Underground excavation construction method for constructing subway station

A construction method and technology for subway stations, applied in underground chambers, earthwork drilling, wellbore lining, etc., can solve problems such as large structural sections and impossibility of application, and achieve the effect of maintaining structural stability and realizing self-stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

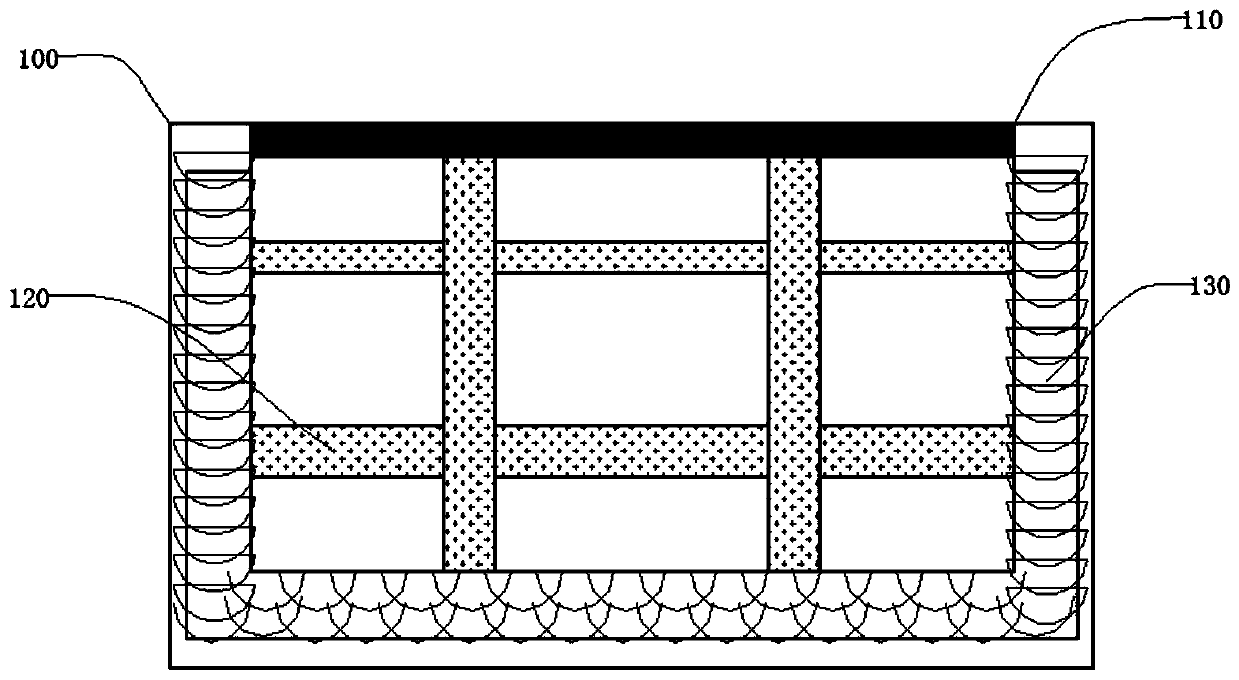

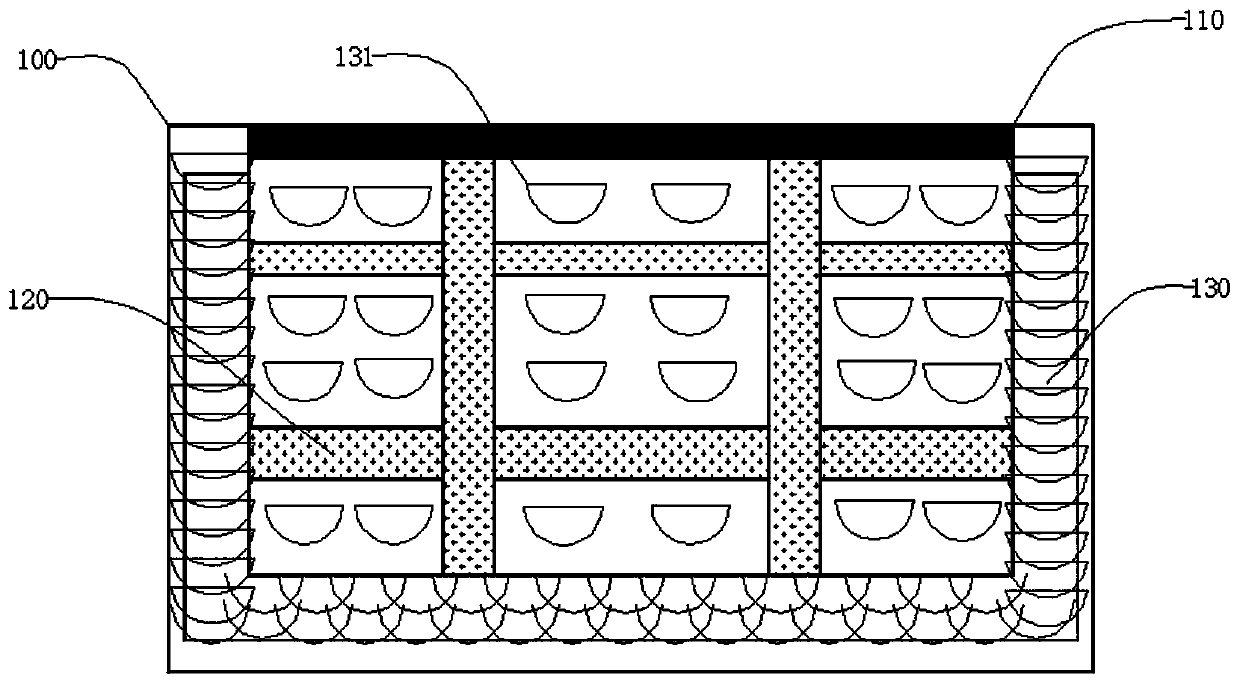

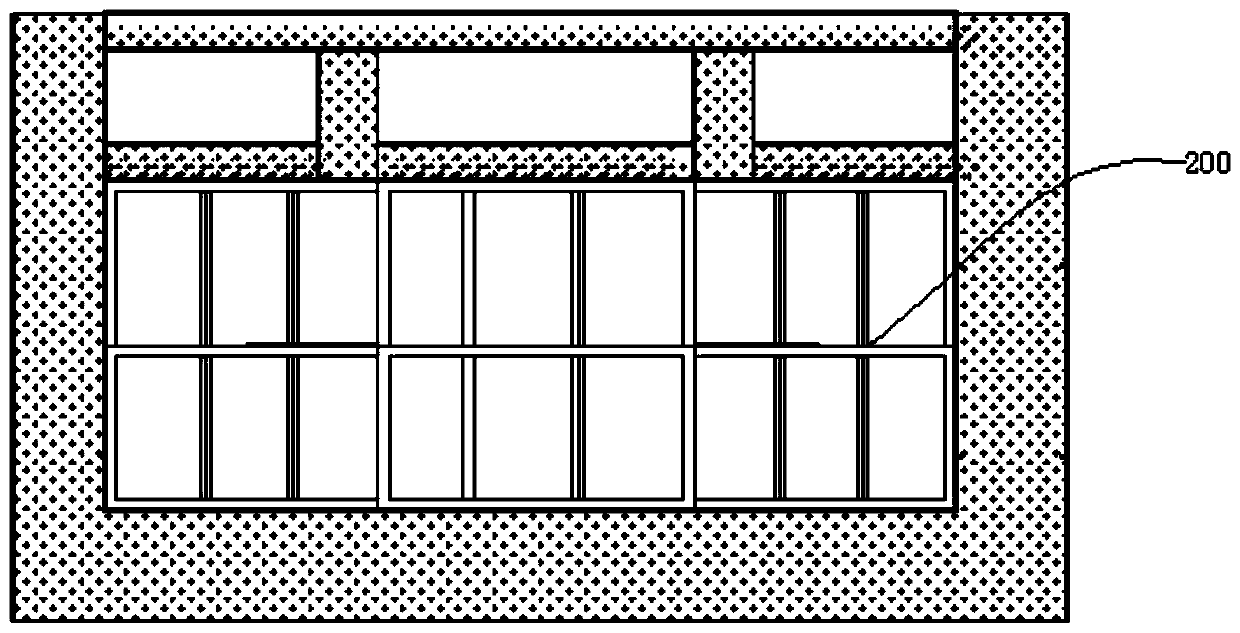

[0029] The core idea of the present invention is to use the matching method of freezing pipe and pipe shed to divide the entire large-section excavation surface into sections, so that each section becomes a small frozen underground excavation. After the freezing pipe is frozen by salt water, a frozen wall is formed to ensure Stability, the MJS (all-round high-pressure jet method) method is mainly used to stabilize the soil on both sides and the lower part of the excavated large section, and can also be used for soil improvement in the excavation section.

[0030] The specific implementation manner of the present invention will be described in more detail below with reference to schematic diagrams. The advantages and features of the present invention will be more apparent from the following description. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com