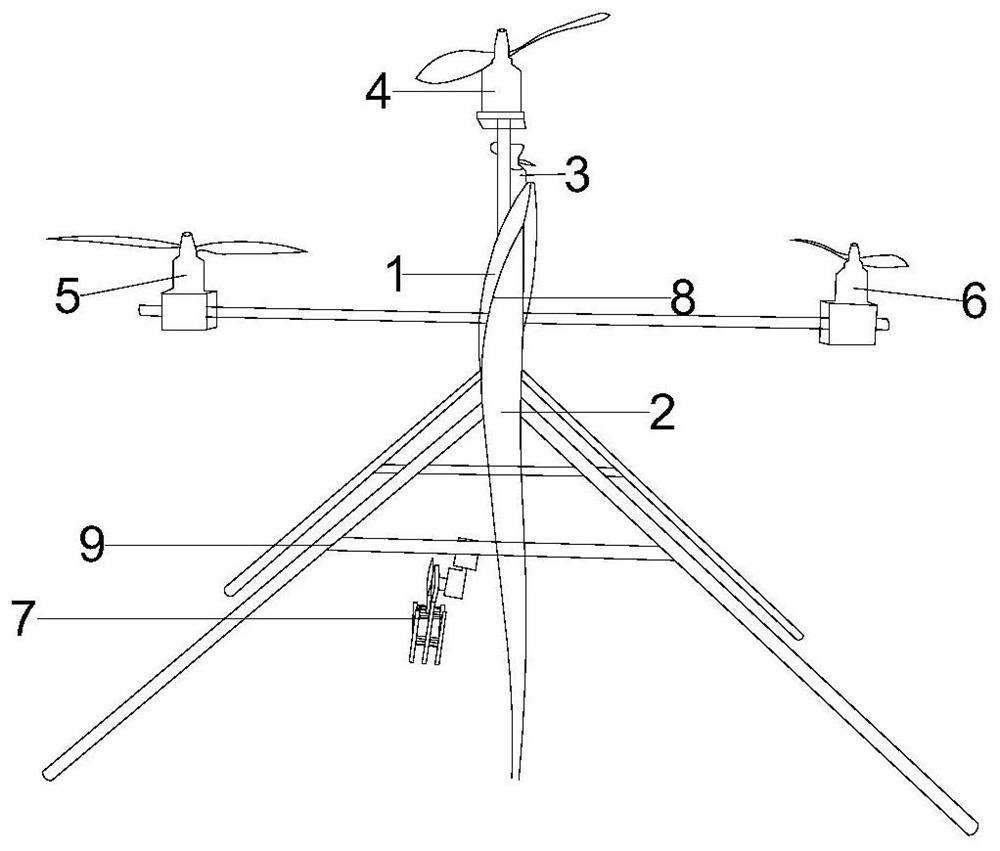

Arc-shaped wing aircraft capable of helical flying

InactiveCN103847964ARealize short takeoff and landingAchieve self-stabilizationAircraftsFly controlShortest distance

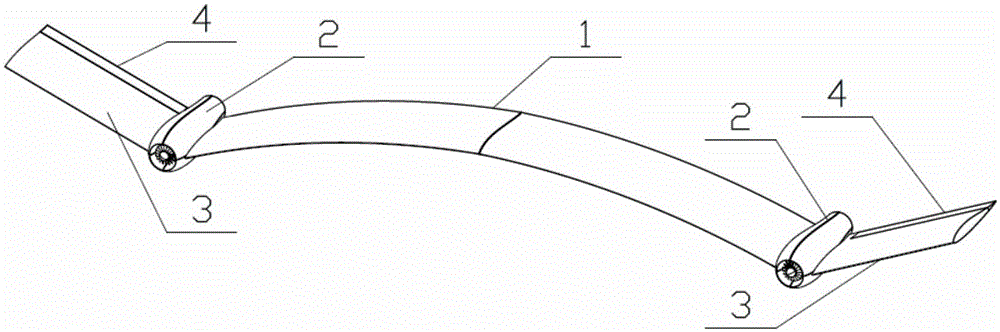

The invention discloses an arc-shaped wing aircraft capable of helical flying. The arc-shaped wing aircraft is characterized in that a central machine body adopts a single arc-shaped wing, the two sides of the arc-shaped wing aircraft are provided with straight wings, and the arc-shaped wing and the straight wings are in a straight flying wing layout in the horizontal direction; two flying modes such as helical-wing flying and straight-wing flying are adopted, the flying process can be controlled, and the short-distance taking off and landing can be achieved; in the taking-off and landing process, the helical type roll-flying action is finished by thrust differential of two ducted type engines, and the short-distance taking off and landing can be realized; the aircraft also has a normal fixed-wing rolling taking-off and landing; the aircraft flies in a helical manner, the arc-shaped wing and the straight wings are wholly regarded as single rotating wings, then the aircraft rotates around the axis of the helical-flying track, and lifting force capable of controlling the flying is provided for the aircraft; lifting ailerons are used for controlling the taking-off and landing of the aircraft, and the flying control in the horizontal direction is dependent on thrust differential and the lifting ailerons of the two groups of ducted type engines; the self stability of an inherent longitudinal and horizontal flying mode of the aircraft is realized by the arc-shaped wings and the dihedral straight wings.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Health-care wine

InactiveCN103382429AAchieve self-stabilizationImprove kidney functionAlcoholic beverage preparationClematisPolygonum odoratum

The invention discloses a health-care wine. The health-care wine belongs to a traditional Chinese medicine health-care wine. The health-care wine has the health-care effect of strengthening kidney. A preparation method of the health-care wine comprises the following steps of putting 30-40g of Chenlixin medicated leaven, 40-45g of dried orange peel, 10-15g of divaricate saposhnikovia root, 9-15g of eucommia, 8-20g of ligusticum wallichii, 12-20g of achyranthes root, 10-15g of adenophora root, 8-10g of white peony root, 10-18g of prepared rehmannia root, 10-15g of notopterygium root, 15-20g of aniseed, 20-25g of jujube kernel, 10-15g of wolfberry, 10-15g of clematis root, 8-10g of radix peucedani, 15-20g of cassia bark, 10-15g of poria with hostwood, 8-12g of polyghace seche, 8-12g of pawpaw, 10-12g of bark of ash, 10-15g of licorice and 10 jujubes into 3500g of liquor, carrying out immersion for 2 weeks, carrying out filtration to remove herb residues, adding 50-150g of rock sugar into the filtrate, and carrying out seal storage, wherein the health-care wine can be eaten after full thawing of the rock sugar.

Owner:田荣侠

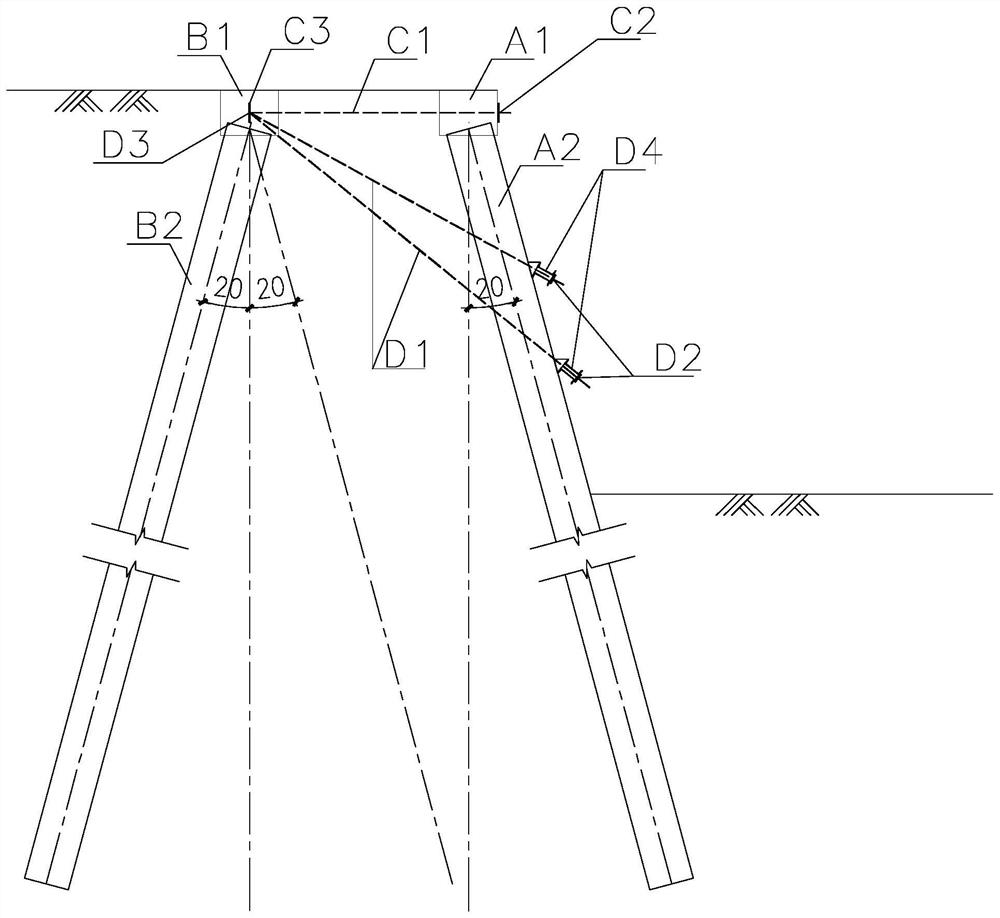

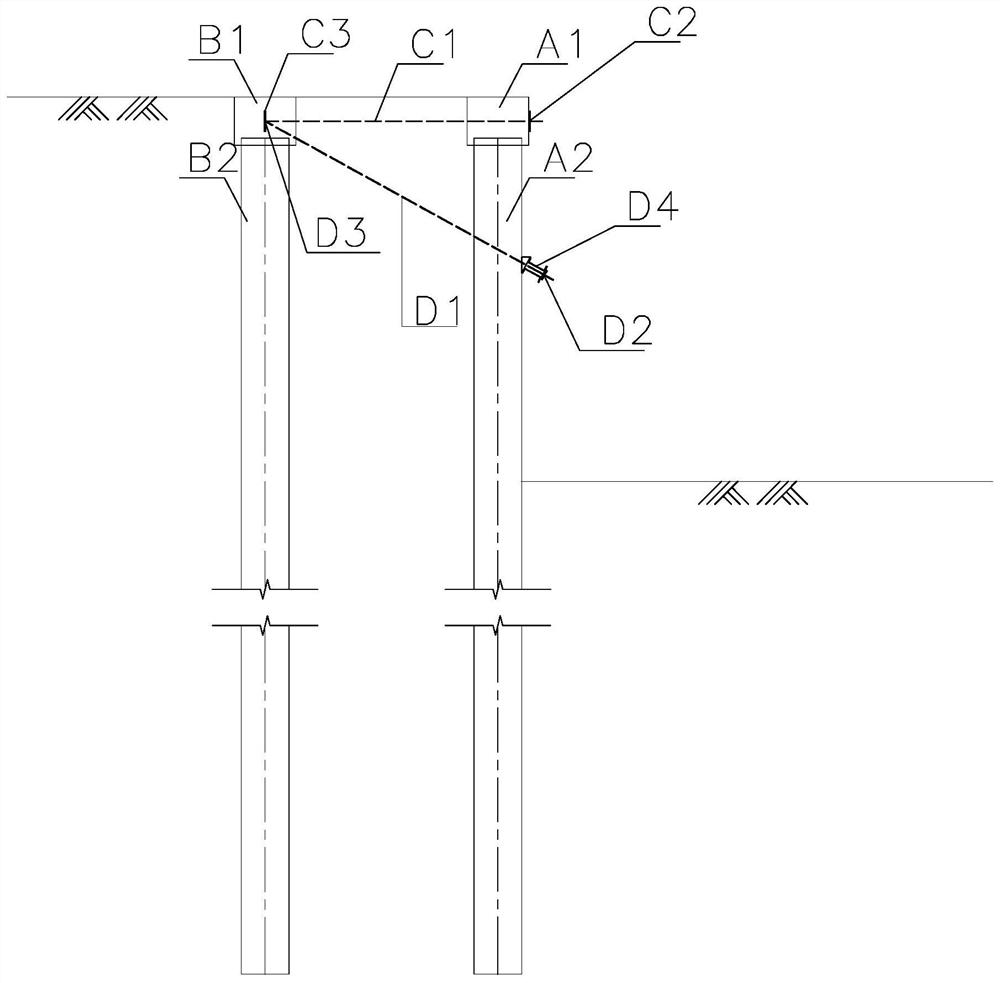

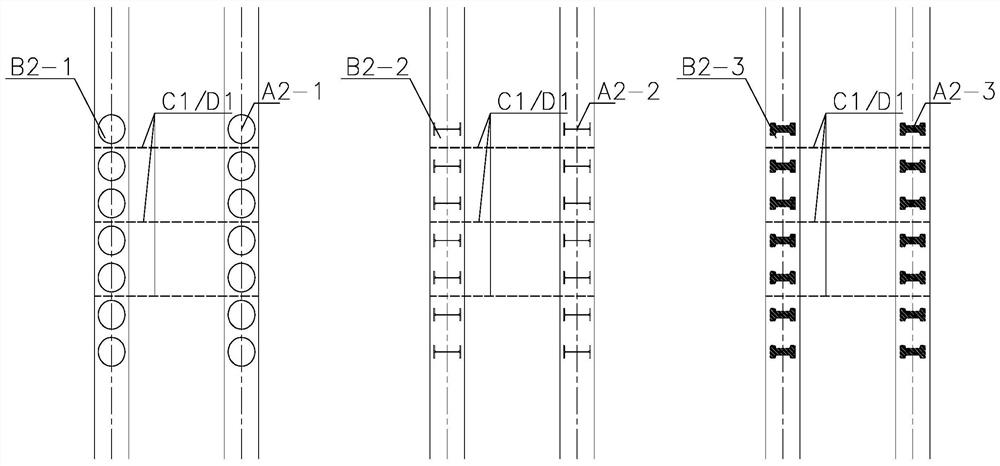

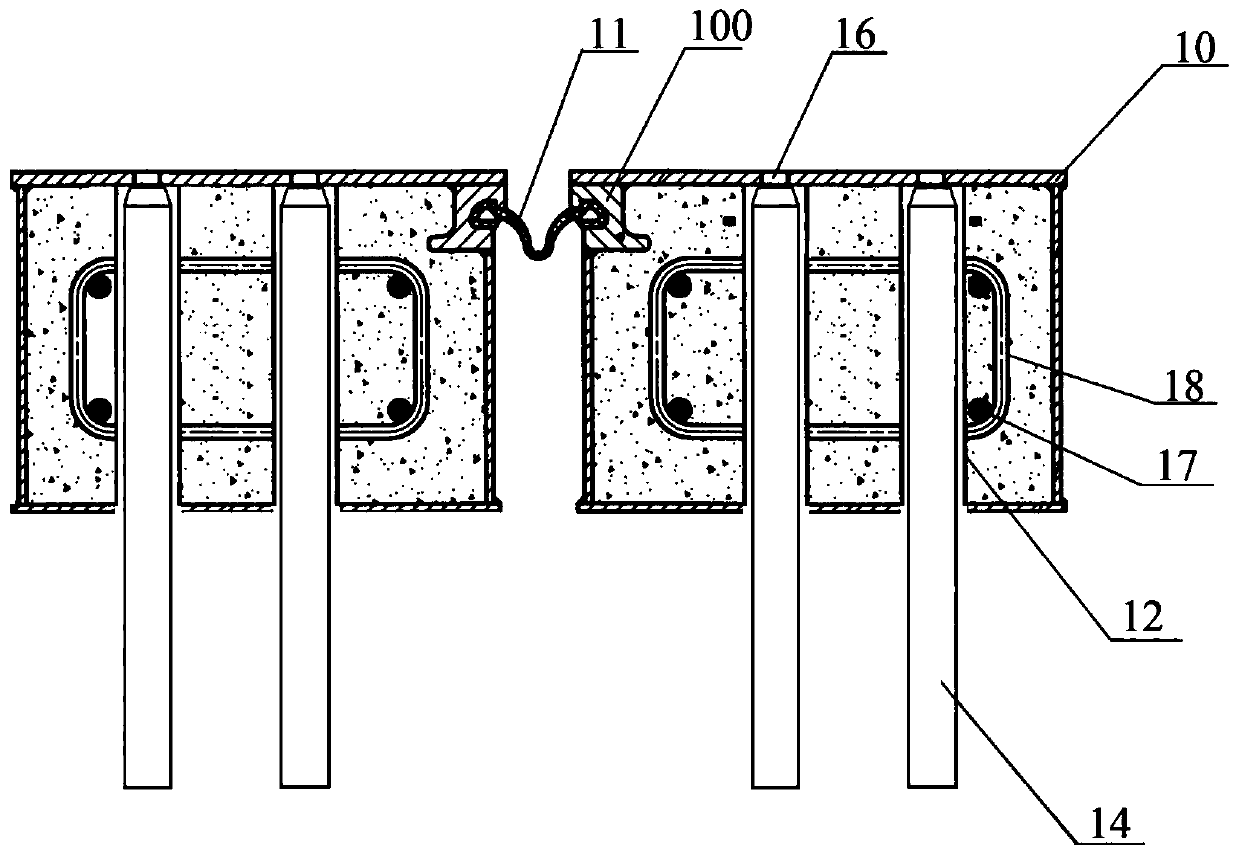

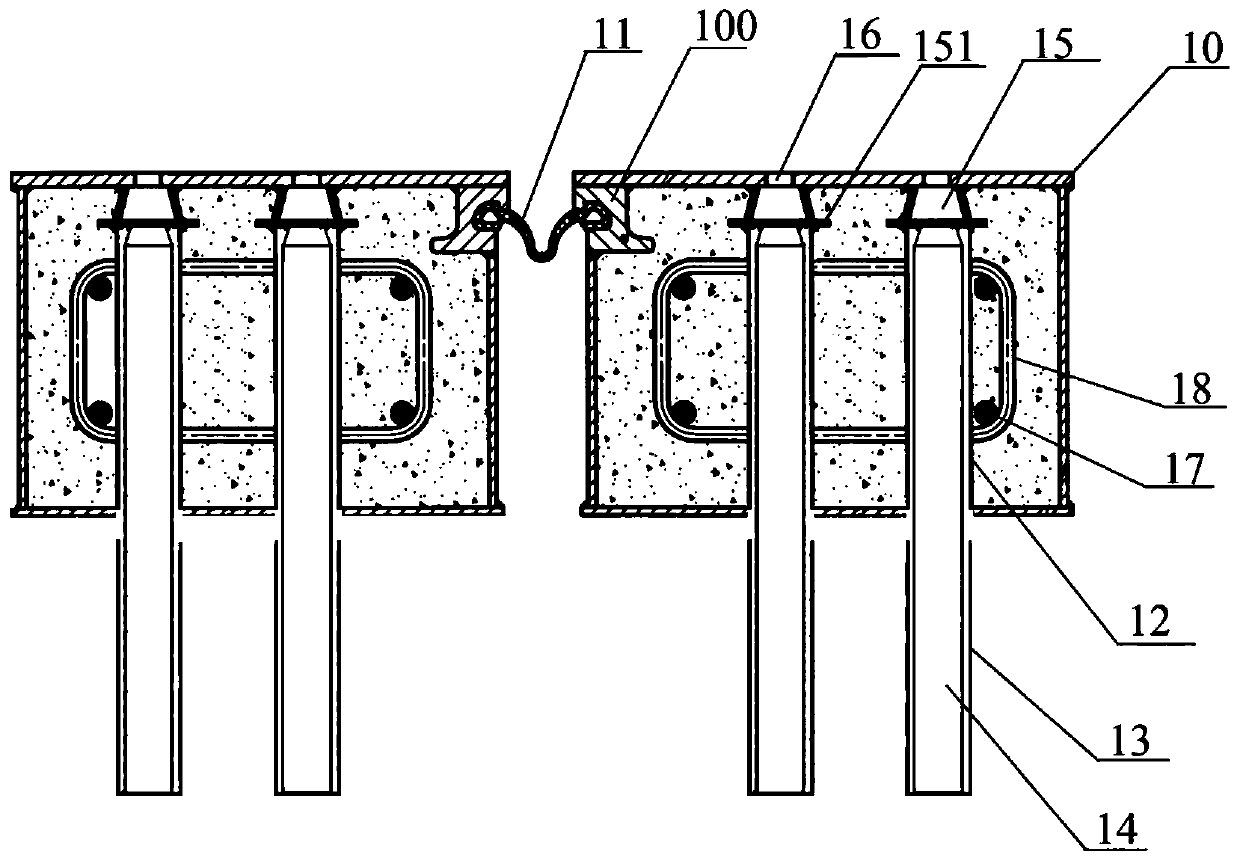

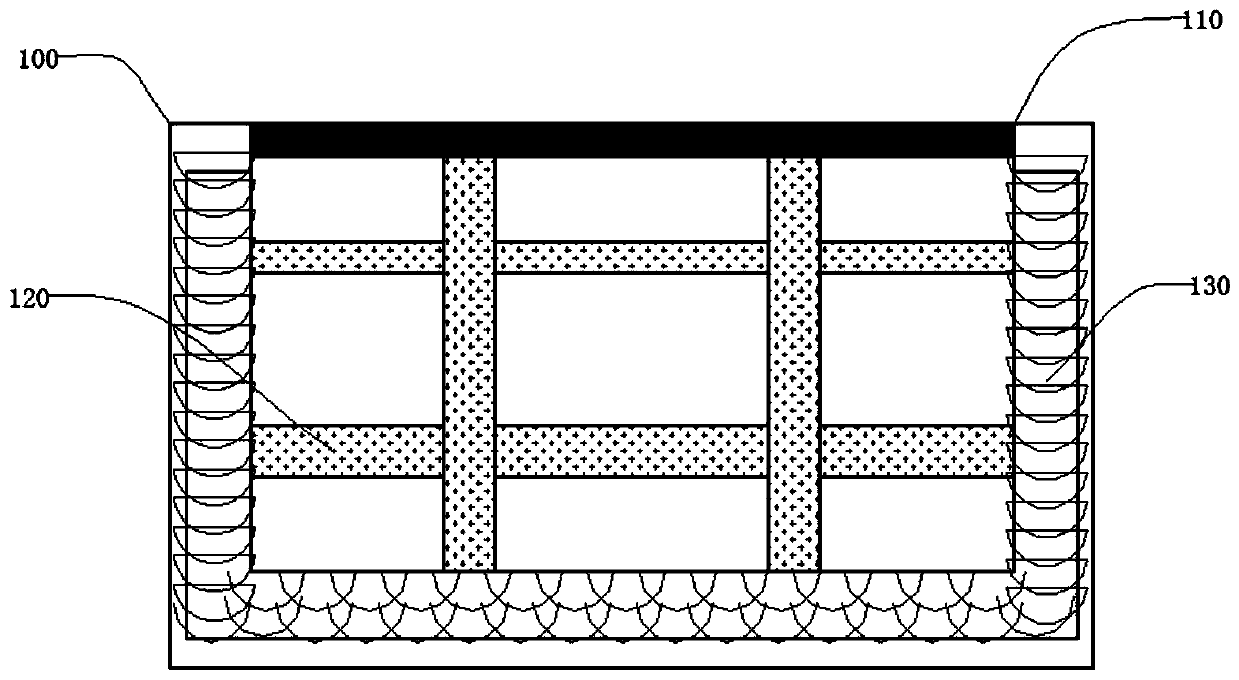

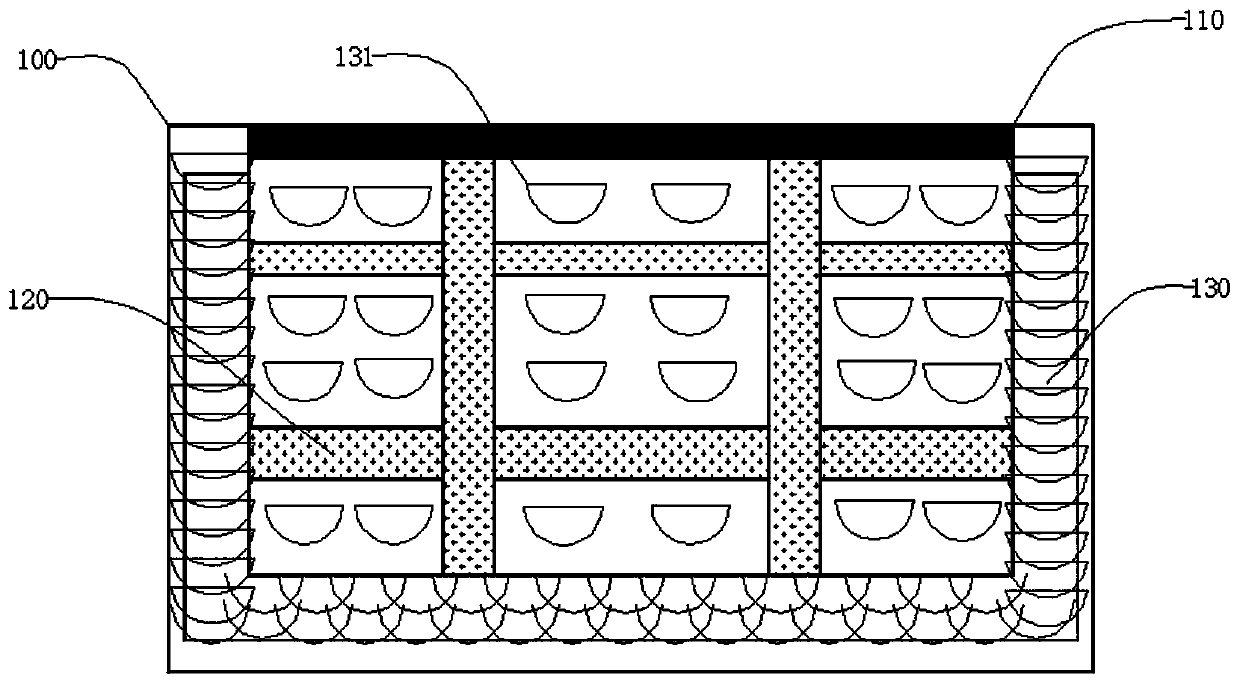

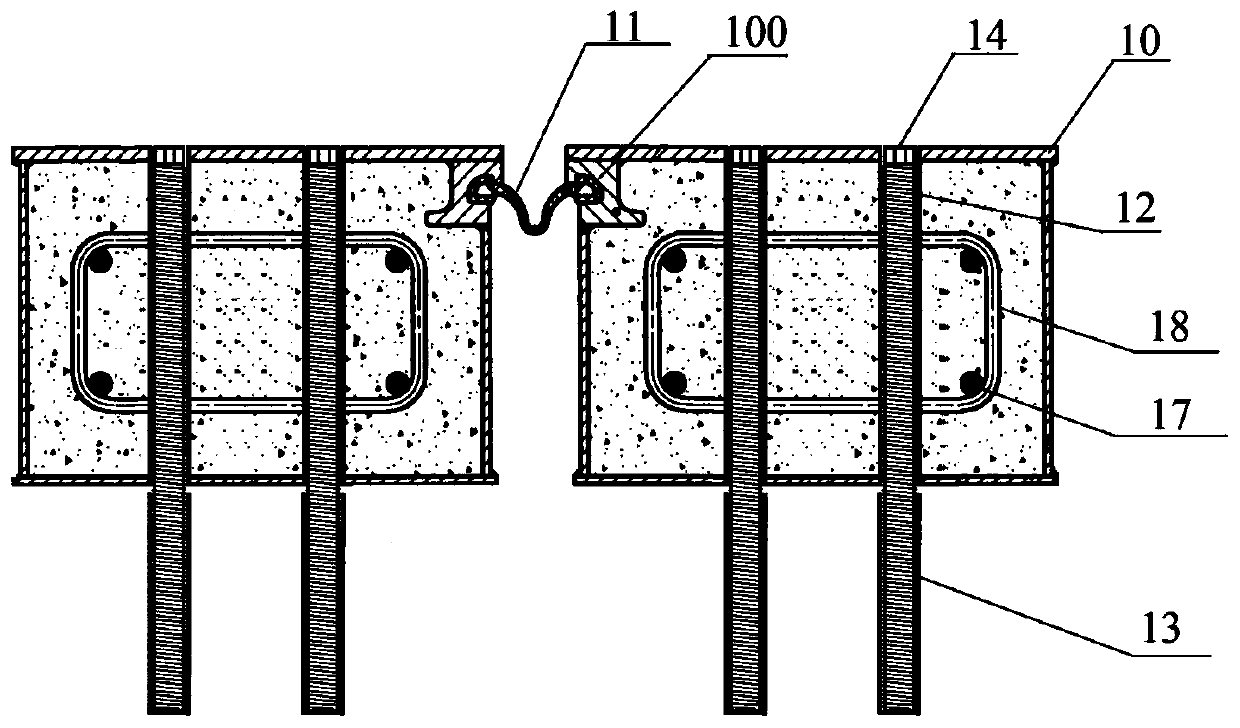

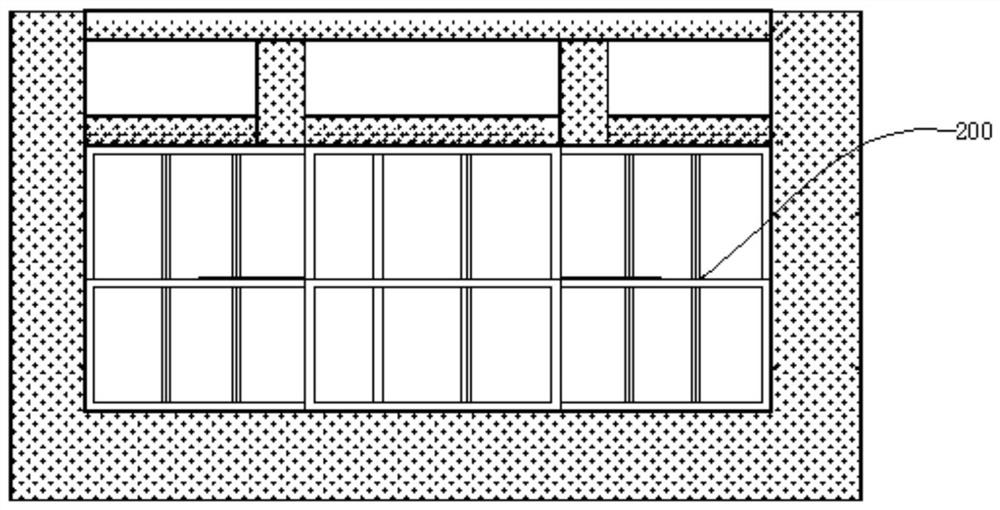

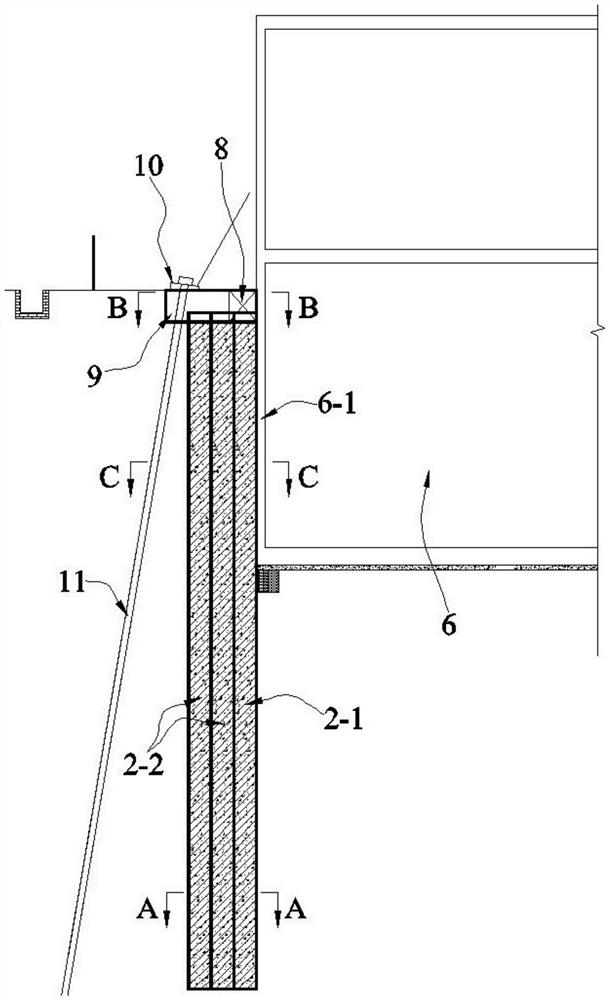

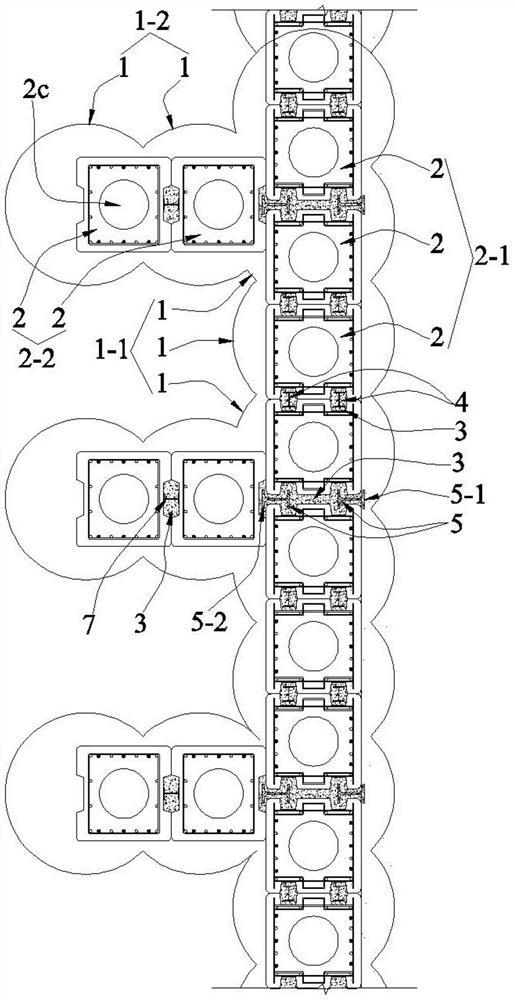

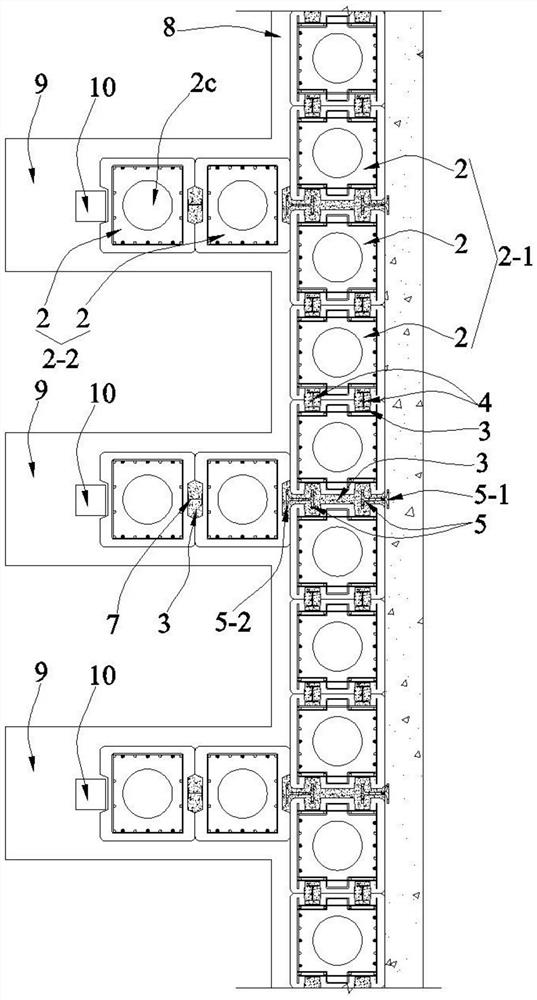

Novel self-stabilizing enclosure system

PendingCN113106985AAchieve self-stabilizationControl deformationExcavationsBulkheads/pilesSupporting systemClassical mechanics

The invention relates to a novel self-stabilization type enclosure system. The self-stabilization type enclosure system comprises front-row enclosure components, rear-row enclosure components and anchor cables, wherein the front-row enclosure components are cast-in-situ bored piles or SMW construction method piles or precast piles, the rear-row enclosure components are cast-in-situ bored piles or SMW construction method piles or precast piles, the front-row enclosure components are vertical or inclined, the rear-row enclosure components are vertical or inclined, the front-row enclosure components are connected through front crown beams the rear-row enclosure components are connected through rear crown beams, the front crown beams are anchored with the rear crown beams through horizontal anchor cables, and the front-row enclosure components are anchored with the rear crown beams through cable-stayed anchor cables. The novel self-stabilization type enclosure system solves the problems that a traditional enclosure system is large in cantilever deformation, a red line is pulled and anchored, a supporting point of a pre-supporting system is too high, deformation control is not good, and enclosure deformation is effectively controlled, and safety is guaranteed.

Owner:城地建设集团有限公司 +2

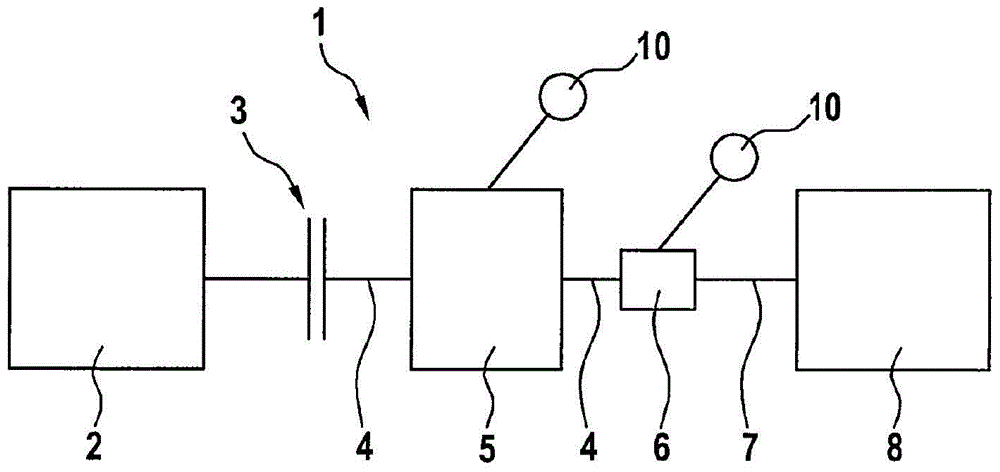

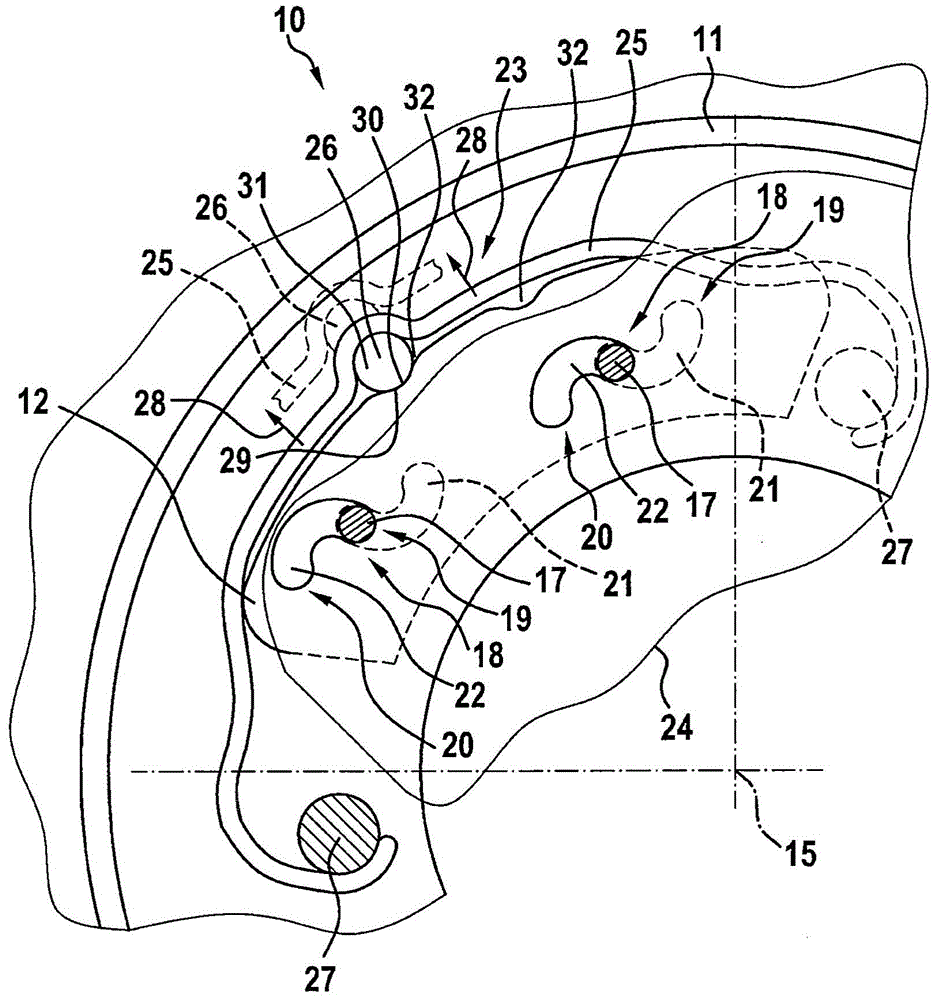

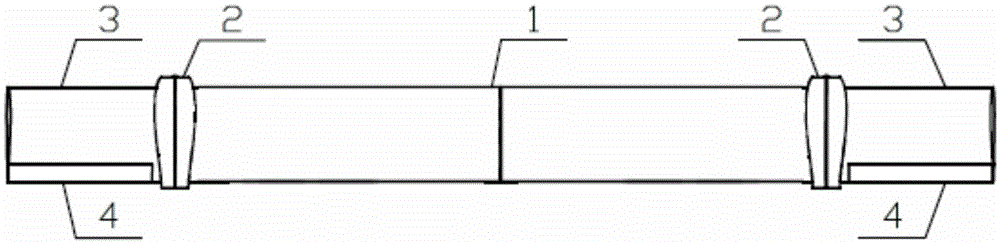

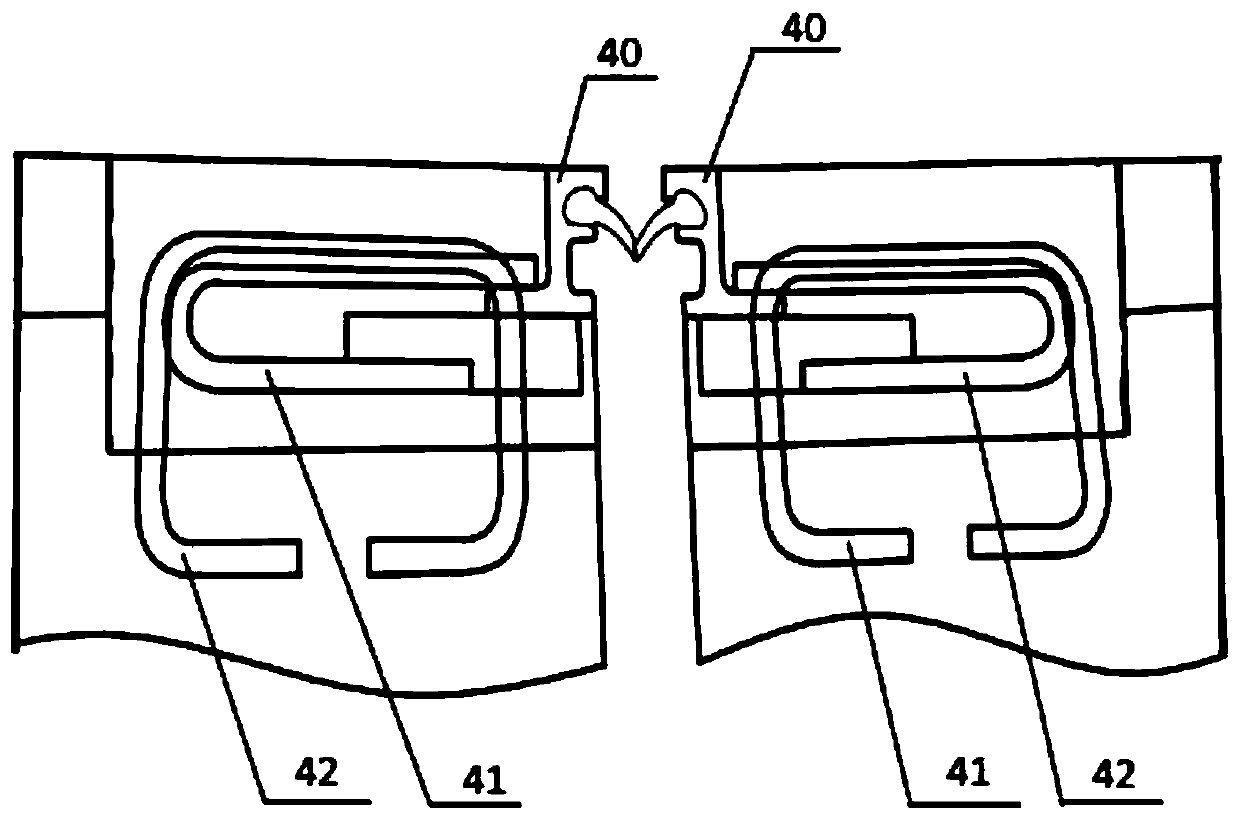

Centrifugal pendulum dampers and drive trains of motor vehicles

ActiveCN104937306BReliable holdUniform force loadingRotating vibration suppressionEngineeringMotor vehicle crash

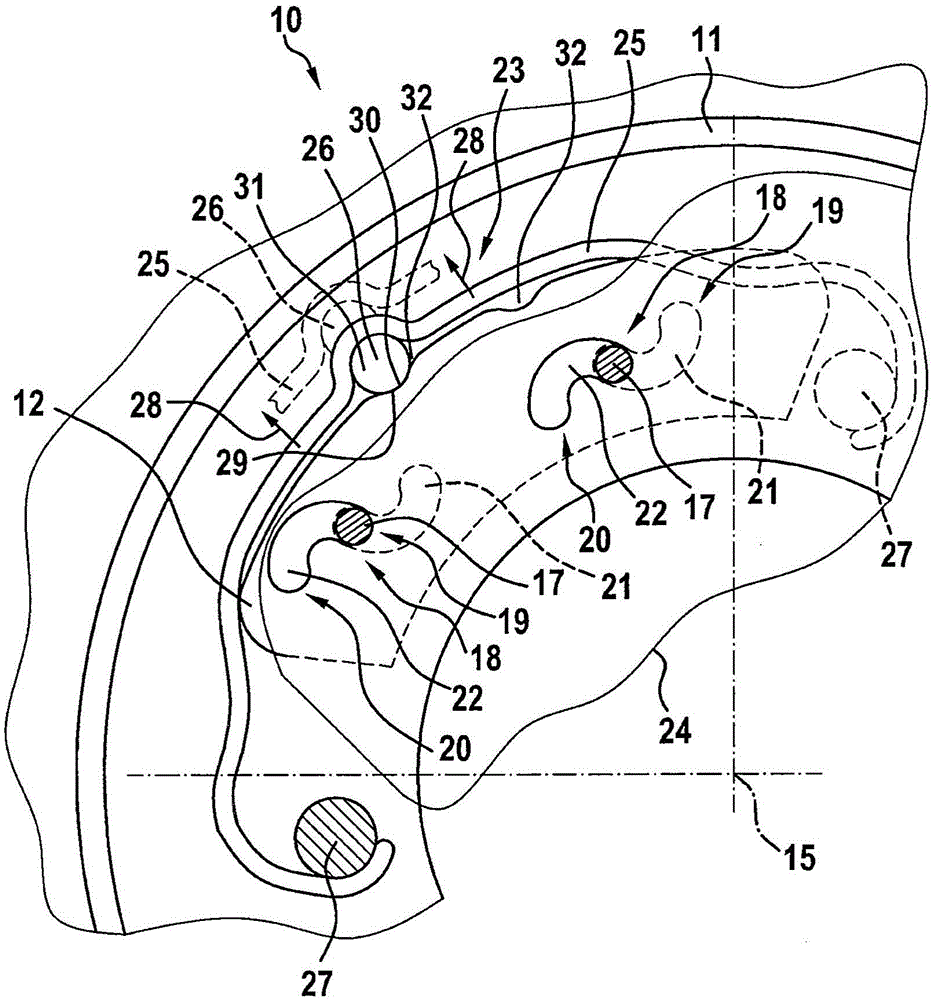

A centrifugal pendulum device includes a pendulum mass carrier, which is rotatable about a rotation axis, and at least one pendulum mass, which is supported on the pendulum mass carrier for movement along a track between end stops which are spaced from one another in circumferential direction in relation to the rotation axis. A spring device urges the pendulum mass in one of the end stops, when the rotation speed of the pendulum mass carrier drops below a limit rotation speed.

Owner:AUDI AG

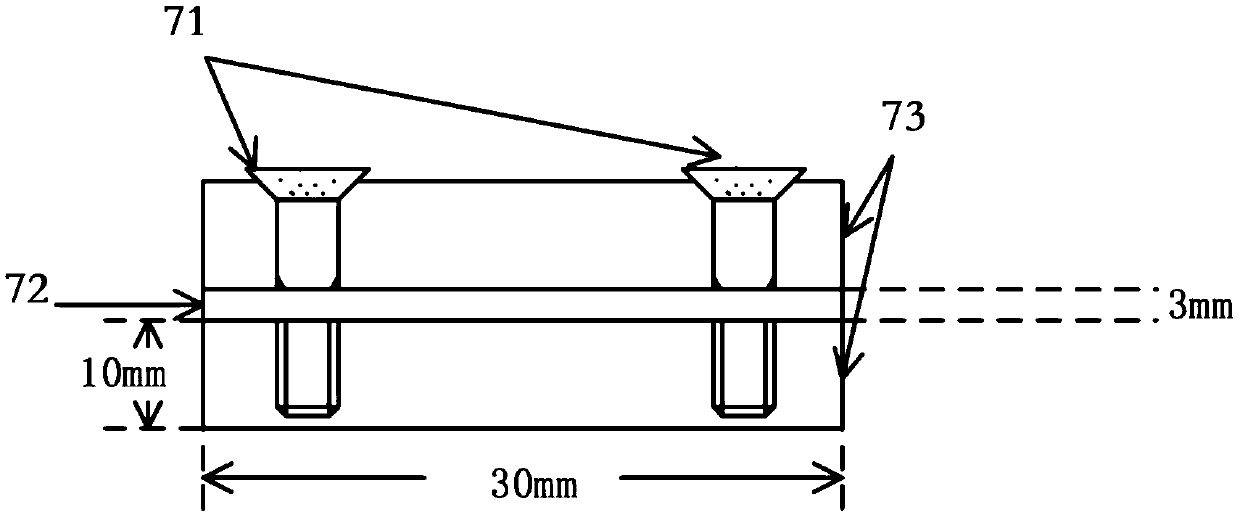

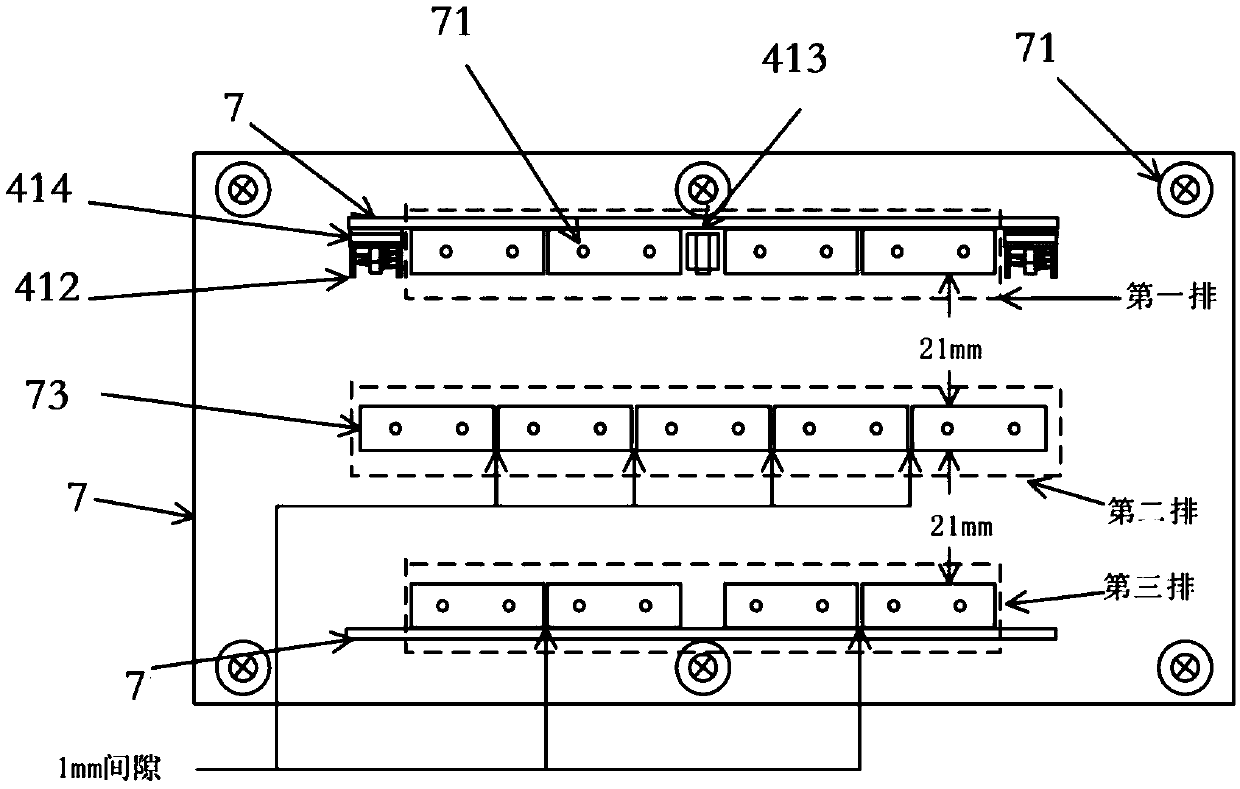

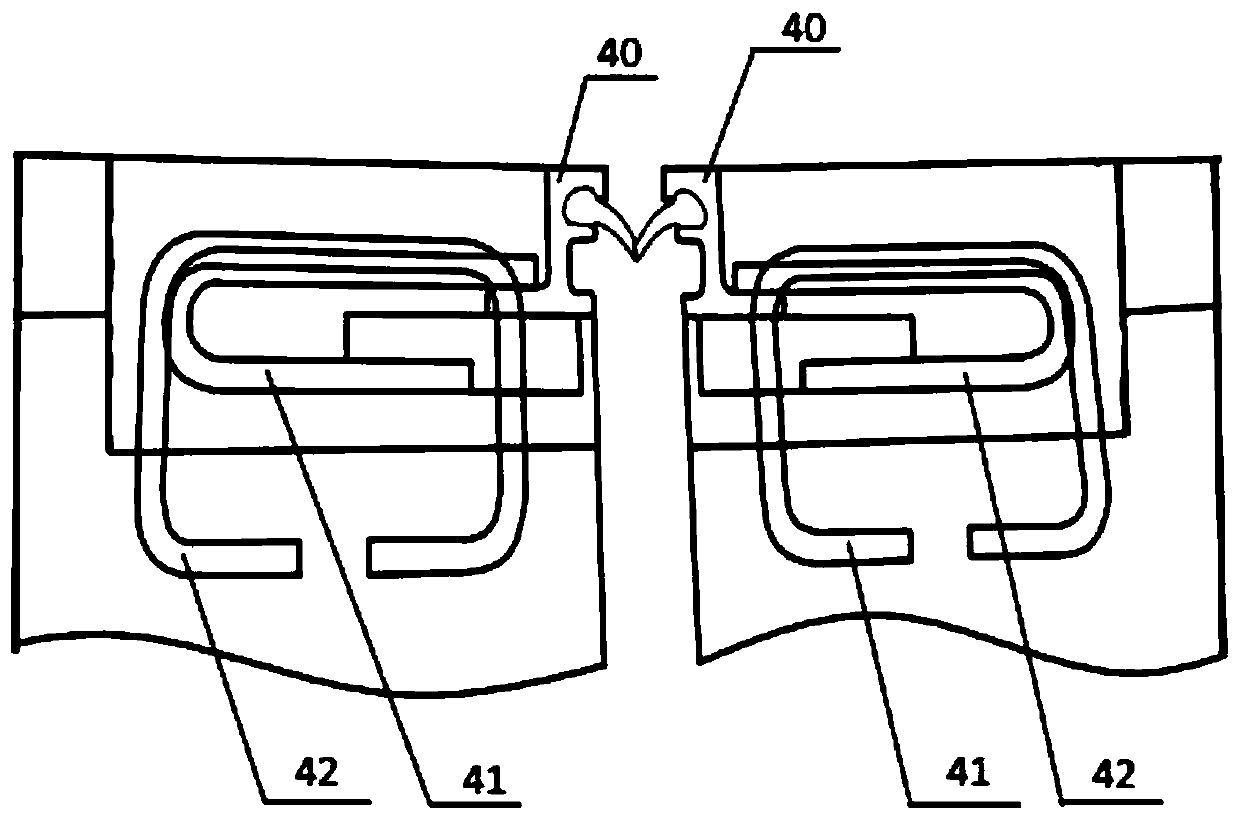

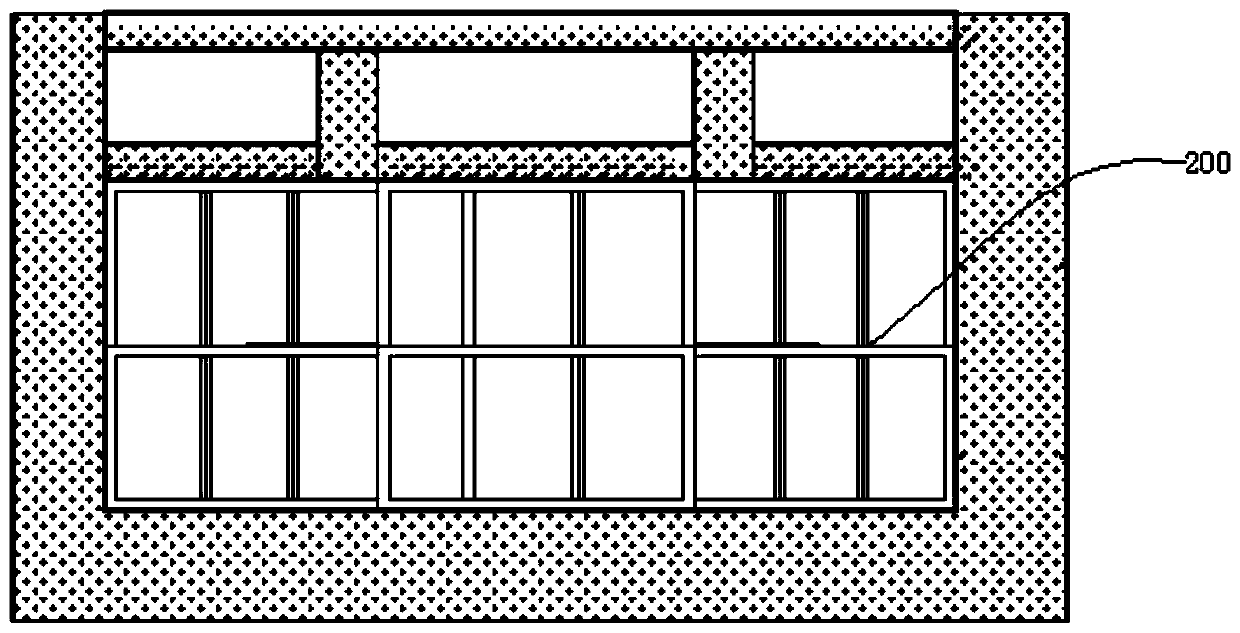

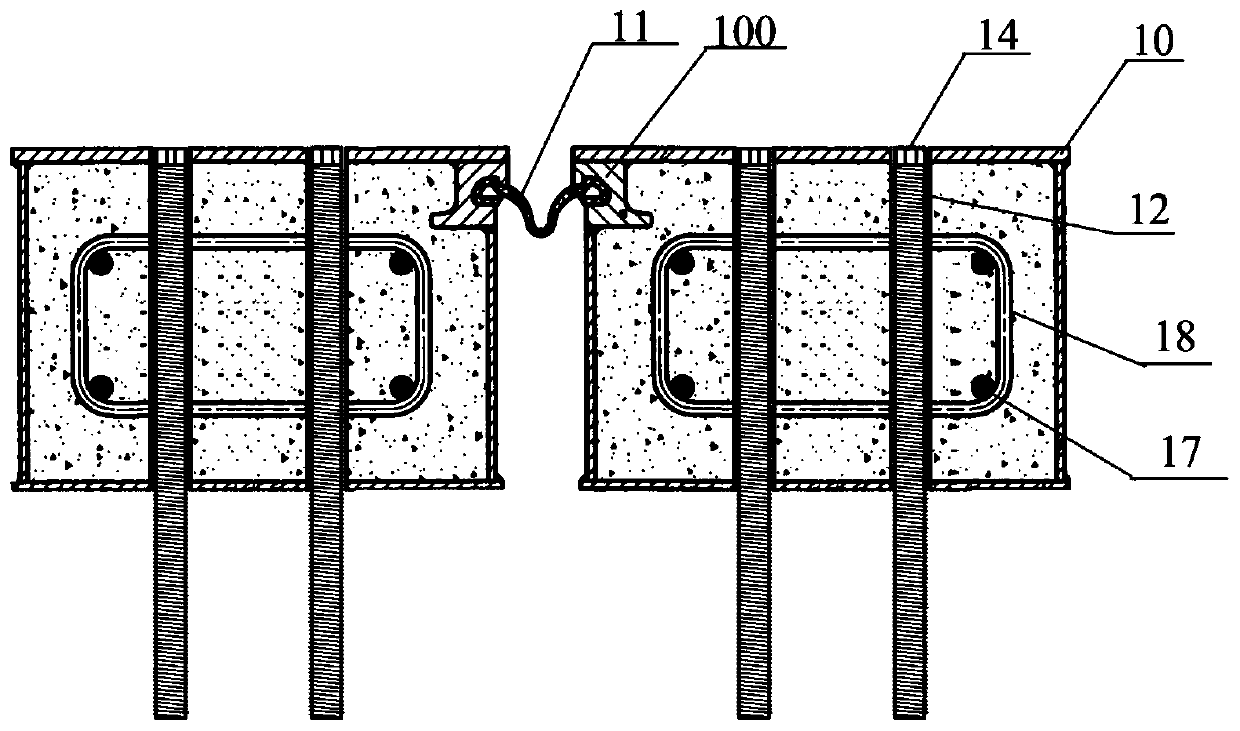

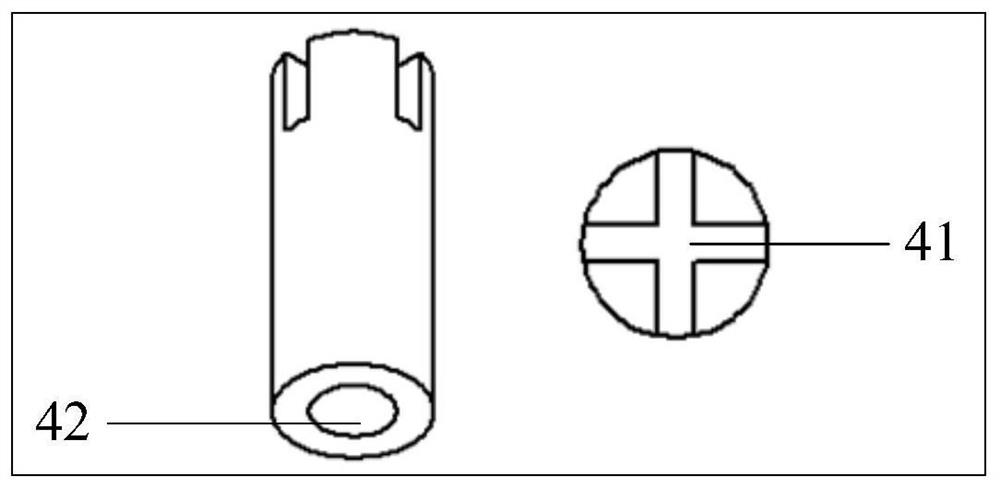

Self-stabilizing rapid-mounted bridge expansion and contraction device and mounting method thereof

PendingCN109853373AAchieve self-stabilizationFast constructionBridge structural detailsBridge engineeringEngineering

The invention belongs to the technical field of bridge engineering parts and specifically relates to a self-stabilizing rapid-mounted bridge expansion and contraction device and a mounting method thereof. The self-stabilizing rapid-mounted bridge expansion and contraction device specifically consists of symmetrically arranged bridge expansion and contraction device single bodies; a rubber strip for bridge expansion and contraction is arranged between the bridge expansion and contraction device single bodies; each bridge expansion and contraction device single bodies comprises a box body, a plurality of first sleeves and vertical pins, wherein the plurality of first sleeves are arranged in the box body, and the vertical pins are arranged in the first sleeves; the upper parts of the verticalpins are inserted and embedded into the first sleeves; glue injection holes are formed in the upper surface of the box body; and the glue injection holes communicate with the first sleeves. The self-stabilizing rapid-mounted bridge expansion and contraction device has the advantages of high quality, long service life, easy mounting, short mounting period, free maintenance, convenient changing, broad market application prospect and the like.

Owner:陕西融创交通科技有限公司

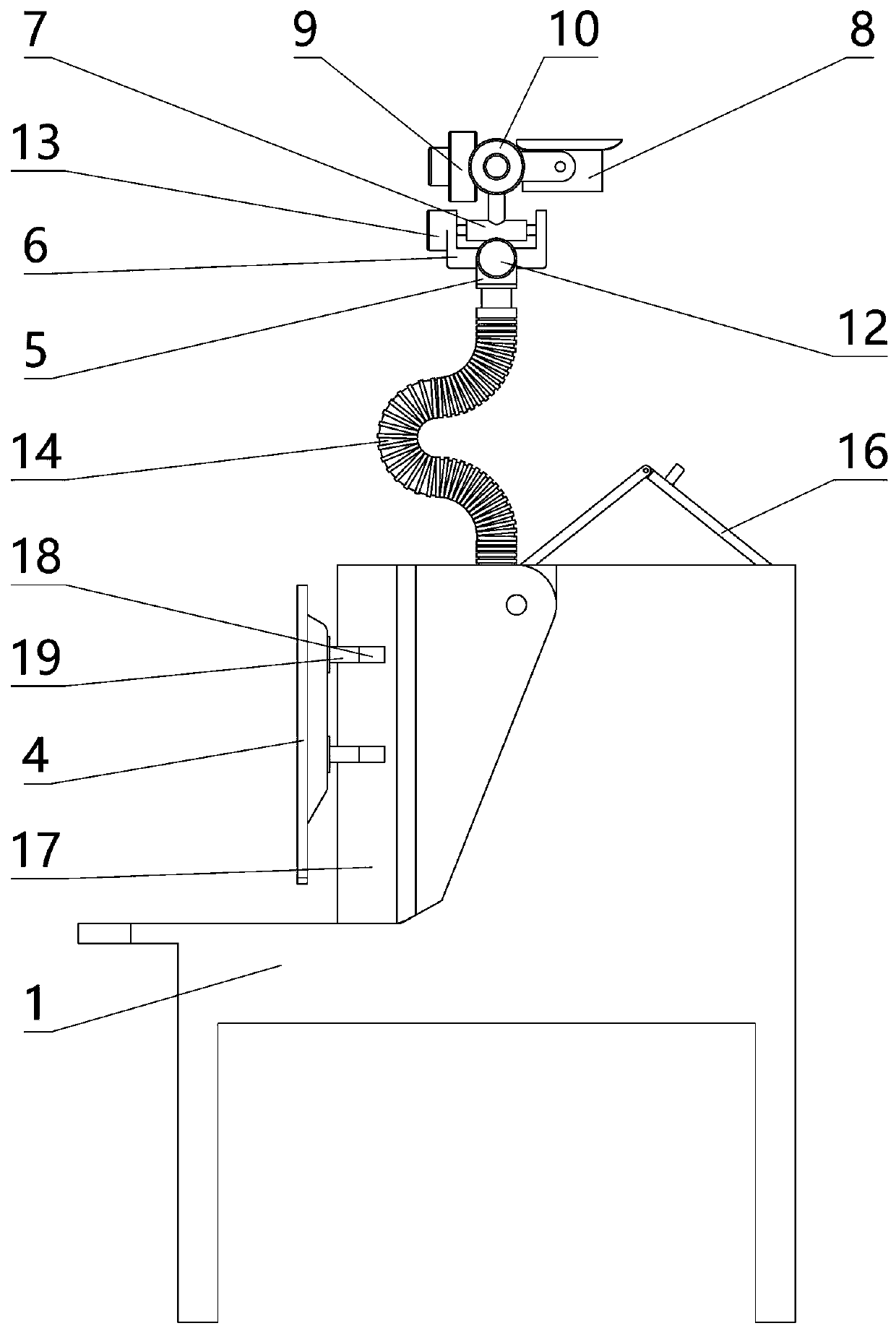

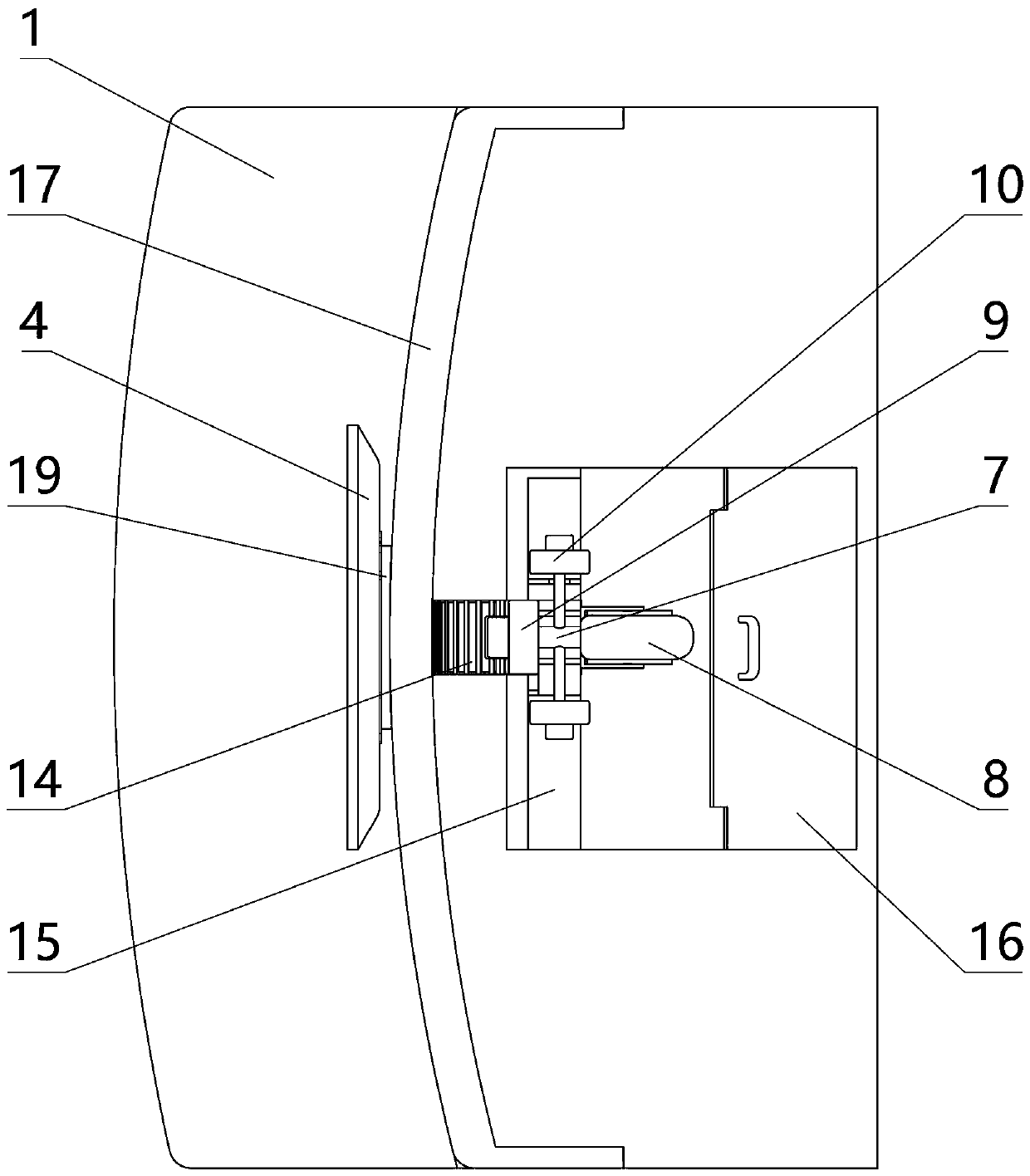

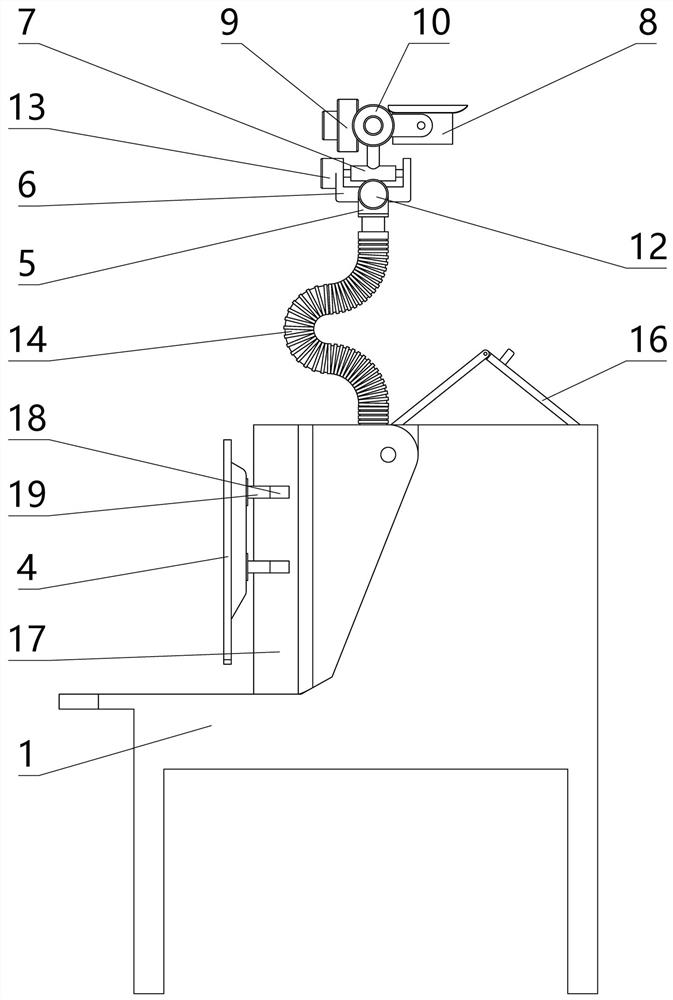

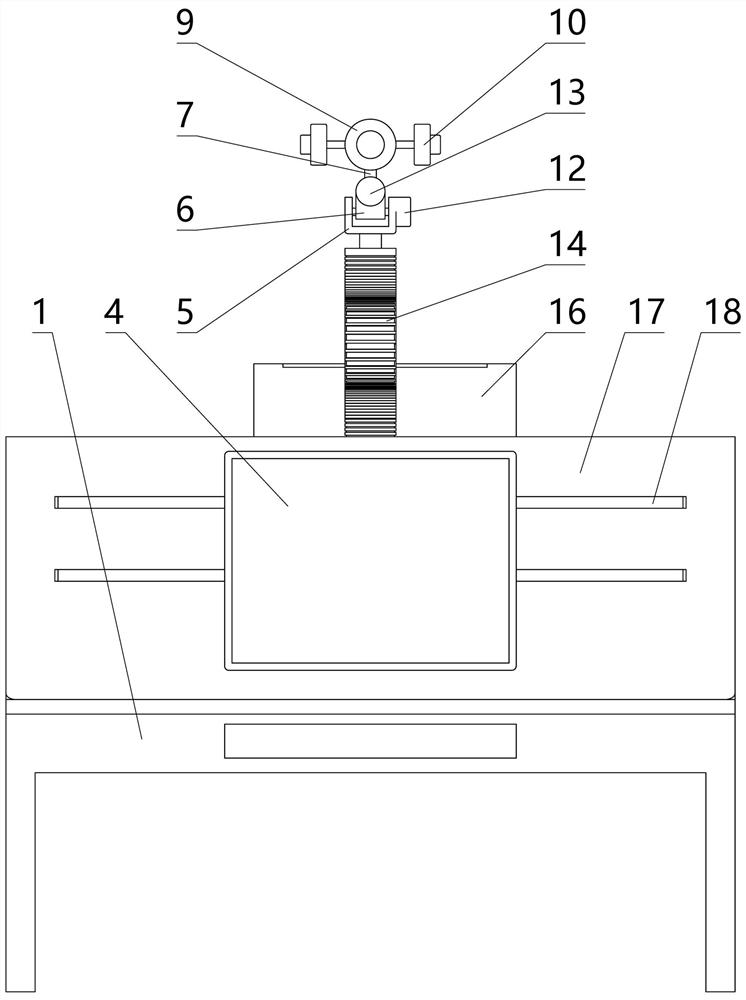

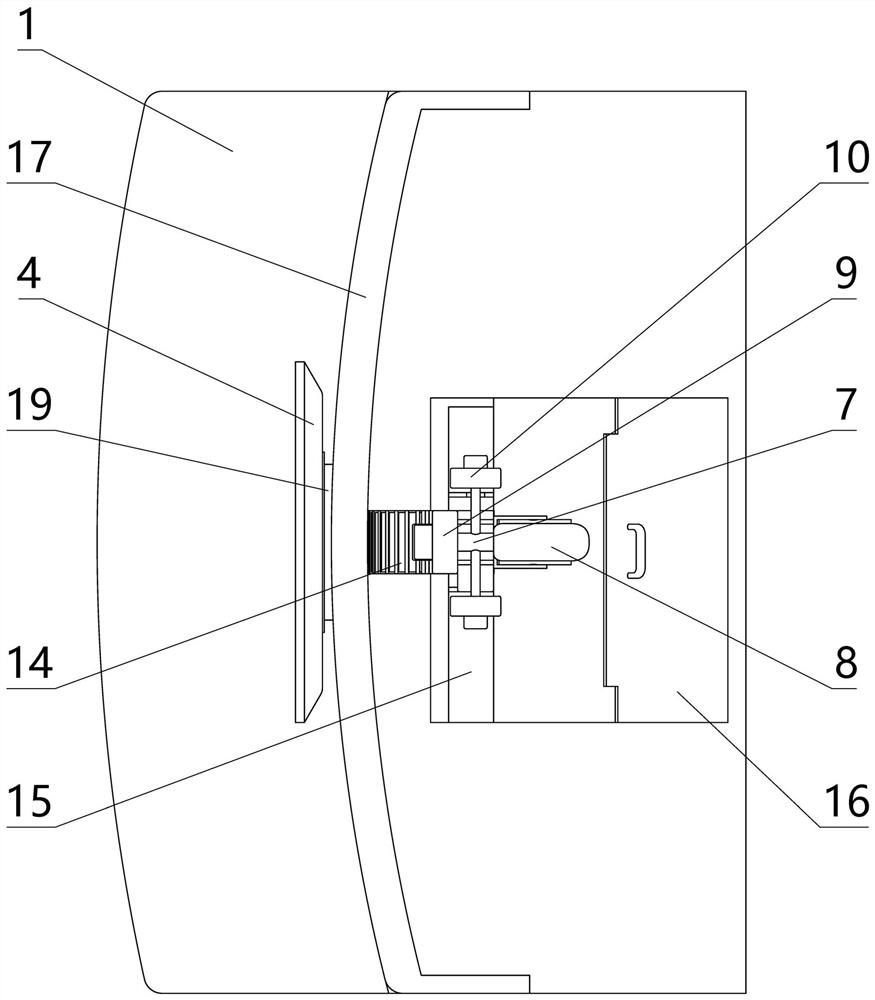

Multifunctional hyperspectral data acquisition device based on self-stabilization platform and measurement method thereof

ActiveCN109520617AHigh precisionImprove reliabilitySpectrum investigationAttitude controlData acquisition

The invention discloses a multifunctional hyperspectral data acquisition device based on a self-stabilization platform and a measurement method thereof. A traditional hyperspectral optical fiber probeand a multifunctional data sensor are integrated on a self-stability augmentation platform, so that attitude control and self-stabilization of the optical fiber probe can be well achieved, and information such as the attitude of the probe, the distance of a collected target object and an image of the target object is automatically collected together with hyperspectral data in a one-key mode during measurement. The device is simple and convenient to use; the error caused by the angle change of a handheld probe in the traditional ground object spectral measurement method is eliminated and the precision and reliability of the hyperspectral data are greatly improve; the device is suitable for the research of the hyperspectral observation angle, such as the measurement research of hyperspectral BRDF.

Owner:北京安洲科技有限公司

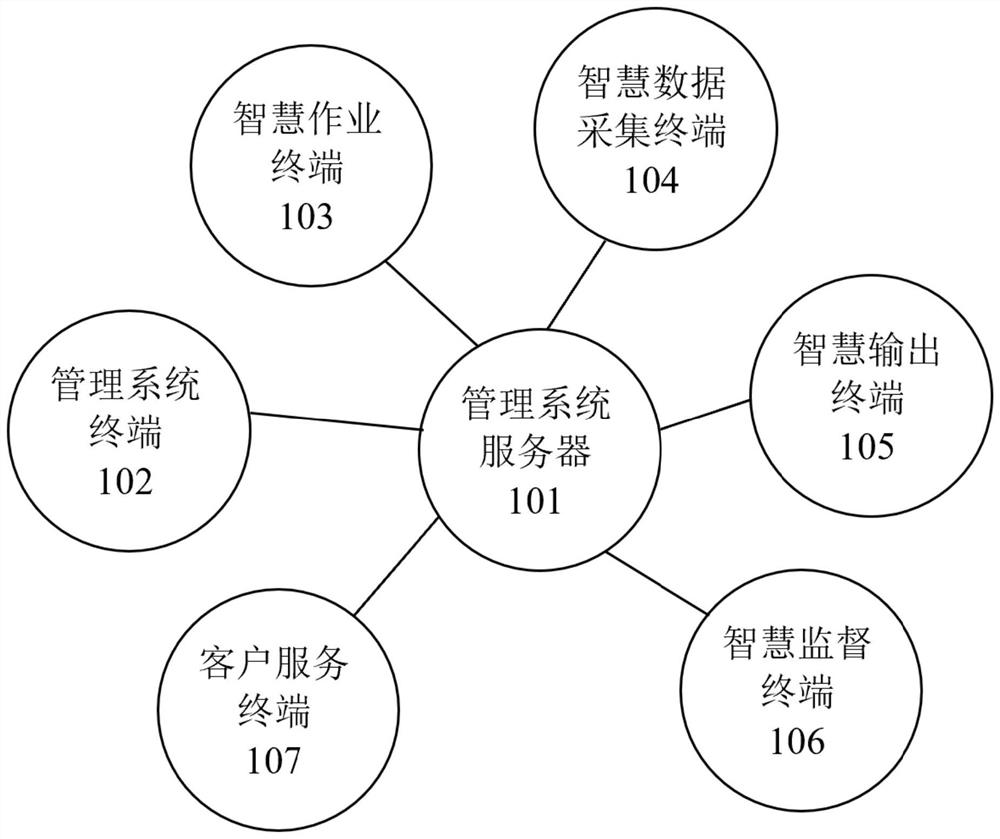

Engineering entity quality data management system and method

InactiveCN111754081AAchieve self-stabilizationReliable measurement dataDigital data authenticationResourcesInformatizationData information

The invention discloses an engineering entity quality data management system and method. The system comprises a management system server, a management system terminal, an intelligent operation terminal, an intelligent data acquisition terminal and an intelligent output terminal. Background personnel operate the management system terminal at a fixed office place to perform global management; an operator operates the intelligent operation terminal on site to be connected with the management system server, the intelligent data acquisition terminal acquires data information and automatically transmits the data information to the management system server through a network, and the operator automatically outputs a report through the intelligent output terminal after confirming that the data information is correct at the intelligent operation terminal. According to the invention, dynamic quality management of the whole process from construction to completion delivery is realized; in the usingstage, a user finds a quality problem, quality responsibility bodies of all parties are effectively traced and judged according to records, data are directly uploaded through paperless operation of informatization means, it is guaranteed that measured data are reliable, the evaluation process is clean and inexpensive, and a construction unit can master the project quality situation in real time.

Owner:深圳瑞捷工程咨询股份有限公司

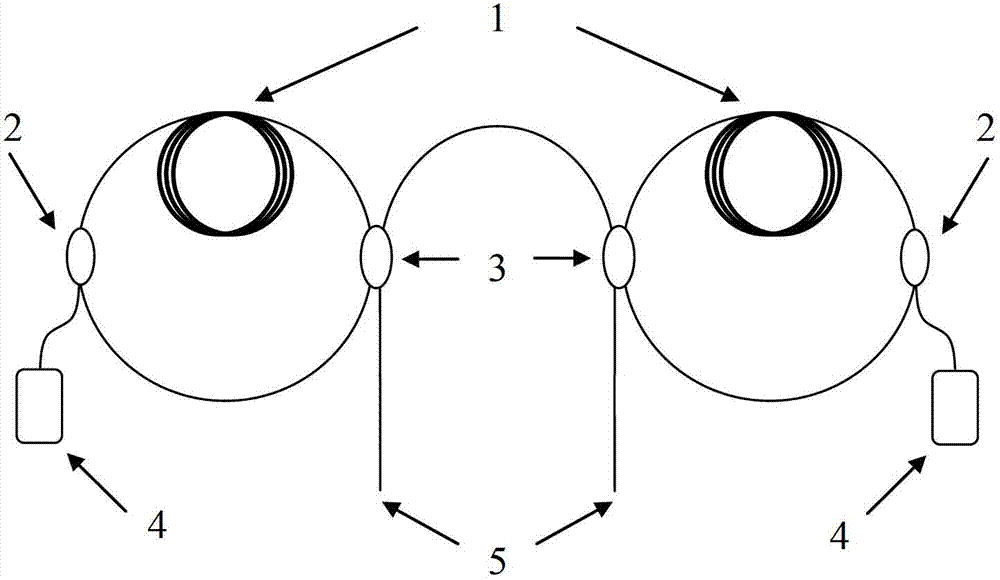

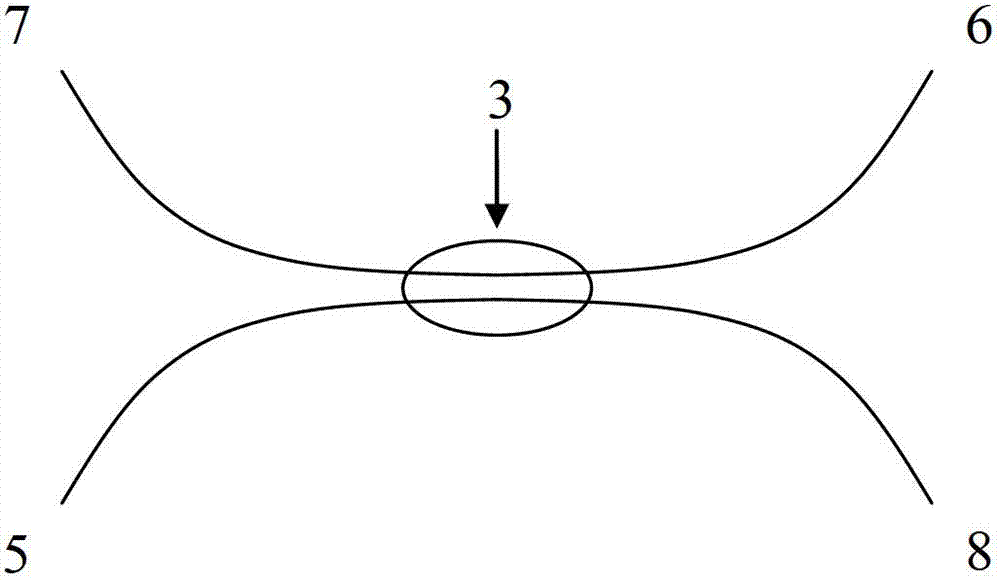

All-fiberized double-path ring laser

InactiveCN103094820AAchieve phase lockReduce volumeLaser arrangementsActive medium shape and constructionFiberBeam splitter

An all-fiberized double-path ring laser comprises two ring lasers with the same structure. Each ring laser is characterized in that two ends of a section of rare earth ion doped fiber are respectively connected with an output end of a pumping beam combiner and a second port of a 2*2 fiber beam splitter, and a third port of the 2*2 fiber beam splitter is connected with a second input end of the pumping beam combiner through a fiber so as to form each ring laser. An output end of a pumping source is connected with a first input end of each pumping beam combiner. Fourth ports of the two 2*2 fiber beam splitters of the ring lasers are connected through a fiber. First ports of the two 2*2 fiber beam splitters serve as laser output ends. The all-fiberized double-path ring laser is small in size, stable in structure, free of the requirements for isolators and fiber gratings, low in cost and capable of achieving self-stabilization of an output laser mode and phase locking of the two paths of the lasers without the requirements for active control.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Two-step preparation method of hollow silica particles

InactiveCN101823719AReduce application performance impactControl thicknessSilicaSilica particleReaction temperature

The invention relates to a two-step preparation method of hollow silica particles, comprising the following steps of: heating ammonia-water to 25-75 DEG C; slowly dripping a part of silica precursor in the ammonia-water for reaction for 5-10 minutes; then adding rest silica precursor at constant temperature; stirring for reaction for a couple of hours; and centrifuging, washing, and drying in vacuum to obtain hollow silica particles. In the system, the weight percentage: water and ammonia-water (25 percent) is 15-150: 1; and the weight percentage of water and silica precursor is 10-30: 1. The silica precursor which is firstly added accounts for 2-20 percent of total amount of silica precursor; and the reaction temperature is 25-75 DEG C.

Owner:NANJING UNIV

Underground excavation construction method for constructing subway station

ActiveCN111350513AAvoid problems prone to land subsidencePrevent subsidenceUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses an underground excavation construction method for constructing a subway station. The underground excavation construction method is characterized by including the following steps of S1, performing construction on the upper side of a soil body of a to-be-excavated area through a pipe roofing method to form an upper pipe roofing support; S2, performing primary metro jet systemconstruction on the two sides and the bottom of the soil body of the to-be-excavated area for pile driving and hole distributing; S3, dividing the to-be-excavated area into a plurality of excavationsections, and performing construction to drive pipe roofing pipes and freezing pipes into soil bodies between every two adjacent excavation sections and soil bodies on the two sides and the bottom ofthe to-be-excavated area through a pipe roofing method and a freezing method to form a freezing wall; and S4, performing excavating and supporting on each excavation section. By means of the construction method, the problem that the underground excavation construction cannot be applied under the conditions of shallow soil coverage and large structural section when the subway station is constructedin the prior art can be solved.

Owner:SHANGHAI MECHANIZED CONSTR GRP

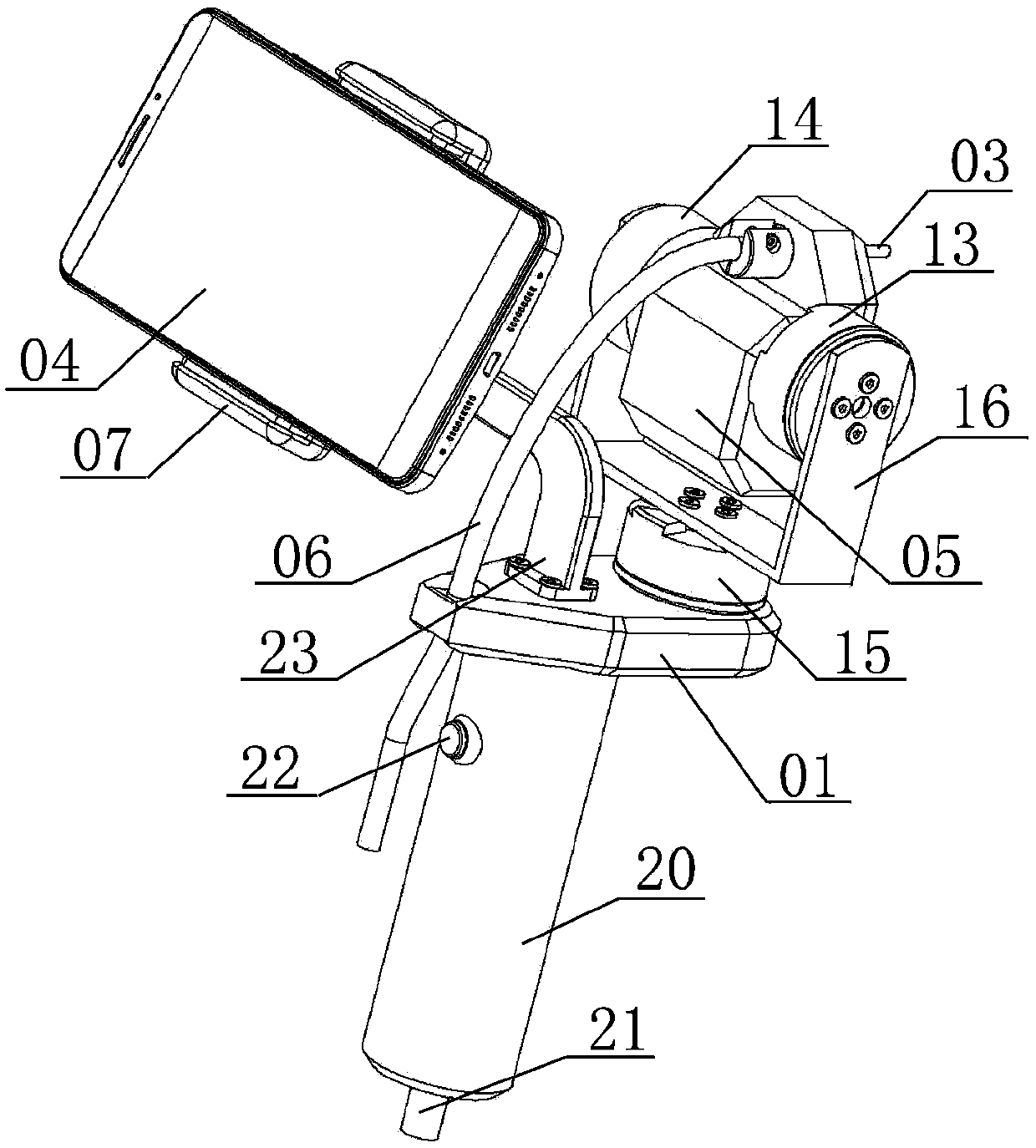

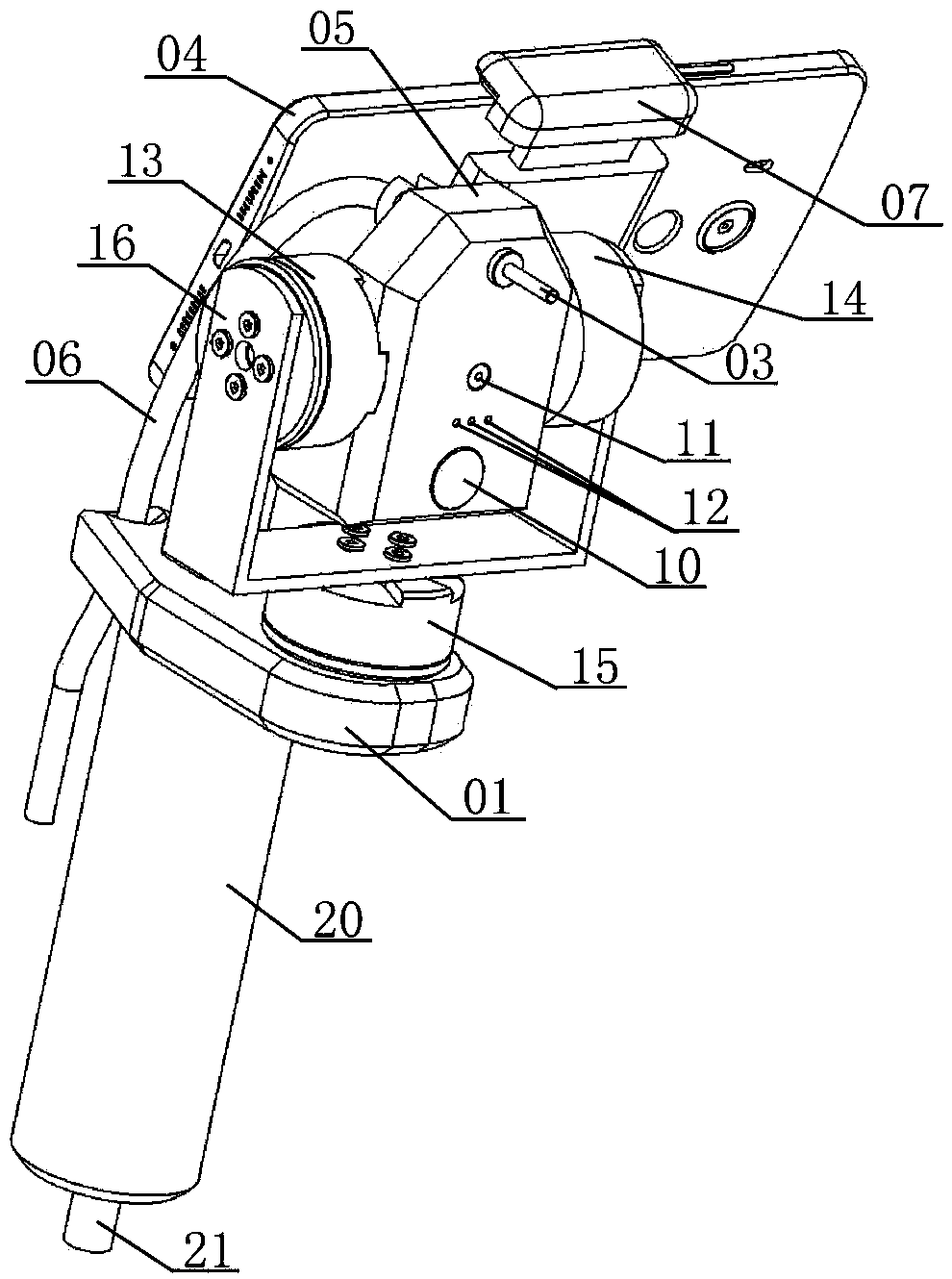

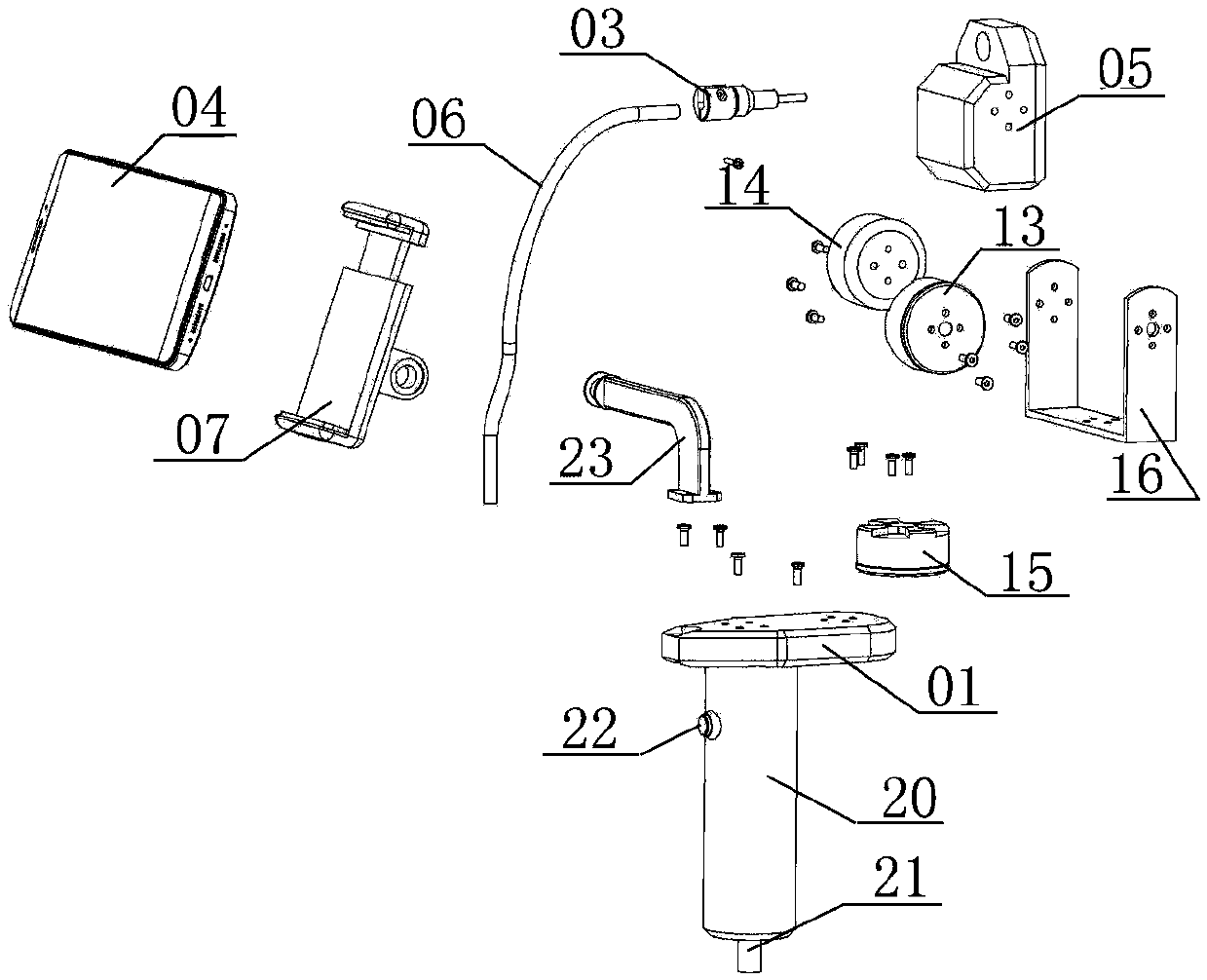

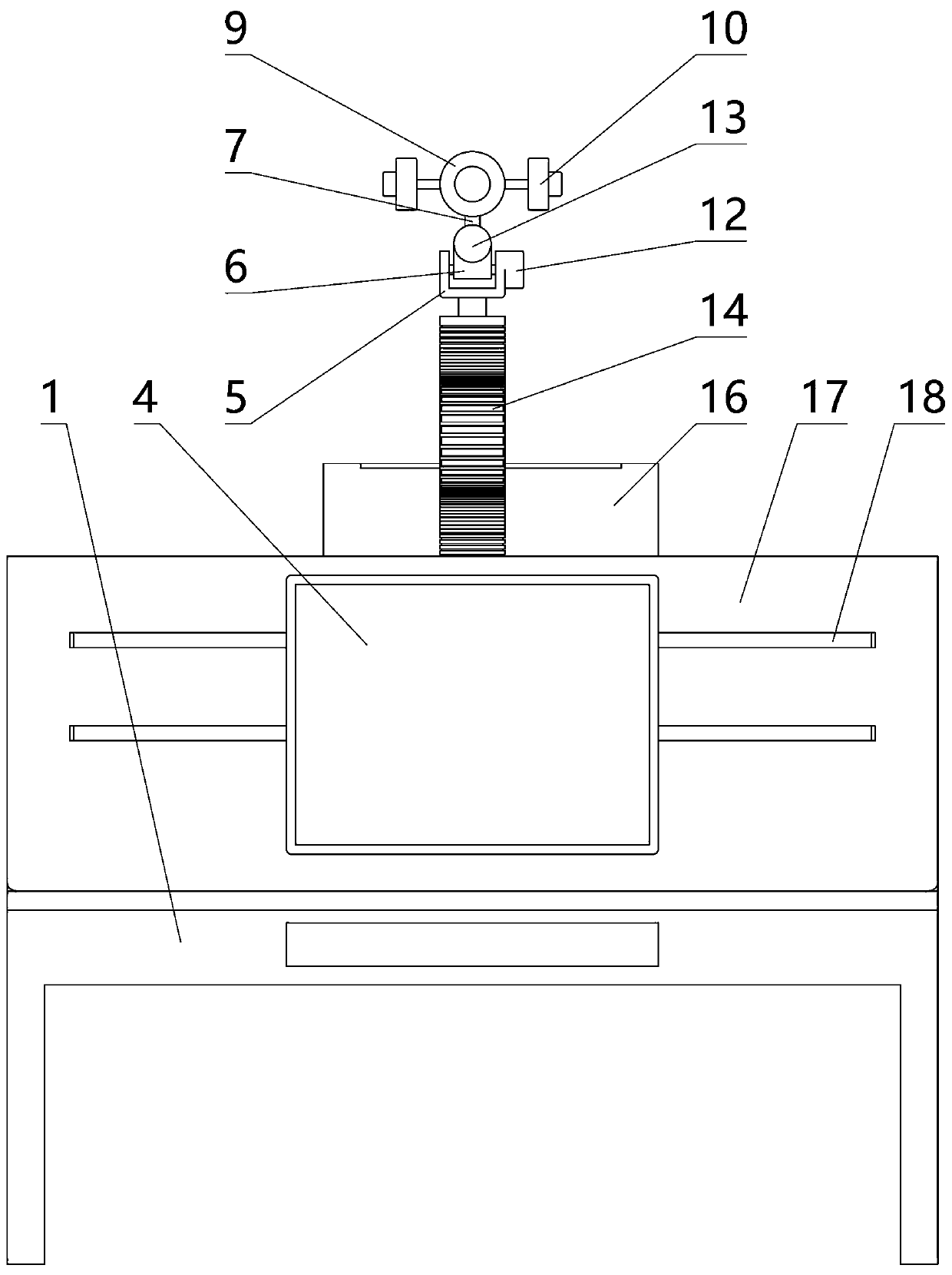

A computer-based digital image processing platform

ActiveCN109714537AAchieve self-stabilizationPrevent accidental shakingProgramme controlTelevision system detailsResonanceVideo record

The invention relates to a computer-based digital image processing platform, which comprises a bearing platform; a processor, a filter and a display are arranged on the bearing platform; a first bracket rotationally connected along a vertical axis is arranged on the bearing platform, a second bracket rotationally connected through a front-and-back axis is arranged on the first bracket, and a thirdbracket rotationally connected along a horizontal axis is arranged on the second bracket; The third bracket is provided with video recording equipment with a horizontally arranged axis and a first rotor, the third bracket is provided with a second rotor with a front axis and a rear axis, and the first rotor and the second rotor are respectively driven by a motor; A first torque motor coaxially connected with the front axis and the rear axis of the second support is arranged on the first support, and a second torque motor coaxially connected with the left axis and the right axis of the third support is arranged on the second support. The second bracket, the third bracket, the video recording equipment, the first rotor, the second rotor, the motor and the second torque motor form a self-stabilization video recording system; Accidental jitter of the video recording equipment can be prevented, and jitter or resonance does not exist when the video recording equipment steers.

Owner:广州科慧健远科学研究院有限公司

Computer-based digital image processing platform

ActiveCN109714537BAchieve self-stabilizationPrevent accidental shakingProgramme controlTelevision system detailsTorque motorDisplay device

The invention relates to a computer-based digital image processing platform, which includes a bearing platform, on which a processor, a filter and a display are installed, on the bearing platform there is a first bracket that is rotatably connected along a vertical axis, on the first bracket there is a The second bracket is pivotally connected to the axis, and the third bracket is pivotally connected along the horizontal axis on the second bracket; the camera equipment and the first rotor are arranged horizontally on the third bracket, and the third bracket is arranged on the third bracket. Two rotors, the first rotor and the second rotor are respectively driven by motors; the first torque motor is coaxially connected with the front and rear axes of the second support on the first support, and the left and right axes of the third support are coaxial on the second support The connected second torque motor; the second support, the third support, the recording device, the first rotor, the second rotor, the motor and the second torque motor form a self-stabilizing recording system; the invention can prevent the accidental shaking of the recording device , and there is no vibration or resonance when the camera turns.

Owner:广州科慧健远科学研究院有限公司

Centrifugal force pendulum device, and drive train of motor vehicle

ActiveCN104937306AReliable holdUniform force loadingRotating vibration suppressionEngineeringCentrifugal force

The invention relates to a centrifugal force pendulum device (10), comprising a pendulum mass carrier (11) that can be rotated about an axis of rotation (15) and at least one pendulum mass (12), which is supported on the pendulum mass carrier (11) in such a way that the pendulum mass (12) can be moved along a track (18) between two end stops (19, 20) that are arranged at a distance from each other in the circumferential direction with respect to the axis of rotation (15). A spring device (23) is provided, which is designed to push the pendulum mass (12) into one of the end stops (19, 20) when the rotational speed of the pendulum mass carrier (11) about the axis of rotation (15) is below a rotational speed limit. The invention further relates to a drive train (1) of a motor vehicle.

Owner:AUDI AG

A curved-wing aircraft capable of spiral flight

InactiveCN103847964BRealize short takeoff and landingAchieve self-stabilizationAircraftsFly controlShortest distance

The invention discloses an arc-shaped wing aircraft capable of helical flying. The arc-shaped wing aircraft is characterized in that a central machine body adopts a single arc-shaped wing, the two sides of the arc-shaped wing aircraft are provided with straight wings, and the arc-shaped wing and the straight wings are in a straight flying wing layout in the horizontal direction; two flying modes such as helical-wing flying and straight-wing flying are adopted, the flying process can be controlled, and the short-distance taking off and landing can be achieved; in the taking-off and landing process, the helical type roll-flying action is finished by thrust differential of two ducted type engines, and the short-distance taking off and landing can be realized; the aircraft also has a normal fixed-wing rolling taking-off and landing; the aircraft flies in a helical manner, the arc-shaped wing and the straight wings are wholly regarded as single rotating wings, then the aircraft rotates around the axis of the helical-flying track, and lifting force capable of controlling the flying is provided for the aircraft; lifting ailerons are used for controlling the taking-off and landing of the aircraft, and the flying control in the horizontal direction is dependent on thrust differential and the lifting ailerons of the two groups of ducted type engines; the self stability of an inherent longitudinal and horizontal flying mode of the aircraft is realized by the arc-shaped wings and the dihedral straight wings.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

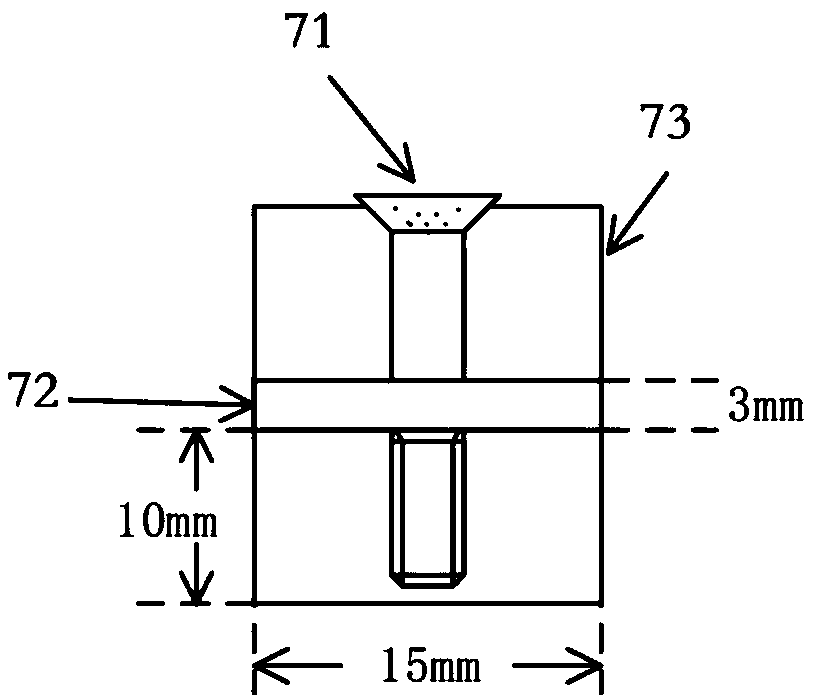

Self-stabilizing bridge expansion and contraction device and installation method thereof

PendingCN109853374AAchieve self-stabilizationFast constructionBridge structural detailsBridge engineeringQuality standard

The invention belongs to the technical field of bridge engineering parts, and particularly relates to a self-stabilizing bridge expansion and contraction device and an installation method thereof. Theself-stabilizing bridge expansion and contraction device is composed of symmetrically arranged bridge expansion and contraction device single-bodies, and a rubber strip for bridge expansion and contraction is arranged between the symmetrically arranged bridge expansion and contraction device single-bodies. Each bridge expansion and contraction device single-body comprises a box body, a pluralityof first sleeves arranged in the box body and vertical pins arranged in the first sleeves, internal threads matched with the vertical pins are arranged on the inner sides of the first sleeves, the upper parts of the vertical pins are connected with the first sleeves through threads, and the first sleeves vertically penetrate through the upper surface and the lower surface of the box bodies. The self-stabilizing bridge expansion and contraction device has the advantages of standardized quality, long service life, easy installation, short installation period, no nursing, convenient replacement and the like, and has wide market application prospect.

Owner:陕西融创交通科技有限公司

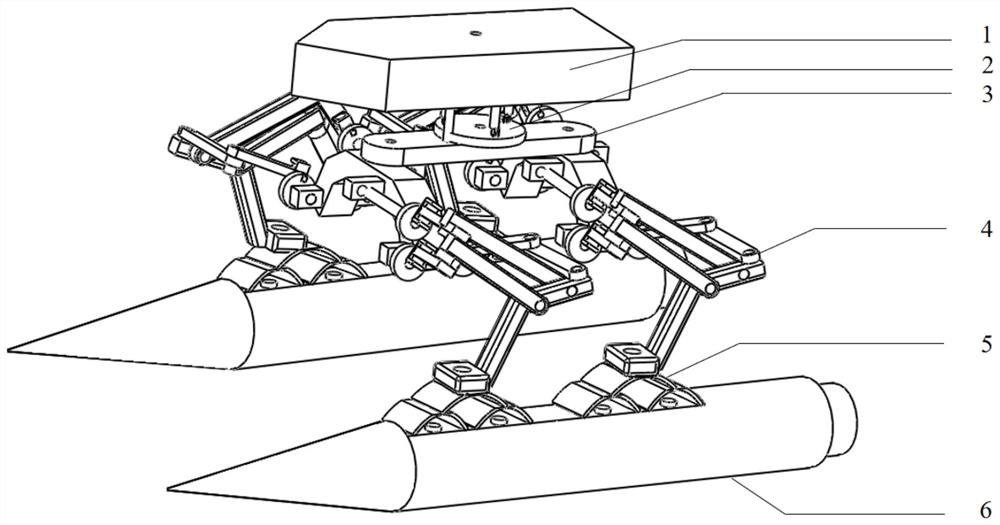

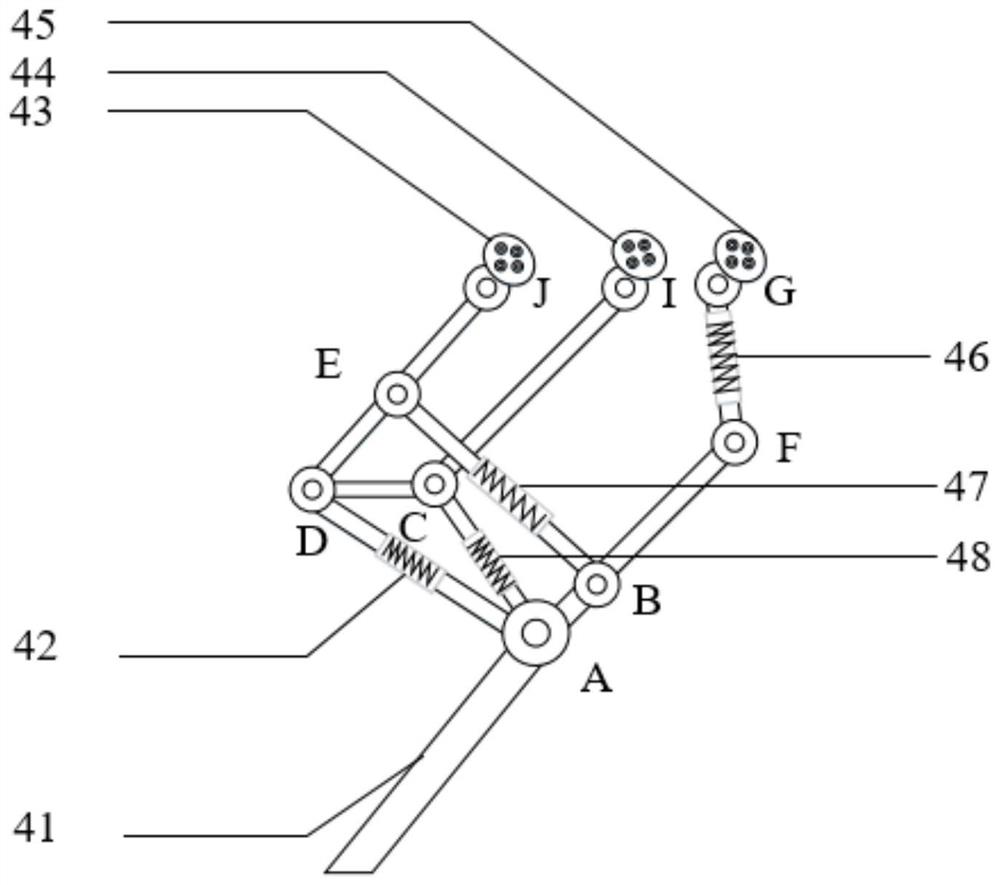

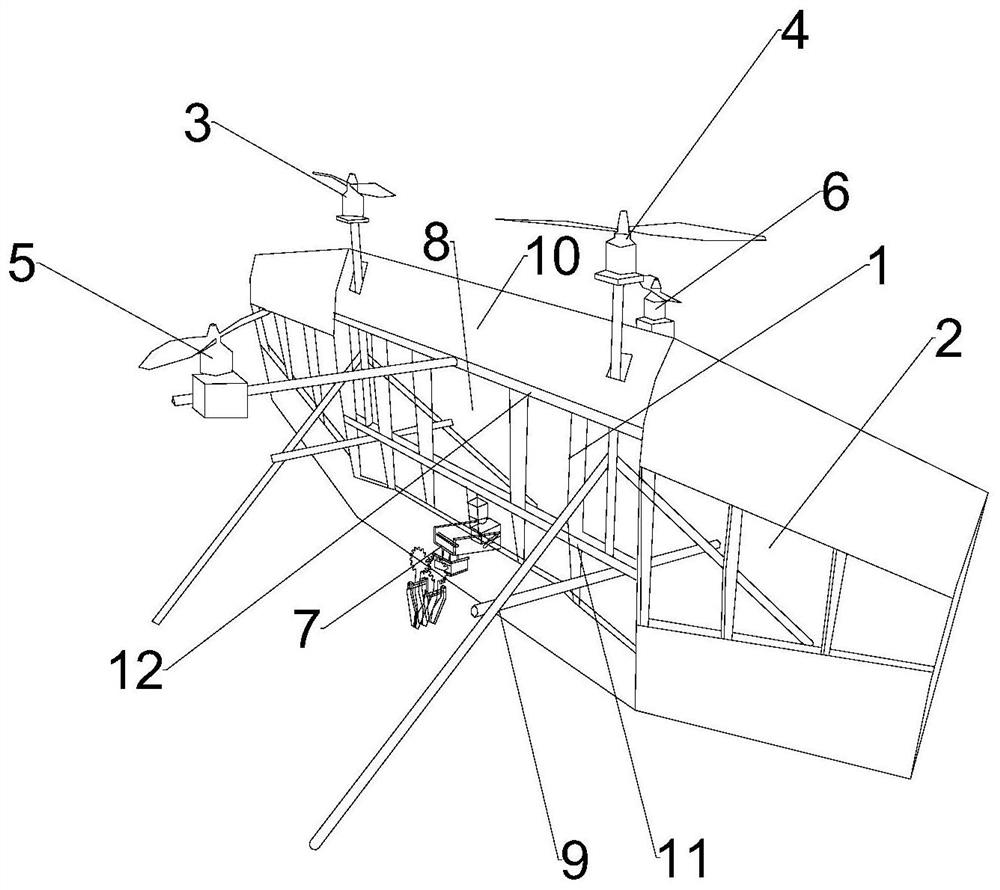

An unmanned ship with three-stage shock absorption and self-stabilization system

ActiveCN109911114BHigh speed sailingSmooth sailingNavigational aid arrangementsNon-rotating vibration suppressionBuoyMechanical engineering

The invention discloses an unmanned ship with a three-stage damping self-stabilizing system. The unmanned ship with the three-stage damping self-stabilizing system comprises double long buoys, dampingbases, cat-like connecting rod type leg damping structures, a six-degree-of-freedom hydraulic self-stabilizing device and a ship cabin, wherein the double long buoys are provided with the four damping bases, the bottom end of each cat-like connecting rod type leg damping structure is connected with the corresponding damping base, and the top end of each cat-like connecting rod type leg damping structure is connected with a connecting bridge; and the six-degree-of-freedom hydraulic self-stabilizing device is arranged on the connecting bridge, and the ship cabin is mounted on the six-degree-of-freedom hydraulic self-stabilizing device. The invention provides an unmanned ship design scheme with a three-stage damping system on the basis of the current situation of application and research ofthe unmanned ship. Through the design of a base damping structure, high-speed navigation under low-amplitude surge is realized; and through the design of the cat-like connecting rod type leg damping mechanisms, stable navigation under high-amplitude surge is realized. According to the unmanned ship with the three-stage damping self-stabilizing system, a bionic structure design is added, and the cat-like connecting rod type leg structures are used as four supports of the unmanned ship, so that the stability and the damping effect of a ship body are improved.

Owner:DALIAN MARITIME UNIVERSITY

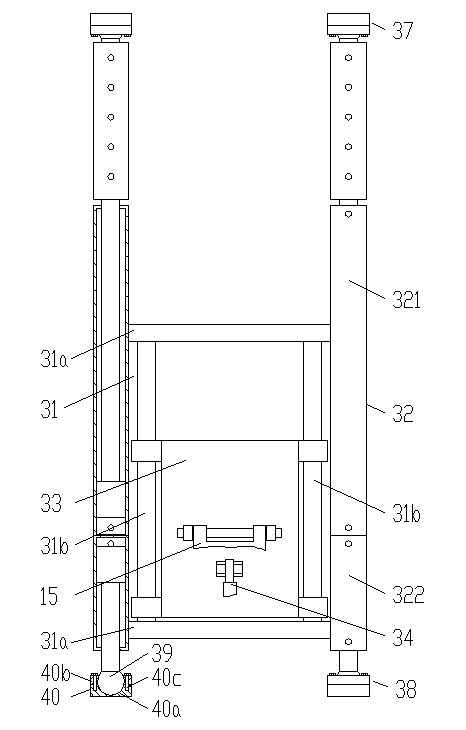

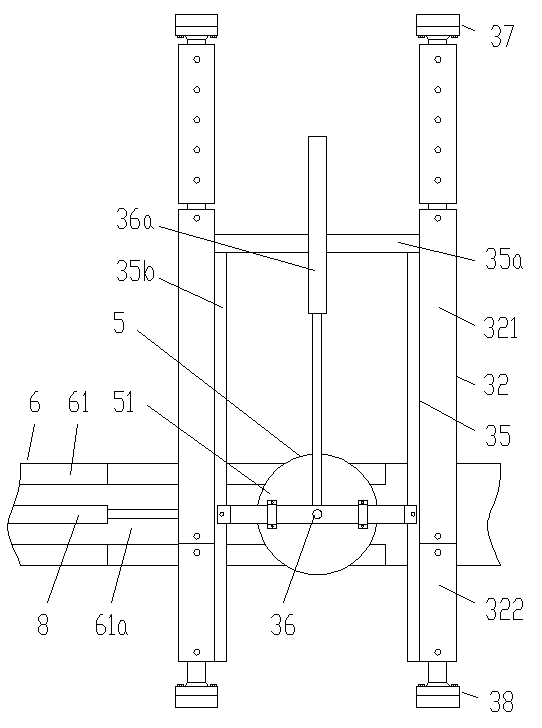

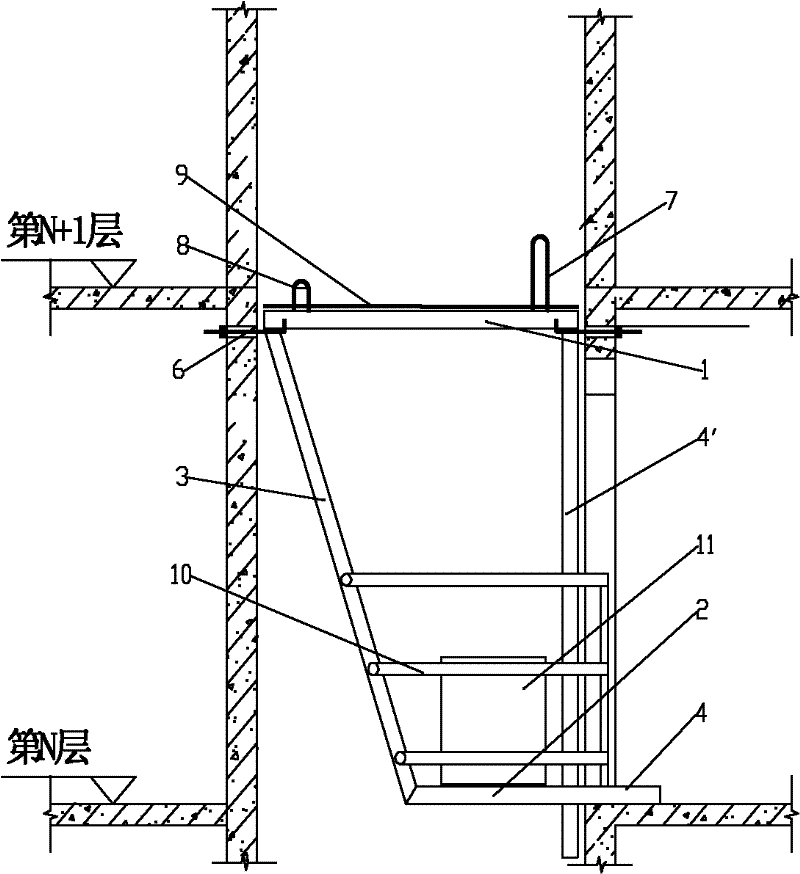

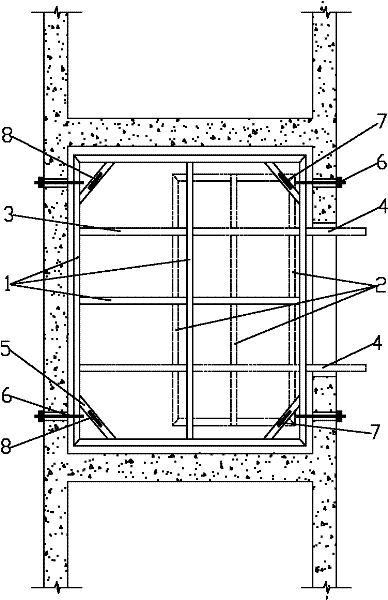

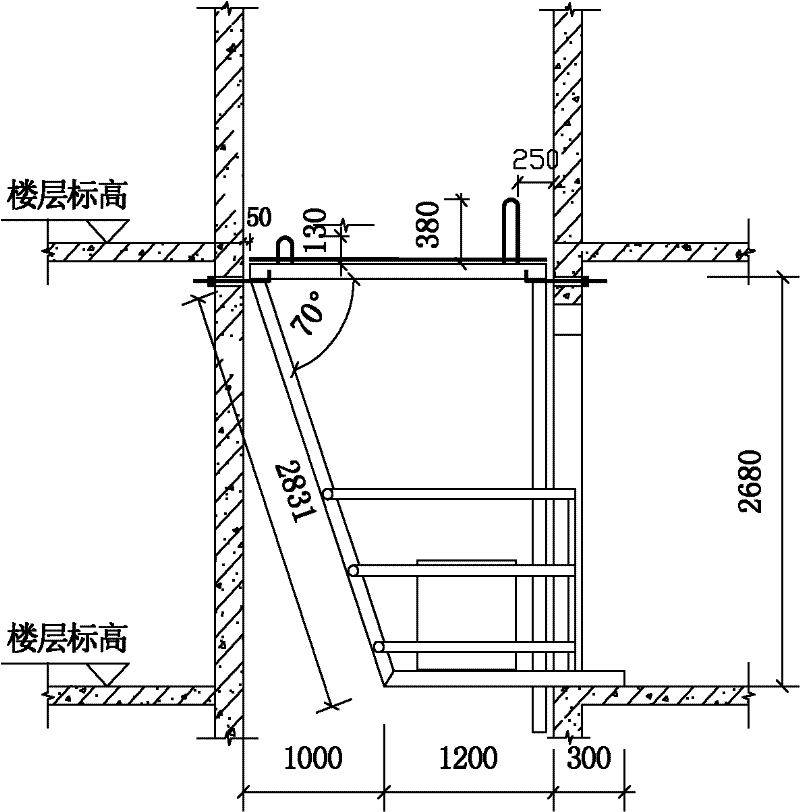

Self-stabilizing operating platform for elevator shaft

ActiveCN102121307BImprove securityIncrease profitBuilding support scaffoldsVertical planeSmallerThan

Owner:CHINA RAILWAY CONSTR ENG GRP

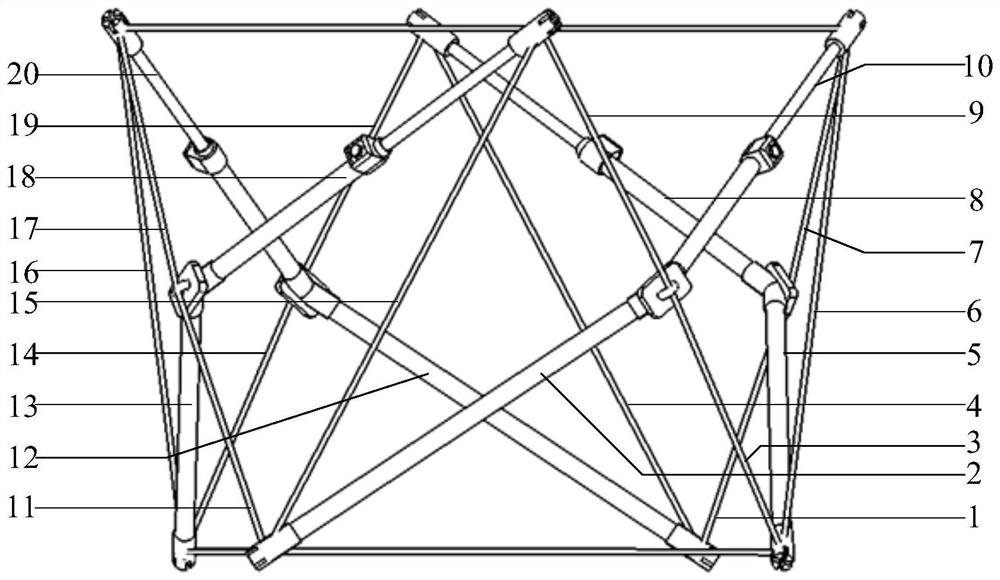

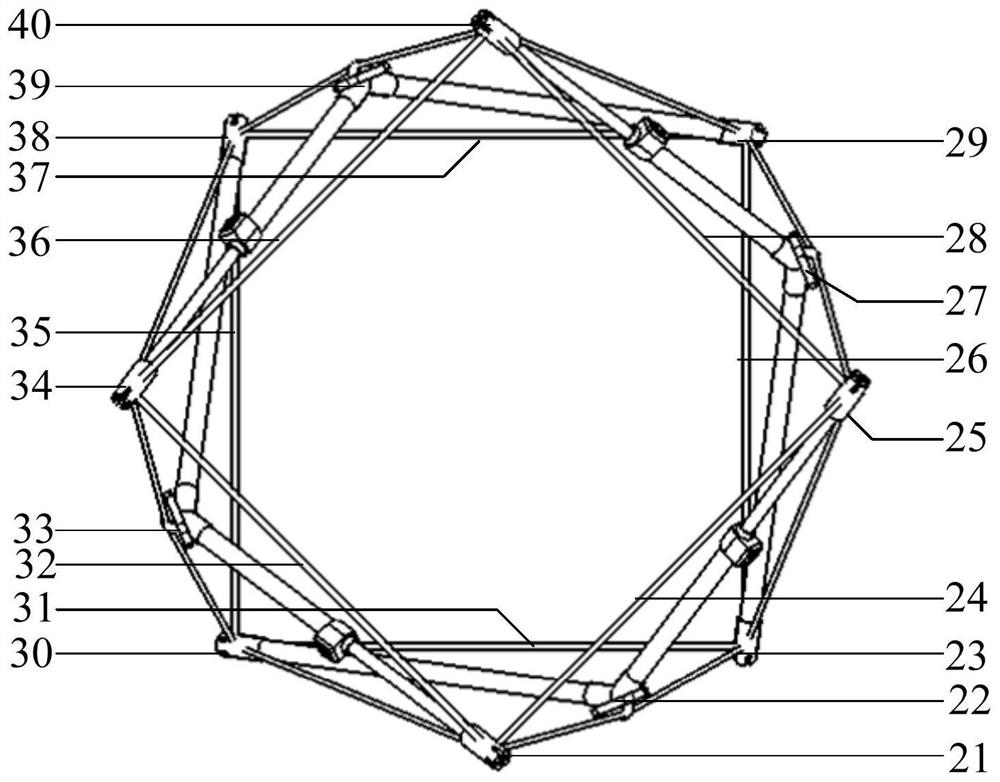

A foldable tent based on a tensegrity structure

ActiveCN111206819BAchieve foldingAchieve self-stabilizationTents/canopiesClassical mechanicsStructural engineering

Owner:HARBIN ENG UNIV

A vertical take-off and landing fixed-wing cargo drone

ActiveCN109080825BLower center of gravityInstant attitude changeVertical landing/take-off aircraftsLevel flightControl signal

The invention provides a vertical take-off and landing fixed-wing cargo unmanned aerial vehicle, which includes a fuselage, a mechanical arm is mounted under the middle beam of the fuselage, a cargo warehouse is arranged above, and winglets and landing gear are symmetrically installed on both sides. The first landing gear is A-shaped, the braces of the two landing gears are fixed to the middle beam through connecting rods, the first power system parallel to the fuselage is fixedly connected to the middle beam through the first carbon rod, and the second power system perpendicular to the fuselage The system is fixedly connected to the upper beam of the fuselage through the second carbon rod. An equipment compartment is arranged above the upper beam. The flight control, receiver, GPS and battery are loaded in the equipment cabin. The flight control signal is connected to the receiver and GPS, and the battery Power the flight controller, receiver and GPS. The vertical take-off and landing fixed-wing cargo unmanned aerial vehicle described in the present invention combines the advantages of the rotary-wing unmanned aerial vehicle and the fixed-wing unmanned aerial vehicle. Greatly increased cruising range.

Owner:天津零一智能科技有限责任公司

Wheel type truck-mounted drilling rig

ActiveCN103277046BEasy to moveSolve the problem of slippageDrilling machines and methodsEngineeringTruck

The invention discloses a wheel type truck-mounted drilling rig which is characterized in that a movable frame with a drilling device is disposed on a body, the body comprises a mining flatbed truck and a hydraulic winch, a support seat is disposed on the mining flatbed truck, a support beam which is used for allowing the movable frame to be horizontal is disposed on the support seat, a guide rail clamp is further disposed on the mining flatbed truck, the movable frame comprises a #-shaped frame, two ends of the two crossbeams of the #-shaped frame are fixedly connected with main support oil cylinders, two longitudinal beams of the #-shaped frame forms two parallel guide rails which are in slide fit with a movable support, the movable support is hinged to the outer end of the support beam, a vertical oil cylinder which is used for allowing the movable frame to be vertical is connected between the movable support and the support seat, an n-shaped frame is fixedly connected between cylinder bodies the two main support oil cylinders, and a drilling rig turn plate is disposed between the n-shaped frame and the drilling device. The wheel type truck-mounted drilling rig has the advantages that the wheel type truck-mounted drilling rig can be moved in a tunnel without damaging sleepers, the drilling rig is good in rigidity, and drilling hole positions can be adjusted conveniently.

Owner:重庆市能源投资集团科技有限责任公司 +1

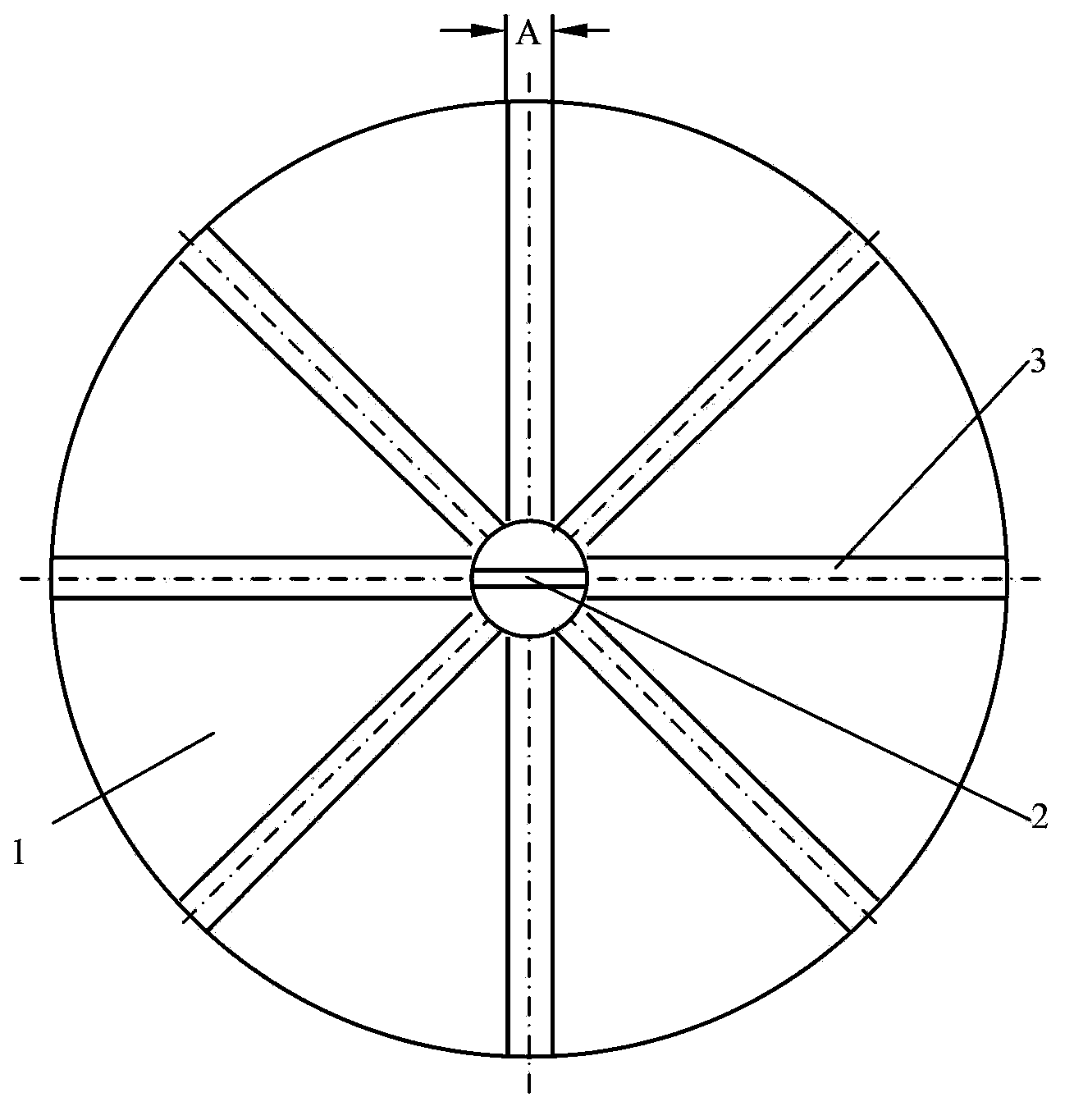

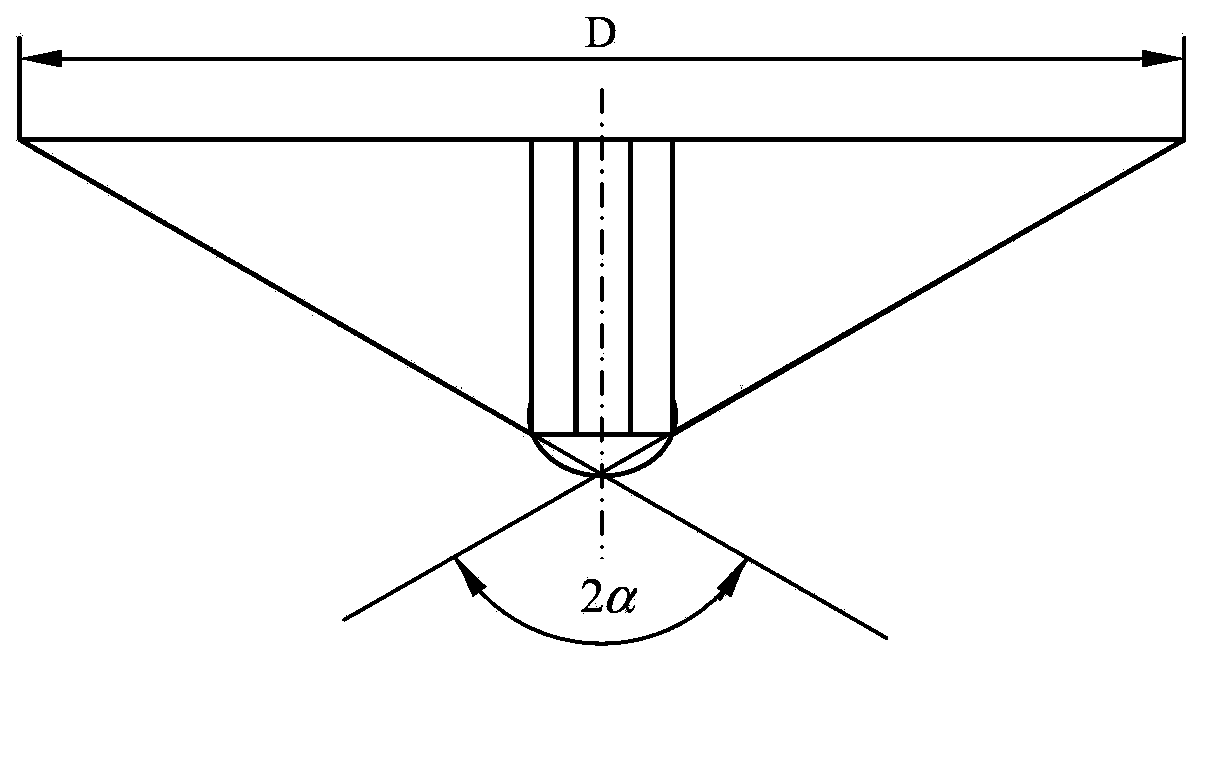

Conical cutter head of a shield machine

ActiveCN102839978BIncrease profitImprove work efficiencyTunnelsStatic friction coefficientWork performance

The invention belongs to the technical field of design of shield tunneling machine cutters, in particular to a tapered cutter of a shield tunneling machine. The cutter, spokes and a shell-shaped tool rest form a tapered structure, and a cone-apex half angle alpha is less than or equal to arctanf, wherein alpha is the cone-apex half angle, and f is the static friction coefficient between the cutter of the shield tunneling machine and a boulder. The spokes are distributed uniformly, the number N of the spokes is an integer, A is the width of the spokes, B is less than min (L, W, H), and L, W, H are determined by geological exploration information, where L is the maximal size of the boulder above in the length direction, W is the maximal size of the boulder above in the width direction and H is the maximal size of the boulder above in the height direction. According to the scheme, the rigidity of the cutter is improved, the interaction between a tool and the boulder is lowered, and the working performance of a shield is effectively improved; furthermore, the energy consumption during boosting can be effectively reduced under the condition of the same tunneling quantity; and the working efficiency can be improved and the energy consumption can be reduced by about 5 percent respectively by preliminary estimation, so that the utilization rate of the shield tunneling machine is effectively improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

A kind of underground excavation construction method for constructing subway station

ActiveCN111350513BAvoid problems prone to land subsidencePrevent subsidenceUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a construction method for underground excavation of a subway station, which is characterized in that it comprises the following steps: S1: using the pipe shed method to construct above the soil in the area to be excavated to form the upper pipe shed support; S2: The two sides and the bottom of the soil body in the area to be excavated are carried out for the first time in all-round high-pressure spraying method construction to carry out piling and hole layout; S3: divide the area to be excavated into a plurality of excavation intervals, and use the pipe shed method and freezing The method carries out construction to the soil between the adjacent described excavation intervals, and the soil on both sides and bottom of the area to be excavated into pipe shed pipes and frozen pipes to form frozen walls; S4: for each Excavation and support are carried out in the excavation section; this construction method can solve the problem that the prior art underground excavation method cannot be applied when the covering soil is relatively shallow and the structural section is large when constructing the subway station.

Owner:SHANGHAI MECHANIZED CONSTR GRP

Two-step preparation method of hollow silica particles

The invention relates to a two-step preparation method of hollow silica particles, comprising the following steps of: heating ammonia-water to 25-75 DEG C; slowly dripping a part of silica precursor in the ammonia-water for reaction for 5-10 minutes; then adding rest silica precursor at constant temperature; stirring for reaction for a couple of hours; and centrifuging, washing, and drying in vacuum to obtain hollow silica particles. In the system, the weight percentage: water and ammonia-water (25 percent) is 15-150: 1; and the weight percentage of water and silica precursor is 10-30: 1. The silica precursor which is firstly added accounts for 2-20 percent of total amount of silica precursor; and the reaction temperature is 25-75 DEG C.

Owner:NANJING UNIV

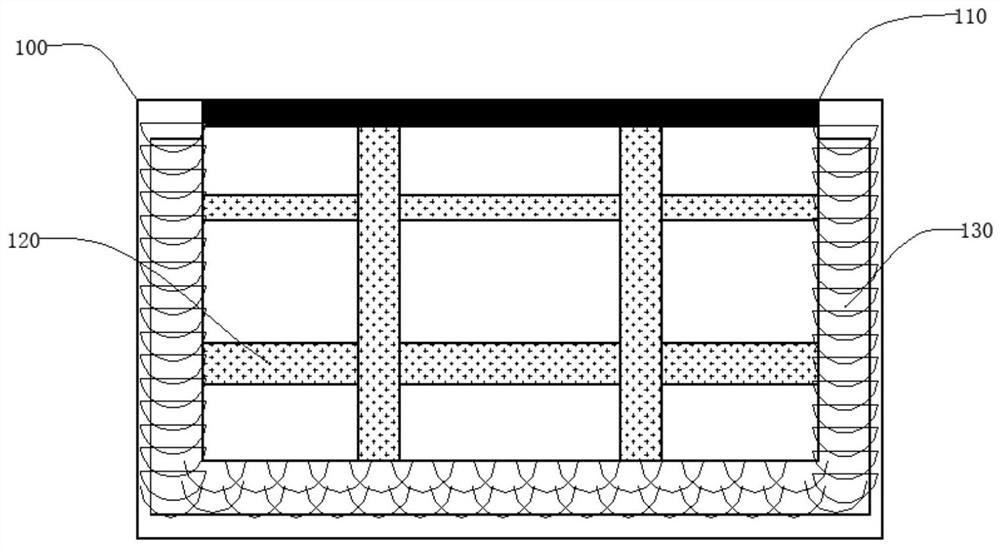

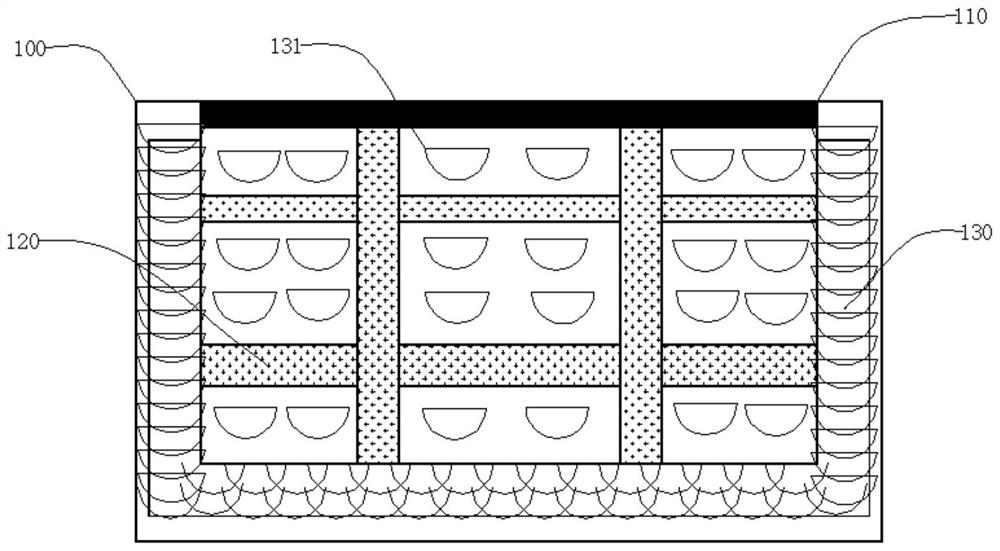

Combined prefabricated retaining wall square pile foundation pit supporting structure and construction method thereof

PendingCN113322971AReduce cut and fillIncrease the usable areaExcavationsBulkheads/pilesFertilizerStructure support

The invention discloses a combined prefabricated retaining wall square pile foundation pit supporting structure and a construction method thereof. A stirring pile, a prefabricated pile, a connecting steel component, an externally-hung steel component and micro-expansion concrete are constructed to form a water-stopping and soil-retaining integrated underground retaining wall, so that supporting stability is provided for a foundation pit, and the foundation pit can be quickly and safely excavated within the enclosure range of the underground retaining wall; and in addition, an externally-hung part of the externally-hung steel component is used for being externally hung on a lining wall of a basement, a fertilizer groove needed by the lining wall of the basement during conventional construction can be omitted, excavation and filling of the foundation pit are reduced, the using area of the basement is enlarged, lining wall embedded steel bars of the basement can be reduced or even omitted, the underground retaining wall can serve as a permanent structure and does not need to be disassembled, the underground retaining wall can also serve as an outer wall of the basement in the construction stage and the using stage, and the construction cost is remarkably reduced. The combined prefabricated retaining wall square pile foundation pit supporting structure and the construction method thereof have the advantages of being safe, short in construction period and low in construction cost.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

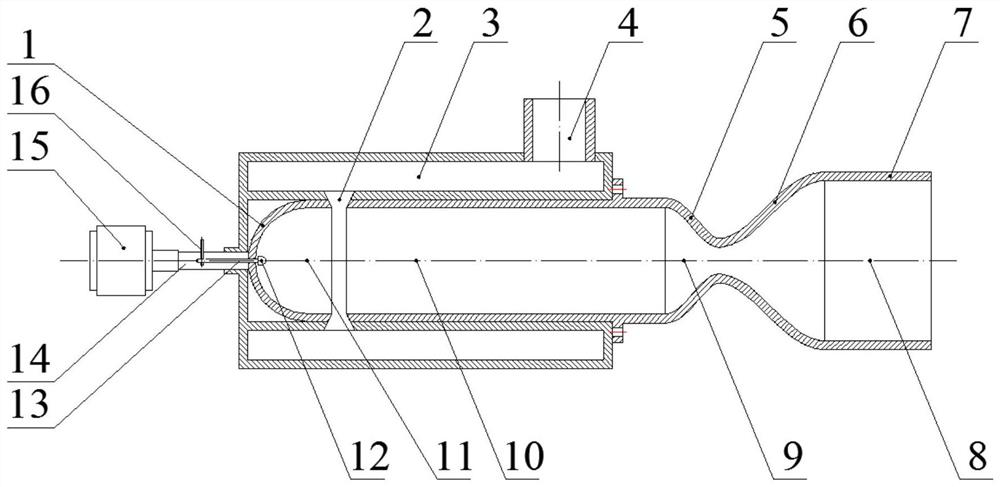

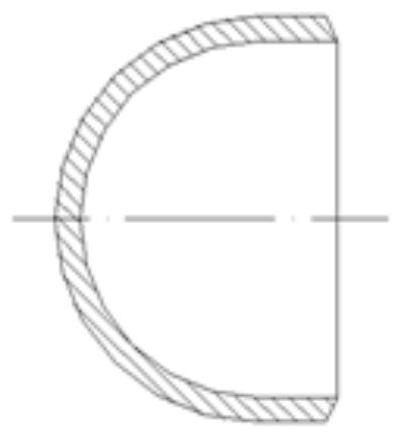

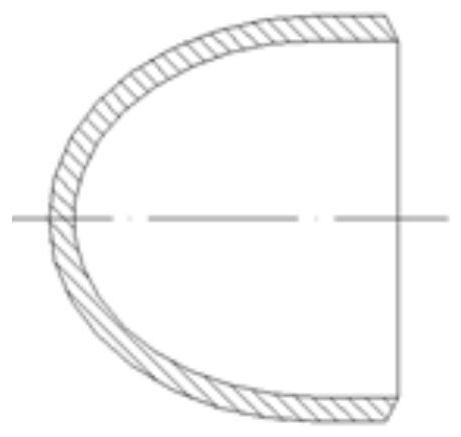

Shock wave focused ignition detonation burner and ignition detonation method thereof

The invention discloses an ignition and detonation combustor by utilizing shock wave focusing and an ignition and detonation method thereof, and belongs to the technical field of engines. According tothe combustor, a primary shock wave focusing chamber performs high-frequency reciprocating translational motion along with a dynamic concave cavity and is periodically connected and disconnected witha gas collecting flow guide cavity, generated shock waves are reflected in the concave cavity, focused to form a local high temperature and directly ignites combustible mixture to crack and oxidize macromolecular fuel in a high-pressure area, so that a large amount of easy-to-detonated activating groups and micromolecular gas are generated; and a secondary shock wave focusing chamber is reverselyarranged relative to the primary shock wave focusing chamber, the reflected shock waves in the primary shock wave focusing chamber are reflected again in the secondary shock wave focusing chamber, focused to form a three-wave structure to form a local high temperature and directly detonates detonation waves in the high-pressure area. The invention further provides an ignition and detonation method. According to the method, two-time shock wave focusing is adopted for ignition, so that the stability of the working process is effectively improved, and compared with a traditional shock wave focusing ignition mode, the method effectively enhances the high-frequency cyclic detonation characteristic.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com