Conical cutter head of a shield machine

A shield machine and cutter head technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as damage in the middle of excavation, large tool consumption, and wear, so as to reduce energy consumption, improve utilization rate, and improve knife The effect of disc stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention provides a conical cutter head of a shield machine, and the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

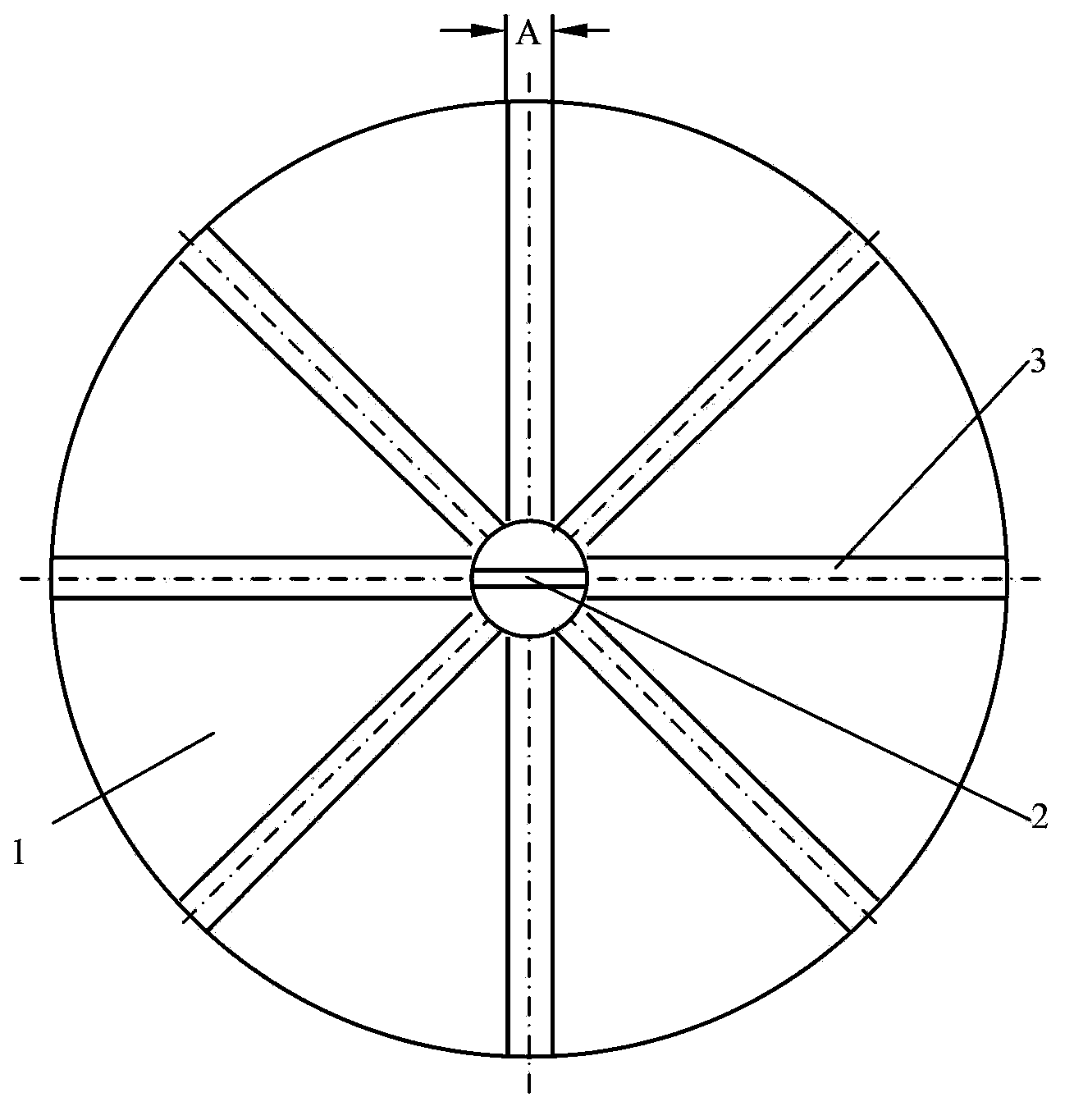

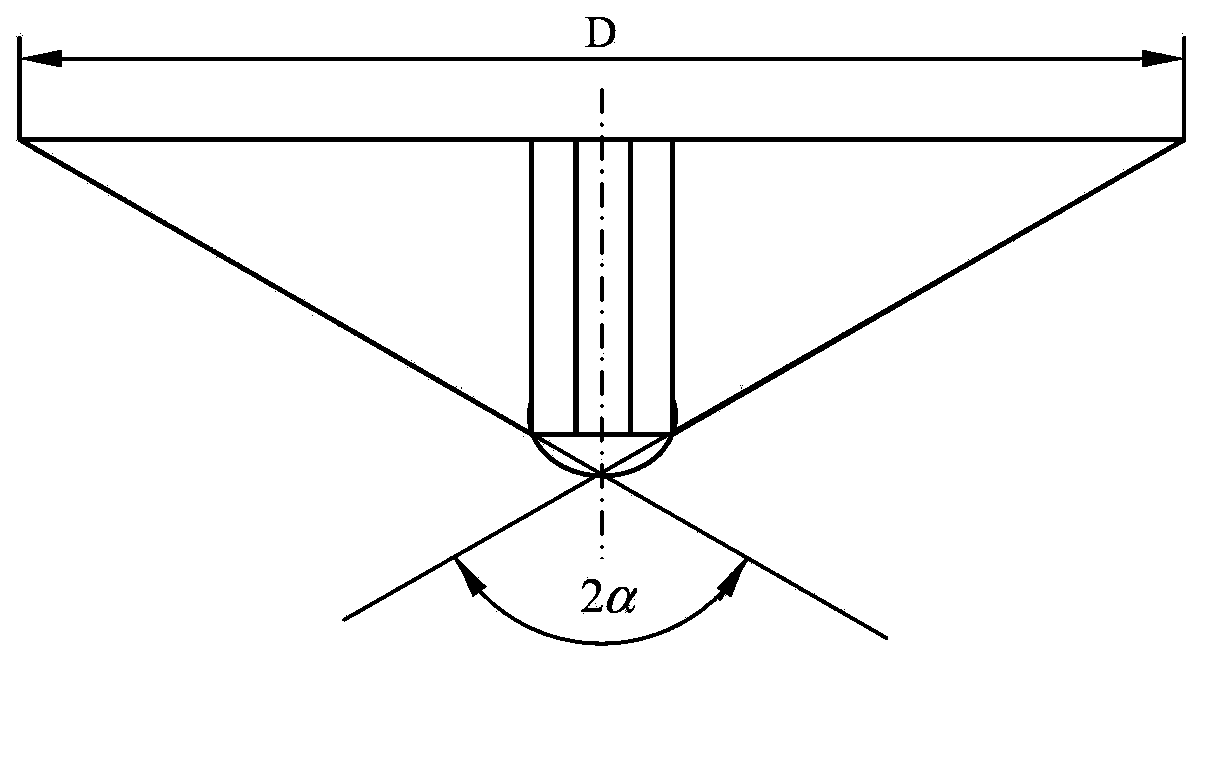

[0014] figure 1 It is the front view of the shield cutter head; figure 2 Top view of shield cutter head. The center position of cutterhead 1 is provided with shell-shaped knife rest, and shell-shaped knife 2 is installed on the shell-shaped knife-rest, and a plurality of spokes 3 with shell-shaped knife-rest as the center outward radiation are installed on the cutterhead 1; At first to the setting of each parameter will be explained:

[0015] D—cutter diameter (m);

[0016] α—half angle of cone top of cone cutter head (rad);

[0017] A—spoke width (m);

[0018] f—Static friction coefficient between shield machine cutter head and rock.

[0019] The cutter head 1 , the spokes 3 and the bell-shaped cutter frame form a conical structure, and then the half-angle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com